Which insulation is better?

The following insulation materials were selected for the experiment:

- Stone wool: Rockwool, Baswool, TechnoNIKOL

- Glass wool: Isover, Knauf

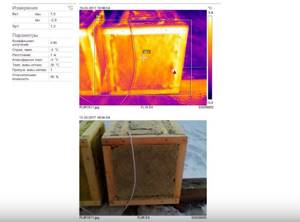

The experiment compared the thermal conductivity of insulation; for these purposes, wooden boxes 50 x 50 cm were constructed, which were insulated with 150 mm thick cotton wool. A 95 W incandescent lamp was placed inside the boxes and remained in the boxes for 60 minutes. Testing of insulation was carried out outdoors at sub-zero temperatures of about -5 - 6 degrees. After each test material was kept in the cold for 60 minutes, shooting was carried out with a thermal imager.

Shooting with a thermal imager is divided into 3 stages:

- Filming the outside of the box (the temperature of the insulation was taken from the outside)

- Filming the inside of the box (we looked at which insulation accumulates heat more)

- Filming the joints of insulation (we looked at which insulation materials better prevent the formation of cold bridges)

Results of shooting with a thermal imager of the outer part of insulation

| Brand | Holding time | Outdoor air temperature | Insulation temperature |

| ROCKWOOL | 60 min | -5C | 1.3C |

| BASWOOL | 60 min | -5C | 1.1C |

| TechnoNIKOL | 60 min | -5C | 1.3C |

| ISOVER | 60 min | -6C | 0.2C |

| KNAUF | 60 min | -6C | -0.8C |

The test results showed that the outer side of the insulation still warms up. This means that heat loss, although insignificant, is still present. It is difficult to identify a noticeable leader or outsider, since the indicators differ slightly. Baswool (1.1C) showed the lowest heat loss among stone wool insulation materials; Knauf (-0.8C) was the best among glass wool.

The insulation showed a significant difference when comparing the internal temperature of the boxes.

Comparison of internal box temperatures

| Brand | Holding time | Outdoor air temperature | Insulation temperature |

| ROCKWOOL | 60 min | -5C | 55.8C |

| BASWOOL | 60 min | -5C | 78.9C |

| TechnoNIKOL | 60 min | -5C | 78.9C |

| ISOVER | 60 min | -6C | 40.3C |

| KNAUF | 60 min | -6C | 61.9C |

The best performance among stone wool was shown by Baswool and TechnoNIKOL (78.9C each). The best glass wool was Knauf (61.9C). As for comparing joints, glass wool insulation showed the best results. This is not surprising, since glass wool fibers are longer and more elastic, glass wool has excellent compression properties. Basalt or stone wool (these are the same thing), denser insulation and less elastic, they are more difficult to install in frame walls. In general, summing up the following winners: the leader among stone wool insulation was BASWOOL, and the leader among glass wool was KNAUF.

Video of a comparison of insulation materials

Source

Insulation for frame houses Hotrock (Hotrock)

Insulation for a frame house

With the advent of frame technologies, the dream of owning your own home has come closer to reality for the average person. The home promises to be durable and strong; it will certainly be comfortable in the summer. However, if you intend to live in such a house all year round, you will have to purchase insulation for the walls of a frame house and take care of insulation.

Which insulation is better?

In the good old days, people insulated buildings exclusively with natural materials - tyrsa, sawdust, straw, adobe, peat, adobe stones. The work is dirty and labor-intensive. There is no point in repeating past experiences today, because modern materials have appeared:

- sheet foam (expanded polystyrene);

- mineral wool;

- extruded polystyrene foam;

- sprayed polyurethane foam;

- expanded clay;

- ecowool.

So, let's choose the best insulation for a frame house :

What remains is mineral wool - glass, stone, slag. This insulation for a frame house has decent characteristics:

- high heat and sound insulation;

- fire safety;

- resistance to rotting (durability);

- vapor permeability;

- resistance to chemical and mechanical stress;

- environmental friendliness.

Tips for choosing mineral wool

Despite all the advantages, this material has a minus: hygroscopicity. If moisture begins to penetrate behind the frame skin, the material will gradually lose its thermal insulation properties. The wet cotton wool is compressed and opens the way for cold air from the street. The attempts of some developers not to remove the cellophane packaging from the material did not justify themselves, since it is enough not to notice a few holes, and, consider, there is no protective film. You will have to carefully study the modifications so that later you are not tormented by thoughts about what kind of insulation for a frame house you bought - good or not so good:

Comparison of modern insulation materials

URSA, ISOVER, TERMOLIFE, PAROC, ROCKWOOL are excellent foreign brands. But you are building a budget frame-panel structure, and when you buy insulation for a frame house, the price becomes one of the determining factors. Russian-made Technonikol basalt products (slabs) are suitable in all respects - including the percentage of resin content. The material is non-aggressive, vapor permeable, and moisture resistant.

We also recommend domestic ISOROC - the density is higher than that of the popular and world-famous ROCKWOOL, and the cost is lower. BASWOOL (BASVUL) is also a material with an affordable price, but does not really meet the requirements for insulating the foundation (ground floor). For this purpose, take a special type of insulation - for example, from the URSA (URSA), KNAUF (KNAUF) product line.

Technological rules for insulating a frame house with mineral wool

What should be the thickness of the insulation in a frame house , which slabs should be preferred - 50 or 100 mm? Experienced builders prefer 50 mm slabs, and assemble them into a two-, three- or four-layer array with offset seams with a total thickness of up to 150-200 mm. Yes, this is a kind of reinsurance, but in the end they always end up with a cozy, warm home. To insulate the floor, the thickness of the insulation should be 250-350 mm, the upper floor and warm attic - 200 mm.

The choice of insulation materials is so extensive that it is easy to get confused. Pay attention to the characteristics of a particular material and study the instructions. Insulation is the most important element of a frame wall; the quality of insulation of a frame house depends on its choice.

Thermal insulation rating 2021: the best modern insulation for the home (top 7)

Modern thermal insulation allows you to keep the room warm in winter and cool in summer, making the house comfortable to live in. In addition, its use helps to significantly save on heating costs. To insulate walls inside and outside, attics, and pipes, different types of thermal insulation are used.

We decided to understand the types and characteristics of these building materials and compiled a rating that presents the best thermal insulation of 2021

.

We were helped by Sergey Ivanov , a foreman with 12 years of experience

.

Currently, the choice of heat-insulating materials is large. Products from different brands vary in price, effectiveness, strength and durability.

Our rating of home insulation includes the following materials:

Which basalt wool is better?

Today, thermal insulation is widely used in construction. It helps reduce heat transfer in places where it is necessary to maintain a certain temperature (residential buildings, food warehouses). Among the different types of thermal insulation, basalt wool is often used, as it is a reliable and optimal way to retain heat in cold winters and coolness in hot summers. Now we’ll talk about basalt thermal insulation and the features of choosing the material.

Contents of the article about which basalt wool is better

- Criteria for choosing basalt wool

- Material Density

- How to decide on the manufacturer of basalt wool?

- Where to buy basalt wool?

How does this insulation work? Basalt wool consists of fibers that do not allow cold and hot air to pass through. This creates a temperature difference between the separated spaces: the street and the room. Thermal insulation allows you to save a lot of money on air conditioning and heating of the room.

Criteria for choosing basalt wool

Many buyers are wondering: which basalt wool is better? The construction market offers a variety of materials from different manufacturers, which differ in many respects: destination (insulation of floors, walls, roofs, etc.), weight, electrical conductivity, ability to withstand loads, level of sound insulation, etc. That is why you should approach the choice of basalt wool extremely carefully and carefully.

1. Fire resistance of a material is the effectiveness of inhibiting the spread of fire over time. The following conditions are considered here:

- smoke formation;

- incombustibility, flammability and fire safety. Consumers want to live in a safe home, so they are willing to overpay considerable sums for this quality.

2. Thermophysical characteristics: vapor permeability, thermal conductivity, resistance to aggressive and chemical environments, non-flammability and non-flammability.

3. Strength characteristics, wear resistance, resistance to mechanical stress, durability and heat resistance.

We have already described these and other characteristics of the material in the article Characteristics of basalt wool. Based on them, insulation is selected for specific purposes.

Material Density

The most important characteristic for insulation is density. The most popular types of insulation have a density of 35, 50 and 90 mm. This parameter affects the destination, the load on the insulation, and installation methods. The first two options are suitable for a private house or cottage; they are used for thermal insulation of walls, floors, roofs and ceilings. Here the material is not subjected to heavy loads.

The best insulation for wooden and frame structures Isoroc Izolight 1000x500x50mm 8 pcs.

- lasting;

- environmentally friendly;

- non-flammable;

- optimal in price and quality.

The top insulation for the home opens with stone wool, which is sold in packs of 8 slabs measuring 100x50x5 cm. One sheet has an area of 0.5 m2, a pack - 2 m2. Material density 50 kg/m3, thermal conductivity 0.034–0.04 W/mK. The material muffles external sounds. It is not flammable, does not absorb water, and does not mold. The cost of packaging is 400–550 rubles. When ordering from the factory, the price is 1600 rubles. for 1 m3, that is, 320 rubles. for packaging excluding transport costs.

Used as thermal insulation for frame-type wooden houses. Basalt material is breathable, it allows air to penetrate freely. This ensures ventilation of the rafters in the attics, which protects the wood from rotting. It is not suitable for insulating external walls, but can be used in lightweight brickwork with laying inside the wall.

TechnoNIKOL Rocklite - now the question! Which is better TechnoNIKOL ROCKLITE or ROCKWOOL? — 22 answers

TechnoNIKOL or Rockwool

In the Construction and Repair the question is now a question! Which is better TechnoNIKOL ROCKLITE or ROCKWOOL? asked by the author Level the best answer is which meat processing plant do you buy meat from? TechnoNIKOL and ROCKWOOL are trademarks that produce the same product, with approximately the same quality; no one will write about the difference in quality; 15 years is not a long time for insulation. It is better to choose smart builders; adherence to technology is the main criterion for the quality of insulation, on which the service life of the insulation depends. The insulation must be cut off from the internal air (via a vapor barrier) and communicated with the external air (through a wind barrier).

Reply from

2 replies [guru]

Hello! Here is a selection of topics with answers to your question: now the question! Which is better TechnoNIKOL ROCKLITE or ROCKWOOL?

Answer from Prorab [guru] Technical characteristics of rockwool insulation: Thermal conductivity 0.039 Water repellent properties In accordance with BS 2972-75, water absorption by volume is no more than 1.5%. Fire resistance NG Vapor permeability 0.55 mg/(m hPa) Mechanical properties Compressibility % no more than 20 (GOST 9573-96) Density 35 kg/m3 Acoustic properties Normal sound absorption coefficient at frequencies, Hz (GOST 16297-80) Dimensions 1000x600x50-200 Packaging Mineral wool slabs LIGHT BATTS are packaged in polyethylene film Technical characteristics of rocklite Density no more than 30 kg/m3 Thermal conductivity at 250C no more than 0.042 W/m0C Water absorption by volume with full immersion no more than 2.0% Water absorption by weight with partial immersion no more than 20% Content of organic substances by weight not more than 2.5% Humidity by weight not more than 0.5%

Reply from

2 replies [guru]

Hello! Here are more topics with the answers you need:

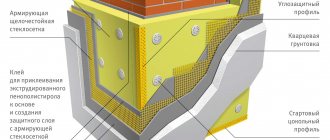

The best thermal insulation for brick walls, floors, flat roofs TechnoNIKOL CARBON ECO 118x58cm 50mm

Made from extruded polystyrene foam. For greater strength and thermal insulation, carbon nanoparticles are introduced into the mass. The slabs with an area of 0.7 m2 have dimensions of 118×58×5 cm. The density of the material is 26 kg/m3. The insulation is hydrophobic, the moisture absorption coefficient is no more than 0.4% of its own volume.

Thermal conductivity at the level of 0.032–0.034 W/mK. The product is designed for operation at ambient temperatures from -70 to +75°C. Sold at a price of 1100–1200 rubles. per package. 1 m2 costs 200–250 rubles.

Due to its strength and durability, extruded polystyrene foam is the best material for thermal insulation of exterior brick walls, concrete and stone foundations, loaded floors, and flat roofs. Can be used in the construction of a brick house with lightweight masonry. In this case, the material is laid in the middle of the masonry.

Usually used for private houses, its use is also popular for insulating external walls in apartments of multi-storey buildings. Thanks to the L-shaped edge during installation, the formation of gaps between adjacent slabs is eliminated.

Reviews

Judging by the reviews, it is easy to install, strong, durable. Does not absorb water, does not rot, does not mold. A significant disadvantage is that it burns with the release of smoke and stench, so it is better to use it for outdoor work. It decomposes under the influence of ultraviolet radiation and therefore requires protection from sunlight.

Pros:

- hydrophobic;

- no shrinkage;

- lasting;

- L-shaped edge;

- 1 m2 costs 200–250 rubles;

- does not rot, does not mold;

- Can be used for floor, flat roof.

Minuses:

conclusions

Knowing the basic performance characteristics, advantages and disadvantages of thermal insulation materials from major brand manufacturers, it will be easier for you to make your choice in favor of one of them. However, unscrupulous businessmen can take advantage of the desire to save money and ignorance of the criteria for choosing a quality product. In this case, it is better to buy mineral wool in our online store, where high-quality products are sold at wholesale prices with the ability to order delivery at a time convenient for you.

Soft insulation for pipes Energoflex Super Protect 22/6mm 2 m

- without thermal lock;

- thickness 6 mm;

- operating temperature from -40 to 95 degrees.

It is a tube made of foamed polyethylene with an internal cross-section of 22 mm and a thickness of 6 mm. The polyethylene tube has a cut, which makes it easy to slide it onto a metal or plastic pipe. The material is soft and easily cut into pieces of the required length.

Thermal conductivity at 0.038 W/mK. Can be used at temperatures from –40° to +95°C. Energoflex Super Protect is sold in 2 m pieces.

The material is used for water supply and heating pipes. Provides protection of the coolant from cooling when passing pipes in unheated rooms. Polyethylene does not absorb water, so it can be used to protect water pipes with cold water, including when laying them in the ground.

Reviews

Users praise pipe insulation for its durability, efficiency, and ease of use. Inexpensive.

Pros:

- thin and warm;

- easy to use;

- cut;

- hydrophobic.

Minuses:

Choice of basalt slabs: ROCKWOOL, TechnoNikol or something else? | ImhoDom.Ru

| 9. April 2013 - 15:43 Dimitry To insulate the attic, I choose basalt slabs. Who will recommend which and why? | THINKING OUT LOUD: In spring and autumn, the solar heated garden shower is inactive: although the sun is shining, the cool breeze does not allow the water to heat up. To warm the water in these conditions, you need to cover the shower tank with a folding transparent cap. It can be made from glazed frames or film stretched over a frame, or from plexiglass. The water in the shower will be warm even in cool weather. Have your own thoughts? Write here There are currently 1 user and 23 guests on the site. Users on the site( extreme only) ★ ★ ★ ★ ★EVERGREEN THEMES:☆ ☆ ☆ ☆ ☆Put #imhodom in your place! ★ ★ ★ ★ ★ |

imhodom.ru

How to choose materials for thermal insulation at home

Note that there is no universal best insulation. For each individual case, you need to select the appropriate material.

To figure out how to choose thermal insulation for your home, consider its types:

- Mineral wool

. Easy to install and insulates well. But it cannot withstand pressure and is not suitable for wet areas. Depending on the type of raw material from which it is produced, there are stone (basalt), glass and slag. Basalt-based home insulation is completely non-flammable and does not chip. Glass wool has two main advantages: it is non-flammable and very cheap. But working with it is not at all comfortable, since the material is itchy and causes allergies. Slag wool is only suitable for attics and non-residential buildings as it is not environmentally friendly.

- Foam glass

. Available in blocks, durable. This is a new and expensive material. - Styrofoam

. Its popularity is determined by its low price. Does not absorb moisture, is partially vapor permeable, does not rot, does not mold. Durable. But it has low strength. Rodents love to build nests in polystyrene foam. The optimal density is 25 kg/m2. - Expanded polystyrene

. This insulation is made from the same material as foam, but it is modern and more durable. Used for walls, foundations, flat roofs. At the same time it provides moisture insulation. Currently, polystyrene foam is the leader in the thermal insulation rating. - Sheet polyurethane foam

. Its properties are similar to expanded polystyrene, but it is breathable and easily absorbs water. - Foam

. It is made on the basis of polyurethane foam or penoizol. Good for insulating walls outside. Covers the surface completely, without cold bridges, due to which the walls after treatment have minimal thermal conductivity. But insulation in this way is expensive - the technology requires the use of special equipment and qualified personnel. - Foamed polyethylene foam

. There is PPE or NPE. Take only PPE - it is more durable. It is used for insulating pipes, internal walls, and floors. There are options with reflective foil film.

- Thermal conductivity

. Shows how much heat in watts the material will lose. The lower the coefficient, the better. The average value is 0.038–0.046 W/mK. - Vapor permeability

. The ability of the material to breathe, allowing moisture vapor to pass through. Quality required for timber structures. - Shrinkage

. It is desirable that it be minimal or absent. Otherwise, over time, under the influence of its own mass, the thermal insulation will decrease in volume and deteriorate its properties. - Hygroscopicity

. Determines the ability of a material to absorb water vapor. Materials with high hygroscopicity are less effective because liquid increases thermal conductivity. Also, such insulation cannot be used in damp places.

- Operating temperature

. Correctly selected insulation for this parameter will serve with high quality and for a long time. For example, in the northern regions frosts can reach -40 and -50 °C. In summer, metal roofs heat up to 80–90 °C. - Flammability

. Insulation materials are flammable and non-flammable. Indoors it is better to use non-flammable or low-flammable ones. Also, non-combustible insulation materials should be used in fire hazardous areas. - Environmental friendliness

. Important for use in residential areas. Environmentally friendly materials do not emit harmful substances. - Firms

. There are a lot of manufacturers of high-quality thermal insulation. Among the brands that have proven their effectiveness are the following: Rockwool, Isoroc, Energoflex, Penoplex, Akterm Nord, TechnoNIKOL, URSA, Hotrock, KNAUF, Isover, Ecostroy.

Material calculation

Differences in the dimensions of mineral wool elements can mislead you. Professionals try to save working time. The price of a mistake is the same for everyone - budget overruns and loss of time.

To perform calculations, use an online calculator. It will take into account all the necessary quantities, parameters and conditions.

A small reminder on using the calculator:

- Please note that not all Russian settlements are represented in the list of cities. Therefore, try to choose options that are minimally distant from the location of your home. This is important because this parameter determines the average winter temperatures;

- all numerical values (thickness) are displayed in millimeters. Just in case: 1 m is 100 cm or 1000 mm;

- We recommend looking at the detailed characteristics of insulation on the manufacturers’ websites. There you will also find recommended prices for this type of product;

- All calculations are approximate, so it would not be superfluous to add 10% to the results obtained.

Having obtained the thickness of the thermal insulation as a result of calculations and knowing the area of the walls, it is easy to calculate the volume of insulation. We hope this is helpful.

Universal stone wool Rockwool Acoustic Butts 1000×600x50mm

Made from basalt using a synthetic resin binder. Available in the form of slabs 60×100×5 cm. The package contains 10 units with a total area of 6 m2 and a volume of 0.3 m3. Thermal conductivity 0.035–0.040 W/mK. Does not burn. Mineral insulation is durable, the time of use is comparable to the life cycle of the building. It fits tightly to structures, leaving no gaps that serve as cold bridges. Packaging price is 900–1000 rubles.

Rockwool Acoustic Butts is used as insulation for the roof of a wooden house, attics, and interfloor ceilings. Also suitable for frame houses: for walls and partitions in frame structures, attics from the inside. It has good noise insulating properties, reducing external noise to 63 dB.

Unlike glass wool, stone wool does not chip and does not generate dust. Not afraid of moisture, resistant to bacteria and mold. Environmentally safe. It definitely requires isolation from the living space; this is achieved by covering the material with film and facing material.

Reviews

Users like this effective insulation for its versatility. Stone wool is not susceptible to mold or rot. Fire resistant, durable, reduces external noise. I don’t like having to work in a respirator; it can cause allergies in some people.

Pros:

- universal;

- does not burn;

- does not mold;

- not afraid of moisture;

- package weight 11.1 kg;

- reduces noise levels;

- high quality and durability.

Minuses:

Rockwool (Elabuga, Troitsk, Vyborg, Zheleznodorozhny)

On the domestic market, Rockwool products are presented in a wide range. There are suitable materials for insulation:

- roofing (Roof Butts);

- facades (Facade Butts);

- internal structures (Light Butts),

- for soundproofing rooms (Acoustic Butts) and solving other problems.

In the Russian Federation, 15 basic lines with more than 50 variants of mineral wool products are sold. Among others: single- and multi-layer rectangular slabs; long mats in rolls; cylindrical coiled products for thermal insulation of pipes; slope-forming elements.

The manufacturer claims that the main advantage is multi-component functionality (“4 in 1” - environmental friendliness, durability, fire safety and acoustic comfort), characteristic of any product based on Rockwool mineral wool.

Disadvantages of insulation appear due to violations of installation technology.

The correct sequence is described in the manufacturer's recommendations. Main characteristics of Rockwool

| Light Butts | Roof Butts | Acoustic Butts | |

| Purpose | Insulation and soundproofing of premises from the inside | Roof thermal insulation | Soundproofing of premises |

| Dimensions, mm | 1,000 x 600 x 50 | 1,000 x 600 x 40-200 | 1,000 x 600 x 50-70, 75, 80-200 |

| Density, kg/m³ | 37 | 160 | 45 |

| Thermal conductivity, W/(m K) | 0.036 | 0.039 | 0.035 |

| Quantity per package(pieces/m²/m³) | 10 / 6 / 0.3 | The quantity depends on the dimensions of the insulation | |

| Price, rub/m³ | 1 267 | 6 666 | 1 950 |

Video instructions for installing Rockwool insulation:

High-quality thermal insulation for home (XPS) PENOPLEX Foundation 118.5x58.5cm 100mm

Modern insulation made of foamed and extruded polystyrene foam. Sold in packs of 4 slabs measuring 118.5×58.5 cm×10 cm. The area of one slab is 0.7 m2. Package weight 10.2 kg. The density is quite high - 29 kg/m2. Can be used at temperatures from -50 to +75°C.

In terms of thermal conductivity (0.031–0.032 W/mK) it is not inferior to basalt wool. Penoplex has low hygroscopicity with water absorption not exceeding 0.4%, which allows it to be used in damp conditions. Price per package 4500–4700 rub.

PENOPLEX Foundation is used for internal and external work. In particular, for a house outside with insulation of walls and foundation. Recommended for a brick house. Due to its mechanical strength, it can be used for flooring in the home. It can also be used as a filler in partitions, inside hollow brickwork. Not suitable for insulating wooden walls.

Comparison of Rockwool insulation with TechnoNIKOL insulation

With the right choice of insulation, you can significantly reduce the amount of heat lost in the building, as well as significantly extend its service life. Everyone wants their home to be as comfortable as possible during a howling blizzard and bitter frost. After all, if there is no wind anywhere in the building, then watching the snow fly will only bring aesthetic pleasure. To ensure a high level of comfort in your room, you should resort to using insulation.

The mineral board of the Rockwool company has a high level of demand in its market segment, because compared to others it is distinguished by the highest level of quality and long-term preservation of performance characteristics.

The Rockwool company comes from Denmark and is rightfully considered a leader in the field of stone and mineral wool. The entire range has the following features:

- the material is produced exclusively using the most advanced technologies, which the company is constantly improving;

- the entire line of the manufacturer is completely safe and does not harm either people or the environment;

- matter significantly reduces the cost of heating the room.

The company was born back in 1909, but the world-famous brand today appeared only thirty years later. At the moment, the concern has expanded, having more than 25 enterprises in all corners of the world. Constant development and improvement allowed the concern to create a high-quality product. It is important to note that Rockwool specializes only in the production of stone and mineral wool, which makes it a narrow-profile enterprise.

The Technonikol company is one of the five largest and most influential European manufacturers in this segment, but produces not only thermal insulation, but also tiles, roofing felt, membranes, primers, mastics and other building materials.

Compared to Rockwool, Technonikol uses not only basalt, but also extruded polystyrene foam to create its products. This material is beginning to be used more often to provide insulation both in our country and abroad. Compared to other insulation materials, this material has less weight, which reduces transportation costs and facilitates installation. But at the same time, it is rigid and durable, which makes it suitable in places where less durable thermal insulation would be inappropriate. The only problem is that the presented material is susceptible to fire, releasing toxic substances during this process. But there is also a wide range of basalt wool.

Rockwool products are undoubtedly of higher quality, since the company specializes in a specific segment and directs all its efforts into it, but TechnoNIKOL is also not far behind in technical parameters, and also has a more affordable price. So it’s up to you to decide which choice is right.

www.tehocenka.ru

Ultra-fine liquid Akterm Nord

A unique material of a new generation. Apply with a spatula, brush, or spray in one or several layers, like regular paint. The difference between Akterm Nord and other types of insulation is that after drying it has no joints. Suitable for indoor walls, as well as for external insulation. One layer has a thickness of 0.5–2 mm.

Complete polymerization takes 24 hours. Recommended thickness is 2 mm. With this application, 3 liters are consumed per 1 m2. It is applied at temperatures from –25 to +45°C, and during operation can withstand from -50 to +140°C. Sold in plastic cans of 3, 10 and 20 liters. Price per package of 10 liters 3900–4200 rub.

Liquid thermal insulation is suitable for application to a primed surface: concrete, brick, metal, wood, foam blocks. After drying it has a white matte color. The coating can be painted or the desired color can be added to the composition.

Suitable for residential and non-residential premises of any type, joints, facades, pipelines, garages. With minimal thermal conductivity - only 0.0012 W/mK - this material is positioned as the warmest.

Reviews

Users include Akterm Nord in the top of the best insulation products for the home. Praised for ease of application, effectiveness, and versatility. Looks beautiful. The disadvantage is the high price.

Pros:

- universal;

- thin;

- thermal conductivity 0.0012 W/mK;

- quickly applied;

- no need to fasten;

- application temperature –50 to +140 °C;

- looks beautiful.

Minuses:

Manufacturers from different countries, offers from companies in Russia and beyond

At the preliminary stage of construction or renovation, many owners of private houses, summer cottages, baths, saunas and other premises, as well as performers of the work, are wondering - which brand of basalt insulation is better ? Given the diversity that exists on the building materials market, choosing the optimal option can become a serious problem for an inexperienced consumer in the relevant field .

TechnoNIKOL stone wool for flooring 8 slabs 1200x600x30 mm. Photo by Leroy Merlin

Information about production features is not always available, so you have to rely on widely available information , the appearance of the insulation and reviews. But there is an alternative solution; it is necessary to compare basalt wool from different manufacturers. Customers are provided with a wide selection of products , but there are not many large enterprises with a good reputation that produce high-quality insulation materials. Some brands and manufacturers that are of increased interest to Internet users are presented below.

Isover

The Isover trademark belongs to the international industrial group of companies Saint-Gobain , whose headquarters are located in Paris. The Group of Companies has representative offices in many countries. Saint-Gobain specializes in the development, production and sale of high-quality materials and effective solutions for creating comfortable living spaces. Successfully operates in three sectors:

- innovative materials;

- construction products manufactured under several brands, in particular insulation materials are produced under the brands Isover, Isoroc, Isotec;

- distribution of building materials.

The company produces mineral wool insulation based on quartz and basalt . Stone wool is produced in factories in Germany, Spain, France, the Czech Republic, Poland, and Romania. In 2011, the company acquired a plant for the production of basalt insulation in Chelyabinsk. And just two years later, Isover stone wool appeared on the Russian market, meeting all modern requirements and quality standards . This was preceded by hard work aimed at modernizing production facilities, attracting qualified foreign and Russian colleagues, interacting with research laboratories and carrying out work based on customer feedback.

Isover stone wool is a reliable material that provides a high level of thermal protection for at least 50 years. The special fiber structure provides floor and wall insulation with excellent acoustic characteristics, which significantly reduces the noise level in the room. Insulation materials meet all basic requirements, they are durable and safe for humans and the environment. These properties have been confirmed by Russian research institutes. Thermal insulation materials are produced in accordance with the European standard EN 13162 and the international standard ISO 9011 .

Under the Isover brand, a wide range of heat and sound insulation materials are sold for all types of buildings and structures. Basalt materials cover all structures requiring insulation and insulation. It is possible to opt for a universal option or purchase products designed specifically for each individual design. The range includes solutions for private and professional construction .

Products for apartments and houses are intended for insulation of the entire house, frame walls, roofs, partitions, ceilings, floors, balconies, facades, siding. The slabs vary in thickness (from 25 to 1150 mm) and heat retention class. Professionals are provided with materials for insulating roofs, frame walls, partitions and ceilings, facades and floors. It is possible to include stone wool for sound insulation labeled “Acoustic” into a separate category.

The manufacturer's Russian-language website makes it easy to choose the best option for basalt wool by correctly selecting the required purpose, scope of application, shape, type of material, load on the insulation, heat retention class and thickness of the products.

IZOVOL

The production of IZOVOL brand products was carried out by the Belgorod Stone Wool Plant . In 2021, TECHNONICOL acquired 100% of the shares of the joint stock company ZNOiM, part of the IZOVOL group of companies. A year later, the integration of the Belgorod plant into the structure of the TECHNONICOL corporation was completed. Modernization and automation of production and logical processes made it possible to increase labor productivity by 17%. In 2019, the product range included materials for shipbuilding and new types of professional insulation for construction needs. Products are supplied to various regions of the country and abroad .

The production of high-quality basalt wool is carried out using a unique melting device , which completely eliminates the formation of slag and ensures maximum melt quality. As a result, the brand’s products are distinguished by high physical, mechanical and consumer characteristics, optimal thermal conductivity, durability, reliability and safety for humans and the environment.

The manufacturer also notes the resistance of the insulation to the effects of bending and rodents. The company's product range includes several lines of stone wool:

- IZOVOL ST , products vary in density, indicators range from 50 to 90 kg/cub.m., used for floors, partitions and sloping roofs.

- IZOVOL B , designed for insulation of ventilated facades, has a protective layer that prevents stone wool from being blown out.

- IZOVOL F , designed for thermal insulation of plaster facades, has high density and strength, water absorption does not exceed 1%.

- IZOVOL K , used for insulating flat roofs, is produced in sheets with an almost square shape, which allows you to quickly insulate large areas.

- IZOVOL KV , used for insulation of single- and two-layer roofing systems, is characterized by increased rigidity and moisture resistance.

- IZOVOL L and IZOBEL L , more universal products, are used for partitions, floors, attic spaces, attic floors.

- IZOVOL LIGHT IZOBEL LIGHT is used as a non-load-bearing heat and sound insulation layer in pitched roofs, ceilings and partitions, floors, attics and attics.

KNAUF

The top lines in the ratings of the best manufacturers of mineral wool insulation are occupied by KNAUF products. The company was founded by the Knauf brothers in 1932 . Initially, the company specialized in the production of plaster mixtures from gypsum, and later construction gypsum mixtures. In 1958, plasterboard production opened. Since the 1970s, ready-made structural parts and construction chemicals have appeared in the assortment. The subsequent stages of development included the production of high-quality insulation from glass and basalt fiber, foamed polystyrene. The company came to Russia in 1993.

Insulation TeploKnauf Wall 50 mm, 6 sq.m. Photo by Leroy Merlin

Now the transnational company includes more than 200 factories located in Asia, Europe, North and South America. For potential clients, it is important to note that the Russian market mainly presents fiberglass-based products. Stone wool is quite difficult to find; you need to contact either the manufacturer directly or the official partners of the German company.

KNAUF insulation products are highly resistant to evaporation, have a low thermal conductivity coefficient, effectively absorb sound, and are produced without the use of dyes or bleaches. Available in slabs and rolls . There are two categories of products:

- Knauf heat is a series of basalt and fiberglass materials used in private construction to insulate various building elements: walls, ceilings, roofs. There is an option TeploKNAUF Bath based on fiberglass.

- Knauf Insulation - materials intended for professional insulation are divided into several types for use on various structures.

Paroc

Paroc was founded in 1930 in Sweden . In 1950, the production of stone wool was opened in Finland, and in Sweden the production of technical insulation and cylinders was launched. Since 1970, packaging has acquired the familiar white color with red stripes . In 1980, sandwich panels appeared in the product range, and products began to be produced under the Paroc brand. 1990-2000s the company actively expands to European and Baltic countries . Today, the enterprise has production facilities in Finland, Sweden, Poland, and Lithuania. The head office is located in the Finnish city of Vanta.

The company produces and sells energy-efficient thermal insulation solutions made from stone wool. The highest quality of basalt fiber provides a unique combination of advantages of finished products : mechanical strength, fire safety, moisture resistance, processability, sound insulation, chemical resistance, environmental properties, elasticity, dynamic elasticity. Customers are provided with insulation in the form of plates, rolls, cylinders, bends, lamellas and lamella mats .

The entire list of materials can be divided into products for construction and technical insulation. The first category includes several groups of products: general building thermal insulation and thermal insulation for walls, plaster facades, sandwich panels, flat roofs, foundations and floors on the ground, insulation and fire protection of ceilings and floors, fire-resistant building insulation, soundproof building insulation. The second group includes technical bends and segments, cylinders, lamella, piercing and OBK mats, mats for OBK and industry, plates, HVAC and OEM plates. Each line has individual characteristics and is designed to implement specific tasks.

ROCKWOOL: Sauna Butts 1000x600x100 mm. and other offers

ROCKWOOL Group (ROCKWOOL) is an international group of companies, the structure of which includes several divisions : ROCKWOOL; Rockfon; Grodan; Lapinus; Rockpanel; Rockdelta; BuildDesk. The division of the same name is a manufacturer of a wide range of solutions based on basalt wool. The company was founded in 1909 in Denmark , the central office is located in the city of Hedehusen. The production of thermal insulation was launched in 1937.

The next four decades saw the expansion of production in Europe and North America . The 1990s were marked by active expansion in the East, the company acquired and modernized factories in Eastern and Central Europe, and increased its zones of influence in Asia. In 1999, the first Russian plant , located in Balashikha, began production. Between 2006 and 2012, three more factories opened . Thus, today the number of production sites located on different continents exceeds 40.

ROCKWOOL is a manufacturer and supplier of comprehensive solutions for heat and sound insulation, fire protection of all types of buildings and structures, in shipbuilding and for industrial equipment. It's that simple. In more detail, clients are provided with materials for:

- fire protection;

- marine and industrial insulation;

- private housing construction, with the help of which it is possible to heat and sound insulate baths and saunas, fireplaces, attics and attics, ceilings, walls, in particular frame walls, the insulation of which can be carried out from the street or indoors, floors;

Reference. Of particular interest is cotton wool Sauna Butts 1000x600x100 mm, designed for insulation of baths and saunas, specially designed for walls and ceilings of steam rooms. Provides heat and vapor barrier (aluminum foil is located on one side of the sheets). They retain heat, which allows you to save on wood and electricity.

- soundproofing;

- roofs;

- facades.

The company offers basalt insulation with middle density indicators; the most chaotic arrangement of fibers ensures high strength. The service life is at least 50 years, during which the wool does not lose its characteristics. The manufacturer notes the following advantages of the product:

- Non-flammability. Insulation materials do not burn, prevent the spread of fire, withstand temperatures up to 1000 degrees, and do not emit heat or smoke in the event of a fire.

- Thermal insulation. Insulation materials allow you to achieve optimal temperature in a room, increase its energy efficiency, and reduce utility costs.

- Soundproofing. Many insulation options absorb, some are more effective, since they are designed specifically for sound insulation.

- Water resistance. Prevents water penetration.

- Environmentally friendly. The materials are easily dismantled and recycled. Basalt wool can be converted into a similar material again and again.

URSA

Despite the interest of Internet users in URSA stone wool, the company does not offer these products, but sells the following categories of thermal insulation materials:

- URSA GEO - fiberglass-based insulation, produced taking into account high environmental requirements;

- URSA TERRA - non-flammable mineral insulation, intended for private housing construction, meets professional standards;

- URSA PUREONE - new generation non-flammable mineral insulation;

- URSA XPS - high quality extruded polystyrene foam materials;

- URSA SECO - modern high-quality membranes and films for vapor and waterproofing, wind protection of walls, ceilings and roofs.

Beltep

The production of thermal insulation of the Beltep brand is carried out by OJSC Gomelstroymaterialy (Republic of Belarus) . The company is one of the largest manufacturers of a wide range of building materials. The main goal of the enterprise is to produce only high-quality products . Beltep stone wool guarantees environmental friendliness, fire safety, energy efficiency, acoustic comfort, manufacturability, and the best price-quality ratio.

The main advantages of stone wool are vapor permeability, non-hygroscopicity, resistance to deformation, low shrinkage, different densities, and affordable price. Using Beltep stone wool, it is possible to effectively insulate various elements of buildings and structures:

- walls, ceilings, floors and partitions;

- frame buildings;

- ventilated and plaster facades;

- flat and pitched roofs.

The range also includes universal materials designed for insulating various structural elements. The products are produced in slabs, the density of which varies from 35 to 190 kg/cub.m., and thickness from 30 to 200 mm.

Euroizol

Basalt insulation of the Euroizol brand is produced in Ulyanovsk . The production of products is carried out by a company of the same name, created on the basis of the Ulyanovsk plant of thermal insulation products, known on the market since 1957. A new milestone in the history of the enterprise began in 2004. Then, together with specialists from the TERMO plant (Slovenia), the automated Heraclith line was launched . Equipping its facilities with innovative equipment allowed the company to become a major manufacturer and supplier of thermal insulation materials with a wide range of applications.

Euroizol products are distinguished by consistently high quality, low water absorption, non-flammability, resistance to deformation, good sound insulation, chemical and biological resistance. The use of unique AeroDraive technologies makes it possible to improve the basic properties of materials.

Euroizol stone wool is used for insulation in private housing construction and in the construction of civil and industrial facilities . It is used for insulation of pitched and flat roofs, floors along joists and under screed, ventilated and plaster facades, partitions, as a filler for sandwich panels, for sound insulation. Available in slabs of various thicknesses (30-200 mm) and densities (25-200 kg/cub.m.).

IZBA

The production of mineral thermal insulation is carried out by the Bogdanovichi Mineral Wool Plates Plant (BZMP). The enterprise is equipped with modern high-tech Italian equipment . The manufacturer notes the following advantages of IZBA slabs: non-flammability, non-hygroscopicity, resistance to mechanical stress, high heat and sound insulation, long service life.

Insulation Izba Light Super 50 mm., 4.8 sq.m. Photo by Leroy Merlin

Products are manufactured on the basis of gabbro-basalt rocks with the addition of a synthetic binder. This composition provides several more important characteristics : low water absorption, biostability, and environmental friendliness.

IZBA slabs are intended for use as a heat and/or sound insulating layer in three-layer and frame walls, partitions, interfloor, basement and attic floors, plaster and ventilated facades, soft flat, pitched and flat roofs with a polymer membrane. The company offers several product lines:

- IZBA Super Light;

- IZBA Light;

- IZBA Standard;

- HUT Venti;

- IZBA Facade;

- IZBA Roof;

- IZBA Roof Top;

- IZBA Roof Bottom;

- IZBA Sandwich;

- Minslab, GOST-9573-2012, four varieties : soft slabs marked “PM”, semi-rigid - “PP”, hard - “PZh” and increased rigidity - “PPZh”.

ISOROC

ISOROC (ISOROC) is a trademark under which mineral wool thermal insulation is produced, owned by CJSC ISOROC, created in 2000, a Russian company with 100 percent foreign capital . In 2021, the company became part of the Saint-Gobain concern. Integration into the structure of a global industry leader opened up new markets for the company and the opportunity to expand its product line. Today the company produces materials of European quality that are in demand in the domestic market.

ISOROC stone wool Super Warm. Teplostroy Photos

The products have low thermal conductivity, high fire resistance, deformation and tear strength, hydrophobicity, sound insulation ability, good vapor permeability, and environmental friendliness. The consumer has several options for building insulation to choose from:

- heat-resistant boards marked “Thermal Protection” for insulating stoves, fireplaces and surfaces near this equipment;

- “Super” slabs - a line of products in slabs and rolls;

- rulers marked “P” and “PP” are intended for three-layer wall structures, frame structures, partitions and pitched roofs;

- “Izolight” and “Ultralight” - lines of materials for a wide range of tasks;

- "Isophas" - a line of products for walls under plaster;

- "Izoruf" - a series of insulating materials in slabs for interfloor ceilings and roofing of buildings;

- "Isovent" - slabs for three-layer and frame walls, ventilated facades, interfloor ceilings, pitched roofs.

Nazarovo

Nazarovo Plant of Thermal Insulation Products and Structures (Nazarovo Plant TIiK) specializes in the production of one of the most effective materials for heat and sound insulation - products based on stone wool. The production process is highly technological, as it is carried out in accordance with the project (Sweden) . This ensures high quality and compliance with stringent international requirements , which are significantly higher than Russian state standards. As a result, the finished products surpass in their characteristics not only domestic analogues, but also materials from global enterprises.

The products of the Nazarovsky plant are divided into four categories:

1) Thermal insulation boards. Used to insulate a wide range of building structures. They are made from basalt energy wool with the addition of synthetic binders with water-repellent additives.

2) Two types of mats: thermal insulation and basalt pierced energy mats with one-, two- or all-sided lining. Refers to the type of non-combustible materials. Used for insulating power equipment.

3) Two types of cords: thermal insulation and basalt energy . Designed for insulation of equipment and pipelines with surface temperatures from -120 to +700 degrees.

4) Heat-insulating energy cylinders . They are used for insulating pipelines with surface temperatures from -120 to +400 degrees. They have a longitudinal through cut, which makes installation and dismantling easier, and they can be reused.

Thermolife

The production of basalt wool under the Thermolife brand was carried out by a company of the same name from Ukraine. Based on publicly available information, it can be concluded that the company is no longer operating. However, it is possible to find Thermolife materials on sale.

Thermolife stone wool has thermal insulation, fire protection and hydrophobic properties, chemical resistance, environmental friendliness, and provides high quality installation and sound insulation.

Used for thermal insulation of internal structures: Light, EcoLight and Cavity; for facade thermal insulation: Facade, VentFasad, VentFasad V and VentFasad N; for roofing thermal insulation: Roofing; Roof B; Roof S and Roof H; for thermal insulation of floors: Pol and Pol-S; for sandwich panels: Sandwich C and Sandwich K; for technical thermal insulation: Techizol 50, 75, Techizol 100, 125 and Techizol 150.

TECHNONICOL: Rocklight and others

TECHNONICOL Corporation was founded in 1992 and is a leading manufacturer of effective and reliable solutions for construction. The structure of the enterprise includes a significant number of production sites equipped with modern equipment from leading European enterprises from Denmark, Germany, Italy, Slovenia, etc. A wide range of products . The corporation's research centers are conducting activities to develop new products . The corporation's representative offices ensure effective cooperation with clients from different countries. The corporation offers consumers a wide range of insulation materials, which can be divided into three classes:

Insulation TechnoNIKOL GreenGuard Universal 50 mm 8 plates 600x1200 mm. Photo by Leroy Merlin

TECHNONICOL - non-flammable materials based on basalt rocks, intended for heat and sound insulation of various structural elements: plaster and ventilated facades, pitched and flat roofs, walls, ceilings, floors. In demand in private and industrial construction. Of particular interest is Rocklight wool , which is intended for use as an insulating layer in pitched roofs. Available in slabs.

BAZALIT - hydrophobized, non-flammable basalt materials for heat and sound insulation of facades, roofs, partitions and ceilings, attics, attics, pipelines of various types, heating networks, as well as for use in sandwich panels. Available in slabs and mats.

GreenGuard. The development of this product has become a qualitative leap in the company’s activities. The revolutionary material is produced using GEOlife technology, which is based on the use of exclusively natural raw materials and natural binders. As a result, the main advantages are: service life is 100 years, odorless, recommended for use in kindergartens and schools, medical institutions, and residential buildings.

Glass wool URSA Terra 34 PN Pro 1000×610x50mm

Glass wool formed into slabs. More convenient to use than roll paper. The slabs with an area of 0.61 m2 have dimensions of 61×100×5 cm. There are 10 pieces in a package. The material is used in the temperature range from –60 to +225 °C. Its comparative characteristics are practically no different from mineral wool.

The test shows thermal conductivity at the level of 0.034–0.037 W/mK. The name URSA is one of the most recognizable in thermal insulation. URSA Terra 34 PN Pro 1000x610x50mm 10 pcs. popular due to its low cost. The price per package is 500–600 rubles, i.e. the cost of 1 m2 is about 100 rubles.

Glass wool is suitable for insulating attics, mansards, wooden floors, for laying in frame structures, for external insulation of wooden houses with the insulation covered with clapboard.

Due to its non-flammability, it is the safest insulation. However, glass wool irritates the skin and respiratory tract, so it must be covered with film. It is better to work in a respirator and gloves. It is not advisable to use it in residential areas, as there are allergic reactions to this material.

Reviews

Users appreciate glass wool for its low price, hydrophobicity, non-flammability, and ventilation. I don’t like the fact that the material pricks, irritates the respiratory tract, and can cause allergies.

Pros:

- cheap;

- not afraid of water;

- does not mold;

- easy to install;

- breathes;

- vapor permeable.

Minuses:

- • pricks;

- • irritates the respiratory tract, may cause allergies.

Comparative test - review of basalt insulation

Insulation of walls with basalt-based mineral wool has recently become widespread. This is facilitated by three main positive properties of basalt wool - good vapor transmission, good thermal resistance and non-flammability.

It is worth immediately noting that in terms of these characteristics, almost all brands of basalt insulation present on the market are very close to each other. If you take cotton wool from different manufacturers of the same density, then the ability to transmit steam, and the thermal resistance and ability to withstand fire will be at approximately the same level.

The same cannot be said about other consumer characteristics, such as ease of installation, cost, accessibility to consumers, packaging quality and durability.

It is these characteristics that we decided to focus on in our review, what we got - read below. To conduct the review, we took four of the most famous brands of wool manufacturers, and from each we chose insulation with approximately the same density. All sheets are considered 50 millimeters thick.

Glass wool Knauf

The production of insulation of the German brand KNAUF complies with GOST for the production of glass wool. The raw materials are silicate rocks and glass cullet; phenol-formaldehyde resin is used as a binding element.

Thermal insulation materials made on the basis of fiberglass are widely used. They can be used to insulate both vertical and horizontal surfaces, subject to minimal load on the material.

Knauf glass wool has several advantages:

Roof insulation: how to insulate?

Manufacturers

When choosing the best insulation for a roof, you should focus on materials with high thermal insulation properties and low weight. After all, the rafter structure does not “welcome” unnecessary “overloads”.

The material itself must be “long-lived” in an environment of seasonal temperature changes, withstanding temperature expansion, having low moisture absorption and at the same time having low flammability. And one more thing... The insulation should play the role of a sound insulator.

The familiar thermal insulating material polystyrene foam as roof insulation is far from an ideal option. He is “afraid” of high temperatures (the sun shines well on the roof in summer), and there’s no point in talking about sound insulation at all (this, of course, is all relative)!

The optimal insulation for roofs is mineral wool, which is divided into two large groups:

- made from basalt-containing rocks;

- made from fiberglass.

In addition to different melting temperatures, the technology for producing mineral wool from glass (400 ° C) and basalt rocks (1100 ° C) is the same. Prepared in the required proportions, the mixture of raw materials is melted to a fluid state. After which it is fed to centrifugal rolls rotating at high speed, as a result of which it is “sprayed” into thin fibers, which are picked up by the air flow and at the next stage are mixed with the binder component. Next, a “carpet” of the resulting fibers is formed, which is molded on special machines and polymerized in heat treatment chambers.

These processes determine the physical and mechanical properties of mineral wool.

Then trimming, packaging, transportation... and installation on site.

Mineral wool is formed in the form of slabs or in the form of rolls.

Among the manufacturers of thermal insulating mineral materials, the following companies should be noted: Rockwool, Isover, Knauf Insulation and TechnoNIKOL. Their big names have become popular household names for materials.

Isover

Izover is a representative of thermal insulation materials that has gained enormous popularity. Its main “vocation” is to improve the thermal insulation properties of buildings, in particular their roofs. Using an isover is a direct path to saving on heating.

Isover is a relatively cheap roof insulation.

What other advantages of this material can be named?

Let's start with the main thing for many happy “foremen” of the construction of their home - isover has an affordable price with high quality, environmental friendliness, significant thermal insulation properties, “longevity” and is easy to install.

Isover will keep the heat under the roof of your home!

Rockwool

Rockwool is an indispensable assistant in energy saving during heating. The building must be warm and at the same time “economical” - these are mandatory parameters of a modern construction project. The organization of insulation of a building depends to a large extent on the insulation of its roof.

An excellent insulation material for a rockwool roof is stone wool made from inorganic mineral raw materials.

Advantages: non-flammable and natural raw materials. The parameters correspond to the highest fire safety class A1.

Rockwool mineral vara can withstand temperatures of more than 1000 ° C, which, together with insulation, makes it possible to create a fire-resistant barrier in the walls and roof of the building.

And that is not all! Due to its “fibrous” nature, Rockwool wool has excellent sound-proofing (sound-absorbing) properties.

Excellent thermal insulator Rockwool

Knauf Insulation

KNAUF is the largest manufacturer of building materials used in interior and exterior decoration. Their thermal insulation materials deserve special attention.

This is mineral wool based on basalt fiber, which has all the positive qualities already listed above. Knauf materials have high vapor permeability, low moisture absorption, and resistance to biological and chemical influences.

Thermal insulation Knauf

Natural insulation Knauf

TechnoNIKOL

TechnoNIKOL is another popular thermal insulation “brand” that offers high-quality thermal insulation materials in the “open spaces” of the construction market. The company’s production “capacities” (37 enterprises) are distributed in the territories of Russia, Ukraine, the Czech Republic, Lithuania, and Belarus.

Teplonikol Corporation owns its own sales network and representative offices in 35 countries. These are modern technologies in the production of sheet and roll insulation for roofs and walls.

Rocklight 1200x600x100mm (density 30kg/m3)

Lamel mat: Length. – 2600-12000mm W. – 1200mm, T. – 20-100mm

Some features of choosing roof insulation

For buildings for individual use, if it is being built for a long time and “for oneself,” use stone (basalt) mineral wool from Rockwool.

The construction of commercial buildings is mainly accompanied by roof insulation with glass wool, because it is at least two times cheaper.

Note! In residential or attic spaces that are simply visited by people, it is recommended to install a wind barrier protective film. It will protect the human respiratory system from fiberglass flying in air currents from drafts.

The thickness of the thermal insulation coating must be correctly calculated. Because the small thickness of the insulation, as well as non-compliance with the rules for installing mineral wool and vapor barriers on the roof, lead to getting wet due to condensation and freezing of the roof structures.

Frost on a “thermally insulated” ceiling

Due to improper installation of thermal insulation material, cold bridges are formed in the thickness of the “roofing cake”, which after some time lead to the appearance of dampness and mold. And there is no point in blaming the roofing - it has nothing to do with it! The reason is below, underneath...

Condensation on the surface of the vapor barrier

Insulation with mineral wool necessarily “requires” the use of a vapor barrier hermetic coating - a special polyethylene film reinforced with mesh. The joints between the film sheets must be glued with special adhesive tapes.

Important! If you do not make a high-quality vapor barrier barter, then warm air from the room in winter will penetrate into the thermal insulation layer. And when it comes into contact with cold surfaces, water vapor contained in the warm air will condense on them, which will lead to soaking and the appearance of dampness.

Properly organized work and the selected insulation for the roof plus vapor barrier of the roof of the house is the key to your long-term “dry” existence in it.

Video: roof insulation

Isover - high quality mineral wool to choose from

The manufacturer offers two solutions: glass wool and stone wool. This is a big plus when choosing thermal insulation, since both of these materials are usually in demand in the construction of a particular facility. Izover has an excellent reputation in Russia and offers thermal insulation only with environmental quality certificates. The constant introduction of modern technologies makes it possible to improve the characteristics of manufactured products and reduce costs. The latest “new product” from Isover is the release of mineral wool with high strength and elasticity, without dust and with a minimum of “prickliness”. In terms of quality, products under this brand are unlikely to compare with more expensive competitors, but in terms of price/quality ratio, Isover mineral wool is one of the best.

Rating : 9.9 points out of 10

Reviews from builders : “Isover mineral wool is cheaper and better than many other insulation materials, so I use it for large volumes.”

Beltep is a good and inexpensive mineral insulation

Basalt mineral wool from this manufacturer is available in two packages: rolls or slabs and is considered a good solution for creating multi-layer thermal insulation systems. The high rating of Beltep basalt wool is confirmed by reviews from construction forums and from individuals.

Among the advantages of Beltep mineral wool insulation:

- fire safety;

- environmental friendliness;

- vapor permeability;

- resistance to deformation;

- acoustic comfort;

- large selection of materials by density;

- low hygroscopicity;

- affordable price.

In addition, the material has high rigidity, is shape-resistant, and is easy to cut and install. When compared with European manufacturers, BelTep is inferior to them in some respects, but when there is a choice between it and many Russian brands, they often buy mineral wool from a Belarusian company. So we can say that BelTep basalt wool is the best competitor to many similar proposals.

Rating : 9.5 points out of 10

Reviews from builders : “I tried Beltep mineral wool in my work. The density is good, it doesn’t sag, it stands clearly between the rafters without falling out.”