Lite Batts

Peculiarities

As I said above, the manufacturer does not recommend using Floor Batts for wall insulation.

For these purposes, there is a special material Light Butts. It consists of lightweight mineral wool slabs. The main difference between this brand and Floor Butts is its lower density - 37 kg/m3. In addition, the Light Butts material has another unique feature - flexi technology.

Flexi technology ensures easy installation of slabs and their tight fit to the frame

The meaning of this technology is that on one side the plate is springy. This greatly simplifies the installation of the slabs into the frame with your own hands, and also ensures their tight fit to the frame posts.

Light slabs are lightweight

Otherwise, the material is made of the same basalt fibers as the floor slabs. Therefore, it has the same characteristics, including thermal conductivity, vapor permeability and moisture resistance.

The only thing is that, unlike floor slabs, wall slabs cannot withstand loads. As a result, they can only be used in frame structures. Moreover, in the case of insulation of frame walls, their height should not exceed three meters, otherwise jumpers must be installed.

Varieties

There are three modifications of Light Butts on sale, which have minor differences from each other:

Light (basic). A universal material that can be used both for internal wall insulation and external insulation in ventilated facade systems. In addition, this insulation is suitable for insulating frame walls, pitched roofs, partitions and floors on joists;

Light Scandic slabs are compressed in packaging, which simplifies their transportation

Light Scandic. The main feature of this series is that the slabs in the package are compressed by 60%. This allows you to reduce transportation costs. After the packaging is unsealed, the slabs regain their original volume. The characteristics of the material, as well as the scope of application, are the same as those of Light Bats;

Light Extra slabs are characterized by increased density and strength

Light EXTRA. The peculiarity of this brand is its increased strength due to increased density up to 40-50 kg/m³. At the same time, the thermal conductivity is the same as that of other plates of the Butts series. The scope of application is also no different, the only thing is that the manufacturer separately highlights the possibility of using slabs in three-layer walls made of brick or other piece materials.

The photo shows Acoustic Butts slabs - they are distinguished by improved sound insulation qualities

Scope of application

Using the material in insulating the facade of a house

Due to its characteristics, insulation has a wide range of applications.

- In construction. The material was used in this direction primarily due to the positive properties and effectiveness of thermal insulation. The raw materials are used in the construction of partitions and ceilings in multi-storey buildings. Also used during the construction of cottages and private houses under a concrete screed.

- In ventilated and non-ventilated facade systems. For the construction of partitions, which will later be designed under the facade, we try to use ROCKWOOL of sufficient elasticity. They perform not only thermal insulation, but also load-bearing function.

Internal thermal insulation of the house with Rockwool insulation - When insulated from the inside. Rockwool basalt insulation is used for this purpose. It is mounted indoors on walls facing the street. Also suitable for insulating other types of partitions, ceilings, floors of any design.

- For the roof. Most often used for insulation when organizing a roof. Shows excellent performance properties for thermal insulation of attics and attics.

- ROCWOOL in the form of cylinders has special properties for thermal insulation of pipelines of any size. This material is securely attached to the surface of the highway and does not require preliminary preparation.

The range includes Rockwool slabs of increased rigidity. They are suitable for insulating wall wells, as well as for insulating street walls or interfloor layers.

When calculating the amount of material for thermal insulation, you must be guided by SNiP standards and the formula R=R1+R2+R3.

We use it correctly

Scandic insulation is used for insulating facades of private houses, attics, interior partitions, ceilings, walls, balconies, external doors for vertical and inclined applications. There is no additional load on the slabs. The increased density has led to an increase in the mechanical stability of the material, but an unacceptable load leads to its deformation, and as a result, a deterioration in the thermal insulation properties.

Using mats of different thicknesses it is easy to achieve the desired layer of insulation. The presence of Light Butts Scandic 150 mm slabs significantly reduces labor costs for installing thick insulation. If the calculations require a layer of insulation thickness of 380 mm, then it is necessary to round it up to a multiple of 150, 100 or 50.

When installed correctly, the insulating layer forms a continuous connection to the frame without the formation of gaps, which avoids heat loss and prevents drafts. The increased density makes the material resistant to mechanical stress.

The insulation thickness for central Russia is 150 mm for external walls and 200 mm for roof insulation. For northern or southern regions, the thickness of the insulation layer must be increased (decreased) by 50 mm, respectively.

You can reduce the time and costs of insulation by using material with a thickness of 100 and 150 mm. At the same time, labor costs are reduced, the amount of waste is reduced, and slabs of greater thickness adhere better to the frame. Cutting must be done with a construction knife. There is no need to cut the insulation millimeter by millimeter; increase the size of the material by 20 mm from the size of the opening being closed.

Frame wall insulation technology

The basis of the house is a wooden frame, sheathed on both sides with sheet material. Between them are thermal insulation boards. Rockwool Light Butts and Rockwool Light Butts Santik are optimal for the job.

Useful: DIY sandwich panels

Wall pie laying diagram:

- installation of a vapor barrier membrane on the inside of the room;

- placement of insulation;

- wind protection fastening;

- outer skin.

The whole process consists of the four stages outlined above. Detailed instructions:

- Vapor barrier. Apply adhesive tape to the inside of the frame posts, remove the protective film and attach the membrane with an overlap of 10 cm. Additionally, secure the sheets with a stapler and glue the joints with tape .

- Laying mineral wool. Cut the insulation according to the size of the cells between the frame posts. Install heat-insulating mats, and, if necessary, install a second layer of mineral wool.

- Wind barrier installation. The membrane is attached in the same way as a vapor barrier - on adhesive tape and fixed with a stapler .

- Sheathing. To install sheet material, you need to fill the sheathing with 20*30 mm slats. Attach OSB sheets over the planks, leaving a gap of 3-5 mm between the sheets.

Parameters and types of Light Butts

It must be admitted that the popularity of Rockwool insulation would be much less if they did not have a lot of unique properties and characteristics that distinguish them from conventional materials.

At the same time, the consumer can choose not only standard Light Butts slabs, but also their improved version - Scandic, which differs in properties during installation and transportation.

Types of materials

Rockwool mineral wool is available in 2 versions:

- standard slabs, the dimensions of which are 1.0 × 0.6 m, and the compressibility has a standard value for brand products of 30%, their thickness is in the range of 50–200 mm in increments of 50 mm;

- improved Scandic slabs, having 2 additional standard sizes (0.6 × 0.8 m and 1.2 × 0.6 m) and the ability to compress up to 60%, the thickness of such materials is 100 and 150 mm.

Thus, Scandic insulation is either more convenient than conventional slabs for transportation even in passenger cars (small size), or, conversely, designed to speed up the installation process (larger version). In addition, the material is produced in vacuum packaging, due to the manufacturing technology of which the shelf life of Rockwool boards increases several times.

Features of insulation material

A distinctive feature of Rockwool insulation - Light Butts mineral slabs is Flexi technology. In practice, this looks like a movable part of the plate, capable of expanding and contracting to simplify installation on both a wooden and metal frame. The springy edge is located on the long side of the slab, while the edge itself is 50 mm wide. It can be easily detected by special markings.

In addition to the technology described, the advantages of Rockwool insulation of the Light Butts type include:

- the ability of a tight junction, eliminating the formation of cold bridges;

- simple and quick installation;

- durability;

- resistance to fire and high temperatures;

- safety against the backdrop of complete environmental friendliness.

The main properties include excellent performance:

- thermal insulation;

- vapor permeability;

- soundproofing.

Light Butts slabs from Rockwool are characterized by minimal thermal conductivity values - from 0.035 to 0.04 W/m°C. The material has a density of up to 50 kg/m3, during operation it can reduce heat loss several times.

Excellent thermal insulation formed using Rockwool mineral wool is not the only advantage. The material is capable of not only maintaining an optimal indoor microclimate, but also absorbing noise. Due to their special open porous surface, the slabs literally dampen sound waves, eliminating noise regardless of its source.

A separate point is vapor permeability. During the day, each person is capable of producing up to 5 liters of steam, so moisture transfer occurs permanently through walls, windows, and doors. Rockwool mineral wool slabs do an excellent job of removing steam, preventing the insulation from rotting from the inside due to moisture accumulation. As a result of this work, Light Butts products manage to maintain favorable temperature and humidity conditions in the house.

An equally important property of the material is fire resistance. Plates based on basalt (stone) wool are able to withstand extremely high temperatures (up to 1000 degrees Celsius) without affecting functionality and service life

Moreover, Light Butts products prevent the spread of fire in the event of a fire and are suitable for installing smoke removal systems.

The manufacturer claims a 50-year service life of the insulation, during which it retains its basic properties, guaranteeing the performance of heat and sound insulation at a high level.

Products are available in rolls and slabs with thicknesses ranging from 25 to 150 mm. The second option is more convenient to use, since the slabs do not require additional cutting.

Summary

The fundamental differences in mineral insulation are insignificant. The emphasis on properties is justified only in product advertising:

- Paroc – all elastic;

- Izovol for a bath - with a reinforced heat-reflecting layer;

- blow-in cotton wool Isover – penetrates into any nooks and crannies;

- Ursa Pureone – thanks to a natural binder, it is environmentally friendly.

But the cost may vary significantly. The situation is complicated by the different values of measures in the price lists.

In this review, prices are reduced to a single indicator (RUB/m³). Therefore, just choose the most profitable option for the current period.

And remember: in the case of mineral wool, it is not the price that heats, but the volume.

Installation

Multifunctionality and ease of installation are important advantages when choosing an insulating material. As customer reviews indicate, Rockwool mineral wool is one of the best options for thermal and sound insulation.

The installation process itself is quite simple, but it requires some literacy. In some cases, slab-shaped products do not even require fastening. As for large canvases, they are fixed using a special glue that is applied directly to the surface of the material. Mineral wool in the form of mats is attached to the surface using a metal mesh and dowels, and if necessary, lathing is used.

For the purpose of floor insulation, Rockwool stone wool is laid under a pre-made cement screed or between joists. When installing the roof, the spaces between the rafters are filled with material, after which the joints are carefully treated with glue, ensuring excellent water resistance.

Rockwool slabs are laid in a checkerboard pattern with maximum density to each other. To create a high level of vapor barrier, foil or a special film is laid under the mineral insulation.

Types of insulation and its application

Rockwool produces a wide range of insulation products. Thus, each of the insulation materials can be applied to different parts of a house or apartment, and all products can be divided into blocks, taking into account the scope of its use:

This is not a complete list of stone wool produced for thermal insulation of premises. Among other things, there are special membranes, aluminum tapes, vapor barrier boards, which are also aimed at preserving heat. Also, some types can be used in different fields. For example, Light Butts, Light Butts Extra, Scandic, Floor Butts can be used for insulation of balconies and loggias, as well as for floors and floors. And, for example, Light Butts works well as a second thermal layer for steam rooms.

Walls using wet facade technology

This method of facade insulation is the most common and has its advantages:

- maximum heat savings;

- reduction of financial costs.

Option for the “wet” method of insulation

So, after all the preparations of the facade, a base profile is installed, which serves to balance the load from the insulation. Next, the thermal insulation layer of Rockwool Butts is installed:

- Along the edges of the insulation, at a distance of 3-4 cm, apply a wide strip of adhesive mortar.

- Next, it is pressed tightly against the wall, but excess glue is removed immediately. The second layer of insulation is pressed against the first with the same force.

- They move from the base profile upwards.

- After 2-3 days, when the adhesive solution has completely dried, the insulation is additionally fixed with dowels. The length of the fasteners must match - in addition to the layer of stone wool, they must fit into the wall.

After all the reinforcements are completed, the reinforcing layer is installed:

- Construction adhesive is applied to the insulation layer, in which a fiberglass mesh is embedded;

- The same adhesive composition is applied on top of the mesh.

It should be remembered that the total layer should not be more than 6-7 mm. After the glue has completely dried, plaster is applied on top for external use.

Two-layer masonry

Model of two-layer brickwork with insulation inside.

Insulation using the homemade method is the easiest way to insulate a room using Scandic or Light Butts slabs. In this case, the insulation is mounted between two rows of masonry. For example, a wall is built using bricks (silicate, ceramic). Next, stone wool is fixed to it using the same method as with the wet facade technology. And then another layer of masonry walls is erected. It can also be made of brick or other building materials - foam block, cinder concrete and others. Rockwool Venti Butts are often used to insulate suspended systems with an air gap.

Frame walls

Rockwool Light Butts is an ideal insulation for frame walls.

Any house consists of two walls - internal and external. In this method, both are insulated. For this, the ideal choice would be Rockwool Cavity Butts or Rockwood Facade Butts:

- the outside of the house is covered with wooden boards;

- a waterproofing membrane is fixed on them, which protects the insulation from moisture, also from the outside;

- from the inside of the house, Rockwool for the walls is installed in the frame posts;

- all gaps and voids are filled with polyurethane foam;

- the internal walls should be covered with a vapor barrier membrane and wood boards should be strengthened on top of it.

Walls from the inside

Insulating the wall of a house from the inside with Rockwool insulation

Not all thermal insulation materials are suitable for interior decoration, as some have very low environmental performance. So, the insulation must meet the following requirements:

- durability;

- high fire safety;

- low heat loss;

- completely environmentally friendly.

All these requirements are met by:

- Rockwool Light Butts Extra;

- Light Butts Scandic XL.

Work on the inside takes place in several stages:

- To prevent the appearance of mold and mildew, the surface is treated with a deep-penetrating primer.

- The sheathing is installed in the form of a metal frame or wooden bars.

- Insulation is installed;

- A hydro- or vapor barrier membrane is stretched.

- Drywall is attached.

Floor under screed

Insulation of the floor under the screed with Rockwool insulation.

Thermal insulating wool is laid on the floor slabs. For greater heat retention efficiency, it is recommended to lay it in several layers in a checkerboard pattern, i.e. when the edge of the upper plate falls in the middle of the lower one. As soon as the insulation is tightly installed, they begin to level the floor - with cement mortar or using wood boards. Next comes the installation of flooring - linoleum, parquet, laminate, wood.

The most popular floor insulation materials are:

- Floor Butts 25 mm;

- Floor Butts I;

- Floor Butts.

Floors on joists

Thermal insulation of the floor along the joists

At the first stage, a Rockwool membrane is laid on the floor, intended for waterproofing. Its joints must be taped. Then log beams are laid, in the gaps of which thermal insulation is laid. It is recommended to strengthen the vapor barrier membrane on top and only then lay the floor covering.

Flat roof

Sloping a flat roof with Rockwool Roof insulation Insulation

of a flat roof should be carried out only from the outside. Initially, Rockwool slabs are laid on the base - Roof Butts, Bondrock, Sandwich Butts K. Next, a cement screed is poured and the roofing material itself is laid.

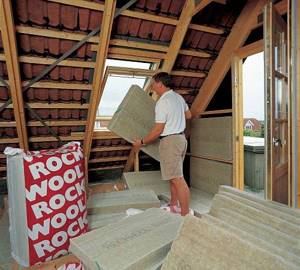

Attics and roofs with rockwool slabs

The attic is insulated only from the inside. So, the insulation is inserted between the rafters and covered with plasterboard or thin sheathing board. In this case, it is advisable to lay insulation in several layers.

Pitched roofing structures and attics

Insulation of the roof above the attic

This work is carried out only after the roof covering has been installed. This will prevent the insulation from getting wet in case of rain or snow. The inner side of the counter-lattice is sheathed with a ROCKWOOL hydro-windproof membrane for roofing. Next, the finished frame of the attic or pitched roof structure is filled with insulation. It is then covered with a vapor barrier membrane and reinforced with a construction stapler. To create an air gap, install lathing in the form of plasterboard, cladding boards or wood boards.

Baths or saunas

Insulation for baths and saunas Rockwool

Rockwool produces special materials for insulating baths and saunas, which have high properties for retaining heat in steam rooms. They retain heat effectively, which helps save on electricity or firewood. Of particular importance is the aluminum coating on one side of the Butts insulation, which significantly increases the vapor barrier properties.

The insulation is installed in two layers from the inside of the room with the aluminum side inward in a checkerboard pattern, that is, staggered. This provides excellent thermal protection. For greater efficiency, the joints are glued with aluminum adhesive tape Rockwool 100 or 50 mm. Next, a sheathing is installed, which provides an air gap between the insulation and the exterior finish. The slabs themselves are mounted against the frame posts. The most common types of insulation for steam rooms are Rockwool Sauna Butts and a second layer of Rockwool Light Butts Scandic 100 and 50 mm.

Technical data

- fire safety Mineral wool of the famous ROCKWOOL brand is absolutely non-combustible and strictly complies with GOST 30244-94 with fire safety class NG.

density of Rockwool mineral wool The dense structure of basalt mineral wool corresponds to the range from 35 kg/cub. m up to 200kg/cu.m. These numbers are not empty indices; they are confirmed by many technical and laboratory tests. And at the same time, it has been proven in practice that the high density of Rockwool materials gives the modified range of manufactured products high energy saving indicators, that is, all wool has almost zero thermal conductivity, preserving the microclimate of the premises. hydrophobicity of stone wool The property of mineral wool not to absorb moisture has been achieved thanks to the latest production technologies, which in turn consists of adding water-repellent agents. Water or condensation does not linger on the surface of the product; all moisture quickly evaporates without penetrating into the material. The water absorption figure is exactly 1.5%. Even in operating conditions with high humidity, Rockwool does not become saturated with water, does not rot or collapse. Its characteristics and forms do not change. vapor permeability The penetration of steam into the thickness of the material and its evacuation occurs instantly. A “breathing” system with a vapor permeability coefficient of 0.25 mg/(m*h*Pa) helps to pass steam through the entire thickness without retaining it or turning it into condensate. Correct installation of mineral mats or slabs with a ventilation layer in the insulating “sandwich” ensures a minimum level of danger of condensation formation inside the heat and sound insulation system of buildings.

mechanical properties and service life Rockwool has the following data: compressive strength with deformation of 10% = 20 kPa and tear strength = 7.5 kPa, which indicates endurance to mechanical damage while maintaining technical characteristics and appearance. One can say about Rockwool mineral wool - the material is durable: it does not burn and does not break. The material has a service life of 50 to 80 years. acoustic index Mid-frequency or low-frequency noise does not penetrate mats or slabs of basalt material. Sound absorption occurs due to the smallest interfiber air cushions. In rooms insulated with Rockwool, complete acoustic comfort is felt. — environmentally friendly products. The material used is harmless to health. It is part of the group of environmentally friendly products. thermal conductivity Thermal insulation depends on the technical parameters of the insulation, mainly depends on thermal conductivity. Rockwool is considered the best insulation. Its thermal conductivity coefficient = 0.036–0.038 W/m K. Here is a clear example: a slab with a thickness of 5 cm can replace brickwork with a thickness of one meter or a wooden beam with a thickness of 45 cm. This illustrative example proves the high heat-saving ability of mineral wool. heat insulators for very hot surfaces

Modifications of Rockwool products: Tech Butts, Wired Mat or Fire Butts are used for thermal insulation of buildings or equipment whose operation is associated with constant high temperatures. These materials are used in the insulation of stoves, chimneys, fireplaces, fireplaces, as well as for furnace equipment such as bakery ovens, boiler rooms, heating mains with hot coolant, forges and blast furnaces. Mineral wool of this level can withstand temperatures above 1000 degrees Celsius. If the temperature level exceeds the specified figure, the mineral wool melts.

Advantages of ROCKWOOL mineral wool

Thermal insulation from the ROCKWOOL brand is able to compete with various materials for similar purposes due to the following qualities:

- The material is environmentally friendly despite the presence of formaldehyde salts in it. All of them go through a polymerization process, so they do not evaporate toxic gases during operation.

- It is a barrier against impact noise and vibration. Almost all outdoor work (in particular, construction) is inaudible indoors due to the unique structure of the heat-insulating layer.

- Basalt slabs practically do not get wet if they are installed correctly. Even the smallest violation of integrity can cause regular accumulation of moisture, which will result in the appearance of dampness and fungus on the walls. Therefore, it is important to properly fix the material on the surface.

- Durability of insulation. Achieved through the random placement of mineral wool fibers.

Users also note the quick and convenient installation of the heat insulator due to its unique structure.

ROCKWOOL slabs are perfectly cut without losing their factory geometric shape.

Knauf (Stupino, Tyumen)

Knauf

Each of the thermal insulation options in the innovative Knauf Insulation line is designed to solve specific problems:

- Knauf Insulation Facade - for insulating walls under ventilated facades and plaster.

- Knauf Insulation Pitched Roof - for thermal insulation of pitched roofs and attic floors.

- Knauf Insulation Acoustic Partition – for effective sound absorption.

High profitability with this material is possible when insulating large areas, such as production or retail sites. When building a private house and apartment, you will pay a little more than for conventional material, but you will receive reliably insulated surfaces.

Pros - declared environmental friendliness, due to the absence of a phenol-formaldehyde binder and packaging (a single package reduces the volume of material by half, a multipack - 8 times).

The downside is the modest size range and price.

Main characteristics of Knauf Insulation

| Knauf Insulation Facade Thermo Plate 032A | Knauf Insulation Pitched Roof Thermo Roll 037 | Knauf Insulation Acoustic Partition | |

| Purpose | Thermal insulation of ventilated facades | Reducing heat loss in the attic floor | Soundproofing rooms |

| Dimensions, mm | 1 250x600x100 | 9 000х1 200х50 | 1 250x610x50 |

| Density, kg/m³ | 34 | 25 | 15 |

| Thermal conductivity, W/(m K) | 0.032 | 0.041 | 0.37 |

| Quantity per package(pieces/m²/m³) | 5 / 3.75 / 0.375 | 2/ 12.2 / 0.61 | 24 / 18.3 / 0.915 |

| Price, rub/m³ | 2 133 | 1 388 | 1 282 |

Review of Knauf insulation. The author of the video showed what happened to the insulation after it was set on fire and rolled with a forklift:

https://youtube.com/watch?v=mq7Hi_1nSgI

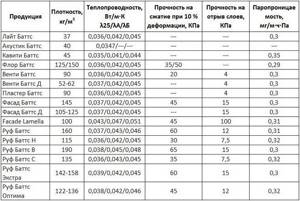

Rockwool technical specifications

Rockwool Butts insulation has high performance characteristics, which once again confirms its popularity among thermal insulation boards.

Technical characteristics of Rockwool

In addition, all products are manufactured using special technologies and have an EcoMaterialGreen quality certificate, which confirms complete environmental friendliness and safety.

Advantages

Thermal insulation with this material has its significant advantages:

- the slabs do not form gaps and cracks due to the increased density during installation;

- reliably protects against the formation of mold, mildew, and rodents due to its high biostability;

- non-flammability of the material;

- moisture resistance;

- high sound and heat insulation;

- springy base, which is obtained as a result of the unique “flexi” technology, which makes installation quite easy and quick.

Scope of application

Light Butts are modern construction pressed slabs made from stone wool. It is obtained by processing basalt rocks, which makes the material strong and resistant to various damages and impacts. So, the scope of their application is quite diverse:

- building's facade;

- interior walls;

- interior partitions, balconies, loggias, attic;

- roof;

- floor coverings;

- entrance doors, garage doors;

- external and internal walls of the apartment.

Rockwool insulation, due to its technical characteristics, has a wide range of applications.

Specification and Dimensions

The manufacturer produces products in two types:

- standard – 60x80 cm (thickness – 5 or 10 cm) – this size is convenient for transportation by car;

- XL – 60x120 cm (thickness – 10 and 15 cm) – in case of transportation by truck.

To roughly understand how much space one package occupies and to facilitate the process of loading and delivering material, you can use the table:

Rockwool insulation size

Mineral wool

The group of mineral wools used for thermal insulation includes:

- glass wool;

- stone wool;

- slag wool.

It is stone wool obtained by melting rocks of volcanic origin that has the best performance characteristics and safety. This served as an impetus for the technical development and improvement of stone wool and, in particular, basalt wool, which made it virtually no alternative.

Stone wool

The definition of stone wool includes any material obtained by melting rock and then blowing out thin threads. Naturally, the mineral composition of fossil resources varies in different parts of the world, which is why the characteristics of mineral wool among manufacturers and brands may vary, as well as the actual performance properties.

Basalt wool

If we consider the mineral wool produced by the Rockwool concern, then it can fully be classified as basalt. A group of gabbro-basalt rocks was recognized as the main ingredient, from which it is possible to blow high-quality fiber with excellent mechanical properties. Equally important is the high-quality combination of additional components, such as a binder, hydrophobic additives, etc.

The development of mineral wool production technology, as well as all the innovative achievements of the Rockwool company, since 1957 after the formation of the design bureau, is associated precisely with the improvement of the properties and qualities of the basalt wool used.

Main advantages of the material

Rockwool heat insulator has a lot of useful properties, each of which requires special attention.

Thermal insulation

Perhaps the most basic and important indicator thanks to which Rockwool has become popular all over the world. One layer of this material (100 mm) can replace a wooden beam 44 cm thick or a layer of brick almost 2 meters thick, which is explained by the low thermal conductivity of stone wool.

Fire resistance

The insulation can withstand temperatures up to 1000 degrees without emitting smoke, heat or dripping burning elements.

Even if a fire occurs, the insulator will reliably protect the building frame and provide the opportunity for timely response and rescue of people.

Clean and environmentally friendly

Rockwool has been awarded the eco-friendly label (EcoMaterial Green) and can even be used to decorate children's rooms and bedrooms.

Economical

The material has a positive energy potential. That is, the amount of energy spent on its production is significantly less than the energy resources that Rockwool saves.

High level of sound insulation

The unique porous structure of the insulation forms small cavities that communicate with each other, as a result of which vibration is minimized and excessive volume of unwanted sounds is eliminated.

Durability of use

Stone fibers intertwined in different directions create a strong frame and ensure long-term stability of the shape of Rockwool layers.

This helps the heat insulator avoid deformation and failure of the slabs, and also prevents a decrease in the thickness of the layer during operation.

Other benefits

The mechanical strength and ease of processing of the material add to its advantages. In addition, Rockwool can be used in structures where the use of insulators that weigh down the frame is unacceptable or highly undesirable.

The technical characteristics of Rockwool allow you to keep the room cool in the summer and keep it warm in the winter. As a result, any consumer is provided with a comfortable atmosphere and coziness. The main condition is to choose the correct thickness of the material.

Insulation safety

Stone wool is considered one of the safest. The manufacturer was the first to receive the well-deserved EcoMaterial Green certificate of conformity. Therefore, the insulation is available for use in any children's, medical and public institutions. This material is of exclusively natural origin; safe resins are used for binding.

Due to the presence of a European certificate, the use of Rockwool thermal insulation in residential conditions is acceptable. There is no phenol in the structure. For this, the manufacturer used high-tech binding resins in the solid state.

Advantages of Rockwool Scandic thermal insulation

All Rockwool insulation is made from stone wool, making it a non-flammable material. It can withstand heating up to +750°C. But it is not recommended to use it in places with temperatures above +250°C, since in this case the binder component begins to deteriorate. The thermal insulation properties of Rockwool are preserved, but the service life is reduced.

Low thermal conductivity helps to significantly reduce home heating costs. In addition to excellent thermal insulation properties, Light Butts Scandic insulation is also good sound insulation, muffling airborne noise. Compared to vapor-tight polystyrene foam, Rockwool stone wool removes moisture from the room, but does not absorb it.

Thermal insulation Scandic, like other stone wool, is not of interest to rodents and insects as food. It also does not support the growth of mold and fungi, and is resistant to acids, alkalis and oils. To prevent water from being absorbed into the Scandic insulation, its surface is coated with a water-repellent component. As a result, drops of water flow from it, rather than being soaked inside.

Scope of application, advice before purchasing and storage rules

Light Butts Scandic insulation is recommended for non-load-bearing structures. It is used for thermal insulation of attics, partitions, floors between floors, walls in low-rise buildings, balconies, floors, baths, saunas, pitched roofs and walls under siding.

Before purchasing, you need to carefully inspect the packaging so that it is not torn. There should be no strong dents or cuts on its surface. When purchasing Rockwool thermal insulation from unofficial dealers, it is recommended to check the quality certificates so as not to buy a fake. Unpacked material is stored only under a roof or some other shelter. The main thing is that the Scandic thermal insulation is not exposed to precipitation. Packages must be kept on pallets. Under no circumstances should pallets be stacked on top of each other. The slabs are laid horizontally. Insulation packages should not be thrown, kicked or pulled tightly.

Reviews

“We bought an apartment last year. Outwardly she looked great. With the onset of winter, problems with heat immediately appeared. It did not warm up to a comfortable temperature from the central heating. I had to purchase additional heaters. To prevent this situation from happening again, they decided that it was necessary to insulate it. According to reviews, stone wool seemed better than glass wool. We decided to buy insulation from Rockwool. The density of Light Butts Scandic is good, it is high quality, hard 100 mm. They insulated all the walls with it. It’s very convenient to install, it fits tightly.”

Arkady, Moscow.

“I bought Scandic insulation to insulate the walls of my dacha. Rockwool was a pleasure to work with. The slabs are really quick and easy to install. The packaging is compact. As the manufacturer Rockwool promised, the products do not crumble or become brittle. After insulation, the skin of my hands did not itch and there was no irritation.”

Kirill, Nizhny Novgorod.

“I was very pleased with the price-quality ratio. And the quality of Rockwool Scandic thermal insulation is really at the highest level, you can’t complain about anything. No wonder he has so many positive reviews. In addition to all this, Rockwool perfectly suppresses noise and does not burn

This is very important for us, since the house is made of timber"

Olga, Rostov-on-Don.

“The choice of thermal insulation is now huge, each of them has good reviews. But in terms of characteristics, Rockwool insulation is closer to me, and from experience. It absolutely justifies its price. Yes, after it there is a slight irritation of the skin, but not as severe as after glass wool. Some people never experience skin irritation at all, as it seems to largely depend on how sensitive the skin is. Rockwool slabs are of high quality; inserting them into the frame without any additional fastenings is a pleasure.”

Vasily, Moscow region.

Price

Prices for Rockwool Scandic insulation depend on its density and thickness. The larger they are, the higher the cost, since production required more raw materials.

Table with prices at which you can buy Scandic series insulation of different sizes and thicknesses:

| Dimensions, mm (length/width/thickness) | Weight, kg | Quantity per package, pcs. | Price, rubles |

| 800x600x50 | 9,2 | 12 | 430 |

| 800x600x100 | 9,2 | 6 | 430 |

| 1200x600x100 | 13,8 | 6 | 650 |

| 1200x600x150 | 17,3 | 5 | 650 |

When working with insulation, it is imperative to use personal protective equipment. Open areas of skin are closed. If the room is not ventilated, respirators are used. Upon completion, a thorough vacuuming is carried out. If the ceiling is insulated, you must wear safety glasses. After installation, hands are first rinsed with cold water, and only then a complete wash is carried out.

Insulation of technical objects

These include heating pipes, air ducts, and industrial furnaces. Cannot be used in the food industry. Marking of this material There are 5 types, their difference lies in density, size, shape. For convenience, there are lamella rolls, that is, there is no need to calculate how to properly cut the material in order to secure it.

Let's consider the characteristics that are significant for the consumer:

- Good level of heat transfer, it allows you to retain up to 75% of thermal energy.

- Saving on material at the construction stage, 5 cm of insulation corresponds to 20 cm of timber, or about 100 cm of brickwork.

- Environmental friendliness and safety for humans. Does not cause allergies, can be used in preschools and medical institutions.

- High level of noise absorption.

- Long lasting.

- Easy to install as it can be cut using a utility knife.

- It does not contain mold or mildew.

There are practically no disadvantages as such, however, such a material must be used with a water-repellent membrane. And there are not representative offices everywhere, which creates some shortage of goods.

Review of the qualities of wall insulation

Basalt thermal insulation in the form of mats is considered the best option for arranging the wall pie of frame walls. The material combines the main properties: heat capacity, vapor permeability, resistance to deformation and fire.

Heat-saving effect and vapor permeability

The main advantage of “stone” mats, which determines their scope of application, is their high thermal insulation ability. Rockwool basalt wool does an excellent job of regulating the temperature inside the house. In winter, insulation protects the room from frosty air, and in summer it keeps it cool and prevents heat from penetrating inside. The insulating mats are tightly joined together. This technology prevents the appearance of cracks - cold bridges.

Elastic stone wool sheets are easy to install; additional fasteners are not needed - the layers are installed in a pre-prepared frame.

An undeniable advantage of basalt insulation is its “breathing” ability. Unlike foam insulators, natural wool allows air to pass through. The frame does not create a thermos effect, and excess accumulated moisture is removed through the micropores of the insulation.

Moisture resistance and sound insulation

Reviews show that stone wool used on walls or floors inhibits the spread of impact and airborne noise. By choosing the optimal insulation layer, you can achieve a reduction in the sound effect within the range of 43-62 dB.

An undeniable advantage of basalt insulation is its hydrophobicity. Stone does not get wet - drops do not linger on the surface, but roll down. The material does not absorb water, which means it retains its thermal insulation qualities.

This property of insulation is very important for external installation, using cotton wool for arranging “wet” areas: saunas, baths

The inability to accumulate water and the mineral base of the heat insulator exclude the emergence of a favorable environment for the development of parasitic microflora, the appearance of rodents and insects. The stone wool composition is not characterized by the processes of rotting, decomposition, and mold formation. Rockwool basalt mats can be reused - their characteristics and qualities are practically unchanged over time.

Useful: Rack ceiling: design features, materials, do-it-yourself installation instructions

Fire safety and environmental friendliness

The key factor in using insulation in residential buildings is operational safety. In this regard, stone wool has succeeded.

Basalt can withstand high temperatures and does not ignite; the heat insulator begins to melt when heated from +1000°C. Rockwool insulation complies with the following safety classes:

- KM0 – completely safe;

- NG – non-combustible materials.

Due to its fire resistance, stone wool insulation is often used as an effective fire barrier.

Rockwool thermal insulator is considered an environmentally friendly product. No harmful components are involved in its production - only a natural mineral and a water repellent that ensures moisture resistance. Stone wool, regardless of operating conditions, does not emit hazardous substances into the environment. In terms of environmental friendliness, Rockwool basalt insulation is ahead of most alternative polymer-based insulation materials. Its use is permissible inside the home.

Mounting methods

To properly install thermal insulation on the external wall of a house, you can use special fastening dowels or an appropriate adhesive base.

Application of special glue

If high-quality and expensive wool is used to insulate the facade, it is necessary to use glue of the appropriate quality. This material must contain a sufficient amount of binder component. Depending on the mass of the insulation mats, it is necessary to select a fixing base. To attach the thermal insulation sheet to the surface, you must:

- pre-print the material and leave it for a day;

- find the wrong side and mark the locations for the glue;

- stir the glue according to the recipe indicated on the package;

- make strokes around the perimeter with a spatula;

- Carefully lift the material and fix it in the desired place on the wall.

It is better not to combine different adhesives with each other in order to save money. This will negatively affect the tightness of the heat insulator.

Fastening to construction dowels

You must first determine what structure the basalt wool has, since there are different types of dowels for solid and porous insulation. To calculate the number of fastening tools, you need to know the height of the building and the wind zone. Approximately 6 dowels are needed to install one square meter of insulation.

The wind strength is always greater at the corners of buildings. Here you need to securely secure the insulation layer. Therefore, the number of fasteners needs to be increased.

It is often practiced to combine glue and dowels when installing insulation for Rockwool walls.

Rockwool technical specifications

Rockwool Butts insulation has high performance characteristics, which once again confirms its popularity among thermal insulation boards.

Technical characteristics of Rockwool

In addition, all products are manufactured using special technologies and have an EcoMaterialGreen quality certificate, which confirms complete environmental friendliness and safety.

Advantages

Thermal insulation with this material has its significant advantages:

- the slabs do not form gaps and cracks due to the increased density during installation;

- reliably protects against the formation of mold, mildew, and rodents due to its high biostability;

- non-flammability of the material;

- moisture resistance;

- high sound and heat insulation;

- springy base, which is obtained as a result of the unique “flexi” technology, which makes installation quite easy and quick.

Scope of application

Light Butts are modern construction pressed slabs made from stone wool. It is obtained by processing basalt rocks, which makes the material strong and resistant to various damages and impacts. So, the scope of their application is quite diverse:

- building's facade;

- interior walls;

- interior partitions, balconies, loggias, attic;

- roof;

- floor coverings;

- entrance doors, garage doors;

- external and internal walls of the apartment.

Rockwool insulation, due to its technical characteristics, has a wide range of applications.

Specification and Dimensions

The manufacturer produces products in two types:

- standard - 60x80 cm (thickness - 5 or 10 cm) - this size is convenient for transportation by car;

- XL - 60x120 cm (thickness - 10 and 15 cm) - in case of transportation by truck.

To roughly understand how much space one package occupies and to facilitate the process of loading and delivering material, you can use the table:

Rockwool insulation size

About the manufacturer

Rockwool is an international company with roots in Denmark. He has been working with insulation based on stone wool since the thirties of the last century. An important step towards development was the acquisition of factories in Germany and a number of other European countries, as well as the founding of our own design bureau in 1957. This gave a powerful impetus to the development of both the Rockwool company itself and the insulation product. Basic modifications of roll insulation and rigid slabs with different performance characteristics were created. The modern product range already includes several dozen highly specialized thermal insulation materials with optimized characteristics.

Officially, Rockwool insulation appeared on our market in 1995 with the opening of a sales office. Already in 1999, the first plant was launched. In total, the market offers products from four factories operating in the Russian Federation using local raw materials and in strict accordance with the technologies and quality control of the international company Rockwool:

- G. Zheleznodorozhny, Moscow region;

- Vyborg, Leningrad region;

- G. Troitsk, Chelyabinsk region;

- SEZ "Alabuga" Republic of Tatarstan.