To effectively transform electric current into thermal energy, a heating element is used.

A tubular electric heater is used in modern electric boilers, stoves, electric kettles and other devices that provide electrical heating.

Heat is released due to the glow inside this device of a nichrome filament, which runs exactly in the center of the tube and is reliably isolated from its surface by a layer of dielectric. Ceramics are usually used as an insulating layer, which transfers heat well without passing electric current to the outer surface of the heating element.

Varieties

Heating elements come in different shapes, power and heating medium.

The most popular varieties:

Tubular

This design is most widespread in water heating devices. The cost of such elements is quite high due to the stainless steel and nichrome used in their production.

These devices, when manufactured with high quality, can last more than 10,000 hours.

finned

The design of the heating element differs little from the tubular one. The only difference is the perpendicularly located stainless steel fins relative to the main heating device. This design allows you to increase the power of the heating element due to a larger heated surface area.

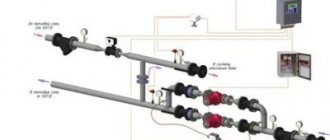

A block of electric heaters that are used in high-power installations, such as electric boilers.

The use of such heating elements allows you not to worry about complete failure of the heating device. In the event that one heating element burns out, the boiler only slightly loses power and continues to function in this state until the time when it is possible to replace the failed heating element without the threat of defrosting the heating system.

Cartridge

Such a heating element is convenient in that it allows you to replace a damaged device even in a water heater filled with liquid in a matter of minutes without depressurizing the tank. Like a cartridge, this element is inserted into a metal shell, which in turn is already in contact with the heated medium.

The cost of such devices is slightly higher due to more precise processing of the heated surface.

Heating element with thermostat

Heaters of this design are used primarily for heating liquids. The thermostat not only allows you to set the required temperature, but also when set to maximum heating does not allow the liquid to boil, eliminating the possibility of such a heater exploding.

Heating elements with built-in thermostats

A heating element separate from the thermostat is rarely used in practice. As a rule, this solution has proven itself only in water heating boilers. Heating elements for heating radiators with a thermostat are much more widespread.

In such “combined” devices, the thermostat is located in a separate tube, and it is easy to replace if it breaks down. When choosing devices in this category, you need to pay attention to the following points:

- Case material. It can be represented by “stainless steel” (the cheapest and most common devices), as well as copper. Copper appliances last longer, but are also much more expensive.

- Power. For a home electrical network, choosing devices more powerful than 2.5 kW is dangerous - there is a risk of overload and short circuit. When using more powerful heating elements, lay a separate power cable.

When choosing a heating element with a thermostat for a battery, you should not focus on expensive models. Practice shows that the durability of devices does not depend on price. The service life is determined by water hardness, loads and stability of the electrical network.

A Question of Choice

Eternal heating elements do not exist today. When heated, the metal gradually becomes thinner at the bending points and sooner or later the filament breaks. Premature failure of heating elements may be associated with overheating; water heating heating elements that are turned on when there is no water in the water heater often burn out in this way.

The correct choice of heating device will allow the device to last for many years without replacing the heating element.

Selection rules:

- It is necessary to check that the seller has documents for the goods being sold. The guarantee that the manufacturer gives for heating elements is also an indirect sign of high quality products. The longer the warranty period, the more reliable the purchased product.

- The correct choice of heating elements cannot be made without selecting a heating element according to the power required to heat the liquid. If the heating element is less powerful than necessary, then the water will not heat up to the temperature for which the water heater is designed. In the case where the element consumes large electrical power, excessive load on the wiring is possible. Therefore, when replacing this element, it is necessary to select a heating element only of the power for which this water heater is designed.

- When choosing, it is necessary to choose modern power supply shutoff devices. The most advanced thermostats in this regard are those that use electronics to regulate the heating temperature. Devices in which the working element is solid heat elements that expand when heated are outdated and have a limited working life.

- The correct choice is only possible if the device can easily fit in the tank , otherwise the installation of such a heater will not be possible.

- You should be especially careful when choosing a heating element that will be installed directly into the heating radiator. In this case, in addition to the size, an important criterion for choosing an element is the number of the thread on which this device will be installed.

- If you need to replace a burnt heating element , then when you go to the store for a new element, you should take the burnt one with you and choose exactly the same size and markings.

Composition of water heating equipment

The simplest water heating or heating element should consist of at least three elements - a water tank, a heating element - heating element, and a thermostat. The tubular heater can be immersed or dry. In the first case, it is made of stainless steel and placed inside the tank. Water is heated by direct contact of water with the heating element.

Dry heating elements are made of ceramic and are located outside the water tank. Heating of the coolant occurs due to the transfer of thermal energy through the wall of the tank. Such elements are easy to replace if they fail.

The thermostat for the heating element is designed to control and maintain the set temperature of the coolant, as well as for emergency shutdown of the tubular electric heater from the network if the boiling process begins (as a rule, this happens when the heating element breaks down).

There are several types of thermostats, each of which is advisable to use with a specific type of tubular electric heating element.

Installation and replacement

To carry out installation work, you will need the following tools:

- Phillips and slotted screwdriver;

- pliers;

- spanners;

If the heating element is being replaced, then before installing a new element, dismantling of the failed heating element is carried out.

Before starting this operation, it is necessary to turn off the power to the water heater by removing the plug or turning off the circuit breakers on the central electrical panel if the boiler is connected directly.

Installation is carried out in the following sequence:

- It is necessary to thoroughly wash the tank from the accumulated scale and wipe it with a rag.

- The new heating element is installed in such a way that the rubber gasket adheres evenly to the surface of the parts being connected. All threaded connections must be tightened to the required torque. When the heating element is installed, electrical wires are connected to it.

- Then the bottom cover is installed and the boiler is filled with water. If there are no leaks, then you can connect the water heater to the electrical network.

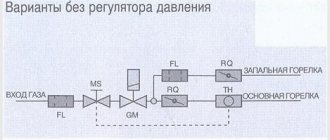

Types of thermostats

The boiler itself is quite simple. You can even install and connect the device yourself. But when choosing a unit, you need to pay attention to what kind of thermal relay is installed in it. For example, if it has temperature control or lacks it. There are several types of thermostats , on the basis of which water heaters are divided into several types:

- Programmable or simple. This affects temperature management.

- Electromechanical or electronic. The control of the device depends on this.

- Mortise or overhead. The installation of the unit depends on this.

The most common types are rod, electronic and capillary thermal switches. Rod models are obsolete and consist of a tube 35 cm long and 1 mm wide. Their operating principle is as follows. When exposed to high temperatures, the tube expands in size, causing pressure on the switch . The disadvantage of this model is its inaccuracy. Because the tube cools too quickly, the boiler runs longer than necessary.

Price

Heating element block with Ariston type thermostat (I)

This device has a built-in thermostat that allows you to adjust the operation of the device to heat the liquid in the range of +20 - 80 degrees. The working surface of this device consists of copper, which promotes maximum efficient heat transfer.

Price – 1000 rubles.

RCT 3.0 KW M6

This device can be used both in factory water heating installations and in self-made water heaters. The heating element body has a hole for installing a thermostat, which is purchased separately.

Cost – 1200 rubles.

TENB-9 stainless steel 220/380V

Heater block for water boiler. On one flange of this device there are 3 elements with a total power of 9 kW. The heating elements are reliably isolated from each other, which allows you to regulate the heating power of the liquid. The heating element is made of stainless steel, this protects the heating element from corrosion and allows the equipment to operate without failure for up to 5 years.

Features of heating elements for cast iron batteries

Tubular electric heaters for conventional and cast iron radiators are practically no different. The only exception is the material of the plug - it must be made of cast iron or an equally heat-resistant material.

In addition, the shape of the outer part of the housing where the thermostat is installed may also differ. In this case, the length of the heating element should be 5-10 cm shorter than the length of the radiator. Otherwise, water circulation and heating cannot be achieved. Therefore, before purchasing, make sure that the heating element with a thermostat is designed for cast iron batteries.

Water heating elements

Sale of water heating elements

Electric water heating elements convert electrical energy into heat and are used in a variety of containers for heating water, solutions, acids, etc. This could be a washbasin, a garden shower, a barrel, a bathtub, a distiller, etc.

Description of water heating elements

Another name is a tubular electric heater. It consists of a copper or steel tube filled with a heat-conducting dielectric and an incandescent filament. At the ends of the tube there are fittings with contacts and threads for securing the heating element. Under the influence of current, the filament heats up and transfers heat through the dielectric to the tube, and it, in turn, to the external environment.

Heating elements differ in power, center distance between fittings, threads for fastening, material, and dimensions. There are heating elements made of stainless steel, and there are copper ones.

Water electric heating element or heating element for wide application wholesale and retail at low prices. An order can be placed on the website or by phone.

Heating element with thermostat for water heater

Today, modern household water heaters successfully cope with the problem of lack of hot water supply. The design of any such device necessarily includes a heating element - a tubular metal rod. It is he who converts electrical energy into thermal energy and then gives it to water, heating it to the desired temperature. The thermostat built into the heating element allows you to set the degree of water heating.

- A heating element with a thermostat is a device of simple design. It consists of several elements, namely:

- A metal tube, the material of which can be titanium, steel, brass or copper with a protective coating against corrosion.

- Inside the tube there is a spiral of wire, which has a high resistivity, which means that when an electric current passes through it, it can become very hot.

- Insulating filler is a material that is designed to prevent the spiral from coming into contact with the walls of the tube.

- Contact rod, which serves to connect the heating element to the electrical network;

- Porcelain insulators located at the ends of the tube;

- Thermal sensor (temperature regulator), which turns off when the set temperature is reached, and turns on again when the water cools down to the lower mark, and so on all the time the water heater is in the on mode.

A water heating element with a thermostat has significant advantages that will ultimately help optimize the water heating process from a financial point of view:

- Thermostats for heating elements allow rational use of resources. When the water in the water heater reaches the set temperature, the heating element turns off and turns on when the water has cooled significantly.

- Simplicity and reliability of design. The water heating element with a thermostat is designed for continuous operation for several years.

- Easy installation. Each water heater model has a special mount for the heating element. Some models provide the ability to use several heating elements simultaneously.

- The low price of a heating element with a thermostat makes it the optimal solution.

Main types

Heating elements come in different capacities. The more powerful it is, the more intensely the liquid inside is heated. Moreover, the thermostat is exactly the part that is the basis. If you have chosen all the technical characteristics correctly and conscientiously follow all the rules for its operation, the water heater will serve for a long time without unscheduled cleaning. So what are they like?

Rod

It consists of a steel tube of small diameter (up to approximately 10 mm) and length (about 25 to 45 cm), which depends on the volume and power of the heater. This thermostat is placed in the heating element tube and it works according to the elementary laws of physics. As the tube heats up, it expands linearly, allowing the switch to be pressed. However, their main disadvantage is inaccuracy and high cost of use. When hot water leaves the tank, cold water entering cools the thermostat very quickly. For this reason, the boiler heats up more than it actually needs, and this increases electricity costs and shortens the service life of its parts.

Rod apparatus

Capillary

This type is considered more progressive. It consists of a polyester body that does not oxidize for a fairly long time. It has a built-in switching device (thermal regulator). Its operation occurs on the principle of the volume of expansion liquid in a capillary tube (the same physical law as in the previous one). The expansion liquid inside the cylinder, which differs in density, changes its density when heated, after which it acts on the installed membrane and turns off the power supply. Compared to rod devices, such devices are more accurate in their readings and, as a result, more economical.

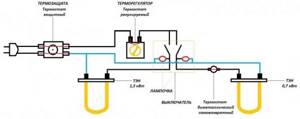

Electronic

Electronic is the most modern type, which means the most accurate and safe.

In turn, they come in two types: safety thermostat and control thermostat. If it is empty at the moment when voltage is supplied to the heating element, then the protection will turn on and turn off the power.

Other types

- Electronic and electromechanical. The first works thanks to special electronic sensors. The second is due to bimetallic elements.

- Simple (the required degrees are set manually) and programmable (higher accuracy).

- Overhead (with electronic control are used most often) and mortise (more intended for mechanical control).

- Designed for boilers with indirect (indirect) heating. They will significantly save your money because they heat water using only power for the heating device. But the liquid that circulates in the heating system cannot heat up above the level that was initially set.

Peculiarities

The thermostat is responsible for the safe operation of the water heater and turns off the heating element when the temperature reaches the set value. If for some reason the thermostat is missing or faulty, then when the temperature, and therefore the pressure inside the sealed housing, increases, an explosion may occur. Therefore, the safety of others depends on the correct installation and operation of the thermostat. Modern models are equipped with an emergency shutdown function for the heating element when there is a low level or complete absence of water in the tank, which is very convenient in case of interruptions in water supply, poor pressure and frequent shutdowns.

The operating principle of the thermostat is quite simple. It consists of opening the contacts of the heating element when the temperature reaches a given point and connecting them when the liquid temperature drops below a given value. Almost all models of thermostats are equipped with an indicator light that shows what state the device is in: a lit light indicates the operation of the heating element, and an extinguished light indicates that the water has been heated to the set temperature and the boiler can be used.

The desired temperature is set on a special electronic display or using a mechanical switch, depending on the model, and can be changed at any time at the user’s request.

More modern and high-tech devices, in the event of a malfunction of the electric heating element, will instantly disconnect it from the network and prevent electric shock while taking a shower with an ungrounded boiler. Also, some models of thermostats are capable of performing their functions even if the electronics fail.

In such cases, an emergency shutdown of the device occurs when the temperature reaches 95 degrees, and in the latest generation boilers - at 105 degrees.

Modern boilers, as a rule, are already equipped with thermostats, among which there are rod, electronic, bimetallic and capillary models.

A rod thermostat is the most common type of household thermostat and is presented in the form of a small tube that expands linearly as the temperature rises and puts pressure on the switch relay. The reverse process with the inclusion of heating elements occurs when the water in the tank cools and its temperature drops below the specified values.

Among the advantages of models of this type, one can note the low cost of devices; the disadvantages include some inaccuracy in operation associated with the proximity of the device to the cold water supply system, which is why the operation of the thermostat is often not entirely correct. Due to constant cooling, the device does not have time to react to the heating of the liquid and does not turn off the heating element. Therefore, the temperature of water from boilers equipped with rod thermostats often exceeds the set values.

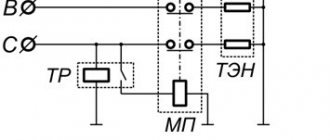

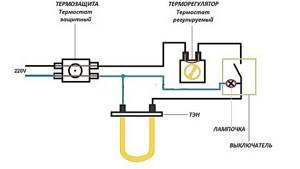

Connecting the heating element

Let's consider the principle of operation and the connection diagram.

They are used for boilers and heating boilers. We take a universal one for 220V and 2-4.5 kW, a regular one, with a sensitive element in the form of a tube, it is placed inside the heating element, in which there is a special hole.

Here we see 3 pairs of heating elements, six in total, you need to connect as follows: set zero to three and phase to the other 3. We insert our device into the open circuit. It has three contacts, in the photo below you can see one in the center at the top and two at the bottom. The upper one is used to switch to zero, and which of the lower ones to phase should be checked with a tester.

We set the regulator to minimum - we ring the lower left with the upper with the tester - there is a sound signal, but not on the second, now we increase the degree and the tester rings the lower right with zero. This means that the power comes to zero (upper) and goes from it to the heating elements, i.e. are powered up. And the lower left pin can be used for an indicator to indicate when the heating element is turned off.