Floor heating systems are becoming increasingly popular today. For many, this is an opportunity to get comfortable coverage under their feet, while others even make a “warm floor” the main source of heating in the house, which can significantly reduce costs during the heating season.

How to implement heated floors if you want the floor covering to be PVC tiles? There are different heating systems, and the range of PVC tiles is very wide. What to choose? We were not too lazy to interview PVC coating manufacturers and put together the requirements and recommendations for laying PVC tiles on “warm floors”.

Quartz Vinyl Adhesive Tile

Quartz vinyl is a mixture of vinyl and quartz sand. The more quartz in the tile, the more stable the material. The stability of geometric dimensions largely depends on temperature. When heated, the material expands, and when cooled, it contracts. When using adhesive quartz-vinyl tiles with “warm floors”, a mandatory requirement is a dry screed (the base must have a residual moisture content of no more than 3%) and the use of two-component glue.

Before laying the tiles, the heating system must be turned off 3-4 days in advance, and turned on no earlier than 72 hours after completion of installation.

Quartz-vinyl tiles Art

East

, as the manufacturer assures, are suitable for use with floor heating systems, but water systems are not recommended. The base temperature is no more than 28 degrees. It is recommended to choose a two-component glue (Homakoll 797 or Forbo 144). When heated, these adhesives do not restore their adhesive ability.

PVC tiles Decoria

rigid, dimensionally stable and has a KM2 fire certificate. Decoria tiles will not become soft when heated. Recommended heating temperature is up to 28 degrees. Suitable for use with both electric heating systems, including film, and water.

Refloor adhesive tiles

contains 30-35% quartz sand. It is suitable for stickers with heating systems, including water ones. And if the heating temperature is not regulated, then, perhaps, only Decoria and Reflor will be able to withstand temperatures above 28 degrees. The main thing is that they are glued with two-component glue and a dry screed.

Alpine

Floor

product representative states that the main limitation for their quartz vinyl tiles is that the heating temperature should not exceed 28 ° C.

The recommended adhesive is Homakoll 164. It is better to combine Alpin Floor PVC tiles and cable heating systems. From practice, brand representatives concluded that water and infrared floors are difficult to set to a stable temperature of 27-28 ° C. It turns out that the temperature at different points is not the same, which can cause defects in the seams.

Vinyl Adhesive Tile

Vinyl tiles are a fairly soft material. When heated, the tile expands greatly. Changes in size can be affected not only by the floor heating system, but also by exposure to direct sunlight. But still, some manufacturers consider it possible to use their vinyl tiles and the “warm floor” system.

Tarkett company

gives the following instructions:

Do not install Art Vinyl tiles on a heating system that does not prevent condensation on the substrate.

Do not allow the temperature of the base surface to heat above 27 ° C.

Before laying modular tiles, the heating system is turned off 3-4 days before the start of work.

Laying is carried out at a room temperature of 15-28 ° C, optimally at 20 ° C.

The heating system is connected no earlier than 72 hours after installation is completed.

Experience shows that when heated above 27 ° C, Tarkett, Forbo vinyl tiles become soft, so we, as experts, do not recommend laying vinyl tiles on “warm floors”. We believe that this material can diverge at the joints and deform under the influence of heat.

Pros and cons of underfloor heating with quartz vinyl tiles

Quartz vinyl tiles have good moisture resistance

Quartz vinyl tiles are a modern finishing material that has the following advantages:

- Multi-layering. Each layer is made from environmentally friendly, safe raw materials. When heating a heated floor, the finishing coating does not release harmful substances into the environment.

- Moisture resistance. This flooring is universal and can be used in rooms with high humidity. This is convenient, since electric heated floors are often installed in the bathroom.

- Wear resistance. If we compare the coating with laminate, in terms of wear resistance it corresponds to class 32.

- Practicality. The coating is easy to care for, it does not absorb dirt and can be cleaned with simple detergents.

- Fire resistance. This material does not burn and does not support a flame, so it can be used in rooms with high fire safety requirements.

- High thermal conductivity. A system with such a coating will heat the room evenly.

- Soundproofing properties. The multilayer structure dampens shock waves and noise up to 19 dB.

- Maintainability. A separate element can be easily removed and replaced with a new one. You don't need to call a professional to do this. During the operation of an electric heated floor, it may be necessary to replace a section of the cable. The finishing coating is disassembled during the repair and assembled after its completion.

The adhesive method of laying vinyl tiles makes it difficult to dismantle it

Like any other material, quartz vinyl has disadvantages:

With the adhesive installation method, it will be difficult to dismantle the tiles. The surface of quartz vinyl laid on a concrete base is cool and uncomfortable to the touch

Therefore, a warm floor in such conditions will be more than appropriate. Gaps form between the tiles - this is the main difference from rolled materials. It is important to carefully level the base before laying tiles. Otherwise, all its defects will be noticeable.

Interlocking quartz vinyl tiles

When laying interlocking tiles on a “warm floor”, the condition must be met - to leave compensation gaps along all walls from 5 to 10 mm. The gaps allow the tiles to move as they expand without damaging the joints.

Art

East

interlocking tiles are recommended for use with electric heating systems; it is not advisable to use water heating. Heating temperature no more than 28 ° C. In general, interlocking tiles are sensitive to temperature changes and change their size. The temperature gap must be left at least 1 cm. This applies to installation with “warm floors” and use on balconies and rooms on the south side, where heating in the sun may occur.

Necessary materials

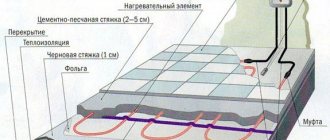

Standard equipment for a film heated floor system

- Thermal film in a roll;

- Contact terminals;

- Set of wires;

- Bitumen insulation on a self-adhesive basis.

- Thermal reflective insulation;

- Heat-resistant polyethylene film;

- Thermostat and mounting box for it. It is selected based on the selected power of the heated floor and the type of installation (built-in or surface-mounted);

- Additional temperature sensor if necessary (one will be included with the thermostat);

- Double sided tape;

- Additional wire for mounting a thermostat. It may also be needed if you install several sets of heated floors in one room (you will need to add up their power to calculate the cross-section). The wire cross-section is selected depending on the power of the system and the material of the purchased wire (see table).

| Wire cross-section, mm2 | Maximum permissible power consumption with copper wire, kW | Maximum permissible power consumption with aluminum wire, kW |

| 1,5 | 3,5 | 2 |

| 2,5 | 5,5 | 3,5 |

| 4 | 7 | 5,5 |

| 6 | 9 | 7 |

Vinyl tiles with locks

Vinyl laminate, like vinyl adhesive tiles, is soft, becomes even softer when heated and is sensitive to changes in size due to temperature fluctuations.

Tarkett says the Dream House Castle Collection can be installed over heated floors, including those with a hydronic system. In this case, the heating system must be connected and operating for at least 4 weeks before installation. The maximum temperature on the base surface is 27 °C. A temperature gap of at least 5 mm is required. To do this, during installation, spacer wedges 5 mm thick are installed between the wall and the first row of vinyl laminate.

Types and types of fastening of quartz vinyl panels

There are several ways to connect tiles:

- Using adhesive locks. Each tile has 4 adhesive strips: 2 external and 2 internal. Thanks to them, the panels are connected to each other. The gap between them is invisible, even by touch it is very difficult to determine. This type of panel must be laid on a flat surface. In the reviews, many write that it is not necessary to remove the old coating, the main thing is that the base is level.

- Glue installation. In this case, the quartz vinyl tiles do not have any locks and are attached to the base of the floor using special glue. This material is attached only to a perfectly leveled surface, preferably on a cement screed treated with a primer solution.

- Glue method. The entire back side of the quartz vinyl panel is coated with a compound that provides adhesion to any type of surface. According to reviews, most people use this method of attaching tile material.

- Groove method. It is similar to the connection of tiles, where there is a tenon on one side and a groove on the other. To install this coating, you also need a flat subfloor surface.

- Connection with a lock. The basis for it is plastic, with spikes located along the edge in such a way as to be fixed in special locks that are located on the adjacent panel. To install tiles with a locking joint, a flat surface is required, since this material is not flexible and ductile enough.

Which PVC tile should I choose for laying on a “warm floor”?

By analyzing the manufacturers' recommendations, the composition of the material, as well as the experience of those who have already laid PVC tiles on heating systems, you can understand which tile is better suited for this purpose.

We would not recommend using vinyl tiles. Still, quartz vinyl is more suitable for conditions of temperature changes and heating. This material is more stable in size, which means that the joints of quartz-vinyl tiles are less likely to break.

If you need adhesive tiles, then Decoria is probably the best option. This tile is suitable for use with any system. You can also choose ReFlor tiles.

Of the quartz-vinyl laminates, Decoria Click and Art Stone win – as the most rigid and dimensionally stable. Art Stone can be used with any heating systems.

If the heating system is cable, you can also choose any ART EAST, Alpine Floor collection. For heating with a water system, interlocking Art Stone, adhesive Decoria and Reflor are suitable, because they can withstand heating above 28 ° C.

Still have questions? Ask our specialists at 8(495)514-56-67.

Keep your feet warm and your head cool . Vinyl flooring is compatible with the most commonly used underfloor heating systems: water, electric and film (infrared). Experts argue about the advisability of using heating in conjunction with quartz vinyl tiles. The fact is that high-quality quartz vinyl is not inferior in thermal conductivity to floor coverings made of natural wood.

That is why the use of heating is unnecessary ; it is recommended only in special cases, for example, on the ground floor, in a bathroom or toilet, on a balcony or loggia, in a children's room, corridor or hallway.

The content of the article

Vinyl laminate and PVC tiles are ideally compatible with heated floors: FineFloor, Vinilam, Decoria, Aquafloor, Corkstyle Vinyline, NOX, Alpine Floor, Art East, Pergo, IVC Moduleo . Observe the temperature regime (heating up to 28°C) - heated quartz vinyl will last a long time!

Tips for choosing flooring

From the assortment presented on the consumer market, the consumer himself decides which floor to choose for his living space. But still, the general opinion of construction specialists and professional designers agreed that it is better to combine the aesthetics of the interior with the technical qualities of the flooring. So, according to their recommendations, it is advisable to make a warm floor in each room using different materials.

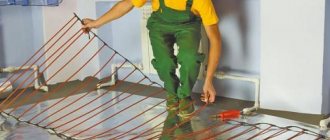

Water floor pipe laying step

Let's look at a few tips on how to make a heated floor comfortable and beautiful at the same time.

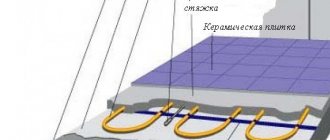

Ceramic tile

Ceramic tiles are ideal for rooms such as:

For the bathroom and toilet it is rational to choose a corrugated product. In this case, your bare foot will not slide on the floor.

It is better to choose ceramic tiles for corridors in dark colors that will hide accumulated dust and dirt.

In kitchens, it is recommended to place products in light colors, due to which you can visually expand the space of the room.

Linoleum

This material is suitable for all types of rooms. When choosing a color scheme, you should take into account the interior of the rooms. The right combination will create an interesting design for the room and emphasize the good taste of the owner. The only place where you can't put linoleum is in bathrooms. High humidity in this room will quickly deteriorate the material.

Laminate

Laminate has a fairly reasonable price, but at the same time perfectly imitates natural wood or parquet boards. Such products will look good in offices, living rooms and kitchens. But in children's playrooms and bedrooms, it is not recommended to install laminate flooring for heated floors. Evaporation of phenol-formaldehyde resins can adversely affect human health.

Having considered the types of flooring that are suitable for a water system and which should be abandoned, beginners will not make mistakes when choosing them. After all, not only the aesthetics of the room design, but also the quality of its heating will depend on a correctly made decision. But don’t forget about installation. Properly performed work will also ensure a long service life of the water heating system as a whole.

Advantages of using quartz vinyl flooring and heated flooring

- Thermal conductivity. Quartz vinyl tiles retain heat.

- Fast heating. Thanks to the small thickness of PVC tiles (up to 7 mm), heat spreads quickly and evenly.

- Environmental Safety. There are no harmful and toxic additives in the structure of quartzvinyl: there is no emission when heated.

- Antistatic. Static voltage does not accumulate on the surface, PVC tiles do not conduct current, and are absolutely safe in combination with a film heating system.

- Stability. Quartz vinyl tolerates temperature changes without consequences.

- Versatility. Quartz vinyl tiles of adhesive or lock type are compatible with all types of heating, except infrared film type .

It is not recommended to use quartz vinyl in conjunction with infrared heated floors : the mats may short out, which will lead to overheating of the surface. For PVC tiles, heating above +50°C is critical. If you choose a high-quality film floor, we use interlocking PVC laminate with glue-free installation.

Warm floors for vinyl laminate - reviews from professionals

There are many reasons why PVC tiles are gaining popularity among consumers of finishing floor materials every day. Until recently, the most popular budget covering was linoleum. This is a pretty good material for any premises, but only under proper conditions of use. In addition, it is quite heavy when rolled, so it is not convenient for transportation. If you accidentally tear the linoleum, it is very difficult to repair the floor, since in order to completely eliminate the problem it is necessary to completely replace the rolled material.

Vinyl tile structure

PVC tiles have a multilayer structure, which allows the material to have such necessary qualities. To make the bottom and middle layers, durable liquid vinyl, polyvinyl chloride and a small part of plasticizers are used. This complex is perfectly combined in the material, making it plastic, hard, and resistant to deformation. The dissimilar layers in the tiles make them pleasant to walk on because they are much warmer than tiles.

Fiberglass is added to the main bottom layer, which appears as a rough surface. Thus, good adhesion of the vinyl element to the base is achieved during installation.

Multilayer structure of PVC tiles

The middle layer of the tile contains colored PVC. It is he who determines the variety of tiles and their patterns. The top layer is also commonly called protective; the durability, reliability of the material, and its resistance to aggressive factors depend on it. This layer forms a transparent polyurethane coating. In the manufacture of vinyl tiles, high pressure is used, which ensures such strength characteristics of the material.

Advantages of PVC tiles

- Compared to linoleum, which is similar in structure, PVC tiles are much easier to transport;

- polyvinyl chloride materials are durable and hard;

- the opportunity to show imagination when styling, make bold compositions from different colors and patterns, and experiment with order;

- moisture resistance, lack of tendency to bloat, deformation;

- ease of repair, damaged tiles can be easily replaced with new ones, without dismantling all the floor material, as is the case with linoleum;

- decent sound and heat insulation;

- The tiles can be easily adjusted to the required measurements without having any special tools.

Checkerboard pattern tiles

Procedure for laying PVC tiles

Since in the case of laminate, it is advisable to lay a special backing under the vinyl tiles. Typically, in this case, the underlayment has an adhesive bottom that provides a quick and strong bond to the subfloor.

Laying PVC floor tiles

Step-by-step instructions for laying PVC tiles consist of the following key points:

- The working base must be level, dry and treated with a primer to increase adhesion;

- The center of the floor is considered the optimal starting point; the first beacon tiles must be glued along the axes defining this place;

- Starting from the beacons, all the other tiles are glued one after another until the boundaries of the room are reached.

- The tiles are glued to a special glue; in extreme cases, regular PVA will do. It can be applied to both tiles and floors. After this, the element is pressed tightly to the floor and rolled on top with a heavy roller to release the air cells and, therefore, increase the adhesion strength to the base. Sometimes you may need double-sided tape, so make sure you have it handy.

- Exposed glue must be removed immediately, then lay the next tile, etc. Most likely, the tiles near the walls will have to be trimmed. An ordinary knife will help to carry out this operation. If you heat the tiles with a hairdryer before cutting, the cutting process will be significantly simplified.

A spatula, knife and glue are the main tools for laying PVC tiles

- When buying tiles, you need to take into account that some of them will be used for scraps, so it is advisable to buy 2-3 square meters more. It’s okay if the tiles remain after installation; if necessary, they will later be used to repair the floor.

- Before laying the tiles, they must be given time to adapt to the specific conditions of the workroom. To do this, it is enough to bring the tiles into the room at least a day before the actual work begins.

- The minimum temperature in the room where installation is planned is 18-20 degrees.

- The baseboards around the perimeter of the room need to be removed and put back when the job is finished. If strong fastening points do not allow this, you can use restrictive tape.

- In order to eliminate the possibility of damage to the pattern, it is better to trim the tiles from the front side.

Laying PVC tiles on a tiled base

Interesting characteristics of PVC tiles

The appearance of the tile creates an excellent imitation of various natural materials. Products from reputable manufacturers are practically no different from their natural counterparts in terms of texture and pattern. The consumer has the opportunity to buy tiles that ideally replicate metal, marble, wood, etc. Using different combinations in finishing, you can achieve the most unusual results. The main thing is that this matter is handled by a professional.

By following the rules and recommendations for proper installation, you can achieve a monolithic effect, when it is difficult to discern the presence of joining seams on the surface. Spacious rooms look perfect in this design.

Advantages of PVC tiles

An innovation in the modern flooring materials market is PVC tiles with a three-dimensional pattern. It is beneficial to use such options in a small room, since such a floor can visually expand the volume of space.

Design features of PVC tiles

The material we are considering boasts precise geometry. This is very useful, because the issue of using moldings and other similar devices in the process of laying the floor disappears by itself. If desired, the installation of the floor from start to finish can be done independently, without involving any extra hands and saving a lot of money. As for the necessary tools, there is nothing special here. The entire arsenal can be assembled with four tools: a spatula, a rubber mallet, a heavy roller, and scissors. To make the cutting process easier, the list should also be supplemented with a hair dryer.

Features of choosing PVC tiles

Due to the special specifics of the tiles, during the installation process there should not be any special problems with access to communications. Even in the most difficult to reach places, the tiles fit perfectly. The material is very flexible and does not crack when folded. There is no need to worry that if heavy materials fall, it will crumble into pieces. If we compare PVC tiles with expensive commercial linoleum, then in terms of strength they are superior to their closest competitor. When installing, pay special attention to ensuring minimal seams.

Adhesive for PVC tiles

The new floor cannot be put into use immediately; you must wait two to three days for the glue to dry completely. Floor cleaning is carried out using a wide variety of detergents.

Underfloor heating system and PVC tiles

PVC coating is fully compatible with underfloor heating systems. It would be better if it was an infrared floor made of film elements. Basically, the need for floor heating arises in those rooms where there is no possibility or need to install another heating system. For example, why install a battery or convector in the hallway, if the tool can be hidden under the floor much more efficiently. The underfloor heating system allows you to maintain the room temperature at an optimal level.

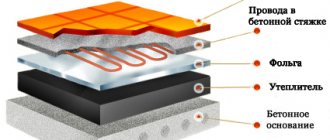

Film heated floor

Material, tools and other devices

To install a heated floor you will need the following set:

- vinyl tiles with a small supply;

- plywood (not always);

- a complete set of infrared floors with all components necessary for complete installation;

- cables for connecting adjacent strips;

- wires for connecting the thermostat;

- vapor barrier film (ordinary polyethylene film) to protect the electrical components of the coating and the vinyl itself from the negative influence of moisture coming from the base;

- heat-insulating screens under heated floors;

- tile adhesive.

Installation of film flooring under tiles

Basics of Safe Use

In order for the infrared heating system to be safe, it is important to make competent calculations and installation, according to technological recommendations:

- install the floor on a flat and dry surface;

- make gaps between sheets of the product of at least 0.5 cm;

- provide grounding;

- choose a film floor and a thermostat of the same power;

- connect the heating elements directly to the machine and power it from the meter.

For your information! For more efficient operation of the floor, it is recommended to install an additional temperature sensor; it will monitor the temperature regime.

Film heating can create comfort in the home. Even non-professionals can install an infrared heated floor under ceramic tiles; the main thing is to strictly follow the installation rules for this system.