Boiler room calculation

Calculation of a gas boiler room is one of the main stages of a gasification project for residential or industrial facilities. When making calculations, the following are taken into account:

- Gas pressure in the pipe. The gas pipeline for production systems must be designed for a pressure of 6 kg/m?. For high power objects – more than 6 kg/m?. Boiler rooms located in residential or public buildings are supplied with gas with a pressure of up to 3 kg/m?.

- Lighting. The total area of light sources and glazed openings must be at least 30% of the area of the largest external wall of the room. At night, the gas boiler and other equipment must be illuminated with fireproof light sources.

- Ventilation. The project must take into account three times the air exchange without taking into account the air that is spent on gas combustion. Ventilation openings are provided to protect against explosive situations.

- Accommodation. The calculation is carried out in accordance with safety standards, which must take into account the distance between building structures and your heating equipment.

- Room area. With a heating equipment power of up to 30 kW, a room with a volume of at least 7.5 sq.m is required, with a power of 30-60 kW - 13.5 sq.m. If the power is from 60 to 200 kW, then the boiler room must have an area of at least 15 sq.m.

Autonomous heat source: wood-fired heating boilers

Read about the features of boiler servicing here.

Regardless of what you want your boiler room to look like, remember the main thing is that when installing and equipping it, you must comply with all established technical standards, since this is for your safety and the uninterrupted efficient functioning of the heating system of the facility.

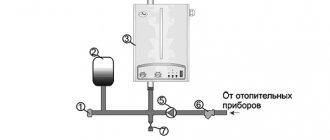

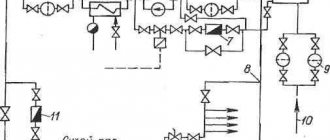

Design and diagram of gas boiler room equipment

If you decide to equip a gas boiler room, then the most important and crucial stage is the implementation of the project. In order to avoid possible mistakes, the right decision would be to contact the appropriate specialists.

The main point in choosing a specialist is whether he or the organization he represents has permits to carry out design work related to the construction and installation of gas boiler houses.

The choice of a suitable location for the heating system lies solely with the customer, but the layout of the gas equipment of the boiler room and its placement is with the design organization. In this case, it is necessary to take into account the basic requirements established at the regulatory level:

- To use a gas boiler whose power does not exceed 60 kW, a separate room is not required. In this case, the heat generator can be installed in any of the rooms that has a window with a window;

- for more powerful equipment (up to 150 kW), a separate room is required (such a room can be the basement or ground floor of the house). At the same time, the walls must be fire resistant. The room should also have a window with a window and a separate exit to the street.

- equipment can be placed in a specially built room made of fire-resistant bricks with windows and a separate exit.

The advantage of diesel boilers is that with subsequent gasification of the facility, the costs of re-equipping the boiler room will be minimal.

Read about what the consumption of a diesel boiler can be here.