Features of soft roof covering TechnoNIKOL

Confirmation of the high quality of TechnoNIKOL roofing is the ISO 9001 certificate, which guarantees the reliability of the manufacturer of this brand. Bitumen is used to make soft roofing.

The following types of TechnoNIKOL products are available for sale:

- rolled materials;

- polymer membrane;

- flexible tiles.

The structure of TechnoNIKOL roof coverings is characterized by a high degree of resistance to mechanical stress and weather conditions.

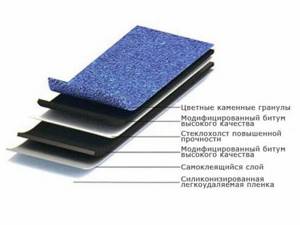

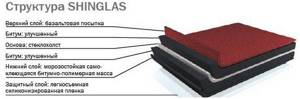

In the production of flexible tiles, fiberglass is used as a base, which is impregnated on both sides with modified bitumen. On the outside, the products are protected from coarse-grained basalt chips. This coating paints the tile sheets in a variety of shades and colors.

On the reverse side of the product there is a bitumen-polymer coating - it is protected by a layer of film. It is removed before installing TechnoNIKOL.

The polymer membrane is produced in three versions:

- based on plastic polyolefins;

- using synthetic rubber;

- with the addition of plasticizers.

The most in demand is a membrane produced on the basis of PVC with plasticizers, which give the roofing elasticity and resistance to the influence of negative temperatures. To increase tensile strength, the base is reinforced with a polyester mesh.

Characteristics of TechnoNIKOL roofing materials

Soft materials for TechnoNIKOL roofing are made from bitumen.

Such products are:

- flexible tiles;

- polymer membrane;

- roll coverings.

The structure of these materials is resistant to weather and mechanical factors.

The soft tiles are based on fiberglass, impregnated on both sides with modified bitumen.

The outer side of the product has a protective layer in the form of coarse basalt topping. It is the coating that gives the roofing carpet made of soft tiles different colors.

The inner side of the product is covered with a bitumen-polymer mixture, in turn it is protected by a film layer, which is removed before installation.

There are three types of polymer membrane: with the addition of plasticizers, made on the basis of plastic polyolefins or synthetic rubber.

A PVC-based membrane with plasticizers is considered the most common.

Plasticizers make the roofing covering elastic and give it resistance to exposure to negative temperatures. Tensile strength is increased by reinforcing the base with polyester mesh.

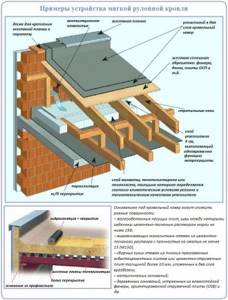

Roll roofing is used for arranging flat roofs of civil and industrial buildings.

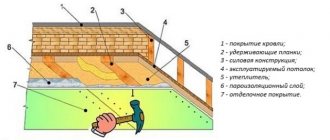

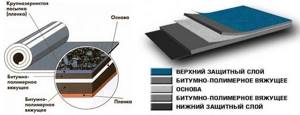

The deposited materials are made on a synthetic basis, their structure is five-layer.

It consists of several layers of bitumen coating, which is applied to a reinforced base, for example, fiberglass, and two protective layers: the outer one is mineral coating, the inner one is polyethylene film.

The advantages of soft roofing sold by the manufacturer TechnoNIKOL include 100% waterproofing of the material, a high level of frost resistance and sound insulation.

In addition, installation of any type of TechnoNIKOL soft roof does not require the use of special equipment.

Since the welded material can easily take the shape of any roof (from pitched to dome-shaped structures), designers are always ready to use it in their ideas.

Technonikol's wide range of soft roofs allows you to diversify the roofs of country houses, especially when it comes to flexible tiles, which are produced in a wide range of colors and can take on different shapes during production.

How to properly install TechnoNIKOL

TechnoNIKOL soft roll roofing is laid on flat roofs of buildings for industrial and administrative purposes. The welded products are produced on a synthetic basis; they have a five-layer structure.

During the production process, a reinforced base such as fiberglass is coated with a bitumen coating on both sides. The material is protected on top with a mineral coating with colored granules, and on the back side the self-adhesive layer is covered with plastic film.

The advantage of this roofing product is its absolute waterproofing, resistance to sub-zero temperatures and sound insulation qualities.

Another positive point: TechnoNIKOL’s soft roof installation technology does not require the use of complex equipment. Since the welded material can easily take the shape of roofs of various configurations, including domed ones, it is often used by designers to realize their original ideas.

A large assortment of soft roofing coverings, especially flexible tiles, which are made in a variety of colors, allows you to diversify the appearance of private households.

How to glue TechnoNIKOL. Fused roofing TechnoNIKOL: installation technology, reviews, description

If you are puzzled by the choice of high-quality, strong roofing material that will “tightly” adhere to the slopes, give preference to proven brands.

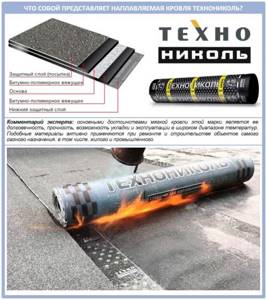

Thus, the built-up roofing from a domestic manufacturer is considered one of the best in Russia. It is presented on the market in several types, for each individual roofing task. Let's study it in more detail, how positive the reviews are, are there any shortcomings and what is the technology for working with such material. And our detailed master classes, expert advice and new

Fused roofing is famous for its qualities such as strength, durability, waterproofness, elasticity and excellent resistance to temperature changes and mechanical deformation. Moreover, this stability is sufficient for all regions of Russia, even with a harsh climate.

Surely you have already heard more than once why fused roofing is so good, especially for low-rise construction, such as a garage or workshop. But let’s emphasize the advantages of roofing from TechnoNIKOL:

- Air and moisture tightness. Having laid such a roof on any roof, you can be completely sure that the entire interior is reliably protected, and the wind will not tear anything off.

- Thermal insulation and noise reduction, which TechnoNIKOL products have, are at a high level. This moment is especially valuable for residents of the upper floors, where neither the roar from the rain nor the footsteps of people can be heard at all. In its own way, this material protects apartments from heat loss.

- Life time. For example, one of the most popular products, Uniflex, lasts at least 20 years!

Of course, the TechnoNIKOL fused roofing is not without all the disadvantages that are generally inherent in such roofing material, and this is the price and rather complex installation, using fire-hazardous gas equipment.

Sequence of installation of roll roofing

When installing coatings made from TechnoNIKOL materials, one of two methods is used:

- mechanical;

- using fusion.

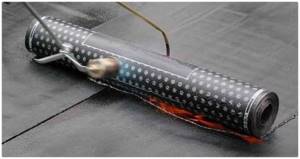

The first of them is used when arranging a pitched roof. To fix the canvases, special mastic and galvanized fasteners are used. In the second case, fusing is performed using a gas torch.

This TechnoNIKOL installation technology is used for work on flat roofs:

- You should start laying the sheets from the lowest point of the roof.

- First, a roll of material is rolled out and adjusted to the contours of the surface, ensuring that the coating extends onto the protruding areas of the roof.

- You need to know how to properly lay a soft roof so as not to spoil the material. To prevent the canvas from moving during the adjustment process and when straightening, one edge must be fixed with a heavy object. Roofers recommend placing the roll upside down a few days before starting work so that the material takes on a round shape.

- When fusing the roof, they use the “pull” method. This technique allows you to monitor how warm the bitumen layer is. As a result, the roofer can see whether the torch still needs to be used. Movements should be done smoothly and evenly. In places where TechnoNIKOL soft roofing is laid overlapping, additional heating must be performed.

- The burner must be held so that both the bitumen layer of the coating material and the base are heated at the same time. When heating is done incorrectly, a bitumen bead will appear in front of the rolled roll.

- During work, you need to monitor the uniform melting of the bitumen layer to prevent the appearance of cold and overheated zones.

- The moment the pattern floats is a signal to the builder that he should roll out the material further. When the bitumen is melted, it begins to protrude along the edges of the canvas. The result is seams about 25 millimeters wide (about

Operation of soft roofing "TechnoNIKOL"

In order for a soft roof to last for many years, you need to adhere to the operating rules.

- It is prohibited to go onto the roof except for inspection, snow removal or repairs.

- To access the roof, you need to lay wooden panels with the exception of a roofing deck made of paving slabs (usable roof).

To move on a soft roof you need to use wooden panels or ridge ladders

- It is unacceptable to lay temporary pipelines on a soft roof that are not provided for by the project, to store building materials, to arrange additional rooms, i.e., to place anything that can put additional load on the roof and on the building itself.

- Wooden stepladders used for inspection or repair must have soft “shoes,” i.e., be lined with felt.

- Defects should be identified and eliminated in a timely manner, and the roof should be kept clean.

- After repair work, it is necessary to inspect the roof to ensure its integrity. Identified defects should be eliminated immediately.

- Preventative inspection of the roof is required to be carried out twice a year - in the fall before the onset of rains and in the summer, with inspection of gutters, junctions, the condition of the protective layer, assessment of swellings (if they appear), etc.

- Cleaning the roof should be done in soft rubber or felted shoes with wooden scrapers or shovels, and when removing snow, do not rake it to the base - leave a layer of 5–10 cm.

When cleaning the roof in winter, the snow does not need to be completely removed, so as not to spoil the roof covering; it is better to leave a layer of 5–10 cm

- Do not sweep debris from the roof into gutters.

The rules are usually indicated by the manufacturer of the roofing material in the operating instructions, and if you do not violate them, then there will be no problems with the soft roof.

Preparing the roof for work

The welded type of roofing is laid on reinforced concrete, or on mineral wool slabs without pouring a leveling screed, or on an asphalt concrete coating, or on a dry base of cement-bonded particle blocks or asbestos-cement sheets.

The preparatory stage involves a number of measures to eliminate protruding elements on the roof. Vertically located pipes, ventilation ducts, parapets are first plastered with cement mortar, applying it to the height where TechnoNIKOL soft roofing materials will be reached.

On the roof prepared for the overlay surface there should be no hard pieces of concrete, holes, sharp protrusions, remnants of reinforcement, or traces of oil, as these will negatively affect the quality and durability of the roofing carpet.

Sharp corners must be removed, dust must be removed using an industrial vacuum cleaner or compressor unit, and oily traces must be burned off. Large potholes and cracks are sealed using a cement-sand mixture, which includes cement grade M 150, and minor cracks are filled with heated bitumen.

Features of the roof base

Fused roofing should only be laid on a flat surface. There are several base options for this type of roof:

- Reinforced concrete slabs, without leveling screed. All seams are sealed with a solution of cement and sand.

- Monolithic thermal insulation, made of lightweight concrete (base – reinforced mesh, bitumen and cement-binding material, fillers).

- Thermal insulation boards made of mineral wool, without additional leveling screed.

- Monolithic screed made from a solution of cement and sand, asphalt concrete.

- Prefabricated screed consisting of flat sheets of asbestos cement, cement bonded particle boards, etc.

Laying a guided roof involves preliminary preparation of not only the base, but also all vertical structures that are located on it. This applies to chimneys, parapets, ventilation shafts, etc. Their walls must be plastered (with a cement-sand mixture) to the same height as the future edge of the roofing material. Minimum height – 25 cm.

The base must be level. All irregularities and protrusions are cleaned or sawed off. Oil stains are burned off and the dust is blown off with a vacuum cleaner. Large cracks or potholes are cemented, small ones are filled with heated bitumen mastic.

Soft roofing technology

Lay the covering on a flat base. The area of gradually increasing irregularities present on the surface should not exceed a size of 2 by 4 meters. Installation is carried out on a dry base, and a moisture meter is used to check the humidity level.

When such a device is not available, then a piece of plastic film is placed on the surface. If after 4 hours there is no moisture on it, then you can begin arranging the roofing.

Before installation, the base is thoroughly cleaned, after which it is primed with a bitumen primer - you can either purchase it or make it yourself from bitumen and gasoline in a 1:3 ratio.

To ensure the longevity of the soft covering on the roof of your own household, the manufacturer’s instructions will help, which describe in detail how to properly glue TechnoNIKOL and arrange a weld-on type of roofing. It must be strictly followed and then an excellent result will be ensured.

TechnoNIKOL for garage roof: varieties and characteristics

How to cover a garage - TechnoNIKOL ! Such a soft roof refers to flexible finishing coatings made on the basis of bitumen. The material is based on fiberglass or polyester , impregnated and coated on the top and bottom sides with a special type of bitumen.

The top side has an additional basalt topping , which makes the material resistant to mechanical, atmospheric and temperature influences. The underside of the material is equipped with a self-adhesive bitumen layer with a protective film.

Technonikol roofing materials is their varied colors. The surface covered with this type of soft roof is not only durable, but also aesthetically attractive.

TechnoNIKOL garage roofs come in the following types:

- soft tiles;

- welded roll coating.

Advantages and disadvantages

TechnoNIKOL soft roofing has many advantages and disadvantages compared to other garage roofing materials:

- Resistant to both high and low temperatures. It will perfectly withstand heat of plus 50 , and frost of minus 50-60 degrees .

- One hundred percent waterproofing even in conditions of heavy rains and active snow melting.

- Anti-corrosion . The material does not rot, does not rust or oxidize at any level of air humidity.

- Resistant to wind and mechanical stress. Even the strongest hurricanes are not afraid of this roof. It cannot be torn off by a strong gust of wind, nor can it be damaged by hail or branches falling to the surface.

- Ease of installation . You can cover a garage with such materials yourself, without the use of special equipment.

- Attractive price. A variety of materials in different price categories will allow each consumer to find an option that suits them.

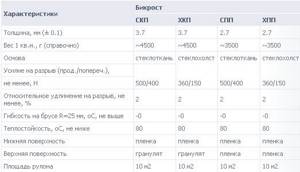

Roll markings and material composition

Immediately after the name, rolls from TechnoNIKOL use additional markings of one or three letters. They indicate the structure of the material, and this determines what specific tasks this particular type of roofing is suitable for.

So let's decipher them:

- Base: X – fiberglass, T – fiberglass and E – polyester.

- Top protective layer: P – polyethylene film, K – coarse-grained coating and M – fine-grained coating.

- Bottom protective layer: P - polyethylene film, M - fine-grained coating, B - ventilated coating or ventilation ducts, E - polymer non-woven fabric and C - self-adhesive side.

Abbreviated markings are also used:

- P is a built-up roof without protective coating. It is intended to be used as a bottom layer.

- K is a coarse roofing material that has an ultraviolet coating. This is used for arranging the top layer in a multi-layer roofing carpet.

Installation technology

How to cover a garage with Technonikol ? Installation of a soft roof is simple, but requires compliance with certain rules and a strict sequence of actions, depending on the type used.

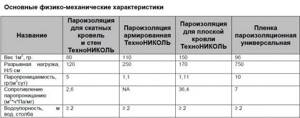

For the vapor barrier layer, it is advisable to use a special TechnoNIKOL . They consist of three layers that will help maintain a balance of temperature and humidity inside the garage.

In addition, the strength of the material allows it to be laid on any, even untreated surface. For pitched roofs , a membrane should be used; for flat roofs , perforated and non-perforated film should be used.

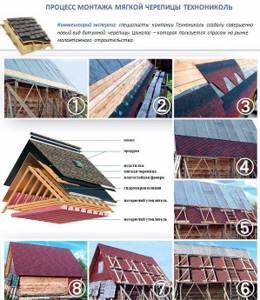

Soft tiles

Shingles from different packages must be pre-mixed to achieve a uniform shade of the coating .

There is no need to remove the protective film in advance; this is done gradually during the installation process. The installation procedure is as follows:

- An underlayment carpet is laid on the base of the roof .

When laying it, pay special attention to the roof components and ventilation holes in the roof.

- Ventilation vents are sheathed with special passage elements and carefully coated with bitumen mastic .

- Cornice and pediment strips are attached along the edge of the slope . Ridge-eaves elements are laid on top of them. If there are no special types of tiles, you can cut off the petals from the ordinary ones. The tiles are attached using a backing and nails 2.5 centimeters from the edge.

- Next, they begin to lay rows of tiles with each next row overlapping and offset by one petal. The edge of the second row of tiles should coincide with the edge of the previous one.

- The outermost tiles along the slopes are trimmed , the vertical row laid along the pediment is coated with mastic.

- The ridge is covered with a Technonikol and ridge tiles.

Calculation of material for soft roofing

When calculating the roof, the most difficult thing is to determine the required volume of flexible tiles. With rolled or piece materials everything is simple - draw a sketch of the roof on a piece of paper, lay out the profiled sheets, rolled material or slate and calculate it.

With soft tiles, this approach is not justified due to the small size of the shingles and their shape. Therefore, the easiest way is to calculate the required volume of bitumen shingles using an online calculator on the manufacturer’s website or third-party computer programs for roof calculations, which give a good, most accurate result.

Video: construction calculator for roof calculations

Manual calculation of bitumen shingles

For those who do not rely on technology, but trust only themselves, we present an algorithm for manual calculation of tiles.

- Draw a sketch of the roof on a piece of paper.

- We calculate its area (width x height).

- Since a flat drawing does not reflect the true dimensions of inclined planes, we multiply the resulting result by a special coefficient depending on the slope of the roof. For reference, for a slope slope of 35° the coefficient is taken equal to 1.221, for 45° - 1.414, etc.

- We get the total roof area and divide it by the area covered by one package of tiles (this figure is indicated by the manufacturer on the package). The result is the number of required packages.

For a more reliable calculation, you should “break” the roof into simple geometric shapes, calculate each of them and add up the results.

Lining and insulating materials are calculated in the same way. When calculating, take into account trimming, possible damage and associated replacement, valleys, ridges, and overlaps. That is, take it with a reserve so that at the end it doesn’t turn out that there is not enough material, but there is nothing like it on sale.

Description of coverage

TechnoNIKOL fused roofing is often a roll coating consisting of five layers.

Its basis is fiberglass (T), designated T in a roll, on which bitumen layers are applied on both sides. Fiberglass consists of interwoven glass fibers and is a fairly durable base.

The material is protected on top with granite topping, and on the bottom there is a plastic film covering the self-adhesive layer.

This coating provides absolute waterproofing, sound insulation, and is resistant to frost.

In addition to roll coverings, they produce flexible tiles and polymer membranes.

In the manufacture of flexible tiles, fiberglass (X) is used, both sides of which are impregnated with modified bitumen. Coarse-grained basalt chips are applied on top, which gives the tiles a variety of colors and shades. Below is a layer of film that protects the bitumen-polymer coating. This film is removed before laying the TechnoNIKOL soft roof.

Fiberglass is less durable than other substrates. It is not elastic enough, it can be damaged during transportation and then crack during installation. TechnoNIKOL coating with such a base is not recommended for use on residential roofs.

Fused roofing is used not only for arranging the roofs of houses. This coating is used for other works:

The light weight of this coating allows you to install it yourself. It's inexpensive and not at all difficult.

Product line for different tasks

Manufacturer TechnoNIKOL has a rather creative approach to the production of roofing materials. Its products not only have quality, but also become an important part of the building design. Let's take a closer look at what exactly is suitable for your roof.

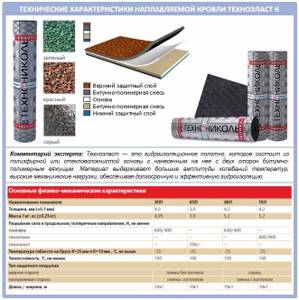

Technoelast: safety and durability

Let's start with the most popular - Technoelast K (note that Technoelast P is used not for roofing, but for foundations). This is a high-quality roofing waterproofing based on fiberglass or polyester, which can withstand high mechanical loads and significant amplitudes of temperature fluctuations.

Pleases with its spectacular design with coarse-grained topping. Technoelast S is close to these properties.

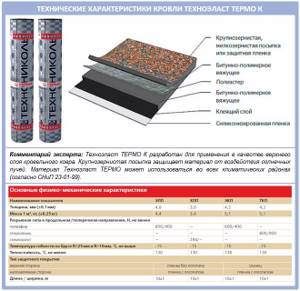

Technoelast Thermo is a multifunctional material that, thanks to a special APP modifier, retains its properties even at such extreme temperatures as +1300°C!

We also note separately Technoelast Flame Stop. This roofing is used to cover buildings that have high fire safety requirements. Here, thermoplastic elastomer is used to modify bitumen.

Let's list all other varieties of Technoelast:

- Technoelast Vent for single-layer “breathable” roofs.

- Technoelast Decor is excellent for the top layer of multi-layer roofing.

- Technoelast Fix is produced for arranging the lowest layer of roofing carpet.

- Technoelast Solo, in principle, is designed for the fire-free method, on the roofs of buildings where such an installation method is not possible, but this roof is laid with both partial fusion and full fusion, if necessary.

- Technoelast Green is excellent for waterproofing buildings where there are green roofs and contact of the waterproofing with roots is predicted.

- Technoelast Titan is more suitable for industrial building structures.

Ecoflex: reliable grip

This roof has the highest adhesive properties. Thanks to them, the roof can be fused to almost any non-combustible base. As a bonus, there are plastomeric-elastomer additives that make this material much more resistant to high temperatures. This roofing material is laid even at subzero temperatures (-5°C).

Uniflex: breathable coating

In addition to its valuable vapor-permeable properties, Uniflex is also good because it can be installed on an old roof without dismantling it. Available in the following types:

- Uniflex K pleases the eye with coarse-grained coating and film on the surface of the fabric.

- Uniflex P – with fine-grained coating on both sides at once.

- Uniflex Vent is a special waterproofing for “breathing” roofs or their restoration without necessarily removing the old carpet.

Designed for installation of roofing carpets on buildings and structures and waterproofing of building structures.

Bipole: a universal material

Such roofs are excellent for installing both new and old roofs. The lower side of this roofing covering is covered with a low-melting polymer film, and the upper side is covered with coarse-grained mineral coating.

Linocrom: protection against moisture

Separately, we note Linocr, which is produced on a non-rotting, durable base and reliably protects against dampness. Resists any weather conditions. Its variety is LinokromREMTKP, just for restoring the old top layer of the roof.

Bikrost: high waterproofing

This roofing allows you to reduce the number of layers. It's all about the structure of this layer: bitumen binder is applied on both sides to a base - fiberglass or bitumen with a profile filler.

Stekloizol: a combination of the best properties

To make this material, three components are glued together: fiberglass, fiberglass and polyester. Suitable for both roof repair and new installation.

Ruberoid and Rubemast: improved qualities

Rubemast, like roofing felt, also consists of cardboard impregnated with bitumen, and there is much more bitumen here, and therefore the properties are much better.

Types of coating

There are several types of polymer membrane:

- based on synthetic rubber;

- based on plastic polyolefins;

- based on PVC with the addition of plasticizers.

The last option is the most popular. Plasticizers give the coating elasticity and resistance to frost. The polyester reinforcing mesh at the base of the material increases tensile strength.

Polyester (E) is the most expensive base, but the most durable and reliable. The polymer fibers in its structure, intertwined randomly, provide high wear resistance of the TechnoNIKOL coating and the ability to withstand high mechanical loads.

Preparing the roof for work

The roof surface must be cleared of debris and any unevenness removed. Large cracks are cemented, small ones are filled with bitumen mastic.

The roof must be dry. To dry it, you can use a hair dryer (heat gun). It is better to lay TechnoNIKOL soft roofing in dry weather.

At the joints with vertical structures, sides are made 10 cm high at an angle of 45 degrees from a solution of M150 cement with sand or a sheet of mineral wool. You can buy ready-made fillets. All vertical ventilation ducts, pipes, parapets, etc. are pre-plastered with cement mortar to the height of application of the TechnoNIKOL material.

Roll roofing installation technology

Installation of TechnoNIKOL roofing is carried out in the following order:

- a layer of primer is applied, which is a bitumen primer;

- strips of TechnoNIKOL rolled roofing covering are spread;

- The sheets are laid from low points of the roof, starting from the corners;

- the roll is rolled out over the surface, capturing the protruding sections of the roof;

- the edge of the roll must be pressed with a heavy object so that the canvas does not move during operation;

- after adjustment, the roll is rolled up again;

- fusing the roll onto the roof is done with a gas burner, moving “towards you”;

- the burner must simultaneously heat the bitumen layer of the TechnoNIKOL coating and the base. If heating is incorrect, a bitumen bead appears in front of the roll;

- The roofer must warm up evenly, smoothly moving to a new place. This will avoid the occurrence of cold and overheated zones;

- molten bitumen protrudes along the edges of the sheet to a width of 25 mm, and a change in the pattern on top indicates the need for further rolling out of the material.

Soft roofing technology

TechnoNIKOL soft roofing is laid on a dry, level base. The surface humidity level is checked with a moisture meter. If such a device is not available, cover the surface with plastic film and check after 4 hours for the presence of moisture on the film. If the film is dry, you can begin roofing work.

Bitumen primer for priming the base can be purchased ready-made, along with the material, or you can make it yourself using bitumen and gasoline in a ratio of 1:3.

The primer is applied to a thoroughly cleaned base.

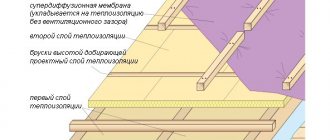

For a flat roof, it is necessary to form a slope towards the drain of at least one and a half percent. This can be done using insulation boards, which are given the required slope during the manufacturing process. Such slabs are produced by manufacturers of fused rolled materials.

When laying such slabs, you just need to follow the direction.

You can form a slope along the guides when pouring the screed.

On flat roofs, the material is laid along the length of the roof. Start installation in the lowest place.

After rolling out the roll, trying it on and cutting off excess material, it is again rolled from the edge to the center using an iron pipe.

The next sheet is laid with an overlap. The side overlap should be 8–10 cm, the end overlap should be 15 cm.

The next layers of soft roofing are laid in the same direction with the longitudinal seams offset by at least 30 cm.

To reduce the waviness of sheets of material, rolls are placed “upside down” before installation. After this they lie more evenly.

Video on the topic: Installation of flat roofs from fused materials

Roof covering in rolls

It is a roofing material, thick paper is its basis. In production, it is impregnated with a bitumen composition with the addition of polymers, and sometimes fiberglass is used. You can find three types on the market:

1. RPP is used only as a lining under the base material. It is sprinkled with talcum powder on both sides and is light in weight.

2. RKK is also used as an additional layer of a full roof. To create greater strength, you should add a sand mixture. This is necessary due to its soft consistency and sensitivity to heat. Selected as waterproofing for walls, foundations or ceilings.

3. RKP coating is the strongest; it weighs more than other types, but it provides a good barrier to rain and snow. To protect against adverse factors, the upper part is treated with screenings or mineral chips. The bottom is sprinkled with talc so that the roll unwinds easily when laying. Advantages:

- simple installation;

- light weight;

- resistance to wet environments;

- long service life.

The pie made from RKP roofing felt is quite light and does not put pressure on the roof. If you have some skills, you can easily make such a roof with your own hands, especially on a flat surface. To lay the covering on a sloped surface, you cannot do without a partner.

The polymers and bitumen that make up roofing felt repel moisture well and protect against rain and snow. Underlay varieties can be used to waterproof foundations. This type does not decompose and is resistant to bacteria. If the work is carried out according to technology, then such flooring can last more than 10 years.

Coating repair

During operation, it is necessary to carry out periodic inspections of the roof, and if damage or defects are detected, repair work is necessary to maintain the structure in good condition.

Minor damage is repaired using TechnoNIKOL No. 71 mastic reinforced with fiberglass mesh. The patch is selected so that it covers the damaged area by at least 10 cm on all sides.

- Clean the damaged area from debris, dust and crumbled protective coating.

- The mastic is applied with a spatula and the reinforcing mesh is embedded in the mastic layer.

- Apply another layer of mastic and a protective coating on top of it.

Minor damage to the rolled roofing is repaired by applying a patch, which is glued to bitumen mastic, after laying a layer of reinforcing material.

Material consumption: mastic - 2.5 kg/m², protective coating - 1.2 kg/m².

When installing a patch for a tear in the roofing carpet, double reinforcement is used.

If the protective coating is lost over the entire roof area, but provided that the roofing carpet is not cracked, an additional layer of Linokrom REM roofing carpet is made in one layer, fusing it onto the existing carpet. If the coating is lost in certain areas, the protective layer is restored with TechnoNIKOL No. 57 aluminum mastic.

Blistering of the waterproofing layer is eliminated by making a cross-shaped cut in the damaged area, followed by installing a patch. The cut layers are folded to the sides to dry and after drying they are glued to the base. A patch made of Linokrom REM material is installed at the incision site so that it covers the incision site by 10 cm on each side.

Loose fasteners for planks and aprons are removed and the elements are re-fastened. Minor repairs to junctions with parapets, shafts, etc. are carried out by replacing a section of an additional layer of roofing carpet. In places where the roofing carpet is mechanically attached to vertical surfaces, instead of the damaged sealant, a new layer of TechnoNIKOL No. 71 mastic is applied, having previously cleaned the surface of the old one.

All of the above concerns current repairs. Major repairs involve the complete replacement of worn-out roof elements with new, more durable and economical ones, which improve the performance of the building.

Polymer membranes

Bikrost is a more advanced type, which is marked with letter combinations: HPP, EKP and others. The first letter stands for the following:

- If the base is fiberglass, then look for the designation with the letter X.

- Marking E means polymer - suitable as a lining.

- T is placed on a material with fiberglass. It may have perforation or be solid.

The second letter indicates the layer with which the top is covered. K is a granular or slate coating. Fine sand coating is marked with the letter M, polymer film - P.

The third letter will tell you what the lower layer of Bikrost consists of. M means fine-grained surface, which is sand; P – polymer. Some types of soft roofing require a self-adhesive base - C.

The main advantages are:

- great strength;

- long service life;

- excellent waterproofing;

- weather resistance;

- good flexibility;

- light weight.

Produced under the Shinglas brand. It is presented in the form of fiberglass, which is covered with bitumen on both sides and sprinkled with basalt chips. They are painted using the ceramization method - heating up to 700 °C with the addition of pigments of inorganic origin. The color turns out to be very durable, it does not fade and does not change shade either under the influence of sunlight or frost. The color changes over time only due to the settling of dust or soot.

For production, modified bitumen is used, the characteristics of which differ from its conventional counterpart. Stone chips are applied to hot viscous bitumen, so it adheres to it better, and the material’s flexibility is also higher. Part of the fiberglass base is located vertically, this also improves quality. TechnoNIKOL provides a guarantee for its soft tiles from 10 to 60 years.

- high anti-corrosion properties;

- excellent sound insulation: while in the house, you will never hear the sound of rain;

- resistance to wind loads, since there is no windage at all;

- waterproof - does not require additional waterproofing.

Such tiles have proven themselves well in the harsh climate of Siberia, where there are frequent temperature changes and roofs are heavily loaded with snow.

How to properly install roll roofing

Installation is usually carried out using the fusing method. This process can be broken down into stages:

1. The surface must be thoroughly cleaned of old coating, debris and dirt. If there is moss and other vegetation, it must also be removed. If the flooring is planned to be laid on concrete slabs, sagging should be removed and cracks should be sealed. The plane is carefully protected from broken elements. After cleaning, the base is dried.

2. Apply bitumen or mastic to a dry and clean surface. These materials provide an additional waterproofing layer.

3. If the roof does not have insulation, then put insulation - mineral wool or polystyrene foam. The latter is installed in two layers with an overlap at the joints.

4. Make a cement screed or lay another row of roofing felt. Then the plane is covered with bitumen again.

5. Now lay the finishing layer. The roll is rolled out in the direction of the installation line. The material is trimmed with a margin; its size will depend on the presence of elements that need to be skipped. The roofing material is rolled into the middle of the roof. Take the following tools: a knife, a burner, a special roller and a holder. Further work is carried out with a gas burner. The gasoline analogue is not suitable in this case, as the likelihood of damage will increase. Use a construction knife to trim roofing material in problem areas. As a holder, you can take a small metal rod, which will be convenient for unwinding the roll. The roller is necessary to ensure compaction.

6. Use a burner to heat the lower part of the soft roof. It will be necessary to warm up the substrate to achieve better adhesion to the base. Simultaneously with the heating process, the roll is gradually unrolled and compacted with a roller.

7. Each subsequent layer is laid with an overlap. One of the sides is made without bedding - it is always placed inside.

After installing the first layer, you should wait until it cools down and then proceed to laying the next layer.

Fused roofing technology

*All materials necessary for individual operations at each stage are selected based on the specifics of the work (type of structure, type of ceiling, air temperature, etc.).

Stripping the base

The most common understanding of the meaning of this operation is to remove debris, dirt, and protruding nails. But that's not all. The presence of various stains on the roof - from oil, fuel or something similar - sharply reduces the quality of adhesion of the welded material. It is these “shortcomings” that will have to be eliminated.

For example, the remains of fuel and lubricants can be burned (subject to the necessary measures). For more thorough preparation, if possible, you should use sandblasting. By the way, it is easy to make from scrap materials. It works on the “spray gun” principle, so if you have a source of compressed air, then this is an excellent option.

Inspection

It is necessary to identify all surface defects - large cracks, depressurized seams, irregularities (with sharp edges). All of them are sealed with appropriate compounds (or knocked down - sticking out pebbles, for example). The most commonly used solutions are based on CPS. For these purposes, it is enough to take the cheapest brands of cement - 100th or 150th.

If the defects are minor - small holes, cracks - then it is quite possible to get by with bitumen-based mastic.

Arrangement of fillets

The screed has already been mentioned. But it’s worth talking about these “bridges” in more detail. They are not always installed, but in some cases fillets are indispensable. If there are vertical structural elements on the roof, then in places where the surface is broken (at 90º), complete adhesion of the roofing material to the base cannot be achieved - voids will certainly form.

To avoid this, the angle is somewhat straightened due to the fact that the upper cut of the fillet is located at approximately 45º. What can such a “transition bridge” be made from? For example, from CPS mortar, mineral wool (hard only), asphalt concrete. If you understand the meaning of this work, then choosing the appropriate material is not difficult.

Primer treatment

This is necessary to improve the quality of gluing of canvases (membranes). It is recommended to use bitumen-based compounds (commercially available). You can cook them yourself.

Here is one of the recipes: bitumen (1 hour) + gasoline (3 hours) - until completely dissolved.

This composition is used to coat the roof over the entire area intended for laying roofing material.

TechnoNIKOL canvases are attached only after the primer has completely dried.

Features of work

- Gluing is carried out from the edge of the roof upwards.

- The roll is placed in the required position, after which it is rolled out a little.

- The edge of the canvas is aligned with the roof cut, heated (blowtorch, gas burner) and fixed to the base.

Next, all the roofing material is gradually glued on. The burner should heat it “from below,” that is, from the side on which the layer of adhesive is located. Moreover, its position is chosen so that both the canvas and the base are heated at the same time. This kind of work (like any other) does not like to be rushed. Therefore, the main rule is gradualism (rolling out the canvas and warming it up).

After securing the first “track”, you need to ensure the quality of fixation of all its edges. If places are found where the material does not adhere tightly to the base, then this area is additionally heated and re-glued.

The laying of the built-up roof must be carried out by two people. While one person is working with the burner, an assistant, using a hard roller, fixes the heated segment of the canvas on the roof.

All other strips are laid using the same method. Their recommended mutual overlap (cm) is about 8 (on the sides) and 15 (at the ends, with a longitudinal connection). “Overlaps” are made so that the fabric covers the bottom one (to prevent liquid from penetrating under the coating).

The joints, as well as the upper edges of the canvases (in the case of their “winding up” on vertical parts) are covered with a special bitumen tape (also sold).

The author once again draws the attention of the dear reader that this is only a general procedure. The main “adviser” in this matter is the manufacturer’s instructions.