One of the most controversial operations is replacing a cast iron sewer riser with a plastic one. Many users believe that the strength and reliability of cast iron pipelines is much higher than that of plastic ones. This is true, but only partly.

Old-style pipes have several very serious disadvantages. Modern elements of the sewer system are noticeably superior in quality and ease of installation. However, many homeowners do not see the point in replacing familiar and still quite strong pipes with thin and seemingly unreliable plastic. Let's look at the features and procedure for replacing the riser.

Advantages and disadvantages of cast iron pipes

In Soviet times, there was no alternative to cast iron pipes. For a long time, no one simply worked on developing alternative types of sewage systems. The main reason for this was the advantages of cast iron sewerage:

- strength, resistance to temperature and mechanical loads;

- durability;

- reliability, ability to work with aggressive or abrasive liquids;

- low noise level.

However, cast iron systems have a number of disadvantages:

- complexity of installation. Each connection must be separately sealed and sealed;

- the heavy weight of the pipes creates a load on the supporting structures. In addition, strong and reliable fasteners are required;

- cast iron is brittle. It does not tolerate sharp impacts or deforming loads. If a crack or chip appears in the bell, it is impossible to get rid of them. Various temporary measures are used, but it is impossible to completely restore the condition of the defective area;

- metal is prone to corrosion;

- the surface of the castings is rough. This promotes the adhesion of organic particles and fat. Over time, the layers increase, change the cross-section of the pipe, and form blockages.

The widespread replacement of cast iron sewers is caused by these shortcomings. Sometimes pipes that are still fully functional are replaced in order to obtain compatible, easy-to-repair parts of the system.

Characteristics of cast iron sewerage

Cast iron sewerage is a system of pipes made of cast iron. This can be either an external or internal network. Sometimes cast iron pipes may form only part of the system, for example, a riser.

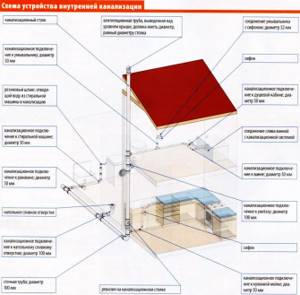

Internal sewage system diagram

Pipes are made of gray cast iron using centrifugal casting. To protect against corrosion, they are often coated on both sides with bitumen.

GOST 6942-80. Cast iron sewer pipes and shaped sections for them. Downloadable file (click the link to open the PDF in a new window).

GOST 6942-80

Cast iron sewer pipes

Prices for cast iron sewer pipes

cast iron sewer pipes

Features of plastic system elements

It is believed that replacing cast iron sewer pipes with plastic ones makes it possible to obtain a more stable sewer system. In general, this opinion is correct. Positive qualities of plastic pipelines:

- light weight, no load on supporting structures;

- smooth surface, less risk of fat deposits;

- simplicity, high speed of installation;

- durability;

- corrosion resistance;

- availability of a complete set of additional elements;

- the ability to change pipes with your own hands;

- attractive appearance.

Disadvantages of plastic elements:

- high noise level;

- relatively low strength;

- high coefficient of thermal expansion of the material.

The presence of shortcomings does not frighten users. Replacing cast iron sewers with plastic ones is becoming the norm. Only in some houses there are still old pipes that have not yet been finished.

Plastic elements are superior to alternative types in all respects. They are cheap and allow you to get any system configuration. Users consider the main advantage to be the speed of assembly and the availability of any components.

Connection types

In addition to the fact that there are differences in the type of pipe connection, they also differ in diameter. For use in residential buildings, 3 standard sizes are usually used:

- Diameter 150 mm, wall thickness 5 mm. These are used if they are subject to high loads.

- Cast iron pipe 100 mm, wall thickness 4 mm. These are usually used to make risers that come from the toilet.

- Diameter 50 mm, wall thickness 4 mm. They are usually installed to drain wastewater from sinks and washbasins, as well as other sources.

When selecting pipes, it is extremely important to take into account both the standard size and the method of connection. Check the quality of the product. Be sure to pay attention to the following points:

- There should be no holes, holes or other defects on the internal and external surfaces.

- Look at the cross-section of the pipeline; you can see from it what the grain size of the material is. It should be uniform and fine.

- The wall thickness should be even - this is one of the most important indicators by which you can determine a quality pipe.

Which pipes are better?

The quality and advantages of PVC elements have made them the undisputed leaders among all possible types of sewage systems. Not a single owner of an apartment or private house misses the opportunity to replace a cast-iron sewer riser with a plastic one. However, metal pipelines are still used in industrial sewer systems. They are resistant to chemical compounds and do not react as strongly to temperature changes. In addition, in industrial site conditions, the mechanical strength of the system is important. Therefore, it is better to choose plastic elements for installation in a home sewer system, while metal structures are suitable for work in an enterprise or main line.

You may also like:

How to disassemble a cast iron sewer - dismantling procedure

Sewage meter: what is it, principle of operation, types

Video review:

Is it necessary to replace the cast iron riser with a plastic one, let's decide. Cast iron sewerage was installed everywhere in the last century, and it had many advantages. The sewer riser minimized noise during operation of the sewer system, and its service life was tens of years. These risers are found in many apartments to this day.

Indeed, if a cast iron pipe is not destroyed by corrosion and passes wastewater well, then there is no point in replacing it. But if the service life of such a riser has already been completely exhausted, as evidenced by its leaks and the appearance of unpleasant odors in the bathroom, then replacing the cast iron riser with a plastic one would be a good solution.

It is worth noting that now when installing sewerage systems, preference is given to plastic. This material is lightweight and sufficiently durable, but its most important advantage is its anti-corrosion. The plastic sewer riser does not become overgrown with deposits from the inside and does not rust over time. The only drawback is its weak soundproofing properties, that is, the use of sewerage is accompanied by noise.

Installing plastic sewer pipes or replacing a cast iron riser with a plastic one is not particularly difficult, and no special equipment is required. The light weight of the pipes and fittings and their simple joining make all the work quick, which is why residents increasingly prefer to carry out such work themselves.

Procedure for replacement

Let's look at how to replace a cast iron sewer with a plastic one. The main difficulty of the procedure is replacing the riser. Most often it is necessary to replace the vertical part of the system in one apartment. This is a rather complex and responsible procedure. It is necessary to carefully remove a section of the old riser, and then insert a vinyl fragment in its place. At the same time, it is important not to collapse the upper part of the old assembly, otherwise you will have to restore everything at your own expense.

If it is necessary to completely replace cast iron sewer pipes with plastic ones, remove all old parts of the system. Work begins from the top floor, gradually going down. This option is considered the simplest. Sequential dismantling is carried out, after which the assembly of system elements begins from below. The main labor costs come from disassembly, since the old elements were connected very reliably. Connecting PVC nodes is not difficult and is done very quickly. First, the riser is installed, and a tee is attached at the required height to drain the horizontal line. Assembly begins from the riser and continues until the very last plumbing fixture.

Sometimes the riser is not touched. All you need to do is replace the cast iron sewer tee with a plastic one. This is done in cases where the vertical part is still relatively new and can stand for a long time. Then only the tee (or crosspiece, if the system configuration is complex) is changed. To connect dissimilar elements, special rubber adapters are used.

All sizes are available for sale. Finding an adapter is not difficult, you just need to know the diameter of the metal pipeline.

Installation of the riser

We strengthen the tee in the cuff, insert a pipe of the required size into the tee. Whenever replacing sewer pipes, it must also be secured. Replacing the riser is no exception. The riser is mounted on the wall using special clamps. The upper clamp is fixed a short distance below the socket, the lower clamp is fixed near the shaped compartment of the compensator pipe.

When the pipe is completely secured, you need to assemble the entire riser, while monitoring the reliability of the sealing connections. The clamp located on top of the riser must be fixed before final assembly, and then check how tight the system is.

Remember that the operating features and design of sewer risers do not imply the replacement of individual parts of the system. If there is a need to repair an old riser, it will be much better to replace it completely than to return to a new repair of the next section after some time.

With your own hands

Let's look at how to replace a cast iron sewer with a plastic one with your own hands. The most difficult option is to dismantle part of the riser in an apartment building. A support structure will need to be installed. On which the upper part of the riser will be suspended after removing the defective fragment.

Procedure:

- using a grinder and a cutting disc, make two cuts in the metal pipeline at a distance of 10-15 cm from each other;

- A wedge or chisel is inserted into one of them. By hitting them with a hammer, they break out a section of the riser;

- a supporting structure is placed under the upper part. It can be an ordinary board, but it is better to make a clamp and hang the riser on the wall. This is an important point, since cast iron pipes are self-supporting and may not be fixed anywhere. If they are not supported with something, the entire riser may collapse;

- the lower part is dismantled, a tee is installed, and the remaining sections of the riser are assembled. It is recommended to insert a section with an audit in order to be able to clean the system from your apartment;

- After connecting the new section with the old one, begin assembling the horizontal section.

Before replacing a cast iron sewer with a plastic one, you need to notify your neighbors about the upcoming work. Otherwise, sewage from the apartments on the upper floors will flow into the toilet. Organizing such events is one of the most difficult aspects. Not everyone can be found at home, so you need to post a notice in the entrance in advance. It is necessary to soberly assess your capabilities. The riser belongs to the common property of the house. If difficulties arise during the work, restoration will be done at the expense of the person causing the problems.

How to switch from cast iron to plastic

On the Internet you can find several methods describing the connection of plastic pipes with cast iron, but they are, at a minimum, irrelevant and, at a maximum, unacceptable for high-quality joining. It is best to switch from a cast iron pipeline to PVC using a reducing adapter and a rubber cuff. In addition, rubber reduction can be used for such purposes, but first things first.

Required tools and materials:

- Hammer;

- Chisel, hammer;

- Strong knife;

- Small "grinder";

- 3-4 cutting discs with a diameter of 125 mm and 1 grinding disc;

- An old chisel, several screwdrivers of different widths, lengths and sharpness;

- Safety glasses, respirator, hat;

- Steel wedge for breaking cast iron pipe parts;

- two adjustable wrenches;

- a large nail puller or a small crowbar to use as a lever.

- Pipe cutter for cast iron pipes. Using such a pipe cutter will significantly speed up and simplify the process of dismantling the sewer, but such a pipe cutter is expensive and is rarely used on the farm.

- An old iron bucket half filled with cold water;

First, you need to determine how the cast iron parts were connected, first of all, the tee (1) or cross (2,3) with the socket (fitting part) of the pipe located in the lower ceiling. To do this, carefully clean the joint, usually it is located above the floor level. But if you have previously made an additional screed or laid tiles on the floor, the connection may be below the level of the existing floor, in which case you may need a hammer drill or chisel. You should work with both the hammer drill and the chisel very carefully so as not to damage the socket of the pipe remaining in the ceiling.

The joining could be done by caulking the seams with ordinary cement-sand mortar, cement mortar, polymer cement mortar, and - the worst option - filling the joint with sulfur. Using an old chisel or a sharp screwdriver, pick out the top layer of the seam between the tee (cross) and the shaped part of the pipe located in the lower ceiling to get to the sealant. If it feels hard to the touch and the chisel slides across the surface with an unpleasant squeak, reminiscent of the sound when you drag a knife across glass, then it is very possible that you have come across sulfur. To be sure, try to pick out a sample and try to set it on fire. If the picked sample ignites, burns with a blue flame and at the same time a caustic gas is released, then you are out of luck - it is sulfur. Then you will need