The thermostat is designed to maintain a set temperature by controlling heating (cooling) elements.

These devices come in several types, ranging from simple mechanical ones to electronic multifunctional and even smart devices.

The principle of operation is that the device has an external temperature sensor, which reports the ambient temperature to the device. This device is used to maintain and adjust the given limit. They are used for maintenance in various devices, such as: refrigerator, heated floor, water heating or heaters, incubator, greenhouses, etc.

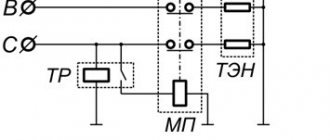

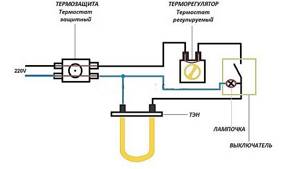

Connecting the heating element

Let's consider the principle of operation and the connection diagram.

They are used for boilers and heating boilers. We take a universal one for 220V and 2-4.5 kW, a regular one, with a sensitive element in the form of a tube, it is placed inside the heating element, in which there is a special hole.

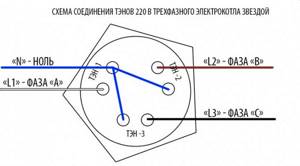

Here we see 3 pairs of heating elements, six in total, you need to connect as follows: set zero to three and phase to the other 3. We insert our device into the open circuit. It has three contacts, in the photo below you can see one in the center at the top and two at the bottom. The upper one is used to switch to zero, and which of the lower ones to phase should be checked with a tester.

We set the regulator to minimum - we ring the lower left with the upper with the tester - there is a sound signal, but not on the second, now we increase the degree and the tester rings the lower right with zero. This means that the power comes to zero (upper) and goes from it to the heating elements, i.e. are powered up. And the lower left pin can be used for an indicator to indicate when the heating element is turned off.

Power regulator for Ten buy in Moscow

Delivery across Russia

Technical characteristics of the 4kW power regulator:

Power regulator 4 kW

stabilized with cooling system and built-in fan

20-80% without condensation.

Technical characteristics of the voltage regulator 6kW:

Voltage regulator 6 kW

stabilized with large cooling system

20-80% without condensation.

The power regulator 4kW and 6kW is an electronic triac voltage regulator of alternating current, allows you to regulate it in the range from 0 V to input voltage (220 V). Thanks to the wide range of adjustment and high power, the regulator will find wide application in everyday life. Can regulate the power of heating elements and incandescent lamps, i.e. regulates the resistor load.

Operation of the device, troubleshooting, tips for efficient operation

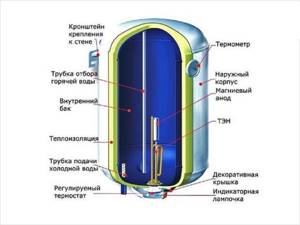

The thermostat for a water heater is one of the components of the boiler protection system (the second is a safety valve). It is needed for convenient operation - thanks to it you can always find out how much stock is currently in the container.

The thermostat also controls the heating process and prevents overheating. If it fails, it needs to be replaced. We can say that this is an element that stops the action of the heating element (heating element) when the temperature has approached the established limits. In the event of a breakdown, the temperature will begin to rise and enormous pressure will form in it. After some time this may lead to an explosion.

Therefore, proper operation in general, as well as individual parts, will save your money and ensure safe use. It is for this purpose that this article will reveal the principle of operation, types, technical problems, diagnostic methods and tips for effective operation.

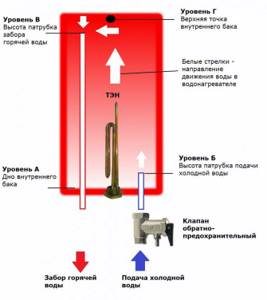

Principle of operation

Externally, they may be very different, but basically their operating principle does not change much. The main part is the heat-conducting rod. It expands when heated and sets in motion a system of contacts, which in turn disconnect the heating element from the network. As the rod cools, its length gradually decreases. Then the thermostat transmits a signal to the heating element, which will soon put the heating element into action again. The temperature that the regulator must maintain is set by the user himself in accordance with his needs.

In short it can be described as follows:

- Setting the desired temperature level using a lever, button or switch

- Measuring temperature and turning on the heating element if necessary

- When the desired division value is reached, the heating element turns off

- after cooling, the thermostat starts working again and heating starts again

Today, there are devices that have an additional function - turning off the electricity supply to the heating element in the event of a breakdown. Thanks to this, the safety of use is increased and the risk of electric shock is prevented.

Types of electric heaters for heating

TENs were invented at the end of the nineteenth century in America. A patent for this was received in 1896. The very first products were a spiral insulated with ceramic material and inserted into a metal tube. Such electric heaters for heating were practical products, but unsafe to use. Mass production of these devices began 50 years after their invention. Since that time, TENs began to be widely used and became one of the most popular heating devices operating from the electrical network. Since then they have changed a lot, they have become more perfect - you can see what they look like now in the photo. Modern devices differ markedly from the very first models, but the principle of their operation remains unchanged.

Main types

Heating elements come in different capacities. The more powerful it is, the more intensely the liquid inside is heated. Moreover, the thermostat is exactly the part that is the basis. If you have chosen all the technical characteristics correctly and conscientiously follow all the rules for its operation, the water heater will serve for a long time without unscheduled cleaning. So what are they like?

Rod

It consists of a steel tube of small diameter (up to approximately 10 mm) and length (about 25 to 45 cm), which depends on the volume and power of the heater. This thermostat is placed in the heating element tube and it works according to the elementary laws of physics. As the tube heats up, it expands linearly, allowing the switch to be pressed. However, their main disadvantage is inaccuracy and high cost of use. When hot water leaves the tank, cold water entering cools the thermostat very quickly. For this reason, the boiler heats up more than it actually needs, and this increases electricity costs and shortens the service life of its parts.

Rod apparatus

Capillary

This type is considered more progressive. It consists of a polyester body that does not oxidize for a fairly long time. It has a built-in switching device (thermal regulator). Its operation occurs on the principle of the volume of expansion liquid in a capillary tube (the same physical law as in the previous one). The expansion liquid inside the cylinder, which differs in density, changes its density when heated, after which it acts on the installed membrane and turns off the power supply. Compared to rod devices, such devices are more accurate in their readings and, as a result, more economical.

Electronic

Electronic is the most modern type, which means the most accurate and safe.

In turn, they come in two types: safety thermostat and control thermostat. If it is empty at the moment when voltage is supplied to the heating element, then the protection will turn on and turn off the power.

Other types

- Electronic and electromechanical. The first works thanks to special electronic sensors. The second is due to bimetallic elements.

- Simple (the required degrees are set manually) and programmable (higher accuracy).

- Overhead (with electronic control are used most often) and mortise (more intended for mechanical control).

- Designed for boilers with indirect (indirect) heating. They will significantly save your money because they heat water using only power for the heating device. But the liquid that circulates in the heating system cannot heat up above the level that was initially set.

Automatic heating element power control

In principle, you can use TRM1, but it is two-position (roughly speaking, either 0 or 20 mA). For more precise regulation, you can look at TRM10 (this is a PID controller). The fact is that your device implements 2 control methods: phase and switching when the current passes through zero. If you have the second option, then TRM1 is also possible. If you have the first one, then only TRM10.

Any OWEN sensors will work with this device. The main thing is to decide on the model and length of the mounting part. https://www.owen.ru/catalog/66285948 https://www.owen.ru/catalog/87380592

TRM10 has a second relay (discrete), but it is used as an alarm.

What about the option with two devices? One for the heater, the other for the valve.

The most common breakdowns

How to detect and eliminate:

- The water is too hot (this may occur due to the failure of the structure that performs the regulating function)

- Failure in copper capillary tube. This part itself is very sensitive to various types of mechanical damage. Unfortunately, it cannot be repaired, only a new one can be installed.

- The adhesion of the heating element and electrical connectors is insufficient.

- The thermostat turns on and off very often (the reason is excessive scale formation, which exceeds the permissible limit).

- The water is not heated enough, although the power of the heating element is very high (this occurs when the adjustment is incorrect)

- Malfunction of electrical components (most often this is due to voltage fluctuations in the electrical network; you need to install a means that will provide uninterrupted power supply or a voltage stabilizer)

How to use it correctly

In addition to the banal failure to follow the operating instructions and safety regulations, heating elements can break due to:

- shell corrosion;

- its rupture as a result of overheating;

- constant changes in mains voltage;

- and just a general depressurization of the tube.

In order for the device to heat your home for as long as possible, you need to follow simple rules:

- When connecting the wires, you should not be too zealous and over-tighten the contact nuts of the output ends of the heating element - they may burst.

- The device must be connected to the network only when it is in water. Otherwise, lowering a heated spiral into water can result in a fairly strong explosion.

- The surface of the heating tube must be regularly descaled. It all depends on the quality of the water, but during constant operation, it is best to clean it once a quarter, avoiding scale build-up of more than 2 mm.

- If there are problems with the quality of the power supply, you should connect an uninterruptible power supply or stabilizer.

- For the coolant, it is best to pour distilled water into the system; the percentage of impurities in it is minimal. They are the reason for the appearance of scale on the shell of the heating element.

- Use residual power supply devices (RCDs) - if the heating element breaks down, it will be immediately disconnected from the network.

- Grounding is mandatory.

It's important to understand. Not every heating element can be mounted in a heating radiator

You need to select specialized models in strict accordance with the required diameter.

Let's sum it up

Follow all these simple rules and instructions. They will help you carry out safe and efficient heating of premises with electric heating elements, which can be used to form local heat sources or complement a centralized heating system.

Diagnosis of failure and selection of a new device

It is quite simple to detect damage in a timely manner in order to avoid unnecessary expenses and maintain your health. What can be detected even with the naked eye is that the water has stopped heating. To check its functionality and serviceability, remove it from the heat exchanger itself, and then put it to measure resistance (Ohm). A special tester is used for this. If the tester does not show any reaction (no changes occurred on the device screen during testing), then we can conclude that the device is faulty and needs to be replaced with a new one. Thermostats cannot be repaired.

We would like to draw your attention to the fact that any independent actions for the purpose of inspection or repair without the appropriate knowledge, skills and compliance with safety rules can cause injury. It is better to seek help from a specialist.

It is best to choose a new one from the same company. Thus, all their parameters will coincide and function smoothly. The form and principle should be similar to the previous one. It is determined by the temperatures that need to be regulated, the quality of the materials from which the device is made, the brand, manufacturer, etc.

At first glance, it may seem that the heating element plays a key role. Some people think that the most important thing is the volume of the device. But experts say that you should not forget about quality and service rules. Set adequate heating degrees, the power of the heating element, carry out regular checks, and also be attentive to the main “symptoms”. This way you will protect full functionality and make it safer for you and your family. Moreover, the service life of household appliances will be extended, and finances will be saved.