It may be news to some that gas boiler equipment requires not only gas, but also electricity. And along with gas consumption, you should also take into account the power consumption of the gas boiler, which is the heart of your heating system.

Now there will definitely be a reader who will object and be right. But he is right in that there are still gas boilers without connection to the electrical network. These are classic floor-standing units with an open combustion chamber; they require a separate room and strict adherence to strict fire safety rules in it.

Non-volatile boilers are currently used in villages remote from cities, in dachas - where there are interruptions in the electricity supply. Or if you want to save on buying equipment. We will talk about modern gas heating equipment, and it only works if there is a high-quality, reliable power supply.

Do you even need electricity for a gas boiler?

There are non-volatile and volatile gas heating boilers. Non-volatile - these are, as a rule, floor-standing atmospheric models that do not require connection to the electrical network. Ignition in them is carried out mechanically (manually), and the combustion process, operation of simple automation and attenuation occurs due to a small current generated when the thermocouple is heated. Accordingly, such boilers do not need to be connected to the electrical network.

Volatile models require a mandatory connection to the mains via a regular outlet: voltage - 220 V, frequency - 50 Hz. These are floor-standing and, most often, wall-mounted boilers with a closed combustion chamber. For the operation of their modules (complex automation with digital displays, automatic electric ignition, turbocharging, etc.), the small current generated by a thermocouple is not enough. It is these energy-dependent models that will be discussed further. Information about the energy dependence of the boiler is also required to be indicated in the technical specifications.

How to reduce energy costs?

We will proceed from the fact that, firstly, electricity consumption directly depends on the thermal power of the heating boiler. And, secondly, most of the electricity consumed is taken by the circulation pump, which circulates the coolant in the pipes so that the pipes and heating radiators warm up evenly.

The boiler usually always operates at night from 23:00 to 06:00. Use a multi-tariff electricity meter, reduced prices apply at night

Let's name a number of specific proposals for those who would still like to reduce energy costs:

- Opt for a non-volatile unit. Most likely, this will be a floor-mounted option. In terms of functionality and comfort, alas, it is not able to compete with its energy-dependent analogue models.

- Buy a volatile device, but of low power. Here, of course, there is a significant limitation - one cannot ignore the number of heated square meters. If, for example, you need to heat 180-200 m² of a private house, then a gas boiler with a capacity of 20-24 kW is needed. And no less.

- Carefully study the product lines of different brands. Each model has its own nuances and, perhaps, for some of them you will see the most attractive power consumption figures in the technical specifications.

- Analyze what makes up the total cost of paying for electricity. Perhaps the share of these costs attributable to a gas boiler is negligible, and attention needs to be switched to other objects that really consume electricity excessively.

- How do you like using alternative energy - say, solar panels or collectors on the roof of a house?

And yet, in pursuit of saving electricity, do not bring your own actions to the point of absurdity. Do not forget that gas units consume little electricity, since their main fuel resource is not electricity, but natural or liquefied gas.

We calculate how much electricity a gas boiler consumes per hour, day and month

The units of measurement for electricity consumption by a gas boiler, like any other electrical appliance, are Watts (W). In technical documentation it is usually indicated as rated electrical power.

For example, the well-known wall-mounted dual-circuit Vaillant turboFIT VUW 242/5-2 consumes up to 140 W per hour. It is easy to calculate its maximum consumption:

- Per day – 24 (hours) * 140 (W) = 3,360 W or 3.36 kW. In value terms (at the current tariff of 5.38 rubles per 1 kWh) – 3.36 * 5.38 = 18.07 rubles/day.

- Per month – 30 (days) * 3.36 (daily consumption, kW) = 100.8 kW. In value terms – 100.8 * 5.38 = 542.3 rubles/month.

- For the heating season (suppose from October 15 to March 31) - 136 (days) * 3.36 (daily consumption, kW) = 456.96 kW. In value terms – 456.96 * 5.38 = 2,458.4 rubles/season.

However, these are only the maximum possible indicators; in practice, a gas boiler does not operate 24/7, and it consumes electricity unevenly: when igniting it, much more is spent. In reality, the values depend on weather conditions and heating mode, usually 50-70% of the maximum values.

It is impossible to determine exactly how much electricity a gas boiler consumes using a theoretical method (which is why only the maximum value is indicated in the characteristics); metering devices (electric meters) are used for accurate calculations.

According to reviews from owners, regardless of the power of the boiler, the average monthly electricity consumption is 40-80 kW.

How to calculate how much gas a household gas boiler consumes

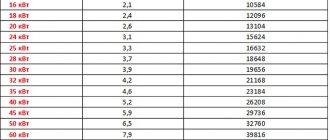

Consumption table of famous models, according to their passports

| Model | Max power consumption, W |

| BAXI ECO-4s 24F | 130 |

| Vaillant turboFIT VUW 242/5-2 | 140 |

| Viessmann Vitopend 100-W A1HB001 24 | 120 |

| Bosch Gaz 6000 W WBN 6000- 12 | 150 |

| Buderus Logamax U072-24 | 130 |

| Ariston CLAS X SYSTEM 24 FF NG | 108 |

The best Baxi gas boilers in terms of price/quality ratio

BAXI ECO-4s 24F 24 kW

Powerful convection unit with two circuits - one of the best in performance and reliability.

Compact despite its weight, it is capable of heating a room up to 240 sq.m. In addition to the heating function, it provides hot water for everyday needs.

Economical, silent in operation, safe.

The work is almost completely automated, additional operator actions are kept to a minimum.

Easy to install and repair, the supplied factory components are of very high quality.

Specifications:

- Type: convection;

- Number of circuits: dual circuit

- Thermal power: 9.30 - 24 kW;

- Thermal load: 10.60 - 25.80 kW;

- Combustion chamber type: closed;

- Efficiency: 93%;

- Control: electronic:

- Placement: wall;

- Heat exchanger: copper/stainless steel.

pros

- high level of productivity;

- high-quality assembly;

- compactness;

- ease of installation and management.

Minuses

- energy dependence.

BAXI ECO-4s 18F 18 kW

Compact convection double-circuit unit with wall mounting . Dimensions

The unit allows it to be installed in rooms of any size.

Long service life is ensured by high quality materials and parts.

a room up to 200 sq.m. At the same time, installation requires the purchase of additional parts, which generally increases its cost.

Easy to install and operate, user control is minimal.

Specifications:

- Type: convection;

- Number of circuits: dual circuit

- Thermal power: 9.30 - 18 kW;

- Thermal load: 10.60 - 20 kW;

- Combustion chamber type: closed;

- Efficiency: 92.5%;

- Control: electronic:

- Placement: wall;

- Heat exchanger: copper/stainless steel.

pros

- high efficiency;

- efficiency;

- ease of installation and management;

- silent operation;

- design.

Minuses

- phase dependent;

- uneconomical;

- expensive components.

BAXI ECO-4s 1.24F 24 kW

Single-circuit heating unit with the ability to connect a heated floor.

The control is electronic, the specified parameters are supported by an automated system.

The closed combustion chamber ensures the highest level of safety.

High-quality assembly and high-quality materials of components ensure a long service life of the device and reduce the risk of breakdown.

The temperature of the batteries is determined within 30-85 degrees, the warm floor is 30-45 degrees.

Specifications:

- Type: convection;

- Number of circuits: single circuit

- Thermal power: 9.30 - 24 kW;

- Thermal load: 10.60 - 25.80 kW;

- Combustion chamber type: closed;

- Efficiency: 93%;

- Control: electronic:

- Placement: wall;

- Heat exchanger: copper.

pros

- price;

- ease of installation;

- reliability;

- low noise level.

Minuses

- uneconomical.

What affects the electricity consumption of a gas boiler?

- Circulation pump . The consumption range, depending on the model and the degree of installed power, is 45-150 W. It is not always involved. Its consumption also depends on manufacturability (magnetic rotors, the presence of a frequency converter, stator compactness).

- Turbine . Consumes from 10 to 70 W, its operation is regulated automatically: the speed depends on the required volume of exhaust gases, i.e. from the operating power of the boiler.

- Burner and electric ignition . Up to 100 W at the moment of ignition.

- Automation . This includes both the electronic board itself and displays, all kinds of sensors, and switching mechanisms.

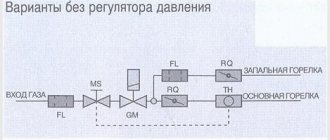

Construction of energy-dependent wall-mounted single-circuit models using the example of Buderus Logamax U072-24.

The best wall-mounted gas boilers Baxi

BAXI NUVOLA-3 Comfort 320 Fi 32 kW

Double-circuit convection model with a copper heat exchanger, closed chamber . Panel

remote control.

The built-in 60 liter boiler allows you to provide 510 liters of water in half an hour.

The digital panel displays operating status information, making it easier to operate the device.

Electronic ignition is smooth, flame modulation allows for efficient fuel consumption.

It runs on natural gas; it can also run on liquefied fuel, but it requires reconfiguring the unit.

Specifications:

- Type: convection;

- Number of circuits: double-circuit;

- Thermal power: 10.40 – 32 kW;

- Thermal load: 11.90 - 34.50 kW;

- Combustion chamber type: closed;

- Efficiency: 93%;

- Control: electronic:

- Heat exchanger: copper.

pros

- high level of security;

- ease of operation;

- efficiency.

Minuses

- dimensions;

- price.

BAXI LUNA-3 COMFORT 1.240 Fi 25 kW

Single-circuit closed-type convection unit . Average dimensions and weight required

a certain level of accommodation.

The power of the unit is enough to heat a room up to 250 sq.m. Quality materials reduce the risk of breakage.

The device is quite difficult to install and configure, so the help of a specialist is required.

Additionally, if you install it yourself, the manufacturing warranty will be voided. The boiler is economical and highly efficient, runs on liquefied and natural gas.

Specifications:

- Type: convection;

- Number of circuits: single-circuit;

- Thermal power: 9.30 - 25 kW;

- Thermal load: 10.60 - 26.90 kW;

- Combustion chamber type: closed;

- Efficiency: 92.9%;

- Control: electronic:

- Heat exchanger: copper.

pros

- reliability of assembly and components;

- silent;

- economical

Minuses

- price;

- difficult to install.

BAXI ECO Four 1.14 F 14 kW

Single-circuit convection boiler for heating medium-sized rooms is easy to install and operate.

The informative display allows even novice users to understand the settings, however, the manufacturer recommends contacting a specialist for installation, otherwise the equipment does not have a warranty.

It is silent in operation, has extensive functionality and is low in cost.

High-quality materials and assembly ensure reliable operation and minimize the risk of breakdown.

Relatively small dimensions allow the unit to be placed in small spaces.

Specifications:

- Type: convection;

- Number of circuits: single-circuit;

- Thermal power: 6 - 14 kW;

- Thermal load: 7.10 - 15.10 kW;

- Combustion chamber type: closed;

- Efficiency: 92.5%;

- Control: electronic:

- Heat exchanger: copper.

pros

- silent;

- rich functionality;

- price;

- quality of assembly and components;

- ease of operation.

Minuses

- inconvenient location of the pressure sensor;

- uneconomical.

How to reduce consumption

It is impossible to significantly influence the consumption rate without compromising comfort, since the actual energy consumption is always optimal, and the values are already insignificant. However, it is still possible to reduce the energy consumption of a gas boiler:

- Fine-tuning the operation of the boiler or programmable thermostat . Since a huge part of the electricity is consumed during ignition, it is logical to reduce the clock frequency (turning the boiler on and off). The most optimal burner operating mode (not only in terms of gas and electricity consumption, but also service life) is burning for as long as possible at the lowest possible power. This can be achieved by setting the hysteresis value (by how many degrees should the temperature decrease for ignition to occur). Another great option is to program the operating mode for a day or a week in advance. Such fine settings are not available on all models of gas boilers; if they are not available, you can set the above parameters using a room thermostat.

In general, we recommend not influencing power consumption, since this is already a fairly small indicator, already optimized by the manufacturer. It would be much more effective to reduce gas consumption, for example, using an inexpensive programmable room thermostat.

How to choose the power of a gas boiler

To select the power of a gas boiler, you can use several methods.

The simplest is to calculate 1 kW of power per 10 sq.m. premises .

This simple approach is most optimal for small buildings with good thermal insulation and double-glazed windows with low ceilings.

In private houses, you should take into account the height of the ceilings and use the formula MK = Qt * Kzap, where MK is the boiler power, Qt is the heat loss of the building, Kzap is the safety factor, which is 15-20% of the design power of the boiler.

UPS for Baxi

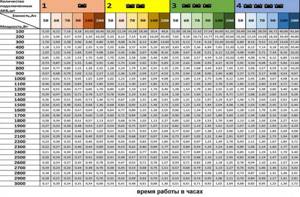

Before the purchase! When choosing a UPS, you first need to know the total electrical power of the system. From the table below you can take the power value for your Baxi boiler . However, do not forget to add the power of external (additional) circulation pumps (if they are installed, for example, on heated floors).

Our company’s engineers have created for you a unique program for selecting a UPS model for a boiler and calculating the required battery capacity. By specifying the power and desired autonomy time, all options are displayed. Use the automated selection system

The best double-circuit gas boilers Baxi

BAXI LUNA-3 240 Fi 25 kW

Unit with convection type of operation . Security is maintained at a high level

closed-type combustion chamber, self-diagnostics and built-in functions of protection against freezing and overheating.

Extensive functionality includes not only heating, but also the provision of hot water up to 15 liters per minute . Does not cause discomfort due to the noise produced.

It is bulky and difficult to set up, so it is recommended to call specialists during installation.

Specifications:

- Type: convection;

- Thermal power: 9.30 - 25 kW;

- Thermal load: 10.60 - 26.90 kW;

- Combustion chamber type: closed;

- Efficiency: 93%;

- Control: electronic:

- Placement: wall;

- Heat exchanger: copper.

pros

- performance;

- extensive functionality;

- high level of protection;

- quality of materials;

- efficiency;

- noiselessness.

Minuses

- high price;

- dimensions and weight;

- difficulties during installation;

- demanding on settings.

BAXI LUNA-3 COMFORT 240 i 24 kW

Convection type codel with open chamber . Complete set, no need

purchase additional components for installation.

It quickly heats the room, but is large in size and takes up a lot of space.

Safety is ensured by automatic diagnostics, protection against pump blocking and overheating . It is possible to connect a heated floor.

Installation and configuration may be difficult for inexperienced users, so the manufacturer recommends using the services of specialists.

Specifications:

- Type: convection;

- Thermal power: 9.30 - 24 kW;

- Thermal load: 10.60 - 26.30 kW;

- Combustion chamber type: open;

- Efficiency: 91%;

- Control: electronic:

- Placement: wall;

- Heat exchanger: copper.

pros

- noiselessness;

- efficiency;

- build quality;

- long service life;

- design.

Minuses

- price;

- difficulties with installation and configuration;

- high prices for components and spare parts.

BAXI NUVOLA-3 Comfort 280 Fi 28 kW

Wall-mounted convection boiler with high power . Capable of heating an area up to

280 sq. m.

Safety is ensured by a closed combustion chamber, built-in protection against freezing and overheating, a safety valve and an air vent.

Electronic control using a remote control, the necessary information is displayed on the information display.

In addition to heating, it supports the connection of a heated floor. It is very large in size and is picky about the installation location.

Specifications:

- Type: convection;

- Thermal power: 10.40 - 28 kW;

- Thermal load: 11.90 - 30.10 kW;

- Combustion chamber type: closed;

- Efficiency: 93%;

- Control: electronic:

- Placement: wall;

- Heat exchanger: copper.

pros

- high level of security;

- a large number of settings;

- high level of efficiency.

Minuses

- volatile;

- separate chimney;

- high percentage of manufacturing defects.

Correspondence table between Baxi boiler models and their power consumption.

boiler model Baxi NUVOLA

- NUVOLA-3 Comfort 240 i, 280 i, B40 240 i, B40 280 i - 110 W

- NUVOLA-3 Comfort 240 Fi, 280 Fi, 320 Fi, B40 240 Fi, B40 280 Fi - 190 W

boiler model Baxi Four Luna

- ECO Four 24, MAIN Four 240, ECO Four 1.24, LUNA-3240 i, ECO Four 1.14, LUNA-31.240 Fi - 80 W

- ECO Four 24 F, MAIN Four 240 F, ECO Four 1.24 F, LUNA-3240 Fi, LUNA-31.310 Fi, - 120-130 W

Recommended On-Line UPS kits with batteries for Baxi boilers

UPS kits up to 225W with internal batteries for short autonomy

Shtil SW250 with two batteries for a total of 60 Ah Gel-grafen

Shtil SW250 with 45 Ah battery

Shtil SW250 with battery 37 Ah Gel

Shtil SW250 with 18 Ah battery

UPS kits up to 400W with external batteries

UPS for boiler Shtil SW500L + 2x60Ah Gel (6-evf-52) in a box

UPS for boiler Shtil SW500L + 2x75Ah Leoch in a box.

UPS for boiler Shtil SW500L + 2x45Ah Leoch in a box.

UPS for boiler Shtil SW500L + 2x18Ah Leoch

UPS for boiler Shtil SW500L + 2 batteries 28Ah Gel (6-dzm-20)

24v UPS with two external batteries: - optimal price-reliability-efficiency ratio

Please note : What parameters must the electrical network have in order to connect a boiler to it?

Everything is standard here: 220 V, 50 Hz, grounding. In principle, the same requirements as when connecting, for example, a washing machine. Grounding must be carried out in accordance with all standards . If there is any potential hanging on it, which often happens, we must fight it. In the absence of normal grounding, it is recommended to install a special stabilizer that provides separate galvanic isolation. It often happens that potential comes through a gas pipe. Then the boiler must be connected via a dielectric adapter. BAXI boilers operate stably in the range from 170 to 250 V.* At 170 W, modern models of BAXI boilers turn off. And when the voltage increases above 250-270 V, the protective element (“varistor”) on the board burns out.** The very characteristic of electricity in the network - a sine wave - must be without interference, so use uninterruptible power supplies designed for computer equipment and producing a rectified current characteristic , Not recommended. Many service organizations, when commissioning boilers, prefer to additionally install a voltage stabilizer. It is recommended to connect boilers to the electrical network through a separate circuit breaker. If the boiler is phase-dependent, it is necessary to ensure that the phase and zero match. This information is from the official website

Note* At a voltage of 180-170 volts, circulation pumps heat up more and their service life is significantly reduced.

** “Varistor” is a protective element that, when burned, prevents damage to the boiler electronics. The varistor is replaced only at Baxi service centers. The ready-made kits offered below are suitable for Baxi wall-mounted boilers of the Four, Luna, NUVOLA series with a consumption power of 80-135 W. This is just one of many options to ensure uninterrupted power supply to the boiler. We individually calculate the optimal options based on your data on power and desired autonomy time. There are no “ready-made” kits as such; they are assembled from two main components:

- UPS - it is responsible for the quality of processing the incoming voltage (in this case it is On-Line), for monitoring the presence of voltage and the timely transition to battery power, for charging the batteries.

- Battery pack - it is responsible for the battery life; the larger the capacity of the batteries in the pack, the longer the reserve time. Their service life depends on the quality of the batteries themselves.

How many batteries should I buy and what capacity? The number of batteries depends on the selected UPS model and is related to the inverter voltage of a specific UPS model. For example, the Inelt Monolith K1000 LT UPS, which has proven itself well during the period of “ice rains,” requires THREE 12-volt batteries for its power supply. You can calculate the capacity using the formula below.

UPS for a gas boiler and its power consumption

If there is a loss of electricity in the network, the gas unit will switch to emergency operation, which threatens the breakdown of expensive components. And a UPS (uninterruptible power supply) will come to the rescue in such situations.

How long a gas boiler can operate in the absence of electricity depends on the capacity of the battery pack. Choose either a UPS with a built-in battery, or a UPS with the ability to connect the required number of battery sections to it

The “line-interactive” type is the most popular UPS, according to numerous customer reviews. They contain a voltage stabilizer, which is able to respond to voltage drops in the network within 10%; if this value is exceeded, a switch to power from the battery follows.

The “off-line” type is an uninterruptible power supply without a voltage stabilizer. They help out in case of a sudden power outage, but do not protect against mains voltage fluctuations.

“On-line” type - the most advanced UPS. They smoothly switch from mains power to battery power and vice versa. The only drawback is that not everyone can afford their price.

At the moment the gas boiler is started, electricity consumption increases by at least two, or even three to four times. Even if this is a short-term moment, lasting a second or two, we still take a UPS for a gas heating boiler to the maximum and with a power reserve. For a gas boiler with an electric power of 100 W, you need a UPS with a power of at least 300 W (with a reserve of up to 450-500 W).

As for the battery capacity, let’s say one battery with a capacity of 50 Ah is enough for 4-5 hours of operation with an electrical consumption of 100 W. To ensure 9-10 hours of operation, you need to have two such batteries, etc.

This table shows the battery life of a gas boiler in hours depending on the power consumption of the gas boiler (electrical power in W), battery capacity (capacity, Ah) and the number of simultaneously connected batteries (one, two, three or four)

And finally, will the UPS consume electricity for its needs? It all depends on efficiency. If we take efficiency = 80%, then for our 300 W UPS the consumption together with the load will be:

300 W / 0.8 = 375 W, where 300 W is the load, the remaining 75 W is the consumption of the UPS itself.

The given calculation example is conditional and is applicable for simple uninterruptible power supplies, namely for the moment when mains voltage surges become above a certain level - more than 10%. When the network has standard 220 V, the UPS consumes almost nothing.

It is better to entrust detailed calculations for calculating the power of the UPS, the capacity of the batteries and the additional costs of electricity in connection with the installation of a UPS in the heating network to an electrician.

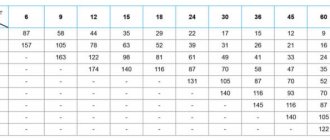

Electric power of Viessmann wall-mounted boilers

The electrical power of a Viessmann wall-mounted boiler is usually in the range from 100 to 200 W.

Capacity table for Viessmann

Name of gas boiler

Power by heat

VIESSMANN Vitopend 100-W 24

VIESSMANN Vitopend 100-W 30

VIESSMANNVitopend 100-W 24 O

To organize electrical power supply for Viessmann wall-mounted boilers, it is advisable to use voltage stabilizers and uninterruptible power supplies with a power of at least 300 VA.

Electric power of Vaillant floor-standing boilers

The electrical power of the Vaillant floor-standing boiler ranges from 50 to 100 W.

Vaillant wall-mounted boiler power table

Name of gas boiler

Power by heat

VAILLANTatmoVIT VK INT 564

VAILLANTatmoVIT VK INT 414

VAILLANTatmoVIT VK INT 324

To organize efficient electrical power supply for Vaillant floor-standing boilers, it is advisable to use voltage stabilizers and uninterruptible power supplies with a power of at least 300 VA. When choosing a power source for a heating system with a floor-standing gas boiler, you should take into account the electrical power of separately installed circulation pumps.

The best single-circuit gas boilers Baxi

BAXI LUNA Platinum+ 1.32 34.8 kW

Condensing model with the ability to integrate with other heat sources - heat pumps, solar panels.

Adjusts to the type of fuel and chimney, the design of the heating system. The controls are very simple, automatic settings are provided for almost any occasion.

Economically beneficial due to high efficiency.

Among the disadvantages, users note freezing of the chimney, so it is recommended to use the unit in areas without severe and prolonged cold.

Specifications:

- Type: condensing;

- Thermal power: 3.20 - 34.80 kW;

- Combustion chamber type: closed;

- Efficiency: 106%;

- Control: electronic:

- Placement: wall;

- Heat exchanger: stainless steel.

pros

- high level of security;

- efficiency;

- wide functionality;

- integration with other heating sources.

Minuses

- high price;

- rarity on the market;

- The chimney freezes.

BAXI LUNA Platinum+ 1.24 26.1 kW

Unit with one circuit . The heat exchanger is made of stainless steel, material

provides not only very high efficiency indicators, but also a long service life.

The manufacturer also provides a considerable warranty period for service.

Electronic control and programmer simplifies the use of the boiler and minimizes operator intervention.

The level of safety is ensured by a closed combustion chamber and additional functions. The power of the unit is enough to heat an area of up to 250 sq.m.

Specifications:

- Type: convection;

- Thermal power: 2.40 - 26.10 kW;

- Combustion chamber type: closed;

- Efficiency: 106%;

- Control: electronic:

- Placement: wall;

- Heat exchanger: stainless steel.

pros

- safety;

- programmer;

- efficiency level;

- silent;

- long warranty period.

Minuses

- uneconomical;

- additional parts are required to install the automatic system;

- price.

BAXI SLIM 1.150 i 14.9 kW

A floor-standing single-circuit unit with a cast iron heat exchanger provides heating of a room up to 140 sq.m..

The heat exchanger is resistant to corrosion, durable, but does not tolerate sudden temperature changes.

Flame modulation allows you to smoothly change the heat supply and reduces gas consumption, which ensures the efficiency of the model.

The control is electronic, which reduces the need for constant monitoring of the unit. If there is an uninterruptible power supply, it works when the electricity is turned off.

Specifications:

- Type: convection;

- Thermal power: 8.50 - 14.90 kW;

- Thermal load: 9.50 - 16.50 kW;

- Combustion chamber type: open;

- Efficiency: 90%;

- Control: electronic:

- Placement: floor;

- Heat exchanger: cast iron.

pros

- connection of a warm floor;

- ease of installation and management;

- quality of assembly and components.

Minuses

- weight;

- average efficiency;

- requirements for placement.