Advantages

A gas stove used to heat a country house or cottage is an effective heating system. Due to the characteristics of the fuel material used and the nuances of operation, they have gained wide popularity. Their undoubted advantages include the following:

- durability, reliability (in fact, there is nothing to break in such a heating device, the warranty period for their operation is 12 years, but in fact a gas stove will last much longer);

- environmental safety (appliances using gas for heating will not harm humans and the environment, unlike boilers running on solid fuel, they do not emit toxins during operation and can be used at any time of the day or year);

- Efficiency at a high level;

- ergonomics (gas consumption is 133 g/h; in areas with mains gas, this value is even lower);

- space saving (unlike firewood, gas does not need a separate storage room, it does not need to be delivered, you can fill the cylinder at any gas station);

- ease of operation (stoves are connected to the main pipeline or to a regular gas cylinder and provide comfortable living conditions).

Flaws

Gas ovens are not without their drawbacks. The equipment itself and its installation are by no means cheap. Natural gas, although the most inexpensive fuel, its cost in our country is systematically increasing.

Gas-fired stoves are quite difficult to install and connect. In the event of even the smallest mistake, you can encounter huge problems in using such devices (they either will not do what they are intended for, or will begin to pose a danger to the life and health of residents).

Features of gas stove heating

The only difference from a simple oven is the energy carrier. Instead of firewood, gas is used, so the arrangement of the network requires equipment with heating appliances, a gas pipeline for supplying fuel, shut-off and control valves and a set of automation and control to maintain the uninterrupted operation and security of the network.

The gas stove is heated with main or bottled fuel. In the first case, the supply is centralized, the pressure is maintained through the main line, the second option is the use of bottled liquefied gas or power supply from a gas holder.

Advantages and disadvantages

Advantages of using gas fuel in furnaces:

- Year-round operation. With a constant supply of gas, the stove starts up at any time, including during inter-seasonal frosts.

- High efficiency. A properly selected unit warms up the house in any frost and is suitable for installation in harsh regions without providing a backup heat source.

- Practicality, convenience. Unlike a solid fuel stove, gas does not have to be stored (unless it is bottled fuel), no slag is formed, the devices are smaller in size and operate without interruption.

- Ease of Management. All devices are equipped with an automatic ignition system, so human participation is reduced to pressing a button to start the furnace. Additional costs are small and consist of preventive inspections of the unit carried out by specialists from the gas company.

Long service life is an additional advantage. The manufacturer's warranty is at least 10 years; if you follow the instructions for use, the service life of the stove increases several times.

The only downside is the price, which is higher than conventional solid fuel boilers. But this disadvantage is eliminated by low fuel costs - today gas is considered the cheapest energy carrier.

About security

During the operation of gas appliances, it is important to comply with all fire safety requirements.

We pay special attention to the rules for maintaining gas cylinders:

- They must be checked periodically and comply with standards. It is mandatory to install reducers that reduce the pressure of the gas leaving the cylinder.

- At the first sign of a leak or a faint smell of gas in the room, be sure to turn off the gas supply and turn the stove back on only after identifying and eliminating the problem.

Wiring methods

Wiring methods differ for liquid and air systems.

Liquid

There are two main schemes for water movement options:

- with natural circulation of liquid coolant;

- with its forced circulation.

The first option is used for one-story houses with a contour of no more than thirty meters. If the pipe length is longer, a circulation pump is required.

There are also several different pipe layouts:

- in one and two pipes;

- horizontal and vertical.

Two-pipe heating allows you to turn off some of the radiators in the house. The horizontal layout makes it possible to turn off the heating on the entire floor.

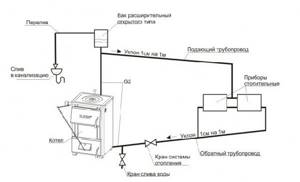

Photo 3. Wiring diagram of a liquid system with natural circulation, which is usually used in small private houses.

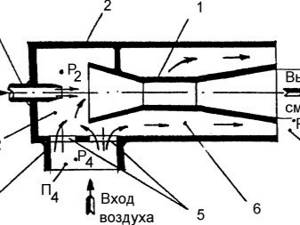

Air

According to the methods of circulation of air masses, there are:

- direct-flow circuit;

- recirculation scheme.

- partial recirculation scheme.

The recirculation scheme, in turn, happens:

- with natural air movement;

- with forced movement in the presence of supply and exhaust ventilation.

The direct-flow circuit was initially used to heat buildings; all hot air was removed from the house, which is extremely uneconomical. The recirculation circuit, on the contrary, kept the heated air inside the building, passing it through the heat generator several times. This is economical, but unhygienic, since the air is not renewed.

Today, the most commonly used scheme is partial recirculation, when heated air circulates inside the house, partially renewed from the outside.

Oven

Gas stove ovens are:

- gas;

- electrical;

- combined (with electric grill).

The optimal choice of the last two types of ovens, since they distribute heat evenly. However, with this choice, you must definitely consult with an electrician to see if the wiring can withstand the resulting load.

Gas ovens can be of 2 types:

- without convection;

- with forced air circulation.

The best choice is a gas oven with forced air circulation, since in this case the likelihood of cooking food that is not cooked through or that is burnt on one side is minimal.

How to choose?

When calculating the quantity for a chamber furnace (that is, the characteristics of a specific model), the total thermal power of the device is first determined. After this, they find out how many gas combustion units can and should be installed inside to ensure the necessary generation. The final stage is to establish the approximate air flow that will need to be supplied to one gas combustion point per unit of time. Further, professionals select specific devices taking into account monograms - if this word does not mean anything to a person, all that remains is to consult with specialists.

To correctly calculate heating, take into account the predicted design air flow

When determining it, the presence of a recuperator and the characteristics of this device must be taken into account. Typically, the power rating of thermal equipment can be found in the accompanying documentation

But sometimes documents are lost, and in the case of an old-style brick or wood stove, or a home-made one, they may not exist at all. Professionals recommend that when rebuilding brick fireplaces, proceed from the fact that their thermal power is 4-5 kW.

If this option does not suit you for financial reasons, you can try to calculate the required thermal parameters based on the area of the heated premises. But even here, sometimes specialist advice is required: accurate determination of heat losses, inspection of the building using thermal imagers. There are a number of other subtleties and nuances.

So, for a Russian stove, as for other bell-type heating systems, switching to gas is strictly prohibited due to safety requirements. If we talk about other types of stoves, then this is allowed, but all equipment parameters must be specified in the design documentation. When selecting burner systems for industrial furnaces, the following must be taken into account:

- design features;

- installation method (hearth, in isolated lines of non-oxidizing heating complexes, etc.);

- automation category;

- fuel combustion method (atmospheric or with forced suction);

- torch type.

For the melting furnace, the use of injection-type devices is recommended. They cope quite effectively with melting non-ferrous metals. According to some experts, you should not buy burners, but make them yourself. There is no choice for the muffle system - in the gas version, such devices are generally not produced by industry. The burners are taken from boilers or they are completely manufactured from scratch. Power is calculated independently.

It is recommended to use a heat generator with integrated heating control. Another important point is the ignition method. The electric igniter depends on a stable power supply, the piezoelectric one is more autonomous.

Oven

The following types of ovens are distinguished:

Gas

Gas stoves cook quickly, but it is difficult to adjust the temperature in them. So, setting the temperature to 50 ℃ (useful for drying vegetables) is very difficult. However, low energy costs (especially if you install a gas meter) and ease of operation often compensate for these features.

They differ from each other in the location and number of heaters. In inexpensive models, the burner is located only at the bottom, but in more expensive ones there is also an upper burner - a grill. Some devices are equipped with a fan that mixes the air and prevents the formation of “cold” zones, which means the dish is baked evenly.

Electrical

Using this option is much more convenient due to more precise oven settings. Those who love to bake should take a special look at these units. Disadvantages: energy costs, long warm-up and cool-down times.

Devices of the simplest modifications have two heating elements - at the top and at the bottom. More complex models already have four heaters: more side heaters are added. Convection allows you to maintain the same temperature throughout the oven and is present in devices of medium and high price levels.

Every housewife should decide which is better, focusing on her own feelings: some are more accustomed to cooking in a gas oven, while others are more comfortable in an electric cabinet.

Kinds

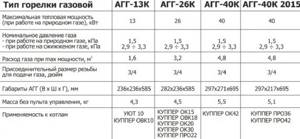

Burners can be of different types. Let's look at the main ones.

Atmospheric

Such devices are quite cheap. The reason is obvious - their production is not too difficult technologically. The operation of atmospheric burners is also simple. Air is sucked directly from the surrounding space. The formation of a gas-air mixture does not require additional effort.

Supercharged

This option uses a fan that actively pumps air. Stabilization of air pressure (pressure) allows you to compensate for almost all negative external factors

What is important is that “fire separation”, which often occurs with atmospheric burners with a significant increase in pressure, is also excluded

The following evidence supports such devices:

- stable operation under any conditions;

- efficiency of 95% or more;

- a fairly high level of safety (determined by the design);

- almost complete combustion of fuel;

- wide range of achieved powers;

- excellent level of automation;

- Possibility of use in furnaces and boilers of a wide variety of structural types.

It is worth noting that forced-air burners are much more expensive than their atmospheric counterparts. Even the most affordable models of this kind cost at least 4.5 times more. However, the main technical advantages fully justify such a fee. When the burner is operating with supercharging, noise of varying volumes may occur. Special protective covers will help to cope with this problem.

Such models are approximately twice as efficient as traditional flare designs. Some people even take tourist-type ceramic burners (for cylinders) and convert them into a boiler or stove. But you can do this only with complete confidence in your actions.

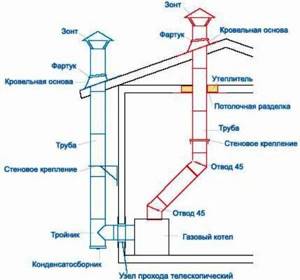

What should a chimney look like?

When connecting chimneys to gas equipment, the following recommendations must be observed:

- The chimney can operate no more than two appliances. If two gas units are switched, they must be placed at different levels relative to each other at a distance of 50 cm.

- If both devices are located on the same level, cuts are installed in the chimney.

- The diameter of the smoke exhaust pipe should not be smaller than the cross-section of the connecting pipe.

- If you need to connect several devices, when determining the cross-section, it is assumed that all units will be turned on simultaneously.

- The pipe must be lined to protect it from condensation: it has a destructive effect on the brickwork. This is done by installing a stainless pipe inside.

- Preference should be given to a cylindrical or oval chimney shape. As for square structures, they are not able to create the effective traction necessary for the proper operation of gas equipment.

- The chimney pipe should only be located in a vertical position: there should be no protrusions on it. It is allowed to make a slight slope (up to 30 degrees), subject to strict adherence to the cross-section of the entire structure.

Prohibitions from SNiP:

- Porous materials cannot be used to make a chimney.

- It is prohibited to lay the pipe in residential or non-residential premises with poor ventilation.

Repairing the chimney of a typically wood-burning stove usually requires some serious effort.

Oven

We talked about how a gas stove works, now we will analyze in detail the operation of the oven from turning it on until the end of cooking. Experts in the operation of gas equipment have developed several recommendations for users that must be followed when using the oven.

- During cooking, there is only a baking tray inside for collecting fat and a grid for storing food - all other kitchen utensils are stored in a special compartment located at the bottom of the stove.

- Before starting cooking, preheat the oven for several minutes at the maximum heat level, and then set the desired level using the rotary control.

- When a dish is being prepared, you should not open the door often - the temperature inside the oven immediately drops, and you can observe the cooking through the glass.

- After cooking, the gas supply is turned off, the regulator is placed in a vertical position, and the oven begins to cool.

You should take out the hot baking sheet using special oven mitts that protect your hands from burns.

How to light a burner correctly

Use the regulator to set the heating mode (usually 9 or 10 on the scale), open the door. At the very bottom in the middle there is a special hole to which a match or a special lighter is placed. There is a red button on the control panel - you must press it to open the gas supply. When the burner lights up, you need to hold the button for a few seconds to heat up the thermocouple that controls the solenoid valve. If you immediately remove your finger from the button, the flame will go out; all actions must be started all over again.

Internal temperature

Setting the desired temperature is very simple - just turn the knob and set the arrow embossed on it opposite the selected mode. How do you know if the actual temperature inside matches the selected cooking mode? To do this, experienced cooks pour a little clean flour onto a baking sheet and watch through the glass to see how its color changes:

- if it turns brown, the temperature is about 230 0C;

- golden color - no more than 180 0C;

- when the color does not change over time - about 100 degrees.

Modern models have a thermometer on the glass, but you also need to know the secrets of determining temperature using grandma’s method - everything can come in handy in life.

Cooking with taste

Previously, in order for a fragrant crust to appear on a carcass or meat, the housewife would often open the door and pour the secreted fat over the dish, but for modern gas stoves this is a long-forgotten technology. Many oven models are equipped with special fans that force hot air to move inside the product, distributing the heat evenly: there is no need to grease or turn over the carcass of the roasted bird, it will be fried equally on all sides.

To cook meat in your apartment as if it were over a campfire, just experiment with setting up the grill. and you can surprise your guests with the aroma of dishes cooked over an open fire in the field. You can add a little liquid smoke from a bottle purchased at a nearby supermarket for flavor.

Recommendations for choosing a home gas stove

When deciding to install a gas stove in your home, you must consider the following features:

When choosing a device, first of all, pay attention to its power, because the temperature in your home depends only on this. The power of the burner will be affected by the future heated area, the number of windows and doors in the house, as well as their condition, wall thickness, etc.

When purchasing a gas structure, you should first ensure that there is sufficiently good ventilation in the house. If there is none and it cannot be improved, then the installation of such a stove is strictly prohibited.

- Consider the configuration of the system you like. In some cases, it is equipped with adapters, which allows you to connect to several fuel sources.

- The design in question is suitable only if the house has no more than two floors, otherwise the entire heating system will be ineffective.

- For ease of use and additional control of the device, a special sensor is mounted in it to determine the level of carbon dioxide. If there is any change in the air, the oven will turn off automatically.

- If you buy a ready-made metal stove, you need to inquire about the documents for the device, which indicate whether it is really safe for use in a residential area.

- It is strictly forbidden to install this type of stove in wooden houses in which the channels are located horizontally.

When purchasing a gas stove, you need to take into account the area of the heated room. It's easy to calculate. For 10 square meters of living space there should be 1 kW of burner power (for a reserve it is better to add 15-20%). Thus, in a house the size of which will be 100 square meters, you need to install a stove with a capacity of 12 kW.

Types of stoves

If we talk about heat capacity, then in this case stoves are divided into two categories:

- Heat-intensive ones have a brick body that accumulates heat and then gradually releases it into the environment. Once turned off, the stove, depending on its size, can still continue to heat the room for 4-12 hours.

- The non-heat-intensive structure is made of metal. It produces heat only when the gas combustion process occurs. After stopping the fuel supply, the device cools down very quickly. The advantages of this design are that it is small in size and weight and can be installed even in small spaces.

Photo 2. Compact ceramic gas oven Elitech TP 4GI. A fuel tank is built into the back.

Ovens in appearance are:

- round;

- oval;

- rectangular.

The appearance of the device only affects its combination with a certain interior.

Reference. The internal design of the stove has nothing to do with its appearance.

Material

The base and walls are usually made of enameled metal or stainless steel.

For the buyer, it is much more important what the hob is made of. After all, this not only determines the appearance, but also how difficult it will be to get rid of the stains.

Enamel

The most popular coating. It looks harmonious, and is available in many color options: white, gray, brown, beige, red and others. If you don't let dirt and grease dry out and burn, it's easy to care for.

The use of abrasive cleaners and hard sponges leads to scratches and thinning of the enamel. The impact may cause a piece of the coating to break off or a crack to appear, so you should be careful when handling it.

Stainless steel

It looks very impressive, is more resistant to mechanical damage, and dirt is easier to remove from it. At the same time, it is more labor-intensive to maintain its appearance: all stains, drops and prints are clearly visible on it. To make the unit look decent, you will have to make a lot of effort and buy special household chemicals.

Glass ceramics

It appeared relatively recently, but is rapidly gaining the love of housewives. This is due to the wide possibilities of design solutions: colors, patterns, shape.

And also with relative ease of maintenance - it is easier to wash off dirt from glass than from other coatings. It is difficult to break, but still possible, so you should be careful. Another disadvantage is the high cost.

How to calculate the consumption of natural and liquefied gas

The main indicator on which the calculation depends is the area of the room and the power consumption of the equipment

Outdoor temperature readings taken during the coldest time are also taken into account.

The amount of natural gas is calculated using the formula: L = Q / (qH x 0.92), where:

- L – calculated volume of fuel (1 cubic meter per hour);

- Q – heating power, kW;

- qН – maximum fuel combustion power, for natural gas 10.175 kW/m3;

- 0.92 – efficiency of a gas boiler/furnace.

On average, for heating a room with an area of 100 sq.m. the calculation will look like this: 5 / (10.175 x 0.92) = 0.53 m3 / h, which corresponds to the consumption of natural gas per unit of time (hour).

Bottled (liquefied) gas is more expensive and its consumption will have to be calculated not by liters, like natural gas, but by kilograms. The heat of combustion of gas remains the same - 10.175 kW/m3 = 12.8 kW/kg, heating power - 5. We get: 5 / (12.8 x 0.92) = 0.42 kg/h, which corresponds to 0.78 liters per hour. Considering that 1 liter of bottled gas weighs 540 mg. Based on the approximate number of days and hours of operation of the bath, you can calculate the required volume.

In order to make a stove for a gas bath with your own hands, you need to decide on three main parameters:

- Material;

- What kind of gas burner will it be?

- Placement of the container – built-in or remote tank.

Now about each of them in more detail.

Methodology for calculating fuel consumption

The amount of gas per month can be calculated using the formula:

Equipment power (kW) x 0.112 (how many cubic meters of gas need to be burned to generate 1 kW), multiply the resulting number by 720 (the number of hours in a month).

For example, for a dacha with an area of 70 square meters. meters you need a design with a power of at least 9 kW. It will burn at least 725 cubic meters of gas per month (with round-the-clock operation).

Homemade stoves for a summer residence

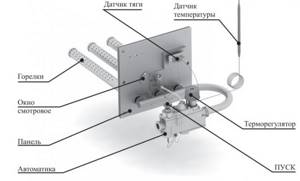

One of the serious stopping factors, which is why many users do not dare to acquire a convenient gas stove, is the high cost of such equipment. However, if you have certain skills in construction, this problem can be solved by reconstructing a conventional wood-burning stove made of brick. The conversion process itself is not very complicated: you need to put a burner in the firebox and make changes to the design of the chimney. This will allow you to switch to continuous operation to maintain a stable temperature in the house.

Thanks to the additional installation of an automation kit, the once primitive stove is transformed into an autonomous heating device. If the draft suddenly disappears, the temperature rises sharply or there are interruptions in the gas supply, the fuses will trip and the furnace will stop working. The main difficulty of such a design solution lies in the labor-intensive process of remaking the chimney.

For the technical possibility of supplying gas, it is necessary to ensure high-quality removal of combustion products in accordance with the requirements of the gas service. Whether it is necessary to start such a complex enterprise at a dacha with seasonal residence is decided by the owner of the house himself. Judging by practical experience, it is more convenient to equip such houses with ready-made models.

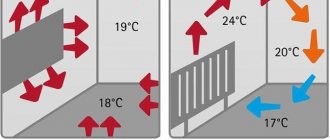

Work principles

- Fluid system. Using a gas boiler, a liquid coolant is heated, which is delivered to the rooms through pipes into radiators (batteries) installed under the windows. The house is heated via an external circuit. The coolant takes a long time to heat up and cool down, so it will take considerable time to heat the house.

- Air system. With the help of a heat generator, air is heated in the boiler room, which is supplied directly to the heated rooms through air ducts (usually through holes in the floor).

There are no radiators or pipes in the rooms. After passing through the rooms, the air is removed through special ventilation grilles.

The bulk of the heated air circulates inside the building, but some is renewed. Such a system can include cleaning, humidification and conditioning of air masses. When operating on gas, it is fully automated.

Types of boilers

There are different types:

- by installation method;

- by power;

- by the number of contours.

Depending on the installation method, there are wall-mounted and floor-standing boilers. Low-power boilers with one circuit and a minimum set of additional equipment are often placed on the wall in the kitchen. More powerful boilers require a separate room (boiler room) and are supplemented with various equipment.

Photo 1. Wall-mounted single-circuit gas boiler installed in a small semi-basement on tiles.

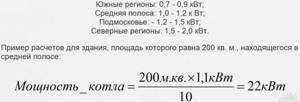

Power

Each boiler has a certain power. When used mainly for heating, the basic calculation formula is used: 1 kW of power per 10 sq. m. of a well-insulated house. For a cottage with an area of 200 sq. m. requires a boiler power of 10 kW. Additionally, it is recommended to add about 15% for peak loads. The planned hot water supply through the same boiler will require additional power.

An expert designer will calculate the necessary equipment parameters, taking into account the material of the walls, the number of floors and windows, the climatic characteristics of the area and other aspects.

Number of circuits

Exist:

- single-circuit;

- double-circuit boilers.

Single-circuit ones are often more expensive and more powerful, but without additional equipment they are intended only for heating. If you want to have hot water supply, you can buy a boiler. A single-circuit boiler of sufficient power can cope with heating a large house and heating a significant volume of water.

Photo 2. Single-circuit gas heating boiler mounted on the wall. Suitable for a large private home.

Double-circuit boilers are smaller in power, cheaper and more versatile: one of their circuits works to heat the house, the second - to heat water.

They have a built-in heat exchanger, and the water is heated either using a boiler included in the boiler, or in a flow-through manner. 15–20 liters per minute is the maximum heating volume for such boilers. They are more appropriate for small houses where few people live.

Reference! Models of such boilers in summer can only be used to heat water with the heating circuit turned off.

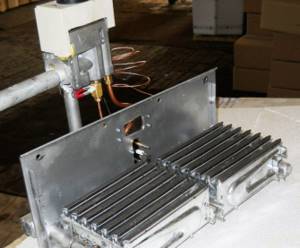

Device

In the vast majority of cases, household gas burners for stoves are designed to be connected to an air heating main. Connection to water circuits is much less common. In some cases, a system is provided that removes heat to adjacent rooms.

A burner device for home or bathhouse consists of:

- valve assembly that regulates the fuel supply;

- steel pipe (usually with a wall thickness of 0.2 cm and a length of up to 10 cm);

- fuel metering cap;

- control knob or button.

Automatic burners are widely used for heating systems in any room. They are much more convenient than designs that do not have automation equipment. Each model is equipped with a strictly defined type of automation. There is virtually no compatibility between these types. Installation of modern burner equipment is very simple and does not require contacting specialists, which is also due to the simplicity of the device.

Rules for safe use

A few words about the safety of household gas stoves. The main rule is to provide good, working ventilation.

To install any devices operating on propane-butane, it is necessary to establish stationary ventilation in the room or ensure constant access of air to the tent

Despite the manufacturer's assurances, the body of most models or the protective grille heats up during operation, so beware of burns and keep children and animals away from heating units.

In devices with three burners, ignition occurs in stages, so some of the gas may leak into the room - this can be easily determined by the specific smell. For this reason, the room or tent must be ventilated immediately after starting the heater.

To install household gas stoves, you do not need to insulate the floor or walls, but you need to ensure that flammable objects are nearby - some models have open flames.

Nuances of installation and use

When installing gas equipment at home or in the country, it is necessary to take into account a number of requirements for it.

Often, to heat a private home, not one, but two devices are connected to the chimney. If two gas units are connected, then they are located at different levels in relation to each other. The distance between them must be at least 0.5 m. It is necessary to make a cut in the chimney if it is decided to mount the heating devices on the same level.

This design can be in the shape of a cylinder, oval, or in some cases even a square. But in the latter option, you may encounter the problem of poor-quality traction.

The gas furnace pipe must have the same or smaller cross-section as the chimney duct. If several heating devices are connected, the cross-section is determined using special calculations

It is taken into account that the units can operate simultaneously

The chimney pipe must be protected from excess condensate. To do this, a stainless steel structure is mounted inside it. The chimney must be installed strictly vertically. There should be no ledges.

It is required to maintain a certain distance between the wall and the oven: it must be at least 5 m.

The heating device must be placed on a non-flammable solid base, the dimensions of which must exceed the parameters of the stove by 10 cm on each side.

Absolutely forbidden

You cannot create a chimney from materials that have a porous structure. It is also prohibited to route the pipe through rooms with poor ventilation.

Kinds

Heat capacity level

Gas heating stoves differ in the level of heat capacity. This depends on the ability of the structure to accumulate heat. They can be carried out under the condition of continuous or periodic operation of the equipment.

- Furnaces with a constant heating cycle have thin walls and cannot accumulate thermal energy. But such devices are able to quickly and evenly heat the room of a country house. These devices consume more fuel and are not as economical and are suitable for periodic heating of premises when the owners visit their dacha.

- Heating devices that turn on periodically are a stationary stove, lined with bricks or fenced with reflective screens. The automatic control system lights the burner when the temperature in the room drops, and after turning off, the stone screen gradually releases heat into the atmosphere of the room.

Furnace material

The price and durability of heating stoves depends on the materials from which the firebox and other parts of the unit are made:

- The best option is a cast iron stove with a combustion door made of fireproof glass. But such a design is expensive.

- The next one is the firebox and walls made of stainless or heat-resistant steel. Such equipment will serve for a long time and reliably, but the level of heat capacity of such stoves is much lower, but in terms of the speed of heating the room they are preferable.

- You can make homemade structures from sheet iron or scrap materials and cover them with bricks/ceramic tiles. This equipment will not last as long as a cast iron stove, but in terms of basic characteristics and price, such stoves can compete with industrial designs,

By purpose

Based on this characteristic, we will single out stoves that operate in a house with permanently residing owners and periodic switching on of the stove.

The main purpose of stoves is the same, regardless of the type of fuel - to heat a residential building quickly and maintain a comfortable temperature.

By fuel type

Stoves running on bottled gas are, of course, good. But if there is an interruption in refilling your cylinder, you will have to freeze.

Therefore, the best option, especially if you live in a wooded area, is a combination stove that can operate on all types of solid fuel and liquefied gas.

Such equipment costs a little more, but its characteristics and operating savings quickly pay for the funds spent on the purchase of combined heaters.

Manufacturers

Russian-made gas stoves (Teplodar, Rus, Troika, Termofor) have good reviews. They are of high quality and are presented on the domestic market in a wide range. They have a nice design, a steel firebox, a door made of metal or heat-resistant glass. Such units are distinguished by high performance, simplicity and unpretentiousness in use. Some models are equipped with special valves that allow you to regulate the temperature.

A gas stove for heating a summer house or private home is a profitable and practical option. If you wish, you can assemble it yourself, but if you make a mistake, such a device can lead to a leak of fuel material and an explosion. Therefore, compliance with safety precautions is very important.