How does a sawdust-chip heating boiler work?

Modern household solid fuel boilers using wood chips and sawdust are completely autonomous stations that require refueling once or twice during the entire heating season. During operation, automatic fuel supply is used into the bunker and subsequently to the burner device.

To increase efficiency, instead of the usual method of burning wood chips, the principle of gas generator or pyrolysis combustion is used. The supply of sawdust and air is controlled by sensitive automation connected to thermostats. The error in adjusting the heating of the coolant is only 1-2°C.

The principle of operation of the burner for wood chips and sawdust

A long-burning solid fuel boiler using sawdust and wood chips operates on the principle of gas generation or pyrolysis. Screw fuel supply is used. The operating principle of a sawdust-chip boiler is as follows:

- A free-standing bunker or room is equipped with a double screw drive. One auger is connected to a receiver into which fuel is loaded, the second is connected to a small drum located on the boiler and connected to the burner device. The rotating feed auger ensures a continuous supply of chips.

- The movement of chips and sawdust through a screw transmission is controlled automatically. The processor that controls the operation of the boiler reads the readings of the coolant heating sensors and compares them with the temperature in the heated rooms. Automation regulates the heating intensity, changing the rate of fuel supply, as well as the amount of air during combustion.

- The wood chips are ignited using an electric or plasma device. The burner bowl is located inside a vertical firebox, which has convection holes for air intake. Combustion is carried out under pressure. Special fans supply air to the bowl of the device, providing a stable flame column.

- A gas-generating type heating boiler operating on wood chips and sawdust is equipped with a vertical heat exchanger surrounding a broken chimney. Inside there is a spiral connected to a mechanical device. As soot accumulates, the mechanism is activated, tensioning the spiral and thus cleaning the channel.

- To ensure complete combustion of fuel, bunker automatic water heating boilers using sawdust are equipped with moving grates. After the wood chips burn out, the ashes are automatically dumped into the ash pan. When burning wood chips and sawdust, a high combustion temperature is maintained, ensuring a minimum percentage of underburning.

- The design is equipped with a water heating circuit and, in some models, a DHW circuit. If necessary, the system is equipped with an indirect heating boiler.

- The combustion process is controlled via a GSM unit. Ignition and shutdown of the station, selection of temperature conditions are performed using any mobile device.

The efficiency of boilers operating on sawdust and wood chips reaches 92%. The use of a lambda probe in the device allows you to adjust the performance within the range of 30-100% (depending on the actual heat needs of the room), which increases the efficiency of the station.

Systems for supplying chips and sawdust to the burner

Automatic solid fuel boilers for long burning on wood chips and sawdust with automatic loading, minimize the need for maintenance. Fuel is supplied via several screw conveyors. The submission is carried out as follows:

- The successor bunker has free access from outside the building. The successor has a screw drive combined with the main storage. After loading the bunker, the conveyor is turned on, feeding the chips into the mechanized storage.

- There are two types of storage, with different ways of feeding wood chips into the boiler. In the first type of bunker, an inclined base is used, forming a cone, at the bottom of which there is a screw transmission. The second method is based on the use of a turner mechanism with blades connected to it. Rotation of the device causes wood chips to fall into the installed auger.

- After storage, the wood chips do not immediately enter the boiler. Pyrolysis heating water boilers operating on sawdust and wood chips supply fuel in portions, unlike similar equipment operating on pellets. A new portion enters the firebox through a special drum connected to a screw transmission that feeds wood chips directly to the burner device. The mechanism ensures precise regulation of the flame and prevents possible ignition of wood chips in the main storage.

Using sawdust or wood chips as fuel for a hot water boiler is especially beneficial if there is a fuel source nearby: woodworking.

Automation of cleaning and ash removal

Heating systems for private houses and cottages using solid fuel boilers, burning wood chips and sawdust, provide maximum automation of work. Removing soot, cleaning the ash pan and the internal smoke channel are carried out through self-cleaning. For this purpose, the following components and systems are installed in the boilers:

- Removing ash from the chimney channel - in the design, for maximum heat accumulation, a broken channel is used. The smoke is not immediately discharged into the chimney pipe, but passes through a special heat exchanger design. The channels contain springs connected to a mechanism that tensions and releases them. The edges clean the chimney channel. Ash falls down.

- Grate bars - to ensure uniform distribution of air in the combustion chamber, solid fuel boilers operating on sawdust are equipped with movable grate bars that are part of the self-cleaning system. After burning the wood chips, the plates are turned over and the ash is thrown down.

- Self-cleaning system auger - at the very bottom of the boiler structure, a screw passes through to remove ash residues. The auger is located under the combustion chamber and the chimney duct. The ash falls directly onto the auger and is discharged into a special box.

The automatic ash removal system effectively cleans the boiler. Station maintenance is required no more than once every 1-2 months.

Principle of operation

Now let's look at the general design of boilers using wood chips and sawdust.

The device body consists of the following elements:

- firebox;

- ash pan;

- coil;

- chimney;

- blower;

- heat distributor;

- sensors

Hargassner boiler structure

In the firebox, on a special grate, the combustion process of woodchips and sawdust occurs, thanks to which all the ashes and ash remain in the ash pan. This device should be cleaned approximately 2 times a month.

Due to the fact that wood chips and sawdust are waste from wood processing and do not form a large flame, the heat exchanger in such boilers is heated by hot gases passing through it.

The heat exchanger consists of tubes that are connected in parallel. It is made of a material that can withstand high temperatures well and does not rust, and it also has such quality as a high level of thermal conductivity.

Sawdust and wood chips are an especially economical type of fuel if there is a nearby source of fuel: wood processing.

Chip boiler Hargassner WTH 150-200

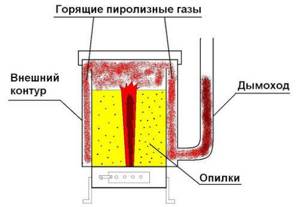

To achieve higher productivity, gas-generating heating boilers using wood chips and sawdust are used, which are heated not only due to the heat from fuel combustion, but also due to the pyrolysis gas released during the combustion of wood.

In order for the gas to be burned, the boiler furnace consists of two separate chambers. In one the fuel itself burns, in the other the gas coming from the first chamber burns.

Design and principle of operation of a long-burning pyrolysis boiler.

Heating boilers operating on sawdust and wood chips, like other heating devices, are single-circuit and double-circuit.

The former are intended exclusively for heating the room, the latter are also capable of heating water. Such units are in demand among owners of private houses, because... They allow not only to provide the house with heat, but also to install plumbing in the house.

The efficiency of boilers operating on sawdust and wood chips is about 90%.

Pros and cons of the technique

The main advantages of using burning sawdust and wood chips as an energy source for the heating system are:

- High efficiency of heating the coolant (usually water, although antifreeze can also be used in a water system), with the help of which the house is kept warm, and sometimes also provides hot water supply.

- Low cost of raw materials. A system based on the use of a sawdust boiler will be especially advantageous if there are one or more woodworking enterprises (for example, furniture factories or sawmills) near the heated premises.

- Ecological purity of sawdust as fuel. Their combustion practically does not release toxic substances into the atmosphere, unlike a number of liquid and gaseous energy carriers.

- Easy to operate and maintain. Almost everyone can use equipment that runs on sawdust and wood chips. And its installation does not require permission from regulatory authorities, as when connecting a gas appliance.

Naturally, such a system also has disadvantages. Among them, it is worth noting the difficulty of storing material that is highly flammable.

This problem is partially eliminated by pressing the fuel, however, sawdust still needs to be stored in a fairly spacious room.

Another disadvantage is the need for periodic cleaning of chimneys, which is due to the large amount of soot and ash generated during operation.

In general, the positive effect that the method of heating rooms with long-term burning of sawdust gives is much greater compared to some of its disadvantages. This means that such systems have a right to exist. And, moreover, over time they can supplant traditional heating options.

Self-production of boilers

When you need a heating device in your home, but don’t want to spend a significant amount of money on purchasing it, you can make it yourself. For this you will need:

Do-it-yourself sawdust boiler - device diagram

- pipes with a round profile 4-5 cm in diameter;

- rectangular pipes 60X40 mm;

- welding machine;

- electrodes;

- Grinder.

The pipes are selected so that they fit in a boiler measuring 36x40x80 cm. Structures with a rectangular cross-section will serve as vertical posts. Round holes are created in them for attaching other elements of the device.

On the wall of the boiler with a door there will be pipelines 5 cm in diameter. For the back, you need the first four rectangles measuring 5x6 cm, and the next four rectangles measuring 4x4 cm.

To connect the pipes, holes of 5 cm in diameter are cut. Cold and hot water will flow through them.

Manufacturing process

The front and rear parts of the boiler are equipped as follows:

- rectangular posts are attached by welding;

- round pipes are installed perpendicular to them;

- pipelines for water supply and drainage are connected;

- the open ends of the pipes are closed with pieces of metal sheets and welded.

The process of making a sawdust boiler

The boiler is checked for leaks - water is poured into the pipes to immediately detect leaks. If everything is in order, the device is mounted in a brick firebox. You can make it yourself using fireproof materials.

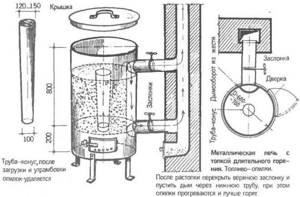

Principle of operation

The boiler is loaded with fuel from the top, from the bottom to the chimney cut. It has neither doors nor an ash pan. Chips and sawdust are compacted with a special weight made from a thick sheet of steel. A pipe is welded to it, through which air is supplied to the firebox. It passes vertically through the lid, its end comes out - the boiler is ignited through it.

The process of a homemade sawdust boiler

The point is to burn the top layer of biomass, the whole process moves downward. This is how the water jacket heats up.

A damper is mounted at the end of the pipe - it helps regulate the air supply to control the rate of fuel combustion. During operation, sawdust becomes less and less, the load drops lower until the boiler is empty. It is released from combustion products through the chimney.

When making your own, be sure to use drawings - this makes it easier to figure out the proportions and shape of the parts. For the device to function properly, it must be assembled correctly.

Sawdust stove

Sawdust stoves, which use sawdust and small wood chips as fuel, are becoming increasingly popular. Such heating units have many significant advantages. The design of such stoves is such that the loaded fuel burns in them for the longest possible time. In addition, sawdust is an environmentally friendly and inexpensive fuel option, which makes heating your home as efficient and cost-effective as possible. A sawdust stove is perfect for heating a greenhouse, workshop, garage and, of course, small and medium-sized residential premises. Such a stove can be assembled on your own without any problems from available materials. For example, barrels, pipe scraps, empty gas cylinders and other similar containers are often used as the basis for the manufacture of the unit in question.

The sawdust stove has an extremely simple design. Traditionally, such a unit includes the following elements:

- fuel loading compartment;

- a vent through which air enters the stove;

- smoke exhaust pipe with valve;

- lid.

The minimum number of structural elements makes the assembly of such a stove extremely simple and quick, and the unit itself is as reliable as possible, because The fewer components a system has, the more stable it is.

A sawdust stove is easily assembled using a piece of thick-walled pipe. The recommended pipe diameter is 400 mm. Prepare a smoke exhaust pipe with a diameter of 100-150 mm. Additionally, you will need a sheet of metal with a thickness of 6 mm.

First step

Make a fuel tank. Cut a hole with a diameter of about 100 mm in the upper part of the prepared metal pipe.

Second step

Make a bottom for the future stove. Cut a circle from a sheet of steel with a diameter similar to the diameter of the body. Make your markings first. To do this, just install the pipe on a metal sheet and circle it with a marker. After that, all you have to do is simply cut out the intended workpiece using an ordinary grinder.

In the central part of the cut out circle, make a hole with a diameter of about 50-80 mm

Third step

Make a pipe to supply air to the stove. The length of this pipe should slightly exceed the height of the firebox. Select the diameter of the pipe according to the diameter of the previously prepared 50-80 mm hole.

In this pipe you need to make about 50 holes with a diameter of about 1 cm.

Fifth step

Make a lid for the stove. To do this, cut a polygonal or round blank from a steel sheet. Create a hole in the central part of the workpiece. The diameter of this hole must match the diameter of the perforated pipe you previously prepared so that the lid fits onto it as tightly as possible.

Also prepare an additional hole closer to the extreme part of the lid. You will install a damper on it to supply air to the unit and control the draft level.

Sixth step

Install a smoke exhaust pipe. To install, first weld the pipe to the hole in the upper side of the housing, and then attach the smoke exhaust pipe to the pipe using a clamp.

The connection between the pipe and the pipe should be additionally sealed using heat-insulating material. Tighten the connection with metal wire from above.

Seventh step

Prepare supports for installing the stove. They can be made from metal profiles. To do this, cut 3-4 pieces of the same length from the metal profile and weld them to the furnace body. Consider the fact that all structural elements made of metal will heat up during combustion. Therefore, it is strictly forbidden to install the stove next to flammable objects.

Experts recommend equipping such ovens with protective screens. The best option is a brick screen. It is enough to simply lay brick walls about a meter high around the stove. Do not leave the oven unattended for long periods of time.

Advantages and disadvantages of sawdust boilers

Any type of heating equipment has its pros and cons. The disadvantages of a sawdust boiler are related to the quality of the fuel. Sawdust has poor flowability, which makes transportation difficult. In addition, they tend to absorb moisture, so they will burn worse than wood and coal. Homemade devices do not have any guarantees of the quality of welds; their appearance is very different from their production counterparts in their ugliness.

But, nevertheless, the device also has positive qualities:

Advantages of a sawdust boiler

- efficiency (compared to other types of fuel, since sawdust is construction waste);

- high efficiency - more than 90%;

- works without harm to the environment, sawdust is an environmentally friendly product;

- one load of fuel can heat a house for up to 10-12 hours;

- fast heating - 30 minutes after startup;

- simple design.

The cost of a homemade sawdust boiler will be several times lower than a branded boiler, even if you buy all the materials for its manufacture in a store and hire a professional welder. And if some parts are found on the farm, the savings will be even greater.

Such boilers are not picky about fuel and its quality, unlike factory ones. There will be chips from pine or birch - it doesn’t matter, the resin released will not harm the device.

The main thing is that attempts to save money do not bring big losses: a boiler assembled with your own hands does not meet safety requirements. It is not durable and reliable, it does not have automatic control systems, so it cannot be left unattended.

Equipment advantages

The popularity of heating appliances that run on wood chips is largely due to the numerous advantages of this technology. self-made sawdust boiler that burns for a long time has the following advantages:

- Safety of use.

- Ability to control raw material consumption and temperature conditions.

- Environmental friendliness of the equipment.

- Minimum fuel costs.

- Fast heating of the room.

- High efficiency.

Self-made sawdust boilers are characterized by versatility and efficiency. With the help of such heating equipment, you can easily heat a room of any size. Thanks to the simple design of the device, you can make it yourself, and subsequently you can buy fuel for free at sawmills or buy ready-made dried pressed sawdust briquettes.

One of the disadvantages of sawdust boilers is their increased requirements for fuel quality and its moisture content. You will also need to periodically clean the chimney from ash and soot. The efficiency of the equipment and its operational safety will directly depend on the correctness of such maintenance.

Features of operation of solid fuel boilers using sawdust

Sawdust boilers for long-term combustion must have periodic controlled loading of raw materials into the furnace, a 3-stage air supply, and the ability to provide the combustion products with repeated (secondary) afterburning. When sawdust is burned in the working furnace, the heat exchanger is heated, the hot air can be immediately removed by the smoke exhaust system or enter the chamber for further gas generation with afterburning of the gases.

Boiler design

The design of a standard boiler installation includes the following components and structural elements:

- fuel loading device or mechanism;

- grate;

- working combustion chamber - firebox;

- heat exchanger block;

- hot air distributor;

- control unit (automation);

- ash pan - a container for accumulating sawdust combustion waste.

If you make a sawdust boiler with your own hands, its design is simplified.

There are two types of designs:

- Single-circuit heating boilers.

- Double-circuit boilers with the additional function of obtaining the required temperature of the secondary circuit water and supplying it to the kitchen, bathroom, and other rooms.

How fuel is supplied

With one portion of loading, the boiler operates for a long time and to maintain a device that heats a cottage or house up to 150-180 m2, manual loading of fuel 1-3 times a day is sufficient. This service takes a few minutes.

For a powerful model that heats a large building, commercial or large industrial premises, a bunker is provided. From it, the filled raw materials are automatically supplied to the furnace in the required volume and at the time specified by the operator. The main components of the fuel supply system: agitator – periodically loosens sawdust (preventing caking) and delivers it to the conveyor; screw (sometimes belt) conveyor for moving raw materials into the furnace.

Making a sawdust stove with your own hands

Oven without external circuit

The easiest way is to make a long-burning metal solid fuel stove from an unnecessary steel barrel. First, carefully cut off the top part. The barrel should not be rusty, the thicker the walls, the better. The service life of the assembled device directly depends on this.

Take a metal pipe or a wooden roller, preferably with some narrowing towards one of the ends and a length approximately equal to the height of the barrel. This pipe will create a void in the center of the sawdust when loading fuel.

The bottom of the combustion chamber is made from sheet steel 3–6 mm thick. The diameter is selected according to the dimensions of the barrel with a gap; a hole is made in the center corresponding in size to the pipe from the previous paragraph. The resulting plate is welded at a distance of 15–20 cm from the bottom of the container

A blower is cut out underneath it, the shape is not important, the main thing is that it is then blocked by a damper

In the upper part of the unit, a chimney is attached to the side through a pipe. The joint is wrapped with thermal insulation.

The recommended chimney diameter is 85–150 mm. They try to make the horizontal section of the pipe longer, but three meters is enough to ensure good heat transfer from the stove. A handle is welded onto the top of the lid.

Next, the legs of the stove are made; they are conveniently made from metal corners. The bottom surface of the barrel should rise above the floor by 100-150 mm.

If a heating circuit with a coolant is added to the resulting system, the sawdust stove will be transformed into a boiler.

There are several possible designs for homemade long-lasting boilers.

One of them was introduced to Russians via the Internet by a user with the nickname bubafonja, and this name was firmly attached to the type of stove.

According to the principle of operation, it copies the Stropuva boiler, produced since 2000 by the company of the same name.

Bubafonya on sawdust has several distinctive features. The air duct passes through the top cover, and a metal plate is welded to its end, located in the fuel chamber during combustion, - a bend, with ribs twisted in a spiral around the central axis of the pipe.

Bubafonya is placed on a base made of refractory bricks and has a condensate collector on the chimney. All pipes, the air duct, the chimney and the chimney, are selected with a difference in diameter, both among themselves and with differences in length, so that the air channel constantly expands, creating additional draft.

Oven with external circuit

To increase the efficiency of the system, an internal fuel tank is sometimes added. In this design, the base of the stove is made up of two barrels - one larger than the other. The optimal difference in diameters is 200 mm. In a smaller container, a round hole is made in the bottom, and it is welded to a steel plate inside the larger one. The cutouts in the parts, of course, completely coincide in location and size. In order to make maximum use of the external circuit of the apparatus for heating the air in the room, the smoke exhaust is transferred to the lower half of the stove. The rest of the design remains unchanged.

The quality of the assembly of a stove for heating with sawdust depends on the availability of a pre-made drawing with parts, cutting accuracy and welding quality. For long-term operation, choose high-quality materials; do not use rusty barrels or sheet steel of insufficient thickness. Ideally, stoves are brewed from large-diameter pipes, rather than simple metal barrels.

When working with such stoves, you should always remember their main features. the metal surfaces of the unit are heated to very high temperatures; it cannot be installed directly on a wooden floor; flammable things, including fuel, i.e. sawdust, should not come into the operating area.

Before starting regular use, home-made potbelly stoves and bubafoni must be tested; the first experiments will make it possible to more accurately determine the amount of sawdust to be laid, the optimal size and duration of opening the blower and, most importantly, the duration of operation of the boiler on one tab.

Equipment options and operating diagrams

Let's consider several options for boiler equipment designed for heating a residential or country house.

Boiler plant

The most convenient and modern is an automated hot water installation that operates on sawdust, wood chips, and shavings.

If you have a large volume of coarse fuel, you can purchase a crushing machine to process the coarse fraction into a fine one. The installation includes the following components:

- Fuel bunker

- Gas generator

- Water heating boiler (combustion chamber and heat exchanger)

- Automatic control unit

The housing design may provide for various options for placing equipment: completely outside or inside the room, as well as with individual units being moved outside.

Description of the work process:

Sawdust is unloaded into the heating bunker by a dump truck (tractor, front loader). To prevent sawdust from caking, a turner is provided in the hopper for periodic loosening. They are fed via a conveyor (belt or screw) into the gas generation chamber, where thermal decomposition of the fuel occurs in a slow combustion mode, releasing pyrolysis gas. Fuel is supplied to the conveyor and to the gas generation chamber automatically.

Pyrolysis gas coming from the gas generator into the combustion chamber burns out completely, heating the water. The content of unburned components in flue gases is minimal: carbon monoxide up to only 1%, nitrogen oxide up to 300 mg/m³. Hot air is supplied to the combustion chamber by a fan, which promotes deep combustion of the components of the pyrolysis gas.

The automation system controls the following processes:

- Supplying fuel to a gas generator

- Fan supply of hot air is proportional to the volume of fuel in the combustion chamber

- Coolant temperature and its change

- Firefighting

Sawdust-fired boilers HARGASSNER (Austria) are typical equipment of this level, used for heating private houses, hotels, offices, and cottages in Europe. The power of such boilers is 25 - 55 kW, heated area is 200-600 sq. m.

Long burning mine boilers

Long-burning mine boilers (Kholmov boilers) deserve special attention. These are pyrolysis boilers of a special design. Their design advantage is that the fuel placed in a special shaft partially dries out, which makes it possible to use sawdust of high humidity for heating.

- Automation (controller) controls the combustion process, the set coolant temperature and the operation of the centrifugal pump.

- The safety system is provided by an emergency boiler cooling circuit and a safety valve.

- Boiler maintenance takes a few minutes 1-2 times a day.

- The use of such boilers makes it possible to heat cottages and small industries with an area of 60-250 square meters. m.

Protective systems and operating modes

In addition to the main parts, the device, which operates on sawdust and wood chips, is equipped with fire protection systems, due to the presence of which it can be considered safe enough for heating residential premises.

The equipment may also have smoke detection sensors that provide timely warning of a fire. And the automatic sawdust boiler can operate in several modes:

Maximum

It is used when there is a significant amount of fuel in the firebox. As the air and water heat up, the equipment gradually reduces combustion intensity, ensuring efficient use of raw materials.

Average

Allowed if longer heating times are required. In this case, fuel is consumed in a much smaller volume until the room temperature drops to the minimum permissible value. At the same time, the mode switches again to a more intense one.

Equipment capable of operating in this way is called long-burning devices using sawdust and wood chips.

"Pause"

It is used when the boiler is no longer needed for heating. The fuel combustion stops and the device cools down.

Tools and materials

Homemade sawdust boiler

If you need a low-power boiler, then the firebox body is most often made on the basis of an old propane cylinder. There are two reasons: the metal is thick enough to last a long time, and its design allows you to easily make a firebox cover. In addition, an old cylinder is not difficult to find or buy. To make a more powerful model, you will need sheet steel at least 5 mm thick or some old large metal vessel.

Another product that you will need to buy is a chimney outlet at an angle of 90⁰, with a diameter of 89 x 4 mm or 107 x 4 mm. A thicker pipe wall will not be a hindrance. To seal the lid, you will need a sheet metal or strip 5 mm thick; a thinner steel sheet, but not less than 3 mm, can be used for the water jacket. To make a round weight, it is better to find metal 8–10 mm thick, an air pipe 40 or 50 mm in diameter. Squeegees with ready-made pipe threads are used as fittings for coolant supply.

Before making a sawdust boiler, you need to prepare the following basic tools and equipment:

- electric welding machine and electrodes;

- angle grinder with metal wheels;

- measuring instrument;

- hammer;

- mites;

- chisel;

- drill press or electric drill.

It will be more convenient to do all the work with an assistant.

Step-by-step progress of work

Rice. 3

Firebox

- The upper part of the barrel is cut off; it will be useful for creating the lower chamber.

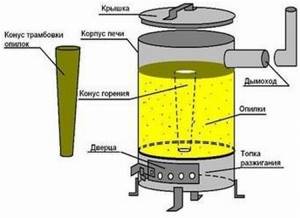

- Sheets of thin steel are given a cylindrical shape. One cylinder must fit perfectly into the other. A cap is attached to the upper (narrower) edge of the cylinder. This creates a combustion cone and a tamping cone.

- The lid and bottom of the boiler are made of thick steel; to install the bottom, the barrel’s own bottom must be cut out.

- A hole with a diameter of 10 cm is made in the bottom. A combustion cone will be inserted into it.

- Rectangular pipes or channels are welded vertically inside the barrel. Their size is slightly smaller than the height of the barrel. This is necessary so that they do not interfere with the lid with the tamping cone from easily closing the boiler. Holes must first be drilled in them corresponding to the diameters of the round pipes.

- At the same level there will be holes in the unit body.

- Pipes are inserted through these holes to supply cold water and discharge hot water. The same applies to the chimney.

- An ignition chamber is constructed from the cut-off part of the barrel. The door can be made from a thin sheet of steel or use a ready-made one purchased in a store. For good traction, you need to drill several holes at the bottom of the chamber.

Homemade sawdust boilers placed in utility rooms do not need to be covered with bricks

In a residential area, this precaution is necessary to avoid burns. The foundation for the boiler must be made

Sawdust is a wonderful material

for heating houses and greenhouses.

They are made of wood, which means that when used correctly, they are only slightly inferior in heat capacity to firewood.

You can get them cheap

, and in some cases even

free

.

- houses;

- makeshift;

- greenhouses

We will also consider in detail all types of heating stoves and long-burning boilers that can use sawdust as fuel.

this fuel, because it is very different from the combustion mechanism of wood.

No matter how tightly the firewood is stacked, air always passes

, and in sufficient quantity to support combustion.

Even loose sawdust allows much less air

, so smoldering quickly fades without supplying additional air to the combustion zone.

Sawdust burners only work effectively when the fire moves from top to bottom

. Therefore, only a layer of sawdust 2–5 cm thick constantly burns.

Another factor that reduces the power of a boiler or furnace is the low combustion temperature of sawdust.

If firewood burns with proper air supply, the flame temperature exceeds 1000 degrees, often reaching 2000 degrees

in tongues of fire.

Moreover, this is a powerful fire

, because the entire mass of firewood emits pyrolysis gases.

The fire temperature of burning sawdust, even with proper air supply, does not always reach 1000 degrees

due to

the weak flow of pyrolysis gases

.

Pyrolysis gases effectively exit only from the top layer 5–15 mm

.

Gas comes out with difficulty from burning or heated sawdust located below, because the sawdust located above interferes with it.

Despite such disadvantages, sawdust is ideal

for boilers and long-burning furnaces.

After all, well-compacted sawdust burns for a very long time.

.

Often, a homemade iron stove burns for 5–8 days with one load of sawdust, providing heating for the entire house.

Step-by-step instructions on how to make a sawdust boiler

Making a sawdust boiler with your own hands is not only cheaper than purchasing a new device, but also sometimes more reliable.

Sawdust boiler design diagram

To work, you need to initially select the following tools:

- grinder for cutting metal and grinding it;

- welding machine;

- electric drill;

- roulette;

- hammer;

- round pipes with a diameter of 4 and 5 cm and with a rectangular profile - from 40 to 60 mm.

Assembling a heating device consists of the following steps:

- The top of a conventional gas cylinder is cut off along the weld line. The edges are well cleaned. This will form the body of the firebox.

- The lid - the part that was cut off - should fit quite tightly. To do this, a edging is welded along the edges of the cylinder. It is made from strips of thick-walled metal.

- A latch and handle are selected for the prepared lid, and a hole is made corresponding to the outer diameter of the air supply pipe. All elements are fastened by welding. Fasteners are mounted to the body that will tightly hold the lid during fuel combustion.

- An opening is made in the upper part of the firebox for the chimney pipe and an iron pipe is welded.

- To make the weight, a circle is cut out of a thick-walled metal sheet, the size of which will suit the internal diameter of the cylinder. A hole is prepared in the center of the prepared part, identical in volume to the one in the lid. Iron ribs are welded to one surface of the round weight to disperse air masses.

- The air supply pipe to the firebox is inserted into the hole made for it and scalded in a circle.

- The most difficult stage is cutting out the water jacket from a metal sheet. It should ultimately have the same shape as the body.

- Metal ribs are attached to the outer side of the cylinder, which will protect the water jacket from deformation under the influence of high temperatures. The prepared metal part is welded in a circle to these ribs.

After checking all the welds, openings are cut for attaching the coolant.

Fuel requirements

The productivity of the heating process depends on the quality of raw materials loaded into the boiler. The main requirements for wood fuel are:

- Density. The efficiency of the heating device is significantly affected by the size of the raw material. The lower the density of the material, the greater the heat transfer during its combustion. The best option is sawdust from a milling machine. The density of such wood waste is on average 120 kg/m³. From 250 grams of such material you can get 1 kW of thermal energy.

- Humidity. Dried sawdust significantly increases the efficiency of the combustion process. The moisture content of wood waste for the boiler should not exceed 20%.

Some models of factory heating units are able to function normally on sawdust with a moisture content of up to 40%. Such designs have a built-in element that rotates the wood fuel. When exposed to high temperatures, sawdust dries quickly.

The humidity of sawdust should not exceed 20%

For ease of storage and loading, compressed sawdust is often used. The amount of thermal energy from such a material corresponds to the volume of heat that is released during the combustion of the same portion of natural wood.

Types of domestic and industrial boilers

Heating units differ in their internal structure. This affects the method and duration of combustion. Any of them will be suitable for your home. For production needs, fully autonomous boiler rooms are installed. This minimizes the labor costs associated with their maintenance.

Automatic equipment

The units are designed for heating large industrial facilities. They have a fully automated control system. The chips are fed by conveyors into the firebox, the controller monitors the temperature and regulates the degree of heating.

Boilers with automatic fuel supply using wood chips are often used on farms.

Top combustion boilers

Equipment with a large firebox. Characterized by gradual combustion - from top to bottom. The heat exchanger heats up longer. At the same time, it maintains the temperature with a small amount of wood waste. The heat load is distributed gradually. The device has lower efficiency due to the large distance between its parts.

Pyrolysis boilers

Long-term burning equipment does not involve the use of fuel to generate heat, but the use of decay products - volatile substances. They smolder in the firebox, forming pyrolysis gas. It passes into the afterburning compartment, where it is processed under the influence of oxygen. Heating control occurs by changing the air injection rate. In its absence, the temperature drops and gas evolution slows down.

A wood chip pyrolysis boiler uses fuel breakdown products.

Chip supply options

It is not economically profitable to create an autoloading unit at home. This requires the installation of expensive elements. And the boiler room occupies a large area.

Manual feed

Autoloading is not installed in top-burning appliances. Some types of pyrolysis devices also require manual feeding. In this case, the upper layers of wood chips burn, and the lower ones smolder.

Auto mode

Loading is carried out by conveyors and augers. Their diameter and pitch are selected according to the size of the raw material. The bunker is sometimes equipped with a turner, which prevents them from caking.

Stoves, boilers and heaters: which is better

When choosing sawdust heating, you must consider the following:

- the volume of water in the water jacket of the boiler should be 10–15% of the total volume of water in the heating system, therefore it is advisable to use forced movement of water through thin tubes;

- Stropuva water boiler 65 thousand rubles , and the price of sawdust boilers made by yourself is 30–50 thousand rubles , including the cost of material;

- air heating not only heats, but also dries the air >;

- water heating pipes can be hidden under the finishing, but air heating pipes will have to be laid in plain sight due to their large cross-section (pipe diameter in cm is equal to half the area of the room in m²);

- it is very difficult to find long-burning industrial heaters (boilers and furnaces that heat air, which is then supplied through pipes through pipes) using sawdust , and their cost often exceeds the price of the Stropuva boiler;

- the cost of manufacturing air heaters is comparable to the cost of manufacturing a boiler;

- the costs of material and installation of water and air heating are approximately the same and amount to 15–20 thousand rubles for one room measuring 15–20 m2;

- the cost of manufacturing a stove is 20–50 thousand rubles , depending on the size.

Heaters and boilers are well suited for heating large houses , because they heat the coolant, which then flows through pipes or ducts to remote rooms. For small houses, it is preferable to have a stove installed at the junction of all rooms.

If someone is not satisfied with the appearance of an iron stove , it can be covered with a brick grate - it will improve the appearance of the stove and will not interfere with air movement.

Advantages of the stove

- Long-term operation on one load of fuel (10-20 hours depending on the model).

- Autonomy of work (no constant human supervision required).

- Relatively small dimensions and weight.

- The ability to use various fuels (the boiler runs on sawdust, coal, firewood, wood chips, pellets), which makes the cost of heating noticeably lower than alternative options.

- Does not require a foundation.

- It does not require regular kindling; long downtime does not in any way affect the durability and performance of the device, which is especially convenient for a country house or cottage.

- Maximum complete combustion of fuel and low ash residue.

- The sawdust stove practically does not smoke.

- It is quite easy to make with your own hands from a simple steel barrel or other available materials.

- Low cost.

Do-it-yourself ovens do not have any serious disadvantages, but there are conditions for which they are poorly suited. Such devices are not used to heat a large house; their purpose is to heat small rooms.

Additional recommendations

If a homemade sawdust boiler is used to heat a private home, it would not hurt to supplement it with some safety equipment . To do this, holes are drilled in the water jacket casing and fittings for temperature and pressure control devices are welded. It would be correct to additionally install a relief safety valve, which would be activated when the pressure rises to 3 bar, and lead the pipe from it to the street.

The hot surfaces of the unit and chimney also pose a danger to people if it is in the house. At the same time, heat spreads where it is not needed - in the combustion chamber. For these reasons, sawdust heating boilers must be insulated. Basalt wool can be used as a thermal insulation material; it can withstand high temperatures well. The insulation layer can be covered with thin sheet metal with a polymer coating, at the same time solving the issue of aesthetics of the appearance of the unit.

In the case when only sawdust is used as fuel, it is necessary to make a device for properly loading it into the firebox. The fact is that this type of fuel does not allow air to pass through well, and without it the combustion process will be weak . Therefore, a pipe with a diameter of 100–120 mm in the form of a funnel is made from thin metal, only the sides of the cone are very flat. The device is placed vertically in the center of the firebox, after which sawdust is poured around it and periodically compacted tightly. When the chamber is full, thanks to the cone shape, the pipe can be easily removed, a load is placed and the firebox lid is closed.

How fuel is supplied

In general, such boilers can operate on any wood fuel, from biological briquettes to ordinary firewood.

Note! In order to operate fully automatically, sawdust boilers must only use wood chips and sawdust!

In order for the device to be able to “feed” on wood, its combustion chamber must be redone. But most modern models already include everything needed for conversion.

Regardless of what type of fuel is used, pyrolysis boilers need it to be dry. If it is wet, steam will be generated during combustion. And if steam mixes with gas, the latter will become heavier, and the combustion process itself will deteriorate significantly. Therefore, it is not strange that every solid fuel device spends up to 1/3 of its power precisely on drying the fuel.

You should pay due attention to the fuel supply, which consists of two elements:

- agitator - it permanently mixes sawdust, which ensures their constant supply to the auger;

Note! Automatic boilers are characterized by the fact that they supply fuel continuously! This will allow you to make a bunker for it, located underground. An underground bunker is good because it not only stores fuel, but it saves free space in the house

Often it is installed in such a way that its highest point is located at the same level as the foundation itself. In the same place there should be a hatch through which fuel will be poured immediately from the transport that delivered it. We also note that the bunker should be located in the room adjacent to the one where the boiler is located, in order to easily set up a fuel conveyor

An underground bunker is good because it not only stores fuel, but it saves free space in the house. Often it is installed in such a way that its highest point is located at the same level as the foundation itself. In the same place there should be a hatch through which fuel will be poured immediately from the transport that delivered it. We also note that the bunker should be located in the room adjacent to the one where the boiler is located in order to easily set up a fuel conveyor.

The best known manufacturers and models: characteristics and prices

When choosing a boiler for sawdust and wood chips, in addition to technical characteristics, you should pay attention to the country and brand of the manufacturer. Northern European countries have learned to squeeze the highest economic performance out of fuel. To this end, they have been working for a long time on improving automation specifically for private homes, and given their desire for comfort and environmental requirements, you should pay attention to the products of the companies Hargassner, Froling, ETA. Of course, if the budget allows.

Russian-made boilers, especially if the developer is a well-known European brand on the market, may well be competitive. At a significantly lower price, they are quite capable of providing both the reliability and comfort of a private home. In addition, they are unpretentious in raw materials and maintenance, and the automation even in European solid fuel boilers is often from China.

Specialized

These are boilers designed primarily for the use of bulk solid fuels.

Pyrolysis Master BIO-15

One of the best sawdust boilers for heating a private home. It also works on wood chips, peat, and sunflower husks. With the use of replaceable burners it can burn straw. Thanks to a five-pass heat exchanger, it has a high efficiency of 91% and has a hopper capacity of 200 liters. The only drawback is its considerable dimensions.

Cost: 185,000-240,000 rubles.

FACI FSS 115

It is produced in Russia, but the developer is Italy. This is an automatic industrial boiler for burning wood waste. Power adjustable within 25-115 kW, efficiency 92%. As additional options, it is equipped with auto-ignition, burner self-cleaning, and remote control. Hopper capacity is 810 liters, fuel is supplied by two augers. Can burn any biomass with a fraction not exceeding 40 mm. The 115 kW model has a huge weight of 1150 kg, which increases the flooring and transport requirements.

Cost: 450,000-477,000 rubles.

Prices: summary comparison table

| Model | Specialization | Cost, rub. |

| Pyrolysis Master BIO-15, Russia | special | 185 000-240 000 |

| FACI FSS 115, Italy-Russia | special | 450 000-477 000 |

| Tis Pro DR, Belarus | universal | 58 500-72 000 |

| PEREKO KSP Duo, Poland | universal | 283 000-498 000 |

| LIEPSNEL L20U, Lithuania | universal | 110 000-125 000 |

Further development of automation of boilers using sawdust and wood chips will provide real competition to gas and electric boilers in terms of comfort and efficiency.

BoilersSolid fuel boilers

Universal models

Boilers using any solid fuel: all types of coal, peat, firewood, wood waste, seed husks, briquettes with varying efficiency, but structurally designed for long-term combustion. They are much cheaper than specialized ones, but also much less effective and practical when working with sawdust.

Tis Pro DR

Excellent inexpensive universal boiler. Furnace steel 5 mm thick is used as a heat exchanger, which is a very good indicator in terms of reliability and durability. It also features a huge firebox; depending on the power, the volume of the combustion chamber can be 80-116 liters. Does not use fan pressure and is non-volatile. Available in 17, 22 and 27 kW versions, efficiency reaches 82%.

Owners often note that the design of the grate is extremely practical: they are separate, cast iron (reliable and easily replaceable). No deficiencies were found due to operating practices.

Cost: 58,500-72,000 rubles.

PEREKO KSP Duo

High-tech Polish universal TT boiler of the highest price category. The innovative burner allows high-quality combustion of fine-grained fuel from eco-peas to oats as efficiently as possible. A water-filled grate in the combustion chamber makes it possible to burn wood and its waste.

Equipped with automation controlled by the ST-480 controller, which, in addition to controlling the central heating and hot water pumps, the boost fan, can also control the operation of the mixing valve and take into account signals from room and street temperature sensors. Available in power variations: 12, 18, 26, 36, 52 kW. In addition to the price, the disadvantages are large dimensions, weight and low permissible operating pressure - only 1.5 bar.

Cost: 283,000-498,000 rubles.

LIEPSNELĖ L20U

Universal Lithuanian long-burning shaft-type boiler with a power of 20 kW. The fuel is coal, pressed briquettes from coal, peat, wood waste, sawdust and other raw materials. The efficiency reaches 91%, but this is only when heating with low-ash coal; when using sawdust and wood chips, the efficiency will be lower. The heat exchanger is cast iron, in a steel casing. The boiler is known for its reliability, quality of alloys used and assembly. Even when using sawdust and wood chips, the burning time of one load can be achieved in 2-3 days.

The only drawbacks, as in the previous case, are the low operating pressure of 1.5 bar and heavy weight.

Cost: 110,000-125,000 rubles.