To create a floor heating system in a room, various materials and methods can be used. For example, the floor can be equipped with an electric or infrared heater. Also, the system is often equipped on the basis of a coolant such as water. To install this heating option, a corrugated stainless steel pipe for underfloor heating can be used. Let's consider the features of its application and installation.

Corrugated stainless steel pipe for heated floors

Important characteristics of pipes for underfloor heating

Now among building materials there are many options for using various technologies and devices for installing a floor heating system that will operate on water. Despite the fact that this heating method is somewhat more difficult to install than using electric heaters, it is still used and is considered quite popular. One of the main elements of this entire system is the pipe through which the coolant will flow. It must have certain characteristics for the heating to work effectively and correctly.

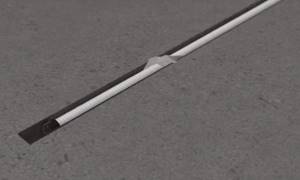

Corrugated Stainless Steel Pipe

Laying corrugated pipes for heated floors

When choosing a water pipe, the following factors are taken into account:

- main operational characteristics - under what conditions this type of pipe can be used;

- features of the installation work;

- thermal conductivity indicators;

- duration of operational life;

- pipe cost;

- flexibility, since during installation of heated floors the pipe will have to be bent many times;

- protection from oxygen penetration, since this element becomes the main cause of rust formation inside the product;

- manufacturer of the material and its reputation.

The use of corrugated stainless steel pipes in the heating system

Attention! The choice of material for floor heating should be made among those types that are intended specifically for heating, and not for organizing ordinary water supply.

The inner walls of the corrugated stainless steel pipe are smooth

Pipes for underfloor heating systems can be made of various materials. Each type has its own usage and performance characteristics.

Table. Types of pipes for organizing floor heating.

| Type of material used in manufacturing | a brief description of |

| Copper | This is one of the oldest materials that was used to equip heating systems in homes. Copper is distinguished by: - long service life and high strength; - antibacterial properties; — corrosion resistance; — the ability to withstand critical temperature changes (from -100 to +250 degrees) without harm. However, copper pipes are very expensive and also have certain operational limitations. They cannot be used if the water is highly acidic or hard. Such conditions reduce the operational period of pipes by half. |

| Metal-plastic | Very popular and high-quality pipes that can easily compete with copper pipes. The advantages of such pipes: - lower price; — long service life (minimum 50 years); - they do not rust; — chemically inert; - lightweight but durable; — smooth, which is why deposits do not form on the surface from the inside. The main disadvantage is the difficulty of connecting individual elements. Poor quality connections can cause flooding of the room and failure of the heating system. Metal-plastic pipes can withstand temperature fluctuations from -10 to +95 degrees. |

| Polypropylene | Pipes made from this material have a lot of advantages, but still it is far from the most popular material. Advantages of use: - environmental safety; — durability; - cheap. They are rarely used for installing heated floors, as they are inconvenient to use - they have a large bending radius. Also, the material cannot be used at sub-zero temperatures - use only from +15 degrees is allowed. |

| Cross-linked polyethylene | Quite durable material. Chemically inert. It is not afraid of temperature changes, does not scratch or crack. |

corrugated pipe for underfloor heating

There is also another type of pipe for sale for installation of underfloor heating - a corrugated pipe made of stainless steel.

Video - Pipes for heated floors

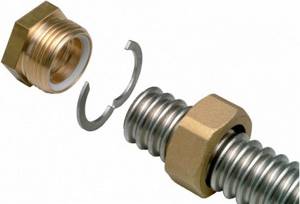

Main Types of Stainless Steel Pipe Fittings

Coupling. The most common type, designed for direct connection of pipes in straight sections.

Rotary angle. Used to change the geometric component of a piping system. Despite the fact that flexible corrugated pipes easily take the desired shape, it is not recommended to bend them with a radius smaller than two pipe diameters.

Branch tee. Allows you to redirect part of the flow from the central highway.

Crosspiece . Used to branch the central flow of working fluid in several directions.

Technological plug. Allows you to completely shut off the working circuit or part of the system according to the project, or for the duration of restoration and repair work.

Transition connector . It is used to splice pipes of different diameters; this is the most practical and convenient type of connecting fittings.

Using a tee, you can route the pipeline in different directions

Stainless steel corrugated pipe for heated floors

This is a fairly new material for arranging heating systems, but it is becoming more and more popular. The reason is simple - the performance characteristics are much higher than other options. A corrugated steel pipe combines plasticity and strength - the basic requirements that the material used for floor heating equipment must meet.

Corrugated pipes

On a note! Corrugated steel pipe originated in Japan at the end of the 20th century, but is now widely produced almost everywhere. The supply leaders are Germany and Korea.

When installing a heated floor system, you need to use materials that will not require replacement over a long period of time. This is a very important indicator, since the pipe system is filled with cement screed and replacing it (the system) will be very difficult. This, of course, can be done, but it will require a lot of money, effort, and time. And corrugated stainless pipe differs from its analogues here too - it does not lose its properties over a long period of use. The average service life is at least 20 years.

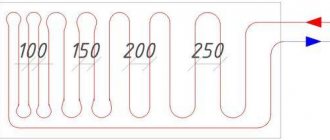

On a note! There are several types of steel corrugations - they differ from each other in cross-section. For example, pipes with diameters of 1.5, 2, 2.5 and 3.2 cm are available for sale. Some factories can produce custom-made products with larger diameters.

Corrugated stainless steel pipes can be used in various fields. They are suitable for:

- heating system installation;

- gas and water pipelines;

- electrical wiring laying;

- arrangement of a fire extinguishing or air conditioning system.

Using flexible corrugated stainless steel pipe

Types of fittings for corrugated pipes

Depending on the task assigned to the installers and the overall estimate of the project, taking into account the installation conditions and pipe diameter, the most suitable type of fittings for stainless corrugated pipes is selected: brass, plastic or steel fittings.

Steel components

The most common, easy to install and most promising type of fittings are metal fittings. They are made from stainless steel, and the chromium content in the alloy can reach 16-20%.

Most often, fasteners for metal pipes are also made of metal, for example fittings for corrugated pipes made of stainless steel or brass.

Advantages:

- do not oxidize when exposed to moisture. The internal surfaces remain clean and there are no signs of corrosion even after long-term use;

- Stainless steel fittings are resistant to mechanical stress;

- Stainless steel components are used in a wide temperature range and are not affected by negative temperatures;

- resistant to water hammer.

Brass fittings are used as transition elements for connecting a stainless corrugated pipe with pipes made of other materials - polymer or a combined type.

The threaded fitting connects the pipes securely, but the threads will need to be tightened with a wrench

Brass fittings are installed using crimp rings or threaded connections. For high-quality installation, use crimping pliers or a set of tightening wrenches corresponding to the diameters of the pipes.

The reliability of compression fittings is equal to that of steel components. The most widespread are brass and copper connecting components from well-known manufacturers of heating equipment.

Using cheap, low-quality brass components is a sure way to achieve the shortest possible time of trouble-free operation of the system. The pipes will perform their function properly up to the area with an incorrectly selected fitting, then a leak of working fluid will occur.

Plastic fittings

Used as connectors in combined systems or for connection to a centralized water supply system. With their help, it is easy to join polypropylene and stainless steel corrugated pipes.

Important! Common parameters for any type of fittings are: anti-corrosion resistance, and insensitivity to sudden pressure drops in the system. The correctly selected type of fittings will allow you to easily install a system of any complexity.

When installing plastic fittings, do not use too much force to tighten the nut; it may simply burst.

Plastic fittings are suitable for connecting metal pipes to polymer pipes

How to make a corrugated pipe from stainless steel

The production of corrugated pipes is a rather complex process that requires high-precision equipment, which reduces the risk of low-quality counterfeits appearing on the market. Corrugated pipe is made from steel strip, which, using special equipment, is turned into a fairly thin tube. Subsequently, the latter goes through a series of clamps that turn it into a corrugation. Next, the product goes through a series of preparatory measures - for example, it is treated with a special gas, which will increase its performance characteristics. The pipe is also fired and then sharply cooled, thereby increasing its flexibility.

Production of corrugated pipes

Attention! Unfortunately, it is visually impossible to distinguish a pipe that has undergone treatment from one that has not. However, this is usually reflected in the price and performance of the product.

Only after going through all the production cycles is the corrugated pipe checked for leaks - it is immersed in a container of water, and air passes through it under high pressure. Defective products are not available for sale.

Scope of application

The excellent performance qualities of corrugated pipes allow it to be used equally effectively in a variety of areas of the national economy:

- industry;

- agricultural enterprises;

- food production;

- chemical and pharmacological enterprises.

But corrugated stainless steel has won true popular love thanks to the ability to quickly and efficiently install any pipeline in an apartment or private house. The flexibility and versatility of corrugated materials are especially valuable in the cramped conditions of city apartments, where literally every centimeter of space can count.

There are often cases when communications have to be completely redone due to the fact that a few millimeters of pipe were missing during installation. A flexible corrugated pipe can always be laid in such a way that its length is exactly as long as necessary.

Corrugation is produced in standard coils of 50 meters, which makes it easy to install even the largest structures. If necessary, you can order pipes of any size and length from the manufacturer.

Note! The scope of application of corrugated pipes is not limited to water supply or heating systems. A hollow and flexible steel pipe will serve as excellent protection against moisture, rodents and mechanical damage for electrical cables.

Advantages and disadvantages

Corrugated steel pipe, like any other product, is not ideal. It has both certain advantages and some disadvantages.

Pros and cons of corrugated metal pipes

Advantages of corrugated pipes in the installation of water heated floors

- Ease of installation, which can be achieved due to the fact that corrugation is a flexible and elastic material. Also, when laying, you most likely won’t need to scratch the walls and spoil the appearance of the room. Connecting individual pieces of material is quite simple thanks to convenient and simple fitting connectors.

- Corrugated steel pipes will not lose their properties even if accidentally crushed.

- The products can withstand significant temperature changes (from -50 to +110 degrees) without damage.

On a note! The pipe itself can withstand heating up to +800 degrees, however, the underfloor heating system also contains plastic elements, so the upper temperature limit is not so high.

- Sudden pressure surges also do not pose a danger to corrugated stainless steel pipes. The limit is 50 atmospheres.

- The material is undemanding - during operation, such pipes do not need to be cleaned or replaced frequently.

- A stainless steel pipe is not afraid of corrosion, and pathogenic microorganisms do not live on it. It can even be used in basements without being filled with concrete, since rodents will not damage it.

- The relatively low price is another advantage of this pipe.

Stainless steel corrugated pipe for heating

Disadvantages of corrugated stainless pipe

There are not so many disadvantages of corrugated pipe, but everyone who considers it as a material for arranging a heated floor should know about them. Disadvantages of steel pipes:

- the price is higher than that of metal-plastic pipes;

- It is quite difficult to clean the corrugation if it is dirty;

- the product will not withstand excessively high mechanical loads - it must be protected with a casing;

- the pipe cannot be used without thermal insulation, otherwise there will be high heat loss. The reason is high heat transfer rates;

- Unfortunately, steel is still afraid of some chemicals.

What are fittings

Installation elements that are extremely difficult for both a professional corrugated pipe installer and a novice craftsman to do without are fittings. This is the name given to the elements of connecting fittings that perform various functions, for example:

- implementation of a sealed transition between two pipeline branches;

- creating a strong connection between pipes of different diameters;

- adjusting, stopping or changing the direction of flow of working fluid in the system;

- increasing the length of the circuit without stopping the entire system, convenient when working with stainless pipes;

- changing the gasket geometry and modernizing the existing system;

- replacing part of an outdated system. Laying a new heating or water supply circuit using steel corrugated pipes.

In addition, the fitting for corrugated stainless steel pipes is responsible for creating branches from any circuit in the system.

Corrugated pipes are used to solve various problems, but their connection without special fittings is impossible

With all the variety, fittings are divided into two categories:

- Seamless elements. They are a one-piece fitting and are extremely reliable, but installation may require specialized tools, for example, crimping pliers.

- Electric welded part. Reinforcement of this type consists of several elements that are precisely fitted together to ensure a minimum gap.

The installation principle is easy to understand and quite simple, and the variety of fittings for stainless corrugated pipes is an excellent solution for assembling the system yourself. If all technological steps are followed, a strong and durable connection is formed.

As a rule, manufacturers of stainless corrugated pipes are not eager to start producing fittings for their products. Economic calculations have shown that this is not a priority for large enterprises. The growing demand in the market for corrugated steel pipes provides the manufacturer with stable profits.

Various countries produce fittings. Components from European manufacturers have proven themselves well. Domestic manufacturers are increasing production volumes while simultaneously tightening quality control of their products.

Important! Before starting installation of the system, it is recommended to lay out the fittings according to the project plan and carefully check for chips and mechanical damage. A missing or improperly installed sealing gasket can lead to leakage and malfunction of the entire circuit.

Different elements are used for gas supply and water supply systems; special attention should be paid to this when drawing up a project.

The easiest way to connect corrugated pipes is with solid fittings

What should you consider before installing corrugated pipe?

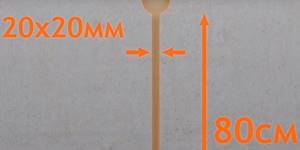

There are several points to consider when developing a project for a heated floor system using stainless corrugated pipes. For example, it is important to remember that the material is sold in large coils, in which about 50 m of pipe are twisted. In a large room, there will most likely be about 2-3 loops of material with a diameter of 20 mm laid. The length of the coils may differ from each other depending on the diameter - there are packages of 70, 90, 120 m.

Advice! To calculate the amount of pipe it is convenient to use various online calculators. In this case, it is advisable to indicate a step slightly larger than when calculating the flow rate of a metal-plastic pipe. When calculating using a calculator, choose a thin-walled pipe - its heat transfer coefficient and the steel corrugations are the same.

Corrugated stainless steel pipe, 20 mm

The corrugated steel pipe is laid at a distance of at least 20 cm from the wall, and at least 30 cm between the loops.

Briefly about this pipe

The peculiarity of the material is its high heat transfer, ease of installation and long service life.

Corrugated stainless steel successfully combines the advantages of several types of pipes. But at the same time, it is very affordable. In addition, there are various fittings for corrugated stainless steel on the market that will make its installation extremely simple.

The scope of application of corrugated stainless steel is quite large. It is equally suitable for creating a heating pipeline and for laying a heated floor system. The pipe bends easily at a convenient angle, which simplifies the installation itself. For example, when creating a heated floor, you can lay a pipeline without violating its integrity.

Important: corrugated stainless steel has shown itself to be excellent not only when creating heating or plumbing systems. Currently they are also used for gas supply

Read more about such pipes in our material - https://kvarremontnik.ru/nerzhaveyushhaya-gofrirovannaya-truba-dlya-otopleniya/

Selection of corrugated pipes for installation of a heating system

Depending on the manufacturer and production conditions, the quality and performance characteristics of corrugations may vary. Therefore, you should choose the material carefully.

It is worth paying attention to the marking of the pipe - it is usually indicated on the packaging. They also look at the integrity of the packaging - it should not be damaged. Unfortunately, sometimes careless sellers try to replace the contents of the package, trying to sell a lower-quality product at a higher price.

It is also necessary to check the presence of all connecting elements, if any are provided in the package. The corrugated pipe itself must be without external damage, dents, or cracks.

Rules for choosing corrugated pipes

It is also better to immediately purchase the required amount of pipe for installing a heated floor, and for this you first need to carry out all the necessary calculations. When choosing, the diameter of the product is also taken into account. The most commonly used corrugations are with a diameter of 16, 20 and 25 mm. It is worth remembering that the heat transfer of a thick pipe is greater than that of a thin pipe, but much more cement mortar will be needed to fill the screed. This means that the floor level will be higher, which is undesirable in a room with a low ceiling.

Prices for corrugated stainless pipes

The price range for corrugated stainless steel pipes is quite wide. The cost of one meter of product can vary from 400 to 1600 rubles. The price will depend on the manufacturer.

One of the most popular manufacturers of corrugated pipes in Russia is Neptun.

Table. Prices for Neptun corrugated pipes.

| Name | Footage, m | Cost, rub. |

| Neptune IWS 15A | 50 | 5050 |

| Neptune IWS 20A | 30 | 4500 |

| Neptun IWS 25A | 30 | 5370 |

| Neptun IWS 32A | 20 | 6860 |

| Neptune IWS 15A | 30 | 3030 |

| Neptune IWS 15A | 20 | 2020 |

Corrugated stainless steel pipes Neptun IWS

Corrugated pipes produced by Ruvinil, Kofulso (Russia), Meibes (Germany), Lavita and Hydrosta (South Korea) are also in demand.

Heated floor pipe circuit length calculator

Go to calculations

Installation of heated floors made of corrugated steel pipes

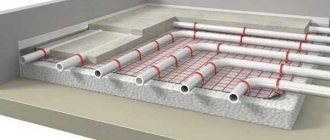

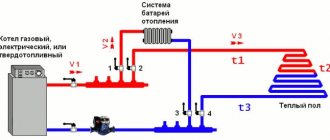

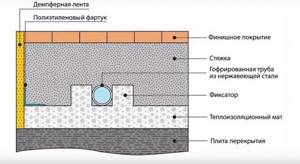

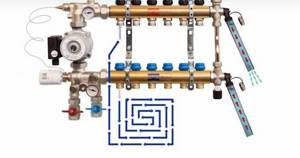

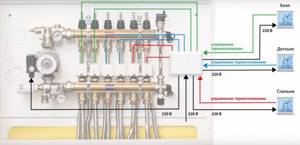

The warm water floor system consists of:

- corrugated pipes;

- circulation pump;

- fittings;

- collector;

- mat with clamps;

- thermostat;

- distribution cabinet;

- mixing unit;

- damper tape;

- plumbing elements;

- thermostatic head with servo drive.

Heated floor diagram

All these elements must be purchased before installation. You will also need a cement mortar for pouring the screed, a plasticizer and a decorative finishing coating for the floor.

Step 1. A niche is created in the wall where the thermostat is installed for its installation, as well as a groove for laying cables.

Niche and groove

Step 2. Prepare the base of the floor. The surface is leveled and cleared of construction debris.

Preparing the base

Step 3. The walls around the perimeter of the room are covered with damper tape.

Laying damper tape

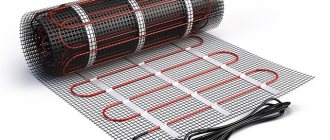

Step 4. Heat-insulating mats with fasteners on the surface are laid on the surface.

Laying thermal insulation mats

Step 5. A distribution cabinet is installed in the designated area.

Installation of distribution cabinet

Step 6. The pumping and mixing unit is assembled.

Assembly of the pumping and mixing unit

Step 7. The node is attached to the manifold.

Connecting the node to the collector

Step 8. The resulting structure is installed in the distribution cabinet.

Installation of the structure in a distribution cabinet

Step 9. The corrugated pipe is laid. Installation starts from the distribution cabinet. The product is placed between clamps on heat-insulating mats. The pipe is laid according to the chosen scheme.

Laying corrugated pipe

Laying process

Step 10. When the pipe is returned to the manifold again, it is cut.

Pipe cutting

Step 11. The pipe is connected to the collector outlets using fittings.

Pipe connection

Step 12. Thermostatic heads with servo drive are installed.

Installation of thermostatic heads with servo drive

Another photo of the process

Step 13. The system is filled with water and checked for leaks.

Attention! When the pipes are filled with water, the automatic air vents close. Each contour is filled individually.

The ball valves at the inlet of the mixing unit are closed. The loop valves on the return manifold also close. The drainage taps are opened and the system is filled with water using a hose on the return manifold connected to the pump. The hose is also connected to a drain valve, which is installed on the supply manifold, so that water can be drained.

Ball valves are closed

The loop valves on the return manifold are closed

Hose is connected

Step 14. The valve on the return manifold opens at the circuit that is currently filling. The pump stops when water flows from the outlet pipe. The valve of the filled circuit closes, but the valve of the next circuit opens. The system is filled in exactly the same way.

The valve on the return manifold opens

Filling the system with water

Step 15. Once the system is filled, the shut-off ball valves are opened and the drain valves are closed. The air vent cap also opens.

Shut-off ball valves open and drain valves close

Step 16. The system is pressure tested. The pressure should be 6 bar. The system is left for a day. If the pressure has not dropped, then you can fill the system with screed. If the pressure has dropped, the location of the leak is identified and it is eliminated.

The pressure should be 6 bar

The system is filled with screed

Step 17. The temperature sensor is installed in the groove in the floor. The groove is sealed with the mixture.

Installing a Temperature Sensor

Step 18. The thermal heads are connected to the thermostats.

Connection diagram

Video - Installation of fittings

Connections

Connecting elements or fittings for corrugated stainless pipes are used when it is necessary to make a turn, but it is undesirable to bend the pipeline.

In addition, using such an element you can:

- connect two different pieces of pipeline of the same diameter (coupling);

- make a transition from a pipeline of one diameter to another (reduction);

- make a branch (a tee is used for this).

We recommend fittings from this manufacturer

Brass fittings are used to connect corrugated stainless steel. These are reliable elements that can provide maximum sealing. Connections are available from many manufacturers.

The advantages of such connecting elements are:

- ease of installation;

- durability;

- reliability;

- resistance to mechanical stress, temperature changes, high pressure.

However, it should be noted that brass fittings also have one drawback: their cost is very high.

Installation features

Currently, when installing corrugated stainless steel, several types of fittings are used:

- with paranitic gaskets;

- with silicone seal;

- high temperature non-gasketed connections.

Let's look at the installation features of each type.

With gaskets

Fittings for stainless steel pipes with paronite gaskets are used equally in heating, water supply and gas supply systems.

The installation principle of such a connecting element is quite simple:

- a piece of pipe is cut off;

- the edge is flared using a manual roller;

- the fitting nut is unscrewed and put on the pipe;

- a paranitic gasket is installed;

- The nut is tightened using regular wrenches.

This connection will be completed quite quickly. At the same time, it is sealed and reliable. The advantage of the fittings is that at any time you can unscrew it and change the worn gasket.

The fitting with a silicone gasket is installed in the same way.