During repairs, improvement of a house or cottage, the owner may have difficulty choosing suitable pipes. Emergency situations occur when an old pipeline leaks and there is a risk of flooding. To get rid of such problems, new high-quality communications should be established. In the modern market, metal-plastic pipes for heating are in great demand.

What are metal-plastic pipes

The products are mainly used in the installation of water supply systems. Pipes have different characteristics, so when choosing, you need to take into account operational features and other technical nuances. There are several types, each of which has its own purpose.

Design

Metal-plastic pipes are a complex structure. Based on the name, it becomes clear that the key materials from which they are made are metal and plastic.

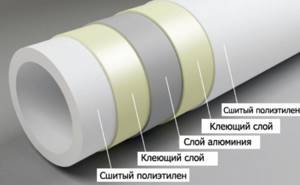

The products consist of 5 layers:

- modified polyethylene (cross-linked);

- adhesive layer;

- thin aluminum layer;

- another layer of glue;

- protective polyethylene shell.

To make the outer and inner parts, plastic is used, produced using a special technology. This makes the finished product hard and resistant to mechanical stress.

Scope of application and possible operating conditions

At the moment, various communications are assembled from metal-plastic pipes, both for private homes and for industrial premises. Most often, the products are used for the installation of heating systems, hot and cold water supply. Thanks to these pipes, the negative impact of oxygen on heating equipment: boilers or radiators is reduced.

It is worth noting the high flexibility of the products, which allows them to be used when installing a “warm floor” system. Metal-polymer heating pipes allow you to create a wide variety of configurations, with many bends and turns, which facilitates installation work.

Metal-plastic is an indispensable material if you need to install plumbing protected from moisture that appears as a result of condensation. Thanks to this advantage, communications can be laid in walls made of plasterboard or concrete. When installing hidden pipelines, most craftsmen use metal-plastic.

When choosing this type of pipe for installation, one condition must be observed - the system in which they are installed must necessarily have a pressure stabilizer. Of course, products made of metal-plastic are practically not afraid of high pressure, but its frequent changes can have a negative effect on the material.

Advantages

The popularity of metal-plastic pipes is explained by their many positive qualities.

Experts highlight the following advantages of using products in heating systems:

- Long service life. Pipes produced by leading manufacturers can last about 50 years.

- They do not clog, do not accumulate deposits and do not rust. Compared to metal analogues, the inside of metal-plastic products is absolutely smooth, and it is not subject to oxidation. For this reason, its properties will not change after years of operation.

- Ease of use. Metal-plastic products are very easy to install - just secure them well. They are light in weight, bend easily and are highly resistant to damage.

- Efficiency. Polymer materials, compared to metal products, have a lower thermal conductivity coefficient, which eliminates possible heat losses.

- Wear resistance. Regardless of the speed at which the coolant moves inside the pipeline, this will not affect the quality of the products.

- The number of connections is reduced. Thanks to the elasticity of the material, the pipes easily bend around irregularities and corners. This reduces the number of fittings to be installed, making the entire system more reliable.

- Availability. Metal-plastic products are now in wide demand; many companies are engaged in their production. Installation work does not require a lot of time and material resources.

As can be seen from the list of positive properties, metal-plastic products are reliable and durable, which is why they are found more and more often in modern communications.

Flaws

Products made from modern materials also have certain disadvantages that must be taken into account before installing a heating system.

The following disadvantages stand out:

- the pipes themselves, as well as the connecting elements, are somewhat more expensive than plastic products;

- small selection of diameters: from 16 to 63 mm;

- if communications are laid in the walls, the joints may weaken over time;

- if water freezes inside the pipe, the likelihood of it bursting increases;

- exposure to thermal radiation and ultraviolet radiation reduces the quality of the material;

- Metal-plastic products are not suitable for installing a fire extinguishing system.

If you follow the rules, then a heating system assembled from metal-plastic pipes will last for many years and will not cause difficulties during operation.

Why do you need a layer of aluminum?

Aluminum foil acts as the third layer in the structure. It is made from pure or alloyed aluminum. This layer is necessary for protection. It makes the pipes oxygen-tight.

The thickness of the foil layer is the most important characteristic that must be taken into account when choosing. It determines what internal pressure the pipe can withstand, and generally determines where it can be used.

The thickness of the aluminum layer varies from 0.2 to 0.7 mm. The best option when laying a heating system is to use pipes with parameters from 0.3 to 0.55 mm.

A solid structure is welded from a layer of foil in several ways:

- Using a laser. This method is used to create a seamless butt joint. Finished products have smooth walls and excellent performance properties. The aluminum layer can be of any thickness.

- Ultrasonic welding. In this case, the ends of the foil are overlapped so that no noticeable thickening is formed in the bonding area. The walls are not perfectly smooth. These are more affordable pipes; when compared to seamless ones, they are not as strong and durable.

To create more reliable systems, it is recommended to choose seamless products.

Bonding layer

Manufacturers use special compounds to connect plastic to metal. Thanks to their properties, the multilayer structure becomes a single whole. Manufacturers use various adhesive compositions and unique formulas known only to them. The user only needs to ensure the safety of the product by studying the quality certificates.

Glue is needed not only to connect different structural elements together, but also to give elasticity to the product. The bonding layer is the most vulnerable point of a metal-plastic pipe. If the glue becomes less elastic, the structure may begin to delaminate and leak.

For metal-plastic products used in hot water supply and heating, the binding layer plays a significant role, and it must be of high quality. Even visually you can determine how firmly the layers are connected to each other. If it seems that they are not fastened well enough, you should refuse to use such a pipe.

What types of plastic are used for production

During the production of pipes, manufacturers can use different types of plastic, which changes the properties of the final product. As a rule, high-strength PEX polyethylene, manufactured using a special technology, is used for the production of heating products. It can withstand a burst pressure of 70 bar. This type of polyethylene has good resistance to chemicals, will not oxidize, and deposits will not form on its internal surfaces. Optimal for creating complex systems and various connections to thermal equipment, for example, batteries or boilers.

PEX polyethylene has a low internal wall roughness of only 0.004 mm. He is not afraid of exposure to high temperatures, up to +90 °C. Compared to polypropylene products, metal-plastic pipes are characterized by less linear expansion.

A more heat-resistant material is PE RT polyethylene. It is a thermoplastic, so it can be welded. Technologies are constantly evolving, and now new pipes are appearing - PERT-Al-PERT. They are as flexible as metal-plastic products, and at the same time they can be connected to the system using mechanical or welded fittings. The consumer properties of PE RT products are higher compared to PEX, and at the same time they are more technologically advanced in production.

HDPE (low-density polyethylene) is also used in the production of pipes. Such products are characterized by high strength and density. They melt at a temperature of +130 °C. At the same time, they are chemically resistant to oils and fats.

Most often, such products are used if it is necessary to install an external pipeline through which cold water will be supplied. For the production of pipes, PE-100 grade polymer is used. Using these products, installation of pressure sewerage is allowed. They are not suitable for hot water supply and heating systems.

Pro et contra

Advantages

What is attractive about metal-plastic compared to traditional steel pipes for heating?

First of all, it is easy to install it with your own hands, without using any complicated tools. Steel requires either welding along with the appropriate skills, or cutting a huge number of threads.

Only compression fittings are installed with a pair of adjustable wrenches. The cost of the simplest pliers for crimping press fittings is at least 6,000 rubles.

The second argument in favor of the material is the service life of metal-plastic heating pipes. They will not require replacement for at least half a century, even in the most unfavorable conditions - provided the system is reset for the summer, which is often practiced in apartment buildings due to intersectional leaks of cast iron radiators. For comparison, I observed the first leaks on the threads of steel pipes 10 years after the house was put into operation.

Finally, metal-plastic does not become overgrown with deposits and rust: cross-linked polyethylene is an extremely low-adhesive polymer.

For comparison: this is what a steel pipe looks like after long-term heating use.

Flaws

There are two of them:

- Relatively high price. A meter of pipe with a diameter of 26 mm will cost at least 140 rubles. The DU20 water and gas pipe, which has the same throughput, costs half as much;

- Low tensile strength. The notorious VGP pipe has a destruction pressure of at least 40 - 50 atmospheres, but here it does not exceed 20.

What diameters are the pipes?

The key characteristic of pipe products is diameter. These values are now standardized, which facilitates the arrangement of communications.

Parameters to pay attention to when choosing pipes:

- Inner diameter. This is the main characteristic on which throughput depends. Also taken into account when selecting fittings.

- Outside diameter. Can vary from 16 to 63 mm.

- Wall thickness. Depending on the cross-section of the pipe, it ranges from 2 to 3.5 mm.

At the moment, metal-plastic products with different diameters are produced, which must be taken into account when arranging the pipeline.

Most popular sizes:

- 16 × 2. The number 16 indicates the external section, and 2 indicates the wall thickness. Such products have an internal cross-section of 12 mm. This product is now the most in demand and is used to install water supply and heating systems in apartments. Due to the properties of the material itself and good throughput, lime will not accumulate inside the pipes, thereby blocking the flow of coolant. The determining factor when choosing is the low cost of connecting fittings. In installation diagrams, this diameter is relevant if you need to make a tap to the faucet in the bathroom or kitchen. To equip main pipelines, products of larger diameter are used.

- 20 × 2. Most often they are used when installing a “warm floor” system. The internal diameter of these pipes is 16 mm. More expensive fittings are produced for them, but the products themselves are characterized by greater throughput compared to the previous version. Therefore, if the water pressure is unstable, it is better to use them, especially if a long route is being made. The products can withstand pressure up to 10 bar, similar to steel products.

- 20 × 26. The internal diameter is 20 mm, the external one is 26 mm, the wall has a thickness of 0.3 cm. With the help of such elements, risers and “warm floor” systems are mounted. This is the preferred choice if pipelines are installed in a private home. Internal pressure surges are possible in the system, so high throughput will not be superfluous.

- 26 × 32. Products with a large diameter are the basis of any heating system. They have high throughput, which ensures a stable supply of coolant. Riser pipes and main pipelines are assembled from them.

- 32 × 40. They are used in both industrial and civil construction. With their help, central or individual heating and water supply systems, as well as water treatment and air conditioning, are created.

- 40 × 50. The wall thickness of such pipes reaches 0.4 mm. They are used if it is necessary to create a technological pipeline that provides water supply or heating in an industrial enterprise. Suitable for laying routes along which chemically aggressive media or compressed air move. This is a reliable and high-quality material that can last at least 20 years.

There is a wide variety of products depending on the diameter. Do-it-yourself heating from metal-plastic pipes is usually done using products with a diameter of 26 × 32.

The use of metal-plastic pipes in autonomous and central heating systems

The use of metal-plastic pipes for the installation of heating networks allows you to save time, effort and money and equip a pipeline that has all the positive qualities of metal and plastic.

To obtain such a result, you must, first of all, understand the differences in the operation of central heating and individual heating:

- In a central heating system, a powerful heat-generating device heats a large volume of water. The heated coolant enters houses and apartments at a temperature of 40 to 95 degrees, but with preventive measures, the water supplied to the pipes can have a temperature of up to 150 degrees. The pressure is usually in the range of 4-5 atmospheres, but since an extensive and branched heating network is serviced, water hammers occur in the pipeline - pressure surges when it exceeds the norm by 2-3 times. For metal-plastic, 95 degrees is the operating temperature limit, and water hammer is a threat of instantaneous destruction of the walls, especially at corners and nodes. Therefore, the installation of metal-plastic pipes in rooms receiving coolant from a centralized system is undesirable. However, the above problems can be solved by equipping the pipeline with pressure stabilizers and temperature regulators.

- A small volume of coolant circulates in an autonomous system; temperature and pressure can be adjusted directly on the heat-generating device. Therefore, in houses, apartments, commercial and other buildings with individual heating, metal-plastic can be used without restrictions.

We recommend that you read: DIY gazebo from a profile pipe

Features of using metal-plastic pipes for heating

Products made of metal-plastic, due to their design features, are suitable for arranging heating systems. But they have one weak side - the presence of an aluminum or foil layer that acts as a base.

The fact is that the polymer material and foil have different thermal expansion. With a sharp change in temperature, polyethylene will increase in volume faster than foil. Because of this, the entire structure may simply delaminate.

When creating a heating system, you must adhere to the following rules:

- It is necessary to reduce the surface tension, for which compensation loops are used. Thanks to them, the likelihood of a system breakthrough is reduced.

- The pipeline must not be exposed to sunlight. If avoiding this is problematic, hidden installation is done.

- Water hammer and spontaneous temperature fluctuations negatively affect product quality. Therefore, it is recommended to minimize the likelihood of these moments.

In any case, you will need to familiarize yourself in detail with the technical characteristics of the product. As practice shows, the main mistakes are made during installation and selection of materials.

What plastic is used in production

When making metal-plastic pipes for heating or plumbing, different types of polymers are used. These polymers are:

- Cross-linked polyethylene PEX or linear PE-RT. This type of polyethylene helps provide pipes with maximum strength, as well as reliability and wear resistance. The main advantage of these types of polymers is that they increase the service life of the device several times. Devices made from this material are highly resistant to temperature fluctuations, mechanical influences and pressure variations, and are used both for the construction of a heating network and for the construction of water supply.

- Low pressure polyethylene PEHD, PE-RS, PE, HDPE is a cheaper and less practical material compared to the first. Pipes made using this type of polymer have a narrow scope of application. In particular, the technical parameters of such products are to limit the temperature of the coolant to +75 degrees. It is recommended to use this material for the construction of water supply systems and transportation of cold water. Low-density polyethylene is unstable to ultraviolet radiation, so if the system is installed outside, it must be protected from sunlight.

If you choose a pipe from MP in order to build a heating system at home or in an apartment, then it is recommended to take into account the type of plastic in order to prevent premature wear of the material. If you save money and buy cheap metal-plastic, then in 5-8 years you will need a major replacement of the structure, so this requires a responsible and competent approach to the selection of pipes.

Fitting

This is the name given to the pipeline elements with which pipes are connected and branched. Despite the plasticity of the material, one-piece fittings are produced, with the help of which complex structures are fastened. At the moment, metal-plastic connecting elements are widespread, since in most cases this modern material is used to create heating systems. All fittings are classified according to the method of fixation.

Detachable

This type of connecting elements is used by many professionals. Its advantage is that in the event of a breakthrough in the system, it is not necessary to dismantle part of the communication for replacement. Fittings provide a more reliable connection compared to soldering or welding.

This is explained by the linear expansion of the material: when heated or cooled, it accordingly increases in volume or returns to its original state. If soldering was used, then these properties of the system can become the main problem, because the likelihood of violating the integrity of the joint increases. By working with fittings, such situations can be avoided.

Due to the fact that these connecting elements are reusable, they are called detachable. The key structural part is the collet, which looks like an O-ring. It is through this element that the required level of tightness is achieved. In addition to the collet, the fitting design includes a ferrule ring and the body itself, which is made of brass.

Press fitting

It is used indoors, since the elements do not withstand frost well, which significantly reduces the service life of the fittings. Installation outdoors may cause an emergency on the pipeline section. To install such a structure, a special tool is used - pliers, with which the ends of the pipes are compressed. Press fittings are produced monolithic. Their design consists of a body, a fitting and a sleeve with a gasket.

One point needs to be taken into account - press fittings are a disposable connecting element, therefore they are most often used when installing a “warm floor” system and laying communications in the walls.

To connect pipes where the pressure can reach 10 bar, these fittings are used, because they are made of durable material. As experts assure, if you follow the installation rules, the connecting element can last about 50 years.

Crimping

The main advantage of this type of connection is ease of installation, so each owner can do the installation with their own hands. But you need to take into account that such fittings are short-lived, since their design uses a rubber seal. The element itself is quite expensive and cannot be monolithic (installed into the wall).

Crimping parts have optimal technical characteristics suitable for arranging water pipelines. You don't need to use special tools to make a reliable and durable connection.

Characteristics and properties

Metal-plastic pipes were originally planned as a universal substitute for metal products. Their technical characteristics in some aspects even exceed those of metal, and this with a colossal difference in price.

Metal-plastic pipes consist of three working layers. The inner layer is plastic or, which is much more common, polyethylene. Polyethylene is very durable. Ordinary polyethylene products, which are afraid of ultraviolet radiation and temperature changes, are no match for it.

The second layer is aluminum. The last layer is made of the same polymer as the first.

Thus, something like a multilayer pipe with an internal metal frame is formed. This is how it is, by and large.

External finishing with plastic improves the technical characteristics of the pipe by increasing its durability. The product has the durability of ordinary plastic, its resistance to corrosion, contact with the external environment, moisture, etc.

Cross-section of metal-plastic pipes

The inner layer of aluminum, by the way, is very thin and strengthens the pipe. It levels its coefficient of thermal expansion, makes it more plastic (metal-plastic can be bent even by hand without fear) and elastic. If you wish, you can install such products yourself. Working with your own hands is easy and pleasant.

Advantages and disadvantages

Now let’s look at the specific advantages and disadvantages of standard metal-polymer pipes, which are abundantly available on the market.

Advantages:

- high strength;

- plastic;

- ease of handling with your own hands;

- low coefficient of thermal expansion;

- large supply of defrosting cycles;

- durability;

- do not corrode;

- We have a huge range of products for every taste;

- the pipes weigh almost nothing, are easy to transport and lay with your own hands.

However, such products have their own disadvantages; now you will find out which ones.

Main disadvantages:

- increased price;

- DIY installation is possible if you have a special tool, otherwise there is a chance of destruction or serious damage to the surface;

- It is still more difficult to install metal-polymer products than plastic ones.

As you can see, there are not many shortcomings, but they do exist. First of all, they relate to what specific tools you use in your work. The tendency to deformation in metal-polymer pipes works in both directions.

Marking

There must be inscriptions on the outside of the pipes. To make the right choice, you need to understand what they mean. Not all types of pipes are suitable for a particular task. The marking is applied by the manufacturer. In metal-plastic products, the materials of the outer and inner layers may differ.

What designations are found:

- PE - R . Indicates that polyethylene was used to make the inner and outer layers.

- PP - R . Material of manufacture: polypropylene.

- PE - X . The composition contains cross-linked polyethylene. There are also other markings indicating the method of stitching the material.

- PE - RT . Made from heat-resistant polyethylene.

After these designations the diameter and thickness of the tube are indicated. Another marking that can be found is PN, which indicates the nominal pressure that the product can withstand. The unit of measurement is usually bars. Additionally, the maximum temperature and type of permissible coolant are indicated.

Combination of metal and plastic

The metal-plastic wall is made of an aluminum base coated with high-density polyethylene. Using the extrusion method, a special adhesive layer is applied to it on the inside and outside. With the help of an outer layer of polyethylene, the product is protected from atmospheric corrosion and mechanical damage.

Aluminum

The middle aluminum layer gives the pipe mechanical and hydraulic strength and makes it oxygen-tight. The thermal deformability of polyethylene is reduced by more than 7 times due to the presence of aluminum.

The edges of the aluminum base can be joined using laser butt welding or ultrasonic lap welding. Laser welding provides a more durable option.

Polyethylene

The inner layer consists of heat-resistant polyethylene. It forms a smooth surface and corrosion protection for the metal. The polyethylene used in production does not contain harmful chemicals. This suggests that metal-plastic pipelines are suitable for drinking water supply. Polyethylene prevents the proliferation and spread of microorganisms in water.

To provide thermal insulation and reduce heat loss, closed-cell pipelines with concentric insulation are used.

Review of manufacturers and prices

Metal-plastic products are manufactured in many countries: Russia, Germany, Italy, China, Turkey and so on. The modern market is constantly growing, so manufacturers have to withstand fierce competition. The main goal of companies is to create truly high-quality products that meet all requirements.

When choosing communications, price is of considerable importance, especially if you plan to equip long-distance highways. Metal-plastic pipes for heating can have different prices per meter, which are indicated on the website of the manufacturer or official dealer.

It must be taken into account that the final figure is formed based on the quality of the product and the popularity of the brand that produces the product. For this reason, there are products on the market at prices starting from 600 rubles per meter. Of course, this is an inflated cost, because you can buy pipes for 50 rubles.

Among the available companies, it is worth highlighting Aquapipe and LTM from Turkey and China, respectively. Despite the relatively low cost, the products are of decent quality and meet all standards.

Metal-plastic pipes for heating, price per meter in rubles:

- Valtec - from 70;

- Fado - from 102;

- Golan - from 175;

- Henco - from 35;

- Kermi - from 78;

- Polvax - from 70;

- Rehau - from 165.

Even well-known brands offer affordable prices for their products. It should be borne in mind that the price also depends on the diameter of the product.

Prices for metal-plastic pipes

metal-plastic pipes

Advantages and disadvantages of metal-plastic products

Before installing heating in a private house using metal-plastic pipes, it is important to become familiar with their positive characteristics and, of course, their disadvantages.

These modern products have many advantages over similar products made from other materials:

- They do not require painting.

- Easy to install - there is no need to use a welding machine for installation.

- They can be embedded in walls and laid in floor screeds.

- They are light in weight.

- The installation process produces little waste.

- Their throughput is one and a half times higher than that of metal pipes of the same diameter.

- They have an aesthetic appearance.

- Stray currents cannot pass through them.

- They are easy to repair and replace.

- If necessary, you can easily install an additional element of the system into the pipeline, such as a heating radiator.

- Combines well with metal elements.

Such pipes have fewer disadvantages:

- High cost of products, including fittings.

- They are hypersensitive to defrosting.

- When using high operating temperatures (about 95 degrees) in a heating system, their service life is reduced by 2 times.

- Due to the presence of a large number of threaded connections, careful insulation is required, otherwise the heating system will leak.

- They should not be laid in places where there is direct exposure to ultraviolet radiation.

How to identify a fake

When installing pipelines, it is very important to use high-quality pipes, which will allow the system to last for decades. Counterfeits are simply not able to withstand the existing loads; after 2-3 years they can leak. In addition, in low-quality products, the aluminum layer deteriorates over time, which can also become a problem.

A few tips to help you spot a fake:

- The pipes must be accompanied by a certificate. Of course, if there are documents, this does not mean that the product is 100% high quality, but if they are not there, this is a reason to think about it. If the supplier is conscientious, he must attach to each batch a corresponding document indicating the originality of the products.

- Visual characteristics. The marking and appearance of the pipe must be the same as indicated on the manufacturer’s website. You need to be vigilant when purchasing products.

- Pipe cut quality. If the aluminum is butt welded, everything is fine, but if the seam is made “overlapping,” the product is of low quality. You also need to pay attention to the thickness of the aluminum - it should be identical throughout the entire diameter. The same applies to the outer and inner layers.

By adhering to these rules, the likelihood of buying counterfeit goods can be minimized. The key to the efficiency of a heating system is properly installed high-quality pipes.

Design features

The technical characteristics of metal-plastic pipes for heating are based on the use of polymer materials. For their production, cross-linked polyethylene is used. But since it does not have the required degree of rigidity, an additional layer of foil is installed to give the products the required properties.

The technology for creating metal-plastic pipes allows them to be produced with different diameters. For this, an extrusion method is used, which consists of attaching an internal and external polyethylene layer to an aluminum base. A special adhesive composition is used as a binding component.

The inner layer has high strength, heat resistance, it does not oxidize, and salts do not accumulate on its surface. Due to the fact that the central element of the design is aluminum, these pipe products are hydraulically resistant. Since the metal is protected on both sides by polymer, it is not affected by negative external influences.

If you lay a heating system from metal-plastic pipes, then with high-quality assembly it will last a long period.

Installation nuances

Metal-plastic has gained such wide popularity primarily due to its ease of installation. An important feature of this product is that it is distributed in coils, and not in separate pieces, like polypropylene products. This allows the pipe to be cut to the length required.

Another point is that the products are very easy to bend without the use of additional tools. Such deformation does not in any way affect the performance characteristics of the material.

Before laying communications, you need to install ball valves, filters and a device for measuring water flow into the system, which is usually done by plumbers.

Connection and connection of metal-plastic products is carried out using fittings, which are sold in all hardware stores. Thanks to their large number, it will not be a problem to choose the right element even for a complex harness.

Sequence of installation work:

- A piece of pipe of the required length is cut with special scissors.

- During cutting, the edge of the product can be damaged. This shortcoming is corrected by such a tool as a calibrator.

- For strong fixation with the fitting, it is recommended to treat the edge of the pipe with a chamfer.

- A union nut and a fitting collet are put on the product.

- The shank of the connecting element is carefully inserted into the pipe; it must fit completely.

- The union nut is tightened - first by hand, and then tightened using a tool.

- Another section of pipe is connected in the same way.

Even a beginner in the field of construction can cope with joining metal-plastic, which can easily be attributed to the advantages of the material. Study the long-burning solid fuel heating boiler using the link.

Production process

The production of metal-plastic (multilayer) pipes is carried out on special automated industrial-type flow complexes. Moreover, during the manufacturing process, not only the products are formed, but also they are computer checked for compliance with quality standards.

- First of all, a metal base (frame) is formed from aluminum foil.

- Then the aluminum billet is sent to the compartment, where its edges are joined using ultrasonic welding.

- By injecting air into the resulting pipe (under a pressure of 4-6 atmospheres), the strength of the weld is controlled.

- After checking, the workpiece enters the extruder, where an adhesive and polymer layer is gradually applied. First, the inner surface of the aluminum billet is processed, then the outer surface. At the same stage, a marking strip - blue or red - is applied to the product.

- At the final stage, the product is cooled: first with air, then in a water bath.

- At the exit, the pipe goes to the so-called quality control department, where the “scanning” and measurement of the geometry of the layers takes place.

- Finally, the product is labeled and wound into coils.

Scope of metal-plastic

Pipes made using new modern materials, called metal-plastic, are a multilayer material of cross-linked polyethylene and aluminum foil. Foil with a thickness of 0.5-2.0 mm is connected to two layers of polyethylene using a special glue, giving the pipes the necessary rigidity and strength.

Each manufacturer uses its own adhesive composition for the production of metal-plastic pipes, and the strength of the pipes, their durability and flexibility directly depend on the quality of the glue.

Construction of metal-plastic pipes

The polyethylene walls of the pipe can withstand hot water passing through them, the temperature of which reaches +95 degrees. Polyethylene forms a smooth surface, due to which microscopic solid particles of lime, which are invariably present in any water, are not deposited on the pipe walls, and corrosion does not form.

As a result of all this, the service life of metal-plastic pipes is up to 50 years, and the water coming from them is always clean.

To decide which metal-plastic pipes are better, you need to decide under what conditions they will work. After all, this material can be used not only for water pipes, but also for installing heated floors, for centralized and private heating systems, in air conditioning and water treatment systems.

Metal-plastic pipes are widely used in housing, civil and industrial construction. They are especially widely used by private developers due to the ease of installation of water supply systems.

Advantages of metal-plastic pipes

Having recently appeared on the building materials market, metal-plastic pipes have gained wide popularity due to their high qualities:

- No corrosion and scale;

- Good flexibility, unlike other types of pipes;

- Possibility of use at low temperatures down to -25 degrees;

- UV resistance;

- Possibility of placement in a layer of concrete;

- Simple and easy installation that does not require a welding machine;

- The connection can be made with fittings made of the same material or with a welding device that fits in a simple bag;

- An aesthetic appearance that does not require constant painting, which turns out to be an important factor when deciding how to choose metal-plastic pipes.

But, like any material, metal plastic has its drawbacks. They consist in the difference in the coefficients of thermal expansion between aluminum and polyethylene. If the pipe is constantly exposed to temperature changes, then we can say with confidence that leaks will soon begin at the joints.

Therefore, when installing metal-plastic pipes, experts advise laying them without tension, with a slight sag, thereby creating the possibility of compensatory expansion.

Brief summary, or which manufacturer to give preference to

Our rating includes 11 of the best Russian and foreign manufacturers of metal-plastic pipes and related accessories. Some brands are known throughout the world, and some are represented mainly on the market of the Russian Federation and CIS countries.

The main criteria for selecting specific manufacturers were indicators of quality and reliability, the availability of innovative solutions and a wide range of models, as well as the optimal cost of goods and their availability.

Our review will allow you to become more familiar with the best manufacturers in order to understand which metal-plastic pipes are best suited for solving specific problems in the field of arranging plumbing heating and plumbing systems.

Attention! This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.