If it is impossible to connect to a central gas pipeline, an alternative to switching to solid fuel or using electric heating can be heating the house with gas cylinders. This method of heating a home is by no means uncommon in our country, because in terms of its characteristics, liquefied gas is no different from main gas, although it is much more expensive.

Heating a private house with gas cylinders

Arrangement of balloon heating

In the vast expanses of our country, there are still areas remote from the main roads and amenities of civilization with several dachas or houses. Is it possible to heat a house with liquefied gas from a cylinder in an area remote from gas communications?

?

In principle, there are no restrictions or prohibitions on autonomous heating of an individual house with gas in cylinders. But heating with gas not from the central pipeline requires significant costs to obtain thermal energy.

Heating a house with liquefied gas is rational when

:

- building area up to 100 m2;

- installation of effective thermal insulation of the building;

- minimal heat loss.

Organizing home heating from gas cylinders can also be considered as a short-term solution, since in the future it is possible to re-equip the existing boiler for power from a central gas pipeline.

Heating of a country house with liquefied gas is carried out using standard 50-liter cylinders. The vessels are predominantly filled with propane and butane, which are pre-liquefied.

Gas heating can also be performed using the following combinations of combustible substances

:

- SPBTL (summer version of the mixture);

- SPBTZ (winter version).

Liquefied gas cylinders

Cylinders require constant monitoring in winter. Even at the lowest temperatures, heating gas mixtures do not freeze, but interruptions in the supply of fuel are quite likely, which is explained by different boiling temperatures (for propane - -40°C, for butane - 0°C).

If we consider a temperature of -10°C, the mixture begins to boil in a gas-filled vessel, and propane evaporates first. Before the butane begins to boil, a decrease in its evaporation can be observed in the bottled gas, which leads to a decrease in pressure below the level required for normal operation of the boiler.

The best possible solution in such circumstances is to heat the cylinder to a temperature at which the butane begins to evaporate. For this purpose, a corrugated hose from the boiler room should be inserted into the box. To transfer heated air through a constructed channel, it is necessary to use low-power duct fans.

Also, when heating in winter, it is possible to organize heating of the box with pipes according to the principle of a warm floor.

Cylinders located in conditions of negative temperatures in a country house or in a private house should under no circumstances be heated with heating cables or heating elements.

Which boiler to use

Gas heating of a private house from cylinders is mainly carried out using a boiler with a water circuit as a heat generator. Moreover, any boiler models designed to burn natural gas are suitable. For normal operation of the equipment, you only need to replace the burner or adjust (replace) the nozzles - most boiler manufacturers include a special kit for liquefied gases in the delivery.

The type of heating device and its power are selected in the same way. However, taking into account the high operating costs of gas heating, you should choose a boiler with the highest possible efficiency, for example, a gas condensing heat generator.

Wall-mounted gas boiler for heating with cylinders

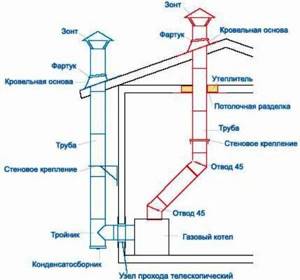

Connection diagram to the boiler

Heating a country house with gas cylinders requires retrofitting equipment and purchasing

:

- boiler;

- special nozzles for gas, if they are not included with the boiler;

- gearbox;

- ramps;

- shut-off valves.

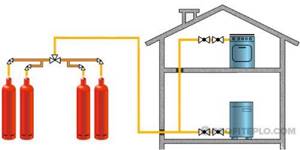

Installation of cylinders in basements or basements is not recommended; the best place for their location is a box made of metal, with ventilation holes made at the bottom and top of the front part

.

Tanks should be placed strictly horizontally; storing full cylinders in a vertical position is not allowed. The box should be located on the north side of the building, if possible in the most shaded place.

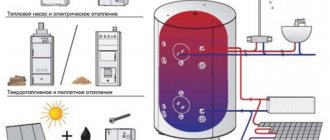

For normal operation of the heat exchanger, it must be connected to a “battery” of 4-5 heating cylinders. Their installation and connection is carried out according to the following scheme.

To install the gas outlet pipeline, a pipe with walls with a thickness of 2 mm or more is used. At the point where it passes through the wall, a sleeve is installed with a diameter larger than the diameter of the pipe by 20-30 mm. The space between the pipe and the circumference of the sleeve is filled with polyurethane foam.

The inclusion of vessels in the system is carried out using a reducer that returns the gas from the liquid back to the vapor state for its subsequent supply to the boiler.

The connection is made in two ways: one common reducer for all cylinders or one device for each of the vessels. The implementation of the second method will be more expensive, but it ensures complete security.

To increase the interval between refills, it is better to connect several cylinders to the boiler at the same time through a ramp - a two-arm manifold that separates the vessels into the main and reserve bundles. Gas first comes from the main bundle, and when it comes to an end, the boiler switches to the spare one. When installing new, filled cylinders, the heater returns to power from the main bundle.

LPG heating system

All connections during installation are made in the form of pipes and hoses; detachable connections are checked for leaks by soaping.

Heating a country house with bottled gas requires compliance with the most important safety rule: filling a cylinder with more than 80% of its volume is prohibited. The reason is the high percentage of expansion of the mixture of propane and butane. Despite the sufficient strength of the cylinder, when its volume is filled above 94% and the temperature rises, there is a high probability of explosion.

Cylinders or gas tank

To store gas in a liquid state, gas tanks are also used - large-volume steel tanks, which, unlike standard cylinders, are often enough for the entire cold period.

Pros and cons of heating with gas cylinders

Infrared heater running on bottled gas

A gas stove for heating a house from a cylinder operates using propane or butane. The main working component is liquefied during the production process and driven into containers. Converting a gaseous substance into liquid form is necessary, since it will require much larger containers for storage in its normal state. Liquefaction of gas allows it to be stored in cylinders in maximum quantities.

The finished cylinders are connected to a reducer, which reduces the pressure, due to which the gas returns to its original state. Heat is released during the combustion of gas inside the boiler.

The list of advantages of gas heating using cylinders includes:

- complete autonomy of the heating system;

- low consumption of raw materials and minimum fuel costs;

- stable pressure inside the pipes;

- no problems during operation and installation.

This type of stove heating also has its disadvantages. Cylinders cannot be left outside in winter; at low temperatures they release quickly freezing condensate, which prevents a stable flow of gas. In this case, the heating system will not receive enough fuel and will turn off automatically.

It is necessary to connect and store cylinders taking into account safety precautions, since in the event of a leak, gas poses a threat to life and health.

In a private house

The cylinders can be connected to a heating boiler - enough for a small house up to 100 square meters. m

The gas stove is suitable for heating a house up to 100 sq.m. With its help, you can create a convenient and effective heating system for any building. For your home, you should choose standard 50-liter cylinders with liquefied propane, butane or mixtures with flammable substances for summer and winter.

For saunas and baths

A gas sauna stove is capable of heating a steam room to the required level no worse than its standard wood-burning counterpart. It is easy to use, quite safe and does not require large expenses. If we are talking about a small bathhouse or sauna, two or three convectors are installed in it, which run on gas from cylinders. For a large bathhouse with an area of up to 150-200 sq.m. It is advisable to create a separate gas boiler room and install a boiler.

Liquefied gas consumption

A house with an area of about 100 m2 can be heated with liquefied gas using a 10 kW boiler. To obtain 1 kW of heat energy, the consumption of 100-120 g/min of liquefied gas will be required at 100% boiler load. If the duration of the cold season is approximately 7 months, then the approximate estimated consumption for the entire season will be about 5 tons

.

But in fact, the consumption will be almost half as much - the automation switches the heater to an economical mode when the room temperature is sufficient or in accordance with the timer readings.

When comparing the costs of heating a cottage or house from a main gas pipeline, heating with gas cylinders will be about 5-6 times more expensive. But in the end it will still be cheaper than heating with electricity.

If you look at the cost of gas in liquid state, then heating a country house from cylinders can be considered not the worst replacement for liquid fuel and electric systems. Moreover, if the region has problems with solid fuel or its cost is too high.

Gas cylinders with a volume of 50 liters

Heating with liquefied gas is the best solution if gasification of a populated area is planned in the near future, since then there will be no need to purchase a boiler again. In addition, you will gain personal experience in handling a gas boiler.

Initial data for calculations

To perform a preliminary calculation, you need to find out the following parameters:

- calorific value (calorific value) of natural gas supplied in your area;

- thermal load on the heating system;

- Efficiency of the boiler that is planned to be installed in a house or apartment.

The calorific value of the fuel is taken based on the value of the lower calorific value of the main gas.

Theoretically, when burning 1 m³ of blue fuel, 9.2 kW of thermal energy is released. In practice, this value differs and, as a rule, to a lesser extent. Due to the same rise in price, some unscrupulous suppliers dilute gas with air, which is why its calorific value can decrease to 7.5-8 kW/m³.

To determine gas consumption for heating a house, it is better to find out the caloric value from the management company, and when this fails, use a reserve figure: 8 kW/m³. If they share with you information about the specific heat of combustion and give you a figure expressed in other units, kcal/h, then you can convert it to Watts by multiplying by a factor of 1.163.

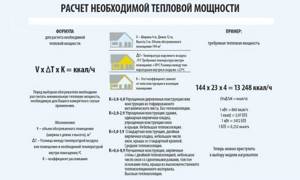

Another important indicator that directly affects fuel consumption is the thermal load on the heating system, which consists of heat losses through the building structures and losses due to heating of ventilation air. The best option is to perform or order an accurate calculation of all heat losses, but in the absence of any other option, you can determine the load using enlarged methods:

- If the ceiling height does not exceed 3 m, then the heat consumption is assumed to be 0.1 kW per 1 m² of heated area of the building. Thus, for a house of 100 m2 you need about 10 kW of heat, 150 m2 - 15 kW and 200 m2 - 20 kW of heat energy.

- Apply 40-45 W of heat per 1 m³ of heated room volume. The load is determined by multiplying this value by the volume of all heated rooms.

The efficiency of the heat generator, which affects the efficiency of fuel combustion, is indicated in its technical data sheet. If the unit has not yet been purchased, then you can take the efficiency of gas boilers of various types from the list:

- gas convectors - 86%;

- boilers with an open combustion chamber - 88%;

- heat generators with a closed chamber - 92%;

- condensing boilers - 96%.

Advantages and disadvantages of heating with liquefied gas

Heating a private house with bottled gas has, in fact, only one significant drawback - the high costs of installation and operation. You will have to pay not only for the gas consumed, but also for the delivery of the cylinders, and they will most likely have to be changed every week.

However, individual heating of a house or cottage with gas cylinders also has its undeniable advantages.

:

- high efficiency and significantly lower labor costs compared to wood heating;

- the possibility of converting the boiler to work with conventional main gas in the future;

- complete independence and autonomy of the system;

- long service life of the equipment;

- high demand for equipment on the secondary market - if necessary, cylinders can always be sold, while returning most of the money spent on them.

Conclusion . Heating using gas cylinders as the only way to heat a home cannot be called profitable in the long term. But as a temporary measure with the future conversion of the boiler to mains gas, it is quite suitable.

Heating with liquefied gas is the use of vapor from a mixture of propane and butane, taken from gas cylinders, a mobile or underground gas holder, as an energy source.

The cost of operating and maintaining a heating system for a private home using liquefied gas, although higher than when operating equipment on natural gas, is lower than when heating with diesel fuel or electricity.

Performing Calculations

A preliminary calculation of gas consumption for heating is made using the formula:

V = Q / (q x efficiency / 100).

- q is the caloric content of fuel, the default is 8 kW/m³;

- V is the required main gas flow rate, m³/h;

- Efficiency is the efficiency of fuel combustion by a heat source, expressed in %;

- Q is the heating load of a private house, kW.

As an example, we offer the calculation of gas consumption in a small cottage with an area of 150 m² with a heating load of 15 kW. It is planned that the heating task will be performed by a heating unit with a closed combustion chamber (efficiency 92%). The theoretical fuel consumption per 1 hour in the coldest period will be:

15 / (8 x 92 / 100) = 2.04 m³/h.

During the day, the heat generator will consume 2.04 x 24 = 48.96 m³ (rounded - 49 cubic meters) of natural gas - this is the maximum consumption on the coldest days. But during the heating season, the temperature can fluctuate between 30-40°C (depending on the region of residence), so the average daily gas consumption will be half as much, about 25 cubic meters.

Then, on average, per month a turbocharged boiler uses 25 x 30 = 750 m³ of fuel to heat a house with an area of 150 m², located in central Russia. Consumption for cottages of other sizes is calculated in the same way. Based on preliminary calculations, it is possible to carry out measures aimed at reducing consumption even at the construction stage: insulation, selection of more efficient equipment and the use of automatic control devices.

Heating with cylinders

Heating a house with cylinders is the fastest and cheapest way to organize the supply of gas-using equipment with propane-butane. It is enough to purchase gas cylinders, fill them, connect them to a common manifold with a pressure regulator, place the equipment in a cabinet - and the group cylinder installation is ready! To combine cylinders, gas trains can also be used, allowing you to disconnect and connect cylinders without stopping the gas boiler, and kits for cylinder installations, designed to automatically disconnect spent cylinders and connect refilled ones.

Heating with cylinders

However, heating a private home with bottled gas has a number of disadvantages:

- the greater the power of the gas boiler, the greater the number of cylinders there should be in the installation;

- the need to frequently replace used cylinders;

- impossibility of complete gas production at subzero temperatures;

- gas cylinders are a source of increased danger.

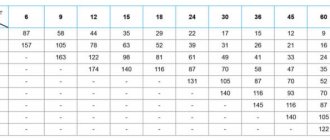

How much gas is consumed to heat a house with an area of 100-200 m2?

When planning to heat a private home, it is necessary to calculate the cost of heating with main gas. During the operation of the equipment, this is much easier to do; you just need to track the readings of the measuring device at the beginning and end of the month. It is equally important to know energy consumption at the design stage. This will help you choose the right devices for the system and determine the quality of the media.

Large areas require considerable costs to ensure comfortable living in a private home. First of all, this concerns heating, so you need to optimize the operation of the heating system as much as possible and find out the resource consumption for servicing the premises.

Calculations primarily depend on the area of the building. Another important indicator is power. According to the standards, it is determined for each room during the most severe frosts for five days. In reality, much less energy is used, since air temperatures can fluctuate within reasonable limits throughout the season.

1. For average consumption, you can take a value of 50 W/m2 for 60 minutes. This means that for heating an area of 100 m2 it will be 5,000 W, for heating a private house of 200 m2 - 10,000 W.

2. You can use the formula: R=V/(qHxK), where R is the volume of gas in m3 per hour, V is the specified thermal power, qH is the lowest combustion rate (10 kW/m3), K is the boiler efficiency.

3. As a result, the consumption of natural gas for a private house of 100 m2 is 5/(10x0.9) = 0.55 m3 per hour, respectively, for heating twice as large an area the figure will be 1.11 m3 per 60 minutes.

A clever meter that saves electricity Pays for itself in 2 months!

4. To find out the daily consumption, multiply the resulting value by 24: 0.55x24=13.2 m3. The parameter for 30 days is determined in the same way - 13.2x30 = 396 m3.

5. If you need to calculate consumption for 1 m2, the monthly figure is divided by quadrature, resulting in gas consumption of 3.96 m3. Since the cold season can last differently in each region, it is recommended to calculate the parameter over 7 months, which will give an average value at the design stage.

To convert into monetary equivalent, you need to multiply the price values for 1 kW/h and the seasonal consumption index. This will give an approximate figure for heating costs for the entire cold period.

Heating from a mobile gas holder

A mobile gas holder is a quick and affordable solution to the problem of temporary gas supply, as well as gas supply to a dacha or small country house. It is a mini gas holder with a volume of 598 liters, mounted on a trailer and having a heating system.

Mobile gas tank for heating a house with propane

Has a lot of advantages:

- gas is heated using the coolant of the house heating system, so stable evaporation of gas occurs at any ambient temperature;

- quick-release connections provide easy connection of the mobile gas tank to the gas pipeline and heating system;

- the trailer allows you to transport the mini-gas tank to a gas station for refueling;

- safety equipment and a level gauge that allows you to control the degree of filling of a mobile gas tank provide increased safety compared to gas cylinders;

- can be sold on the secondary market.

Heating from a gas holder

Gas consumption for heating 1 m² of area of a country house, taking into account hot water supply, is on average 25–30 liters of gas per year, i.e., heating a cottage with an area of 200 m² with permanent residence requires about 5000–6000 liters of LPG per year. Gas consumption greatly depends on the quality of the house’s thermal insulation, mode of residence, presence of a swimming pool, etc.

Using a gas tank for heating a home is the most comfortable way to supply gas-using equipment with liquefied gas.

Liquefied gas for heating is taken from a special container - a gas holder

The advantages of gas tank heating at home include the following:

- there is no need to carry and carry cylinders or transport the tank to a gas filling station;

- an underground gas tank does not take up space on the site and does not spoil its appearance;

- the propane-butane mixture located inside the gas holder intensively evaporates almost completely due to geothermal heat;

- the volume of the gas tank can be selected so that its refilling will be required once a year or even less often, and draining gas from the tanker into the gas tank takes no more than 20–60 minutes;

- the volume of the gas holder can be sufficient to operate a gas stove, boiler and power plant at the same time;

- due to the presence of built-in safety equipment, underground placement and the use of a two-stage pressure regulator with a safety relief valve (PSV), the gas holder is less dangerous than a gas cylinder;

- The external and internal gas pipelines are made permanently, and a thermal shut-off valve and a gas alarm with a shut-off valve are installed on the internal gas pipeline, which further increases the safety of gas use.

The disadvantages of a gas holder for heating include its relatively high price and the need for excavation work.

Standard and real consumption

According to the standards, thermal calculations of premises are carried out for extreme conditions - the coldest winter five-day period. The boiler unit must have sufficient power to replenish the heat losses of the house in conditions of prolonged frosts characteristic of a particular climate.

As a result, we have the following situation:

- The boiler power is designed for maximum load;

- boiler equipment is selected with a small power reserve;

- When selecting the power of the unit, the gas consumption for cooking and the use of other equipment operating on this fuel is taken into account.

Accordingly, it makes no sense to calculate gas fuel consumption based on the rated power of the boiler unit. In real conditions, during the heating season (in the main territory of the country it lasts about 7 months), the temperature fluctuates over a significant range.

Attention! According to the above, in order to calculate the average gas consumption for heating, the design, and not the nameplate, power of the boiler should be divided by 2.

Example: for simplified calculations of coolant consumption, the standard value of thermal power is used: 1 kW per 10 m 2 of a private house. This means that the estimated power of the boiler unit for a house of 100 m2 will be 10 kW. Therefore, the thermal power indicator (Q), which we need to calculate the average fuel consumption, is 10/2 = 5 (kW).

Heating with main gas

To calculate gas fuel consumption, use the following formula

:

V = Q / (Hi × ηi)

, Where:

- V (m 3 /hour)

– the volume of gas that needs to be consumed to obtain a certain amount of thermal energy; - Q (kW)

– design thermal power that allows you to maintain a comfortable temperature level in the house; - Hi (kWh/m3)

– indicator of the lowest specific heat of combustion of gas, standard tabular value (details below); - ηi (%)

– boiler unit efficiency, an indicator of how efficiently a gas boiler uses the generated thermal energy to heat the coolant.

Let's look at the specific heat of combustion of gas. Main networks mainly use G20 gas, but G25 gas can also be used; information can be obtained from your local gas supply organization. G25 gas has a higher nitrogen content, which reduces its energy potential.

| Type of natural gas | Hi (lower specific calorific value) | Hs (highest specific heat of combustion) |

| G20 | 34.02 MJ/m3 = 9.45 kWh/m3 | 37.78 MJ/m3 = 10.49 kWh/m3 |

| G25 | 29.25 MJ/m3 = 8.13 kWh/m3 | 32.49 MJ/m3 = 9.02 kWh/m3 |

In addition to the Hi

, which we need for calculations, the table shows the

Hs

- it is used when calculating fuel consumption for condensing boilers. This new generation equipment is more efficient due to the fact that during the steam condensation process, an additional 10% of thermal energy is removed.

Attention! Hi into the formula

in kWh/m3.

Boiler efficiency (ηi)

indicated in the product passport. If the document contains two indicators (for the lower and higher calorific value of gas fuel), use the smaller coefficient for calculations, since it more accurately reflects the real capabilities of the boiler.

Example: let's calculate the average consumption of main gas G20 for a house with an area of 100 m2. In this case, we will assume that the house is insulated and the calculated thermal power is 9.6 kW, and the efficiency of the boiler unit is 0.92%.

As we already know, the calculated thermal power should be divided by 2, i.e., Q = 9.6/2 = 4.8 kW.

Thus: V = 4.8 / (9.45 × 0.92) ≈ 0.56 m 3 /hour.

Let's calculate the fuel consumption of G20:

- per day 0.56 × 24 = 13.44 m 3;

- per month (on average) 13.44 × 30.5 = 409.92 m 3;

- during the heating season (7 months) 409.92 × 7 = 2869.44 m 3.

To calculate the annual financial costs of heating, multiply the resulting value by the cost of one m 3 of main gas in your region.

Let's calculate the gas consumption for heating a house of 150 m2

. If the fuel is main gas G25, the boiler efficiency is 0.92, and to calculate the design power, a standard indicator of 1 kW per 10 m 2 was used, i.e., Q = 15/5 = 7.5 kW.

V = 7.5 / (8.13 × 0.92) = 1.002 m 3 /hour.

Let's round up to 1 m 3 / hour and calculate the annual consumption: 1 × 24 × 30.5 × 7 = 5124 m 3.

This calculation system helps to obtain an average value - on cold days the intensity of fuel consumption increases, on warm days it decreases relative to the average.

Costs for heating with liquefied gas

The consumption of liquefied gas for heating a house is calculated so that:

- understand the level of financial costs for purchasing fuel;

- determine the optimal size of the gas tank or count the number of gas cylinders, develop a suitable schedule for their delivery.

Calculations are carried out according to the same scheme as in the case of using main gas, but the volume of liquefied gas is measured in liters.

Liquefied hydrocarbon fuel G30, which is mainly used for autonomous gasification systems, is a propane-butane mixture with the following characteristics:

- fuel density 0.524 kg/l;

- specific heat of combustion 45.2 MJ/kg = 23.68 MJ/l = 6.58 kW/l.

Important! To fill the gas tank, fuel with different percentages of propane and butane is used (summer and winter), so carefully consider the choice of liquefied gas and take into account its characteristics when making calculations.

Let us apply the formula V = Q / (Hi × ηi) that is already familiar to us to calculate the volume of liquefied fuel required to heat a house with an area of 200 m2

.

We will assume that the calculated consumption corresponds to the standard (1 kW per 10 m 2), i.e., Q = 20/2 = 10 kW. Boiler efficiency is 0.92%.

V = 10 / (6.58 × 0.92) = 1.65 l/hour.

Therefore, the approximate annual consumption will be: 1.65 × 24 × 30.5 × 7 = 8454.6 liters.

By adding to the obtained value the fuel consumption for a gas stove, etc., you can determine what size of gas holder you need to choose in order to refuel it 1-2 times a year.

If gas is supplied in cylinders, we can calculate the amount required for heating. The total volume of the cylinder is 50 liters, but they are not completely filled, so the volume of liquefied fuel is about 42 liters.

8454.6 / 42 = 201.3 cylinders for a house with an area of 200 m2 per heating season (7 months).

So, by substituting into the formula the values corresponding to the parameters of your home, the characteristics of the fuel and the boiler unit, you can easily calculate the average gas consumption for heating.

Benefits of Propane Heating

Cost of 1 kWh of energy

| Fuel | price, rub. |

| Natural gas | 0,61 |

| Liquefied gas | 2,24 |

| Diesel fuel | 3,86 |

| Electricity | 4,12 |

Liquefied petroleum gas as a fuel has certain advantages even over natural gas and significant advantages over diesel fuel:

- availability: installation of a gas tank takes place in 2–3 days, and its refueling is usually carried out the next day after receipt of the application;

- the cost of autonomous gasification of a country house is often comparable to the cost of connecting to the main gas pipeline;

- complete autonomy of the system: there is no distribution network and, accordingly, no accidents in it;

- unpretentiousness: simple operation, high reliability and infrequent refueling (1-2 times a year or less);

- the cost of a gas boiler is significantly lower than a boiler running on diesel fuel;

- liquefied gas is used for heating, cooking and gas power plants;

- when supplying natural gas in the future, the gas boiler can be easily reconfigured, and the gas holder is used as a source of backup fuel;

- the burner of a diesel boiler produces noticeable noise (60–75 dB), and a gas boiler operates almost silently;

- Diesel fuel combustion products contain sulfur oxides that are harmful to plants (especially coniferous trees) and the inhabitants of water bodies;

- a diesel fuel boiler requires annual labor-intensive and expensive maintenance: cleaning the heat exchanger, replacing nozzles and fuel filter, adjusting the burner;

- subject to qualified installation, proper operation and timely servicing, the service life of gas wall-mounted boilers is 15–20 years, floor-standing boilers - up to 25 years.

To install a heating system, you will need a source of thermal energy. This can be main or liquefied gas, firewood, electricity or liquid fuel. The most profitable option is gas. But not all settlements have mains gas. In this case, use its liquefied version. If you decide to use a gas cylinder for heating, you need to familiarize yourself in advance with the advantages and disadvantages of such systems, as well as understand the nuances of their design.

Using a propane-butane mixture

Autonomous heating of private houses with liquefied propane or its mixture with butane has not yet lost its relevance in the Russian Federation, although in recent years it has noticeably increased in price. It is all the more important to calculate the future consumption of this type of fuel for those homeowners who are planning such heating. The same formula is used for the calculation, only instead of the lower calorific value of natural gas, the parameter value for propane is set: 12.5 kW with 1 kg of fuel. The efficiency of heat generators when burning propane remains unchanged.

Below is an example of a calculation for the same building of 150 m², only heated with liquefied fuel. Its consumption will be:

- for 1 hour - 15 / (12.5 x 92 / 100) = 1.3 kg, per day - 31.2 kg;

- on average per day - 31.2 / 2 = 15.6 kg;

- on average per month - 15.6 x 30 = 468 kg.

When calculating the consumption of liquefied gas for heating a house, it is necessary to take into account that fuel is usually sold in volumetric measures: liters and cubic meters, and not by weight. This is how propane is measured when filling cylinders or a gas tank. This means that it is necessary to convert mass into volume, knowing that 1 liter of liquefied gas weighs about 0.53 kg. The result for the example above will be:

468 / 0.53 = 883 liters, or 0.88 m³, propane will have to be burned on average per month for a building with an area of 150 m².

Considering that the retail cost of liquefied gas is on average 16 rubles. for 1 liter, heating will cost a considerable amount, about 14 thousand rubles. per month for the same cottage on one and a half hundred square meters. There is reason to think about how best to insulate walls and take other measures aimed at reducing gas consumption.

Many homeowners expect to use fuel not only for heating, but also to provide hot water supply. These are additional costs, they must be calculated, plus it is important to take into account the additional load on the heating equipment.

The thermal power required for hot water supply is easy to calculate. You need to determine the required volume of water per day and use the formula:

- c is the heat capacity of water, equal to 4.187 kJ/kg °C;

- t1—initial water temperature, °C;

- t2—final temperature of heated water, °C;

- m is the amount of water consumed, kg.

As a rule, economical heating occurs to a temperature of 55 °C, and this must be substituted into the formula. The initial temperature varies and lies in the range of 4-10 °C. For a day, a family of 4 people requires approximately 80-100 liters for all needs, provided that it is used sparingly. It is not necessary to convert the volume into mass measures, since in the case of water they are almost the same (1 kg = 1 l). It remains to substitute the obtained value of QDHW into the above formula and determine the additional gas consumption for DHW.

see also

- 07/26/2016 Formulas for calculating heat loss at home

- 07/11/2016 Two-pipe water heating system: varieties and installation

- 07/14/2016 Types of electric heating of a private house

Bottled gas heating and what is it?

Heating systems that use liquefied gas to heat the coolant are the type we are describing. If methane gas circulates in the central line, then the cylinders are filled with propane or a mixture of butane and propane. Heating with gas cylinders in a private house is done if it is not possible to connect to a centralized gas supply.

Such systems are used in houses with an area of 70-100 square meters. In this case, the building must be well insulated to minimize fuel consumption. Also, to save gas, it is recommended to use not only a boiler running on this fuel, but also electrical heating appliances.

Important! The fuel is in cylinders under high pressure, so disassembling or damaging the containers is prohibited.

Pros and cons of balloon heating

Gas heating from bottled gas has the following advantages:

- The cylinders contain fully purified fuel, which promotes complete combustion in the boiler chamber. As a result, no slag or ash remains.

- Gas-fired heating equipment does not need to be connected to power supply systems, so such heating can be called energy-independent.

- The heating system works stably and smoothly, and its operation is easy to manage.

- Ease of operation is an additional advantage of bottled gas heating.

- The price of gas is the lowest in comparison with other types of fuel.

- The efficiency of such a system is quite high and reaches 90-95%.

- If necessary, heating equipment can be converted to operate on mains gas.

- An impressive service life can also be considered one of the advantages of such heating.

Used cylinders can be sold on the secondary market to offset some of the costs. If you install a double-circuit boiler running on liquefied gas, you can not only heat the house, but also provide it with hot water supply.

The disadvantages of heating with propane or a mixture of propane and butane are the need to regularly refill gas storage tanks. In addition, for the correct and uninterrupted operation of the system, certain conditions must be created.

Reviews

Maria, Volgograd: “We installed a gas boiler using cylinders for heating in a country house. It takes about 2 bottles every 5-6 days. At first there was a problem: in extreme cold, the gas in the cylinders located outside did not evaporate and did not enter the boiler. After insulating the cabinet, this problem disappeared.”

Vasily, Moscow: “In winter, when gas consumption is quite high, we had to replace the spent cylinder too often. They suggested a solution: connect several cylinders into one line using reducers. When one runs out of fuel, the tap from the other opens. In gas heating from bottled gas, we are pleased with the lower monthly costs compared to electric boilers (the difference is almost twofold).”

Using gas heating from cylinders in a private home is an ideal solution in places where there is a need to bypass mains heating. You can purchase factory equipment, or convert old equipment into cylinders. A liter of liquefied gas from a cylinder is more expensive than main gas, but in general gas heating is much cheaper than electric heating.

Connection diagram for gas cylinders to a heating boiler

To connect the cylinder to the boiler, a special reducer is used, which converts liquefied fuel into a gaseous state. It is in this form that it is supplied to the heating equipment. If several containers are used at once, then the same number of reducers will be needed to connect to each cylinder. This is much safer than connecting several containers at once through one common gearbox.

Important! If you use several cylinders, you can increase the operating interval of the equipment on one fuel fill.

To assemble the entire structure, a two-arm collector is used. This is a special ramp that divides all containers into two groups. One group is the main one. From it, gas enters the boiler first. The second group is the reserve group. It is used after the main group runs out of gas. Switching from one group to another occurs automatically. At the same time, a characteristic signal is heard. After refueling and connecting the tanks of the main group, the collector begins to consume fuel from these cylinders.

All containers with fuel are installed from the boiler at a distance of no closer than 200 cm. It is best to allocate a separate room for these purposes or fence off a compartment in the furnace room. It is prohibited to install cylinders in an uncovered place exposed to sunlight.

To connect containers, metal pipelines with a wall thickness of less than 2 mm are used. In the place where the pipes pass through the walls, protective cases are installed, and all openings are filled with foam. A durite hose is used to connect the pipeline to the heater.

Fuel economy

The basic rule is: if the house is properly insulated, then fuel consumption for heating can be significantly reduced. The owner needs to make thermal insulation at the proper level: equip the roof and walls with foam plastic or mineral wool, make a floor of expanded clay, and make a screed on top, change the windows and organize a good seal on the doors using rubber sealing tapes.

There are several ways to save fuel, for example using batteries and heated floors

Other necessary ways to save gas:

- The design of the heating system can also be different, therefore, finances will be spent differently. Instead of radiators, heated floors are used and excellent heating of the room is obtained. It is known from the laws of physics: the lower the heat source, the better for the house, because hot air flows spread through the rooms in a convection manner, that is, from the bottom up.

- The next obvious benefit . The temperature in the radiators can reach up to +90°C, and the floors emit up to +50°C.

- Another way to save money is to temporarily heat the room. If the country cottage is empty, then it makes no sense to actively use heating at full power. It is preferable to set a slightly positive temperature so that the pipes do not freeze.

In this video we will look at how much gas heating costs:

Modern heating equipment simplifies operation so much that you can control boiler automation remotely through a mobile provider, turning on the system in advance before coming home. In addition, this allows you not only to turn the device on or off, but also to change the temperature mode.

Components for cylinder heating systems

Heating using liquefied gas is done using the following components:

- heating equipment with a gas burner;

- reducers for connecting cylinders;

- fuel containers with a capacity of 50 liters;

- ramp;

- rubber-fabric sleeve for connecting the pipeline to the boiler;

- shut-off valves.

The connection diagram is very simple, so it can be implemented by hand. When choosing a suitable gas boiler, give preference to units operating at minimum pressure and maximum efficiency. Consider what type of fuel the boiler is designed for. There are units that run only on liquefied gas. But if in the future you plan to connect the main gas supply, then it is better to prefer universal models that can operate on different types of fuel.

The gas boiler burner must have narrow nozzles that are designed to operate under high pressure bottled gas conditions. Units designed to use mains gas have wide nozzles. If liquefied fuel is supplied through such devices, an accident may occur.

Boilers designed to operate on LPG (liquefied petroleum gas) have special nozzles and a gas valve. To independently convert a conventional boiler to operate using liquefied fuel, you will need to purchase the necessary parts.

How to calculate gas consumption?

To calculate fuel consumption, you need to know the power of the heating equipment. When determining it, they use the rule that for every 10 square meters of heated area, a boiler power of 1 kW is required.

Thus, to heat a house with an area of 100 square meters, you need a boiler with a power of 10 kW. To generate 1 kW of thermal energy, approximately 0.12 cubic meters of gas per hour are consumed. To heat such a house for one hour you will need 1.2 m³ of fuel. Knowing this number, it is easy to calculate the daily fuel consumption. It will be 28.8 cubic meters.

At first glance, it seems that gas consumption is quite high. But these values are valid only for continuous operation of the boiler during the first warm-up of the system immediately after its startup. In the future, the equipment will operate in automatic mode and fuel consumption will decrease.

As a rule, to maintain the temperature in a house with an area of 100 square meters within 22°C at sub-zero temperatures outside, you will need about three cylinders of fuel per week. If at night the temperature is maintained 4-6 degrees below daytime, then fuel consumption will be reduced by a whole cylinder.

If the containers are used to heat a summer cottage for seasonal residence, then the operation of the boiler can be adjusted so that during the absence of the owners in the building the temperature is maintained within +5°C. This will ensure economical fuel consumption. As a result, to heat a small house for 7-10 days you will need only one cylinder of liquefied fuel.

How to save money?

The financial costs of maintaining a comfortable microclimate in the house can be reduced by

:

- additional insulation of all structures, installation of windows with double-glazed windows and door structures without cold bridges;

- installation of high-quality supply and exhaust ventilation (an incorrectly executed system can cause increased heat loss);

- use of alternative energy sources - solar panels, etc.

Separately, it is worth paying attention to the advantages of the collector heating system and automation, thanks to which the optimal temperature level is maintained in each of the rooms. This allows you to reduce the load on the boiler and fuel consumption when the weather warms up outside, and reduce the heating of the coolant that is supplied to radiators or a heated floor system in unused rooms.

If the house has a standard radiator system, a sheet of thin foam heat insulator with an outer foil surface can be glued to the wall behind each heating device. Such a screen effectively reflects heat, preventing it from escaping through the wall to the street.

A set of measures aimed at increasing the thermal efficiency of a home will help minimize energy costs.

How to avoid heat loss

Fuel consumption for heating a house depends on the total area of the heated premises, as well as the heat loss coefficient. Any building loses heat through the roof, walls, window and door openings, and the floor of the lower floor.

Accordingly, the level of heat loss depends on the following factors

:

- climate features;

- wind roses and the location of the house relative to the cardinal directions;

- characteristics of the materials from which building structures and roofing are constructed;

- presence of a basement/ground floor;

- quality of insulation of floors, wall structures, attic floors and roofs;

- quantity and tightness of door and window structures.

Safety precautions when using gas cylinders

If liquefied gas is used to heat your home, you must adhere to the following safety requirements:

- When the system freezes, it is prohibited to use open flames to heat the cylinders. In case of any fire within the house, fuel containers must be removed as far as possible from the fire.

- If a separate room cannot be allocated for fuel containers, then it is impossible to install the cylinders near the cellar or basement, because the gas can fall down. If it gets into the basement, it can lead to an explosive situation or poisoning of people who go down into the room.

- When connecting containers, a leak meter must be installed to minimize the likelihood of explosion and fire.

- It is prohibited to store empty cylinders in the house. For these purposes, a separate building must be allocated, located no closer than 10 meters from the house.

Attention! To ensure safety, the system is inspected and preventive maintenance performed every 4 years.

The nuances of using cylinders in winter

If bottled gas is used to heat a country house, then in winter you need to take care to protect the fuel from freezing. This is especially true for buildings for seasonal use, for example, dachas, when the owners come to the house only on weekends.

If fuel containers are stored outside the house, then at sub-zero temperatures the pressure in them decreases. If the pressure drops significantly, heating equipment may stop working. To avoid this situation, containers with fuel during cold weather are installed in a special cabinet with a built-in ventilation system. Non-flammable insulation is used to insulate the cabinet.

If there is no such cabinet, then it is better to store containers with fuel in an extension to the house, in which there is no heating, but a positive temperature is constantly maintained due to good insulation. Do not forget about other safety requirements when choosing a suitable place to install cylinders for the winter.

Nuances of installation and use

When installing gas equipment at home or in the country, it is necessary to take into account a number of requirements for it.

READ How to install a water heater with your own hands diagram

Chimney

Often, to heat a private home, not one, but two devices are connected to the chimney. If two gas units are connected, then they are located at different levels in relation to each other. The distance between them must be at least 0.5 m. It is necessary to make a cut in the chimney if it is decided to mount the heating devices on the same level.

This design can be in the shape of a cylinder, oval, or in some cases even a square. But in the latter option, you may encounter the problem of poor-quality traction.

The gas furnace pipe must have the same or smaller cross-section as the chimney duct. If several heating devices are connected, the cross-section is determined using special calculations. It is taken into account that the units can operate simultaneously.

The chimney pipe must be protected from excess condensate. To do this, a stainless steel structure is mounted inside it. The chimney must be installed strictly vertically. There should be no ledges.

Installation

It is required to maintain a certain distance between the wall and the oven: it must be at least 5 m.

The heating device must be placed on a non-flammable solid base, the dimensions of which must exceed the parameters of the stove by 10 cm on each side.