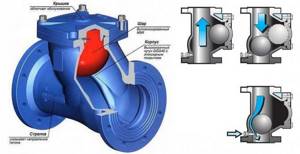

A check valve is a type of pipeline fitting, the purpose of which is to prevent a change in the direction of fluid movement in the pipeline. The device automatically allows flow in one direction and stops flowing in the opposite direction. Refers to direct-acting protective pipeline fittings.

Before purchasing a 110 or 50 mm sewer check valve, it is important to understand the features of different types of locking mechanisms and their operating principles. It is also recommended to find out all the information about the existing sewer system.

Installation is quite simple; additional equipment is usually not required. It is important to purchase the device from trusted sales outlets, and also make sure that there is a warranty from the manufacturer.

Why and who needs it?

The purpose of a sewer check valve is to block the flow of liquid in the opposite direction. In this regard, the main area of application emerges - apartments on the lower floors in high-rise buildings, especially in old buildings.

In multi-storey buildings, owners of apartments on the first floors very often have problems with toilets, from which the contents of the sewer flow out. The blockage usually occurs somewhere in the “beds” - horizontal pipes in the basement. Then all the contents rise through the pipe to the first branch and pour out through the first accessible point - the toilet, spilling onto the floor, sometimes even bathtubs and washbasins are filled. To solve this problem, you need to install a check valve on the sewer. It will cut off the reverse flow going into your apartment. True, a problem will arise for those who live on the floor above - fecal water can even rise up there. Then they will also have to install a sewer return valve. The drain column usually does not rise above this level - it pushes through the plug and everything goes away.

However, residents of high floors should not rejoice - they too may suffer. Sometimes blockages occur somewhere between floors. This happens mainly due to violations of the sewerage operating rules - someone flushes objects that should not be there, they get stuck, and a traffic jam forms. In this case, toilets on any floor may overflow, depending on where the blockage occurred. So, on any floor except the last one, it makes sense to install a check valve - “just in case.”

Example of installation in a private house

The third group of consumers are owners of private houses. In principle, the sewer system of a private house should be designed in such a way that the reverse flow of wastewater is impossible. Even if this is the case, many prefer to play it safe than to later remove foul-smelling “treasures” from the house. A check valve for a sewer in a private house also performs another function - it prevents rodents and other living creatures from entering through the sewer pipe.

Ventilation in the bathroom and toilet is described here.

Why is the device needed?

A sewer check valve is a device that is designed specifically to prevent leaks and backflow of water due to clogged sewer lines. Sometimes even a package that accidentally gets into the pipeline leads to blockages and flooding of the apartment.

To protect the room from the reverse movement of sewer system waste, a special valve is installed that operates automatically. A similar mechanism is used not only in offices, cottages, residential buildings and industrial premises, but also in heating and water supply systems (for the pump).

Their operating principle is quite simple: if the waste liquid begins to move in the opposite direction, the locking mechanism stops this movement, as a result of which flooding does not occur.

In most cases, the need to install the device arises in the following situations:

- regular entry of debris and large objects into the sewer system, as well as other violations of operating rules;

- a long period of use of the pipeline, during which a layer of grease with dirt particles has formed on the inner surface. This significantly increases the likelihood of clogging;

- the slope of the sewer pipeline is too large or small, because to ensure free gravity flow of liquid, it is important that a certain speed of movement of the wastewater be maintained;

- bends located at a perpendicular angle to the sewer pipe. As a result, the speed of water movement changes sharply and a water blockage may occur.

If in a multi-storey building with a single riser, residents of first-floor apartments installed a check valve for the sewer system at 50 or 110 millimeters, then flooding with drainage can occur even on the 2nd floor. The liquid will not get further up, because... pressure will most likely cause the blockage to clear.

In country houses, similar locking mechanisms are also often installed. However, then it is recommended to install them on the street, after collecting all the branches of the sewer pipes into a single one.

Types of check valves and their operating principle

The main purpose of a check valve is to block flow in the opposite direction. To do this, a movable barrier is installed in these mechanical devices. The basic principle of operation is that in a quiet state, the mechanical damper is lowered down, blocking the lumen of the sewer pipe and preventing reverse flow from passing through. When drains appear, it rises (moves to the side), the drains go away, and it closes again. This equipment differs by the type of this barrier and the principle of its operation.

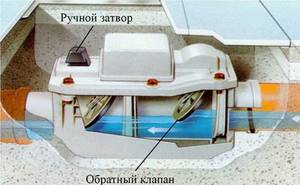

Rotary (petal)

This type of sewer valve has a spring-loaded round membrane (plate). If the flow moves in the “right” direction, it turns, rising upward does not interfere with the drainage. If the movement begins in the other direction, the membrane (plate) is pressed against the rim inside the valve, tightly and hermetically blocking the lumen of the pipe. Some models have a manual shutter. This is the second membrane, which can be controlled using a button mounted on the body.

Due to the shape of the membrane, such shut-off valves are also called petal valves, and sometimes you can hear the term “flaps” - this is because of the way they work - the membrane slams shut if there is no drain.

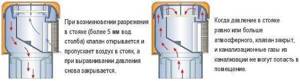

The figure shows how a sewer check valve works

The device itself is larger than the pipe on which it is installed. So in the pipeline there is first an expansion and then a narrowing of the lumen, and these are potential places for blockages to form. To make it possible to quickly remove blockages, a removable cover is made in the upper part of the check valve body. By removing it, the problem can be quickly resolved.

Lifting check valve for sewerage

This type of shut-off device for a sewer pipe is so named because when the sewage flows in the “correct” direction, the shut-off element rises up. The drains put pressure on the plate blocking the passage, compressing the spring and it rises. There are no drains - the spring unclenches, the passage is locked. When wastewater enters from the “wrong” side, there is no way to open the passage. This is achieved by the nonlinear shape of the body.

Sewage lift valve design diagram

A lift check valve is more reliable, but is designed to clog frequently and requires periodic cleaning. Why do you need to remove the cover (unscrew the four bolts), clean or replace the mechanism.

Ball check valve

Another option for a locking device in a check valve is a ball. In these devices, the internal structure of the case plays an important role. Its upper part is designed so that when the drains pass, the ball rolls into a special recess in the body, opening the passage.

Structure of a ball check valve for sewerage

When the pipe is dry, it blocks the cross-section; when the flow passes in the opposite direction, it blocks the lumen of the pipe. The main disadvantage of this design is the leakage of drains during flooding - the ball and the side wall of the housing do not always fit perfectly, which leads to the fact that some of the drains still leak out. But there will definitely not be mass flooding and a geyser from the toilet.

Why you need an air valve in the sewer system and how to install it, read here.

Wafer

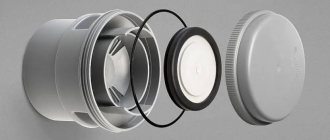

Many people like this type of check valves more because of their miniature size. This is a very small cylinder with a rotary valve installed inside. It may consist of two parts, which are attached to the central rod, or it may look like a small plate, in one place attached to the wall of the housing using a spring.

Wafer check valve

Despite its compactness, it is better not to install this type of check valve on a sewer: this is plumbing equipment and it will not work well on a sewer. The second disadvantage is the impossibility of quick cleaning - the design is such that you can only get to the valve by disassembling the connection.

What it is

An air valve or aerator is a device designed to maintain a certain pressure in the sewer and remove unpleasant odors, generated gases, etc. from it. Many homeowners use a ventilation outlet for such purposes, but it does not solve the problem of pressure drops, due to which may disrupt the operation of the entire drainage system.

Remote control valve

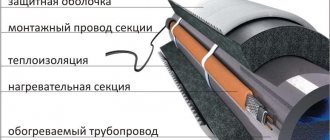

The air valve is an example of a classic non-return diaphragm device. Thanks to the presence of a flexible partition, it prevents sewer odors from penetrating into the room or outdoor environment.

Principle of operation

According to application, there are the following types of valves:

- Membrane;

- Cylindrical;

- Lever.

Membrane ones are made from PVC. Most often, they are installed at the entrance of a waste pipe, which is connected to the sewer system as ventilation. When pressure changes, the membrane changes its position. Due to this, gases cannot leak through the valve back into the sewer. It should be noted that such an aerator will only work if there is oxygen access to the drain pipe.

Air valve design for sewerage

Cylindrical ones are made of steel or its alloys. They are a design that visually resembles a shut-off valve. They consist of a metal body with a thread and a cover of standard diameter. Often this is 110 mm, but there are also more exotic models. The lid is installed on the base; when direct pressure is applied, it opens, allowing water, waste, etc., to pass through, after which it returns to its original position. Due to the fact that it opens inward, the likelihood of a “return” of waste is extremely low. This is the optimal solution for ensuring sewerage protection in a private home.

Video: using a non-return air valve for sewerage

The lever version is often used in unventilated sewers. It consists of a metal body and a movable lever. The device is configured manually. The drains move in the direction preset by the arrow. This is convenient for urgent repairs.

In addition, vacuum and automatic valves are now produced. They differ in the ability to customize the workflow. The vacuum works without presets - it opens the way for wastewater in one specific direction. Automatic can change it depending on needs.

Vacuum valve

According to the type of locking mechanism, valves are:

- Rotary locking mechanisms are similar in design to pneumatic locking mechanisms. In them, the control valve is a spool and a lever. Attached to pipes by tapping. Under the influence of the drainage, the spool rotates, due to which the water flows down the riser. Such a system is considered very reliable and durable;

- Ball is used exclusively on small diameter pipes. For example, washbasins or showers. Here the locking mechanism is represented by a metal ball of a certain size. To ensure that wastewater does not return. The ball is connected to a spring that controls its operation;

- Wafer is characterized by its small size and convenient installation method. They are installed on the pipe using a thread, so they can be used on both metal and plastic bends. For the latter, you need to use a compression fitting. The locking mechanism in this design is a flexible membrane, which changes its position depending on the pressure of wastewater. There are two-sided and one-sided;

- Lifting ones are ideal for vertical wide risers. Their operating principle is to change the position of a vertical PVC membrane. The drains act on it from below, raising the constipation. After this, water return is impossible due to the presence of vertical fastenings.

What are they made of and what sizes do they come in?

The most common sewer check valves are made of plastic (PVC) and cast iron. If your sewer pipes are plastic, it makes sense to install the same valve, choosing it according to size. The situation is exactly the same with cast iron. The point is not that the materials are not suitable, but the need for additional adapters, which make the design even more cumbersome.

According to the installation method, the shut-off valve for the sewer can be horizontal or vertical. Select the type depending on the installation location. It must be installed with the same diameter as the pipe; narrowing is not allowed. Accordingly, there are valves for each size. The parameters of some are shown in the table.

| Name/manufacturer | Diameter | Body/damper material | Application area | Price | Notes |

| VIEGA / Germany With two valves | 110 mm | polypropylene/polypropylene | External sewerage | 150$ | Two dampers, the second with manual locking |

| CAPRICORN / Poland For internal sewerage | 50 mm | polypropylene/polypropylene | Internal sewerage | 25$ | Single valve |

| Mc Alpine / Scotland Simple design | 32,40,50,90,110 mm | plastic | Internal wiring | 11-21$ | Has small dimensions |

| Capricorn / Poland With stainless steel valve | 110 mm, 160 mm | ABS/stainless steel | Universal | 53-84$ | Emergency manual closing mode |

| Ostendorf / Germany German sewer check valve | 50 mm / 110 mm | PVC/PVC | Universal | 13-24$ | Emergency manual locking |

| Polytron / Russia Russian sewer shut-off valve | 110 mm | Polypropylene | Outdoor installation | 14$ | Emergency manual locking |

| Politek / Russia Manufacturer Politek | 110 mm | Polypropylene | Outdoor installation | 23$ | Emergency manual locking |

Work progress

If you plan to install a check valve in a residential high-rise building, you must:

- 24 hours before the start of installation, notify all residents about the upcoming work;

- perform a shutdown using valves installed in the inlet section of the cold and hot water supply to prevent unauthorized entry of water into the sewerage system circuit;

- notify all neighbors immediately about the very beginning of work to replace the device;

- After completing installation of the product, turn on the water in the entrance.

The work itself on installing a device with a threaded connection type is carried out in the following sequence:

- choose a location for installing the device and cut out a part of the pipe there that is equal in size to the length of the valve;

- cut threads at the ends of the pipes;

- clean the remaining chips;

- take a strand of flax fiber of such length as to ensure the number of windings is 1.5 - 2 times greater than the number of thread turns and lay it clockwise, wrapping the entire length of the threaded section;

- apply a layer of sealant over the wound flax;

- Screw on the valve and tighten the fastening using a wrench or torque wrench.

A useful video on the process of installing a locking device in a bathroom can be viewed in the video:

When and where to put

As already mentioned, a sewer check valve is a rather cumbersome device. In apartments, bathrooms are usually small, it’s difficult to find a place, but you have to - if you don’t want to have a geyser instead of a toilet.

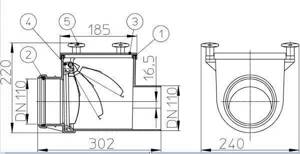

The exact dimensions of sewer valves depend on the diameter of the pipe on which the device is installed. For example, for a 100-diameter sewer pipe, the minimum length is 40 cm, height and width are slightly less. Such a box must be installed in front of the entrance to the riser.

Non-return valve for sewer installed

In this case, you often have to break the floor, already laid tiles - you need to align the holes in the body with the pipes, center everything, and monitor the required angle of inclination. This prospect is especially pleasing if renovations have recently been made. In this case, there is also an option - to embed a check valve into the riser above your entrance. But such work involves interference with the general building system (installation of plumbing fixtures on your branch does not fall into this category), and they require written permission, you will have to notify residents, shut off the water, and representatives of the operating organization or water utility will work. In general, it’s still a hassle, which is why this method of solving the problem is used very rarely.

If there is no place for a common device, install sewer check valves on each plumbing fixture - separately on the toilet, bathtub, washbasin, sink, etc. This is if pipes from each of the devices go to the riser separately. If you have only two directions - to the toilet, and then to the bathtub-washbasin-sink, etc., then it will cost you to install two devices - one personal one on the toilet (the diameter coincides with the diameter of the outlet pipe) and the second - a common one, on a branch that goes to all other devices. Its size must match the diameter of the distribution pipe, and most often it is 50 mm.

See how to install a toilet with your own hands here.

General information

Important! Buy the device from a reputable place of sale and be sure to ensure that there is a warranty.

A sewer check valve is a shut-off mechanism that prevents the reverse movement of water due to blockage and prevents leaks. Even a package accidentally falling into the pipeline can lead to clogged sewers and flooding of housing.

A sewer check valve is installed in private houses, offices, apartments, as well as in water supply and heating systems (for a pump).

The mechanism itself is a cylinder with a small spring inside and a round overlapping plate. The check valve is initially closed using a spring.

The spring becomes weaker with water pressure, and the valve opens, allowing water to pass through. If a leak occurs, the pump or something else stops, and the power of the water flow decreases, the shut-off plate closes. A check valve prevents unpressurized water from flowing back.

Installation rules

The main thing to consider is the direction of movement of the wastewater. It is indicated on the body by a large arrow. The device must be rotated so that the normal direction of the drains coincides with the arrow. Further installation features are as follows:

- Installation of a plastic check valve on a sewer is carried out in a standard way for this type of pipe: there is a socket and a rubber seal. The straight edge of the pipe is inserted into this socket. Such a connection is already airtight, but for greater reliability, the joint can be additionally coated with plumbing silicone.

- Installation of cast iron models - using sealing rubber bands and bolts that tighten the mounting plates, there are models with sockets - for traditional installation on tow and filling the seam with sealant.

- It must be installed so that there is free access to the lid - periodically the check valve on the sewer becomes clogged, so it needs to be cleaned.

It will be necessary to provide access to the lid - install a removable grille

Correct and incorrect placement

Each device, open or closed, has the direction of movement of the drains drawn on the body.

Indicated by an arrow or triangle. It is in the direction of the water that the water seal is installed. The shutter only works in one direction and in different positions: whether the device is vertical or horizontal. If all installation conditions are met, in the first minutes it will be clear that the device is functioning and water is passing through the membrane.

The correct position of the device is also determined by the installation method. From the socket to the empty end (that is, into the socket), only the empty end of the pipeline can be inserted. On the other side there is only a connecting extension of the pipe with a rubber seal.

Incorrect placement can lead to permanent problems with the device. A device installed incorrectly or in the wrong place will immediately show its failure. Any work begins with reading the instructions, installation of the codpiece is no exception.

Difficulties that may arise if installed incorrectly:

- Hard to reach place. The device requires constant monitoring after installation, therefore, if the shut-off valves are located in a corner or under a layer of concrete in another inaccessible place, it is not possible to maintain it.

- The device was installed in violation of the technological process. Leaky joints, constantly leaking lids - seals are an unpleasant sight. If the rubber bands in the socket are not lubricated with oil during installation, they will ride up or fall inward. Even when all the joints are attached to each other tightly and tightly, they can leak due to the rotation of the O-rings.

- The throttle cannot be installed immediately after the rotating part of the system. During movement, the drains gain decent speed, which means they create pressure. The pipe became clogged or could not cope with the backflow, and the valve closed. The problem was not immediately detected and water continued to flow from the plumbing fixture. The flow of water approaching the membrane will receive resistance and can knock the outlet out of the connecting joint. Therefore, the device is installed strictly on a straight section.

- The valve installation direction is incorrect. Any device has a water movement indicator; installation must be carried out according to this figure. If the device is turned over or placed with the lid down for inspection, the unit will stop working.

Problems you face

A typical situation for an apartment building: different pressure in each of the risers. In a pipe with cold water, the pressure may be higher than in a pipe with hot water and vice versa. The pressure can easily increase at any time, but more often than not it drops unexpectedly due to a leak or even a pipeline break. The effect of the difference in flow pressure is often noticeable when two taps are opened in one apartment at once. For example, the faucet in the kitchen is open, hot water flows from it, and at the same time cold water begins to flow from the sanitary shower head. One stream replaced another.

In many houses with centralized water supply, hot water is turned off for at least two weeks in the summer. During this time, in apartments where heating devices are installed, the liquid supply valve from the central system is closed, and hot water from the boiler is released through the same pipes. Sometimes residents forget to turn off the valve on the water heater, including the water supply from the central riser. Cold liquid with high pressure blocks the flow of warm liquid, squeezing it out. As a result, only cold water is supplied from all taps. Then it goes to the central riser, in a few minutes all residents will be washed with cold water.

The second option is more common and can happen in any apartment. When using a shower mixer, a situation similar to the one described above occurs. If the pressure in the hot water riser is higher than in the cold pipe, you will get boiling water in both taps. In this case, the meter will spin very quickly, counting cubic meters even if water is not used. There will be hot liquid not only in the riser, but also in all apartments below and above.

There is one more reason that completely excludes the influence of the human factor. This situation occurs as a result of failure of the valve on the mixer. Inexpensive Chinese taps fall into disrepair every one and a half to two years. They are affected by water quality: chlorine, rust and other impurities. As soon as the shut-off lever breaks, water will rush into the adjacent pipe and the liquid will be displaced. A single-handle faucet in the kitchen can have the same effect. When the mixer handle is lowered, it opens both valves; if the pressure of hot or cold water is higher, one liquid displaces the other, spreading throughout the system.

In all the described cases, at the end of the month you will receive a very decent bill for the cubic meters of water pumped up by the reverse flow. Another trouble awaits children: injuries are possible as a result of supplying a hot stream to a cold tap. In addition, things can be damaged; instead of cold water, liquid at a temperature of up to 80 degrees is supplied to the washing machine through a hose.