Knowing the principle of operation of a turbo deflector, it is quite possible to make such a device with your own hands, spending one working day on assembly and installation. The simplest design and light weight make it possible to install the device on almost any chimney with an annular cross-section. The design of the turbo deflector looks quite attractive, so owners often install it on the chimney even for aesthetic reasons, instead of the old mushroom visor.

What is a turbo deflector

A very nice device, reminiscent in shape and size of a medieval oriental headdress - a turban. Essentially, this is a nozzle on the upper section of the ventilation pipe:

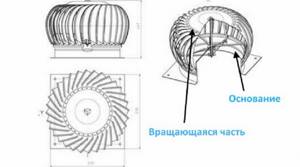

- The housing of the ventilation turbo deflector is a set of spiral strips of metal, assembled and fixed on a flat steel “top” - a platform;

- The design allows the pumpkin-shaped body to rotate at low speed around a vertical axis.

The rotation speed of the shiny body is low, only 3-5 rps, so a correctly installed turbo deflector in a slight breeze does not create any discomfort, does not make noise or squeaks.

For your information! According to owner reviews, installing a turbo deflector on the chimney is the best way to scare away annoying birds from a warm chimney.

In this capacity he has no equal. The moving shiny surface of the turbo deflector blades turns out to be much more effective than conventional weather vanes and stationary mushrooms above the ventilation pipe.

Causes of deterioration in traction

First you need to determine the cause of the deterioration in traction. Therefore, first of all, the general condition of the chimney and all associated elements of the system is checked.

This is done very easily. First, the entire heating system is completely turned off, after which the amount of soot in the chimney is measured using a long probe. This value should not exceed 2 mm.

The reasons for insufficient draft in the chimney are conventionally divided into 2 groups: external factors and design features.

Among the design features:

- the use of tees, elbows along the smoke exhaust duct, bypassing obstacles that create aerodynamic resistance;

- incorrect installation and adjustment of the damper;

- incorrect height and diameter of the chimney, which does not meet the requirements of the manufacturers of heating or water heating boilers.

External factors mean:

- placement of the draft outlet below the roof ridge, which under certain conditions can lead to a draft “overturning”;

- the presence of large objects near the chimney, forming an area of high pressure or, conversely, vacuum;

- the predominance of strong winds in the region or, on the contrary, calm,

All this can have a significant impact on the traction force and create additional resistance, thereby reducing its level. To avoid this, it is imperative that you take certain steps to increase or stabilize the draft so that your furnace or boiler operates more efficiently.

What is a turbo deflector used for?

The first thing that comes to mind upon a superficial acquaintance with the device is the question of why it was necessary to make such a complex design for the nozzle on the chimney. After all, with proper planning of the chimney or ventilation, its performance should be abundant.

A turbo deflector is a device that can increase thrust in a pipe without using any additional energy sources. The unusual design of the nozzle does not have an electric motor, as in conventional supply and exhaust ventilation systems.

It is clear that a mechanical turbo deflector is inferior in air performance to systems based on electric fans, but more often the nozzles are on a pipe and are not designed to compete with powerful electric motors.

The nozzle is used for ventilation ducts or chimneys:

- In technical buildings with high levels of gas pollution or high humidity. You can install a ventilation pipe with a turbo deflector, and this will help get rid of basement dampness;

- In rooms and living spaces that remain closed most of the time, without constant heating. This usually reduces the efficiency of stationary supply and exhaust ventilation, so for such buildings they traditionally install low galvanized exhaust ducts with a nozzle;

- Buildings or private houses, sandwiched by neighboring buildings, with high terrain or plantings of trees, changing the profile and direction of wind flows above the roof.

The turbo deflector attachment for the pipe turned out to be very useful for a summer house or country house where there is no electricity, the room is heated once a week during the next visit on the weekend.

For your information! The characteristics of the turbo deflector are selected in such a way as to create additional draft to the existing vacuum in the main chimney pipe, nothing more. This device cannot replace a standard ventilation duct with a pipe.

Selection rules

You can select the optimal deflector based on the goals and tasks assigned to it. It is also worth considering the conditions in which it will operate.

A simple chimney is a cap on a wood-burning chimney, made in the form of a regular umbrella, and has the following advantages:

- maintains the necessary traction both in calm conditions and in the movement of air masses with a power of up to 10 points;

- does not create excessive pressure on the pipe, due to which even in a severe storm the chimney remains in its place; rather, the umbrella itself can break off and fly away;

- has a simple and understandable design;

- practically does not coke or clog, and is quite easy to clean;

- due to the imperfection of the aerodynamic structure, it is insensitive to the shape of the umbrella; if the building is located in the wind, then the chimney can be made in the form of a tent, this greatly simplifies its use and opens up great opportunities for the implementation of design ideas.

At the same time, there are serious disadvantages, such as:

- in weak winds it reduces draft, and the stronger the heating element works, the weaker it is. This is quite dangerous, since in cold winter weather, in the absence of wind, the stove can “choke” and breathe fumes into the living quarters;

- in strong winds, on the contrary, it creates too much draft. This significantly reduces the efficiency of indoor stoves and fireplaces;

- in gusty winds it can cause blowing into the pipe and creating a reverse draft effect.

The aerodynamic open model maintains sufficient draft in any wind for efficient operation of stoves and boilers using liquid fuel and gas. Such deflectors can freeze, they easily become littered and quickly become covered with soot and soot, however, they are easy to clean.

The disadvantages include the following:

- complex body of rotation;

- as a result of the load created by air masses, the umbrella itself can easily fly off the chimney, and at the same time, the direct mechanism of the device can collapse the pipe itself;

- with strong gusts of wind from force 8, the lateral pressure on the structure increases significantly and further increases in accordance with the power law;

- open structures are quite poor at reducing strong dynamic loads resulting from gusts of wind, which is why in no case should such a model be placed on pipes made of brick;

- the modification cannot be used for pyrolysis heat-generating mechanisms, otherwise, when wind occurs, all pyrolysis gases will be sucked out and the stove or boiler will simply go out;

- not suitable for creating design elements, since it is unsuitable for decoration; all kinds of blotches and figures only worsen the overall aerodynamic status of the structure as a whole.

By the way, an interesting study was conducted in the USA. There, at one time, they studied issues related to open deflectors and installed them on locomotives to check the degree of increase in efficiency at low speed. At the same time, the result was the most depressing - at mid-speed, fire began to burst out of the pipe and not a single train was able to reach its maximum speed. In general, the open version of the deflector should be recommended for all types of heating devices, with the exception of pyrolysis ones. At the same time, it must be checked and cleaned at least once a quarter. It is optimal for a chimney with low draft force, it is most effective for wood-burning sauna stoves; not a single case of people burning out due to the ventilation deflector in saunas has been recorded.

The closed or as it is called “perfect” type has such advantages as:

- provides stable draft, which is sufficient for stoves and boilers of any type;

- not prone to freezing and clogging from the inside;

- Dust and ice formed on the outside do not significantly change the operation of the device.

There are also disadvantages, however, users claim that they are not so significant, namely:

- when exposed to strong winds, it gives maximum pressure on the pipe, and then increases linearly, so the chimney under the deflector should be further strengthened with guy wires;

- has rather complex design and technological parameters;

- cannot be used as a design element, since any additional elements significantly reduce the overall level of aerodynamics.

Models may differ in appearance, purpose and material. Most often, plastic, stainless steel or aluminum are used to produce deflectors. In rare cases, copper may become a raw material for production. Many users prefer the sandwich model.

Is a turbo deflector worth the money?

Often, in an effort to avoid unnecessary heat losses during the heating season, owners build ventilation in the house with a minimum performance margin. In winter there is still enough capacity, but in summer the flow of fresh air is vital for a comfortable stay. In this situation, installing a turbo deflector on the pipe turns out to be a cheaper and more practical solution than reworking the chimney pipe or ventilation shaft in the house.

Another problem that most gardeners and summer residents have to face is related to storing crops in homemade cellars. It is not easy to regulate the humidity inside an earthen storage facility using a ventilation pipe, so the situation can be significantly improved by installing a turbo deflector on the hood.

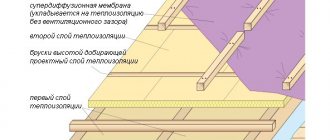

In a similar way, you can get rid of condensation and excess humidity in the attic, in the glazed balcony or in the garage. Initially, the idea of using a rotating turbine was aimed at increasing the productivity of moisture removal and drying the under-roof space. Years later, it turned out that such an important advantage as ventilation with a turbo deflector without electricity can solve a lot of problems, including in old buildings with clogged and crumbling air shafts.

Of course, the size and weight of the turbo deflector are limited by the large windage of the structure, therefore, despite the attractive idea, it is practically impossible to completely provide ventilation of the room without the use of pipes, only using a blade system, and the effectiveness of such a solution would be low and would completely depend on the wind force at street.

Principle of operation

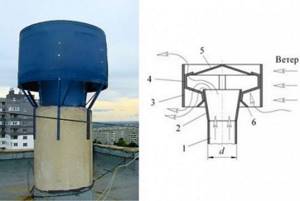

The ventilation deflector can deviate from any, even the smallest breath of wind. However, it is not just deflected, but also fixed in such a way as to create optimal conditions for the effective removal of combustion products through the equipped chimney

It is important that the wind does not interfere with this process. The mechanism of action of the deflector is that it is attached to a pipe, which removes smoke and fumes and at the same time creates an obstacle to the free movement of air flows

According to the laws of physics, the more intensely the volume of air moves in a flow with a changing cross-section, the greater the pressure drop, which leads to a decrease in pressure. The power of the wind flow acting on the chimney creates a certain vacuum near the head.

The flow of air masses, when faced with an obstacle, flows around it, and the air itself penetrates into the ventilation system through specially equipped openings at the top and bottom, while the air rarefaction increases and orients the direction of the air column upward. The ventilation deflector operates with optimal efficiency along a ventilation line with horizontal bends and spans. This is the condition under which the hot air draft increases by at least 10–20%. Of course, the wind, like other natural phenomena, behaves differently every time. Its influence varies: it can blow the chimney from top to bottom, in this case the small holes located at the bottom of the deflector will help, they will draw gases towards themselves. Gusts of wind can be directed from bottom to top, then the air will pass through the annular holes at the top of the device. Air masses can move in a horizontal plane, in this case both the upper and lower openings work.

To level out this drawback, many craftsmen mount another additional cone of the same size as the base one and connect both elements. Thus, the deflector umbrella is equipped with two differently directed cones. This allows the device to work with maximum efficiency in all weather conditions. If the chimney is not equipped with this device, grease and soot will gradually settle on the ventilation pipe, to which dust and debris will begin to stick over time. All this, over time, causes a decrease in the cross-section of the internal ventilation duct and further damage to the entire system as a whole.

Related Posts

- Ventilation deflector: installation features

- Backdraft in the chimney

- Coaxial chimney for gas boiler

- Why chimneys become contaminated with soot and how to get rid of it yourself

- The door handle creaks: causes of the problem and solutions

- How to update old tiles in the bathroom

- How to cut metal using a grinder

- Why does the air conditioner gurgle when not working when there is wind?

- Dimensions and installation of pipes for a bath

- How to glue fiberglass correctly?

- Chimney in the garage through the wall: stages of arrangement

- Restoring the handle of a plastic window

- Types of chimney pipe caps and do-it-yourself element installation

- What and how to drill into the tiles so that they don’t crack?

- Chimney through the wall: features, rules of calculation and installation. chimney device and its installation (125 photos)

- How to seal the joint between the bathtub and the wall? 8 popular options

- What sizes of sandwich pipes are best to use for a chimney?

- How to make a potbelly stove in the garage with your own hands

- Caring for matte and glossy stretch ceilings

- Stages of renovating a children's room

- How to properly install a hood for a geyser

- Dry Stream: photos and videos

- Mounting a mirror on the wall in various ways

- Options for making shelves for the garage with your own hands

- How to repair a plastic window with your own hands at home: advice from a professional technician

Read with this

- Ventilation deflector: installation features

- Backdraft in the chimney

- Coaxial chimney for gas boiler

- Why chimneys become contaminated with soot and how to get rid of it yourself

- The door handle creaks: causes of the problem and solutions

- How to update old tiles in the bathroom

- How to cut metal using a grinder

- Why does the air conditioner gurgle when not working when there is wind?

- Dimensions and installation of pipes for a bath

- How to glue fiberglass correctly?

Turbo deflector design

Therefore, the turbo deflector uses wind energy; a wind of 2 m/s is sufficient to increase draft in the ventilation system or chimney. The maximum air flow speed is usually limited to 20 m/s.

The design of the deflector nozzle for the pipe consists of three parts:

- The body is a turbine made of two dozen thin metal blades with a curved surface;

- Shaft with bearing support connected to the housing;

- Mounting ring installed on the ventilation pipe. In the center of the ring there is a support sleeve to hold the shaft in a vertical position.

Previously, the turbo deflector was sold with the expectation of installation on round galvanized pipes used in the installation of modern ventilation ducts. Today you can buy several options for adapters and mounting rings that ensure reliable retention of the device on an asbestos-cement pipe or brick edge of a ventilation shaft.

There can be no problems with traction

Ready to install rotary deflector

The purpose of any ventilation system is to remove polluted air and excess moisture from the premises, that is, to ensure normal air exchange. This will take place if the ventilation duct functions efficiently and correctly - the draft in it is excellent. If there are problems in this regard, they are often provoked by rain, snow, or wind masses entering the canal shaft. Also, poor draft can be caused by incorrect placement of the ventilation pipe, its insufficient height or incorrectly selected diameter of the air duct. The installation of a rotary deflector is designed to eliminate such shortcomings of natural ventilation.

How does an air turbine pipe attachment work?

The operating principle of the turbo deflector is based on the effect of asymmetric air flow around the dome-shaped body of the device. Regardless of the direction and strength of the wind, the air flow, moving perpendicular to the axis of rotation, flows around the left half at a lower speed than the right. When interacting with the open edges of the blades, the air flow is slowed down and at the same time imparts rotation to the body.

On the right half of the turbo deflector wheel, the blades face in the opposite direction, so the incoming air flow flows around the surface without resistance and loss of speed. As a result of the Bernoulli effect and centrifugal force, flue gases or polluted air are thrown out of the housing at a speed only 30% slower than the wind. True, the gases ejected from the turbo deflector are dispersed unevenly in the surrounding space.

Maintenance and troubleshooting

Almost the only malfunction of the device is the lack of rotation of the impeller.

There may be several reasons for this:

- Insufficient wind force or no wind at all. You need to make sure there is enough wind for the device to work properly.

- The bearings are jammed. In this case, check whether there are any mechanical obstacles to their rotation. If necessary, lubricate or replace the bearing.

- The deflector has frozen. You need to check the device or wait for the temperature to rise.

- Mechanical damage. It is necessary to check whether a foreign object has entered the device.

The turbo deflector used for ventilation is a fairly simple device and does not require frequent maintenance.

To extend the service life of the ventilation deflector, it is enough to lubricate the bearings once a year (after winter). For processing, litol is used, a waterproof lubricant based on recycled petroleum products.

To lubricate or replace a failed bearing, disconnect the cap, open the retaining ring with a special tool - a puller - and lubricate or replace the bearing.

Unlike pliers, a snap ring puller works by unclamping. Without it it will be difficult to remove the ring

You may also find useful information on how to properly clean the ventilation shaft, discussed in our other article.

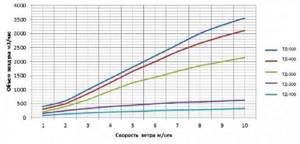

Turbo deflector performance

There are quite a large number of estimates of the efficiency and performance of a turbocharged deflector, from advertising statements about increasing pipe thrust by 4-6 times, to minimalist estimates of 20-30%.

In reality, the increase in thrust using a turbo deflector in ideal conditions and with average winds is 150-250%.

As can be seen from the graph, the theoretical performance of the device increases almost linearly with increasing wind speed over the pipe. In practice, such growth is only possible if it is possible to place the turbo deflector in the most favorable location on the roof.

Effective ways to increase chimney draft

Designing a chimney is complex and responsible, on the correct execution of which the efficiency and safety of using the heating device depends. No heat generator is capable of functioning normally without a pipe that removes smoke from the room. Smoke is a mixture of gases containing residual products of fuel combustion. The appearance of smoke inside a heated room is a sure sign of an incorrect design of the chimney system, which entails the risk of fire and carbon monoxide poisoning. This article will tell you what backdraft in a chimney is and how to prevent its occurrence.

How to calculate the performance of a turbo deflector

Typically, a turbo deflector is simply placed at the outlet of a vent or chimney without any additional flow analysis, and the base value is used to calculate the performance of the turbo deflector. This value is indicated by the manufacturer in the labeling of the turbomachine; for example, the most popular model TD 400, according to its passport, has a capacity of 400 m3/h with a base wind speed of 2 m/s.

To calculate the required number of turbo deflectors, it is enough to take the required air exchange rate in the room and multiply the coefficient by the volume of the room. Next, the resulting value in cubic meters of air is divided by the basic performance of the turbo nozzle, and the number of devices is obtained.

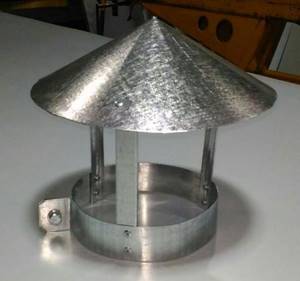

Rotary turbines for the exhaust system

These are the most popular devices for this purpose. Compared to other designs, their productivity is 20-25% higher.

The advantage of using them is that they do not use any energy source during operation.

Always rotating in one direction under the influence of the wind, the turbine head creates a vacuum inside the ventilation pipe, which promotes the active process of air circulation.

In addition, elegantly made of steel, it also serves the function of protecting the pipe mouth from atmospheric precipitation.

The head part is made of aluminum strips up to 0.5 millimeters thick, and the base is made of steel sheet painted in RAL colors.

Rotary turbines can be used on round, square or rectangular ducts or chimneys. In addition, they can be used for chimney systems.

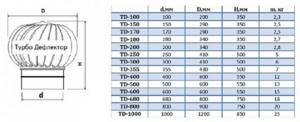

Turbo deflector dimensions

The popularity of the turbocharged nozzle is quite high; it is widely used for private households, apartment buildings and even in the construction of industrial facilities. The smallest diameter of the ventilation pipe is 100 mm, the largest size of the ventilation shaft is 1000 mm.

In addition to models with a classic round seat ring, turbo deflectors with transitional box-shaped bases are also produced. Such nozzles can be installed on ventilation ducts on high-rise buildings made of bricks and blocks.

For your information! It is believed that the turbo deflector maintains its performance characteristics if the area of the landing ring differs from the quadrature of the pipe or shaft cross-section by no more than 15%.

In practice, when choosing a suitable turbo nozzle option, preference is usually given to models with higher productivity; the nozzle efficiency is higher, although it increases the load on the pipe.

What does the modern market offer?

The turbo deflectors produced today from different manufacturers look very similar to each other, but in fact they have significant differences. And today they are produced by such brands as Turbomax, Turbovent and Rotavent.

Rotavent differs from other designs in the built-in canopy, which additionally protects the chimney from water penetration. It also uses a double-block bearing, which is lubricated with a special compound and withstands high flue gas temperatures well.

Thanks to this, the power of this design is retained for many years. At the bottom, the Rotavent is equipped with a release flange attached to the base, which allows it to be easily disconnected from the pipe.

But Turbovent is not installed on the chimney for coal stoves and wood-burning fireplaces. The thing is that here the maximum temperature of the flue gases is 250°C.

Therefore, these products are now actively used for natural ventilation systems, as well as for gas fuel boilers. And Turbovent is made of aluminum with a thickness of 0.5 to 1 mm, and its base is made of galvanized steel 0.7-0.9 mm and painted according to the RAL catalog.

Further, Turbomax is called a natural thrust supercharger. It is based on AISI 321 steel with a thickness of 0.5 mm. This turbo deflector is suitable for ventilation pipes and smoke ducts, as they are designed for exhaust gas temperatures up to 250°C.

How to make a turbo deflector with your own hands

There are two options for a homemade turbocharged nozzle that you can build with your own hands, the performance of which will be only slightly inferior to industrially manufactured products.

In the simplest case, the housing of the turbo nozzle for ventilation can be made from a cylindrical steel container.

To make blades, just make vertical cuts and bend the edges outward. The housing is mounted on the axis of rotation without any bearings; the mounting ring is cut out of a piece of metal chimney and secured to the ventilation with a regular clamp. The appearance of a homemade turbo deflector is inferior to industrially manufactured models, so such products are used primarily for ventilation pipes in cellars and outbuildings.

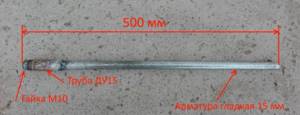

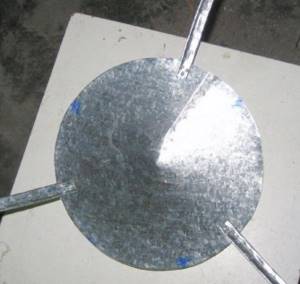

For the second option, you will need to make a drawing or use the dimensions from the photo below.

First of all, you need to make a fastening; for this, a strip with a thickness of at least 3 mm is best suited.

The diameter of the ring can be taken from the diagram, but it is better to first measure the pipe along the cut edge.

The second important element is the shaft and bushing.

The steel grade and diameter are not particularly important, the main thing is that the parts are made of the same material.

Ways to increase traction

If the draft force is in the chimney duct of the heating device, eliminating this defect is not always easy. Experienced stove makers use the following methods and methods to increase it:

- The first thing to do if you suspect insufficient draft in the chimney is to clean the pipe. To do this, call a chimney sweep or remove soot deposits from the inner surface of the chimney with your own hands using a metal stove brush.

- A significant increase in the power of the chimney can be achieved by increasing the height of the chimney above the roof surface by adding several additional segments. Using the same method, the chimney is removed from the zone of wind pressure from a ridge or higher building.

If you were unable to find a solution to the problem of lack of draft inside the smoke exhaust duct on your own, seek advice from an experienced stove maker who will tell you what to do and correct the defect in the most rational way.

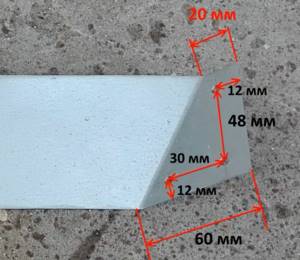

Drawings of turbo deflector blades

The most complex element of a turbocharged nozzle is the blade or blades.

Since the turbo deflector body is formed by bent profiled elements, the main condition for a high-quality attachment will be the accuracy of the geometry of each blade.

As an example, you can use the diagram in the photo.

To bend the workpiece, you need to step back 20 and 60 mm from the edge and draw a bend line. Next, we retreat 12 mm from the front edge and mark the points for drilling three holes.

All that remains is to bend and rivet the blades to the top cover of the turbo nozzle.

Manufacturing and installation of a deflector

The deflector has been tested in action by more than one generation of home/cottage owners. Its effectiveness has been proven repeatedly, so it is not surprising that the device is in demand. And demand, in turn, creates supply.

The price of such offers can sometimes be steep - not every thrifty owner is willing to pay $140 for a simple device.

Image gallery

Photo from

Design of a simple deflector

Device clamp diameter

Diameter of the chimney protection cap

The height of the umbrella above the clamp

Ventilation element assembly procedure

It will cost much less to assemble a deflector from scrap materials. Especially if you want to build something useful with your own hands. The entire production process of the device will take 2-3 hours - the time depends on the dexterity and skills of the assembler.

The process of making a reflector that enhances traction with your own hands consists of the following stages:

- create a drawing;

- make blanks;

- assemble the device;

- install and secure it to the chimney.

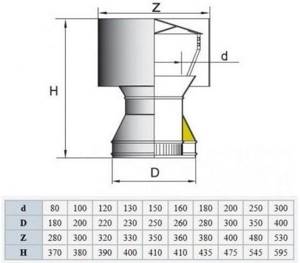

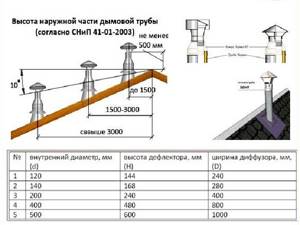

The first stage of creating a drawing is best done on paper. To do this, it is important to correctly calculate the diameter of the inlet pipe and the diameter of the cap. And also, the height of the deflector itself.

There are special tables that show diffuser sizes for the most popular pipe diameters. If the chimney is non-standard, then you will have to do the calculations yourself (+)

To avoid mistakes, you can use generally accepted formulas for your calculations.

The main role in the calculations is played by the internal diameter of the chimney pipe:

- height =1.6-1.7*diameter;

- diffuser width = 1.2-1.3*diameter;

- cap width = 1.7-1.9*diameter.

Once you have the formula, all that remains is to correctly measure the internal diameter of the chimney pipe and substitute the resulting value. Knowing the dimensions, you can begin to draw the contours of the blanks on paper.

It is best to create a prototype of the finished paper product after creating a drawing. This will make possible errors and shortcomings more clear. If there are none, then you can proceed to the second stage - creating real metal blanks.

In the process of creating prototypes of the parts of the future deflector, it is best to use paper. If something fails, you can always correct your mistake

The material can be used as a sheet of galvanized or stainless steel with a thickness of 0.5-1 mm. Sometimes you can come across the opinion that it is best to use copper for the deflector.

This statement has the right to life if you accidentally have an unnecessary sheet of copper in your garage or workshop. Otherwise, such an expensive purchase will not justify itself. And the service life of stainless steel cannot be called short enough to neglect this material.

When the blanks are cut with metal scissors from the prepared sheet, you can begin the assembly stage of the product. To do this, you can use a riveter and a drill or welding. When working with welding, you need to be extremely careful so as not to accidentally burn through a section of the future deflector.

If you plan to use rivets, then it is convenient to make allowances for connecting the parts together on a rolling machine. If this is not the case, then a hammer will do just fine. Having made allowances, you have to connect the parts evenly together, make holes with a drill and install rivets.

The legs for attaching the cap to the base of the deflector are attached at an equal distance from each other

The cap must be secured to the base with legs, which are also drawn and cut from a stainless steel/galvanized sheet.

All parts of the product are connected to each other with rivets - this is the fastest and safest method of fastening. Welding requires skills and such a product will not look so attractive

When the 3rd stage is finished and the homemade product is ready, you can proceed to the last and most important moment - installation on the chimney.

Installing a roof deflector

The last stage of manufacturing a deflector for a chimney pipe is to install it in its permanent location - on the chimney. You can install either a home-made device or a purchased design yourself. There is no difference - you still have to climb onto the roof.

To avoid problems with installation, even a purchased model that comes disassembled must be assembled at the bottom, securely fixing all the fasteners. Only after this can you take the necessary tool and head to the chimney.

Depending on the type of pipe that acts as a chimney, mounting options will differ. Sometimes it is enough to use several screws or add an additional clamp

When installing the deflector on the chimney pipe, you must carefully drill holes for mounting. Then all that remains is to securely fasten the screws or rivets and check whether the installed device is tilted in different directions.

If it dangles, then you can additionally install a clamp. This option is suitable if the chimney is not lined with brick.

For brickwork with a square or rectangular chimney cross-section, you will have to use special adapters. When the work is completed, you can test the deflector you installed yourself by lighting the stove/turning on the heating boiler.

Another important point is the spark arrestor. Whether it is needed or not is looked at in a particular house. You can make a spark arrestor yourself from stainless steel sheets or metal mesh.

If the roof covering is soft and can easily ignite, then it is important to take care of additional protection against sparks flying out of the chimney when the heating boiler is operating.

Installing a turbo deflector

Mounting to a pipe is not particularly difficult or labor-intensive. To install the deflector, you only need to align the nozzle body with the axis of the ventilation pipe.

If the diameter of the mounting ring turns out to be slightly larger than the cross-section of the pipe, then the problem is solved by winding up the spacer material; you can use tin or thin galvanized metal. Rubber gaskets cannot be installed, in this case the turbo deflector and pipe will rot in a few months.

After alignment, the body is fixed to the pipe cut with four self-tapping screws.

Types and characteristics

Nowadays, there are many types of deflectors for ventilation, among them the main ones are:

- Tsaga deflector;

- Grigorovich deflectors;

- H - shaped deflectors.

There are open structures that are divided by shape:

- can be flat;

- semicircular;

- with an opening lid or gable.

According to the principle of operation it happens:

- rotary deflector;

- turbine.

Like a weather vane.

Next, we will look at the most popular types of ventilation deflectors.

Chimney deflector

Very often, deflectors are installed on the chimney; it is installed in order to provide good draft for removing smoke. Thus, the deflector increases the operation of the equipment by twenty percent, this increases better fuel combustion and improves heat transfer.

Also, installing a deflector prevents atmospheric precipitation and various debris from entering the chimney.

Air conditioner deflector

Such designs are almost nothing like classic deflectors. They are screens - reflectors that redistribute the air masses produced by the air conditioner.

Therefore, air masses are directed not at a person, but at the floor or parallel to the ceiling, dissipating without losing their pressure.

Rotary deflector

This type of deflector increases the operation of the natural supply and exhaust system by four times, and at the same time, such a deflector does not require connection to electricity.

The rotary deflector consists of a movable head with blades, which are mounted on a base and attached with bearings.

The operating principle of the rotary deflector is as follows:

The wind gets into the blades and due to this the head begins to move, thereby the air is discharged and the thrust increases.

Thanks to the bearings, the head rotates at a constant speed, even in strong winds.

Vane

Deflector - weather vane is a special device, the body of which moves along with curved visors; they are connected to a bearing mount.

There is a weather vane on top of the structure; it allows the entire device to always be “downwind.”

This device works like this: air masses pass between the canopies, accelerate and create a rarefaction zone, due to this, traction is increased, fuel burns better and air exchange improves.

Such designs are good to use to prevent backdraft, flame extinction and sparking.

You can make such a design yourself; to do this, you need to install the structure on the cut of the chimney pipe; the fastening will be a bearing assembly and a ring.

Base deflector

Such deflectors are designed to ventilate basement floors and rooms, as well as to remove moisture. Such devices can be used in both forced and natural ventilation systems.

Another base deflector prevents various small animals, dirt, and meteorological precipitation from entering the basement.

The length of the deflector pipe is easy to adjust and, if necessary, it can be extended or sawed off to the desired height.

Operation of the turbo deflector

The design of the turbo nozzle is quite unpretentious and reliable. If the rotating cap is installed on the pipe according to all the rules, then the turbo system can serve without maintenance for several years in a row.

Experts recommend that after installing the turbo deflector, remove the cap every two years, check and lubricate the bearing. For high-speed small-sized turbochargers, you can use motor oil; other models are lubricated with Litol or any other high-quality grease.

The most unpleasant incident that happens with a turbo deflector is associated with freezing of condensing moisture along the edge of the pipe. The design will not suffer from this, but the efficiency of the turbo nozzle is reduced to zero.

Turbine installation rules

Ventilation turbines can be installed directly on a pitched or straight roof, at the outlet of a chimney or ventilation shaft. The placement location depends on the application of the turbine.

To ventilate the under-roof space, a turbine with a base diameter of 315 mm is used. It can serve 50-80 m2 of roofing - the exact area depends on the slope of the roofing - the smaller the angle, the greater the number of turbo deflectors that need to be installed.

For installation on a pitched structure, select the highest point on the slope. When improving the ventilation systems of residential premises, installation is carried out at the overhang of the ventilation shaft.

When installing on a flat roof base, you need to take into account the height of the snow cover and install the turbo deflector above its average for a particular region. In any case it should not be lower than 180 mm

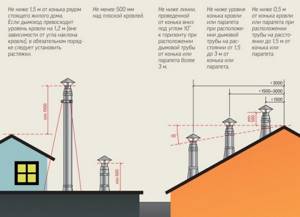

When installing a rotary turbine on a chimney pipe, the calculation of its height is carried out together with the device. That is, the turbo deflector, as part of the chimney, increases its length.

The rules for placing the chimney relative to the ridge remain the same as when installing a pipe without any nozzles:

- If the distance from the ridge to the pipe is less than or equal to 1.5 m, then the pipe is raised 0.5 m above the ridge.

- The height of the pipe, placed at a distance of 1.5 to 3 m, can be equal to the height of the ridge.

- When the distance is more than 3 m from the ridge, the top of the pipe should be no lower than the level of a conventional line drawn down 10° from the height of the ridge.

To reduce heat loss in winter through the ventilation system, the manufacturer allows the use of dampers (for residential premises) or adjustable air intake devices (for warehouse and production areas).

The height of the pipe head relative to the ridge must meet certain rules. Otherwise, there is a high probability of reverse thrust occurring. And although this phenomenon is excluded with an installed deflector, incorrect placement of the pipe can lead to worsening movement in the channel

Owner reviews about the turbo deflector for ventilation

Sergey Alexandrovich Zaslavsky, 33 years old, Novorossiysk

The idea of installing a turbo deflector on the garage and cellar ventilation pipe was suggested by a neighbor. I installed the turbo head myself in half an hour, without even checking the quality of the bearing lubrication. As if on purpose, half an hour later a rain squall came. The turbo deflector roared like a turbine, but there wasn't a drop of water in the garage. I liked the work of the nozzle, I will definitely make it for the attic and for the boiler room pipe.

Viktor Anatolyevich Spesivtsev, 68 years old, Omsk

At first I didn’t even believe in the capabilities of the rotating attachment; it looks like a beautiful toy, nothing more. My son gave it to me, I had to install it. I have a canopy attached to my house, and it’s hellishly stuffy under it at noon. I put it on the roof for testing, I liked the result. I bought four of them and put them on the roof of the house. The neighbors laughed, but this year I saw two of them, they were also standing, which means they assessed it correctly. The only drawback is the high price.

Vladimir Barlevich, 45 years old, Moscow

I don’t recommend installing it, I had a turbo deflector at my dacha, no effect. I moved it to a pipe in the outbuilding, closer to the road, and a week later it was stolen. The neighbor says that he placed it incorrectly, they wouldn’t have taken the trinket, but since it was stolen, it means the thing is worthwhile.

General information

Draft is a natural phenomenon in which air moves from one zone to another, namely from an air area with high pressure to an area where the pressure is lower. All this happens thanks to a special ventilation type device - a special channel in the chimney. Using such an aerdynamic process, humanity began to use stoves, fireplaces, boilers for heating, and bringing warmth into the house through the use of fuels such as firewood, coal, peat, etc.

Measurement methods

If there is any doubt that the draft in the chimney is at a sufficient level, a check should be performed. The easiest way is to check using a device such as an anemometer. If the device readings are approximately 10-2 Pa, then the thrust can be considered normal. But this method has a certain disadvantage, namely that the measurement accuracy is low. This will only apply to the use of inexpensive devices. For example, if the thrust is less than 1 Pa, then the device will show that it simply does not exist. This suggests that better quality measuring devices are required.

Professional devices for checking chimney draft are distinguished by accurate measurements and a fairly high price. Such devices are usually used only by experienced stove-makers.

If you don't have an anemometer, you can use one of the following methods :

An obvious sign of whether there is a draft or not is the smoke that may enter the room. If the room starts to smoke, then the draft is poor, and then there is a high risk of carbon monoxide poisoning.

By the smoke.- By the color of fire. If you look closely at the color of the fire, you will understand how strong the draft is in the system. So, if the fire inside the firebox has a white tint, and crackling sounds are heard when burning, then the required indicator is at a high level. A red-orange tint will indicate a low level of traction force. If everything is functioning correctly, the flame will have a golden yellow color.

- Using a match. If you light a candle or match and then bring it to the heating device, then at the optimal level of draft the flame will begin to tilt towards the firebox, and if the flame burns evenly, we can say that there is no draft at all. If the light begins to tilt away from the chimney, then there is only one explanation for this - there is a reverse draft.

- With a mirror. This method is often used to check the traction. You should bring a small mirror to the chimney, and if condensation appears on it, then the draft is small.

Please note that draft inside the chimney is formed due to the difference in pressure inside the room and outside. In a room that is constantly heated, the pressure will be higher than outside it!

During the operation of a stove or fireplace, owners of private buildings note that the exhaust force often decreases during certain periods of time, and in order to improve the situation, it is necessary to make a draft amplifier for the chimney with your own hands.

Reasons for decreased cravings

But in order to begin manufacturing the device, you must first understand why the traction force has decreased. It is for this reason that you should first check the condition of the chimney, and be sure to see what other elements are in the system and in what condition they are.

This is quite easy to do, but first you need to completely turn off the heating system. After this, it is necessary to remove soot from the chimney if it is more than 0.2 cm thick (a long probe will help determine this indicator). There are many reasons why there may be no draft in the chimney. They can be divided into two groups - factors that act from the outside, and design features.

The second ones include:

The use of elements such as tees and turns along the smoke exhaust.- Incorrect damper installation or adjustment.

External factors are:

- The installation of the chimney outlet is lower than the roof ridge. This circumstance very often leads to cravings getting worse.

- The presence of large objects near the chimney. Because of this, a large area of increased or decreased pressure begins to form.

- Strong winds or calm prevail in your area.

All these factors affect traction force. This may create increased resistance. To prevent this from happening, certain measures should be taken. Thanks to all these actions, heating equipment will be used more efficiently and its service life will be longer.

Reasons for reverse thrust:

- Design flaws for the chimney. Low pipes increase the risk of reverse draft. The higher the pipe is located, the better the process of extracting exhaust smoke and gas will be. The optimal height is approximately 5 meters.

- Correspondence of the pipe diameter to the furnace device. Powerful stoves require a chimney with a pipe of sufficient cross-section. But in this case, moderation is important, since using too wide pipes will make the heating process unprofitable (all the heated air will, in every sense, fly into the pipe). You cannot use several pipes of different cross-sections in a chimney!

- Using not entirely smooth pipes . Chips, unevenness, roughness, etc. are an obstacle to normal traction. Over time, the chimney opening may narrow due to the build-up of soot and other combustion products, which can complicate the process of lighting the stove and its normal operation.

- Absence or disruption of the ventilation system . Open windows and drafts will not help the fuel combustion process in any way, but will only distort it, making it unsafe and completely useless.

Chimney ducts made of metal are many times worse than brick pipes, since rapid heating and equally rapid cooling will not benefit the heating system as a whole, and in particular for the chimney.