Home » Equipment » Warm floor

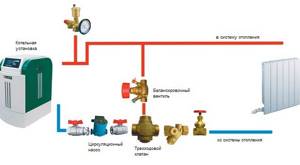

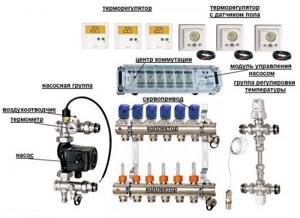

For an underfloor water heating system, it is recommended to install an automatic control unit. The equipment allows you to control the temperature in the room and regulate the operation of the liquid line.

The simplest device for controlling heating is a three-way valve. Its operation can be done manually, using valves, but achieving a certain mode in the room will be difficult.

Purchase thermostatic equipment. It is used in Moscow and other large cities. It allows you to make underfloor heating autonomous. How does a thermostat work? What is its working pattern?

Installing a three-way valve in a heating system: installation nuances

Installing a three-way valve for a heating system is not difficult if you have plumbing skills.

And if the heating system was installed by yourself, then no questions should arise during the process. But when installing the equipment, you should pay attention to its body. It is marked with an arrow in the direction of water flow.

If you ignore the arrow and install the tap in reverse, there will be no talk of any adjustment.

If the system is complex and installation is difficult to understand, it is better to invite a specialist

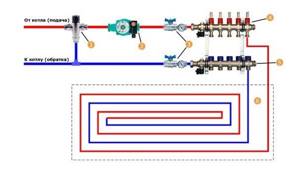

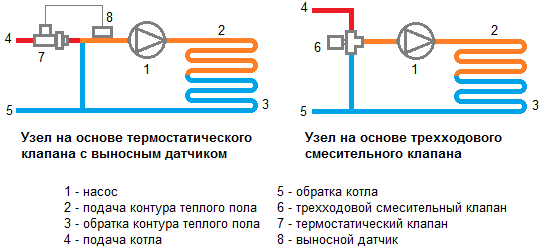

A three-way valve is installed between the boiler and the manifold (if equipped). The tap is connected to the supply, return and output to the heating radiators. In this case, the “return” is mounted as a branch. In other words, the supply of hot coolant passes through a three-way valve, and from the return, using a tee, a branch is drawn off, which connects to the tap.

Installation Features

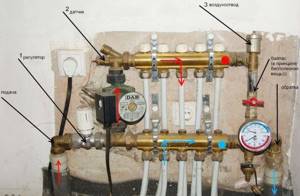

A three-way valve is most often included in a mixing group, which, in addition to the valve, includes:

- check valve;

- circulation pump;

- temperature sensor.

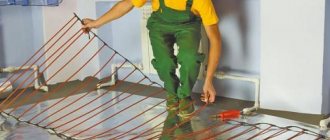

According to this diagram, installation is performed in the following order:

- a pump is installed on the supply, which pumps hot water heated by the boiler;

- after it comes a temperature sensor that determines the heating level of the coolant;

- then a three-way valve is installed to mix the flows to a given temperature.

- a valve with an outlet is fixed on the return circuit and connected to the cooled coolant entering the three-way mixing valve.

As a result, the coolant with the temperature required for uniform and efficient heating enters the water heated floor pipeline.

If it is intended to install a floor heating system in small rooms, then the installation of a three-way valve is carried out without a mixing unit. The installation sequence of the mixing device in this scheme is somewhat different:

- a three-way valve is attached to the hot liquid supply from the boiler;

- after it a temperature sensor is installed;

- then a circulation pump is installed that delivers water with an adjusted temperature to the heated floor circuit.

Main functions and features of the device

Based on the principle of operation of the element, you can guess the origin of its name - a three-way valve performs the main function - it passes water from different sources through 2 channels:

- High-temperature coolant from a supply pipe connected to the central heating riser or boiler-heater;

- Cool water that has cooled during circulation through the water circuit.

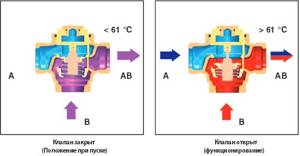

The flows mix with each other inside the valve and leave it through the third valve at a temperature set by the owner. The device operates continuously, since mixing is carried out during each operating mode of the heating circuit in the floor screed.

The operating cycle has the following sequence: heating - heat release - mixing of cooled water - heat release - mixing. The proportion in which streams of different temperatures are mixed must be controlled automatically and continuously.

Otherwise, the performance of heat exchange between the floors and the air in the room will not be directly related to possible changes in temperature degrees. In this case, the owner will have to set the water heating parameters manually.

Heating systems

The presence of a heat-sensitive head allows mixing hot water into the mixer without the participation of the owner. It is she who is responsible for the throughput capabilities of the valve based on the temperature of the mixed water streams, ensuring the specified parameters at the outlet.

Three-way valves can be used in different conditions and have different purposes, so there are several types of them.

Home heating systems with batteries connected to an autonomous boiler require the simplest device. A three-way valve is relatively inexpensive and is simple in design, so you can install them yourself. In this case, the flow mixing volumes are manually regulated by the owner himself.

DHW systems

In the hot water supply, a three-way valve is needed to ensure a safe water temperature - a person should not get burned. The devices have a simple and understandable design and differ from heating analogues in a special protective block, the purpose of which is to shut off hot water if there is no cold water in the pipes.

Water heated floor

The three-way valve as part of the water circuit has a complicated design, since it is needed to maintain the coolant in the specified temperature range depending on the ambient temperature.

The mixer uses a three-way valve to adjust the heating intensity of the home automatically, without the intervention of the owner. The faucet has a handle for adjustment, as well as a printed measuring scale on which you can make manual adjustments.

It is necessary to install a circulation pump that will maintain optimal pressure in the heating water circuit. This is a very important point for the correct operation of the unit in which the coolant is mixed.

Where should a 3-way valve be installed and when is it not needed?

Before selecting a three-way valve, it is advisable to make sure that it is really necessary. After all, on the Internet and in real life there are enough advisers who poorly understand the essence of the issue. So, let's list the situations when this valve is really needed:

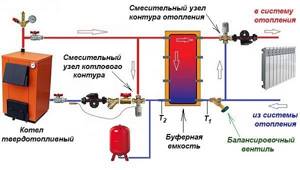

- To protect the solid fuel boiler from the supply of cold coolant and condensation on the internal walls of the firebox.

- To regulate the water temperature in heating circuits.

- To limit the heating of the coolant in underfloor heating circuits.

A lot has been said about condensate, which provokes the formation of sticky growths on the walls of the TT boiler chamber, including. It appears during the heating process, when the temperature in the firebox is already high, and cold water comes from the heating system. To avoid this, the supply and return lines are connected by a bypass, where a 3-way valve is installed. It forces the coolant from the boiler tank to flow in a small circle, and only when heated to 50-60 °C does it begin to add water from the system.

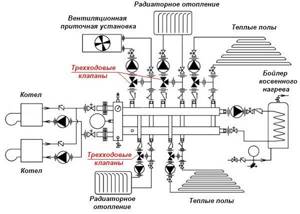

Regulating the temperature in heating circuits using a mixing unit is necessary in the following cases:

- in complex heating systems, when several lines with different temperature conditions must be connected to a common comb, for example, a radiator network, heated floors and an indirect heating boiler;

- when connecting the same consumers to a buffer tank - a heat accumulator;

- when supplying heated water to the heat exchanger of a ventilation air handling unit used for air heating of a country cottage.

Since a coolant with a temperature of no more than 50 °C is sent to the heating circuits of heated floors, and 85 °C can be supplied from the boiler, this should be limited. Usually (but not always!) the issue is resolved by installing a mixing unit with a 3-way valve on the distribution manifold. The latter mixes chilled water from the floor circuits with the “external” coolant coming from the boiler.

Now let’s identify situations where the purchase and installation of a mixer (or separator) is not necessary:

- If the length of each loop of a water heated floor does not exceed 50-60 m, which is quite possible to achieve, then regulation is done without a mixing unit. Instead, RTL type heads are installed on the return manifold, limiting the flow by the amount of coolant.

- When 2-3 heating units alternately operate to heat a private house, maintaining a constant network temperature of at least 40 °C, then there is no need to install a three-way valve for a solid fuel boiler.

- In heating systems with natural water circulation. The reason is the pressure drop across the valve, which prevents the movement of coolant. The same applies to heat accumulators operated according to a gravity flow scheme.

If you are interested in why it is better to choose RTL heads and how they control underfloor heating circuits, watch the video from an experienced master and our expert Vladimir Sukhorukov:

Expert advice

Before choosing control equipment, you need to decide what area needs to be heated. If you will be heating a bathroom, part of the floor of a bedroom or a children's room, there is no need to purchase fittings with a thermal head - it is easier to use a manually operated three-way valve than to install a full-fledged expensive mixing unit.

The cost of a mixing and distribution unit with shut-off and control valves, a manifold, a pressure gauge, and a Mayevsky tap exceeds the cost of all pipelines (if they are made of polymer and not expensive copper).

If the underfloor heating system includes several rooms, then it is necessary to order a project from a qualified plumbing engineer before installation - it will indicate the characteristics of the valve. If there is a large area of heated floors and a large number of rooms, one or more mixing units will be needed.

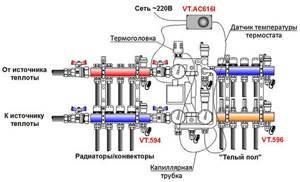

The connection diagram of each unit includes a manifold - a distribution comb, to which heating pipelines are connected. A three-way mixing valve and pump are installed in front of the manifold. The valve can be with a thermal head or with sensors, a controller and an electric drive.

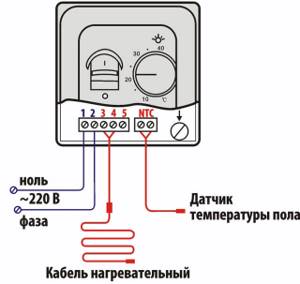

Water floor thermostat sensors

Before using the control device, you need to learn how to regulate the temperature of a heated floor and what elements the system consists of.

Thermostat sensors monitor temperature:

- heated floors;

- indoor air.

The fact is that when installing a thermostat, a number of conditions must be observed:

- there should be no sources of cold or warm air in the immediate vicinity of the device;

- sunlight cannot fall on it;

- absence of drafts;

- it must be placed so that the device can most reliably display the temperature in a given room, which means it must be installed at a height of 1 to 1.5 meters from the floor surface.

A remote floor temperature sensor is a small device attached to the end of a long cable. This device must be fixed to the floor at a distance of no less than 50 centimeters from the walls. It should be installed at an equal distance with respect to the nearest pipes containing the coolant. The opposite end of the cable is brought to the thermostat and connected to the required terminals (read: “Correct installation of the heated floor thermostat and operating conditions”).

Install the floor sensor before pouring the screed when laying the heating circuit. But since devices can break, to ensure the possibility of replacement, it is advisable to place them in a special corrugated sleeve. The end of the hose located in the screed should be insulated, otherwise cement mortar may get into it

The second end is placed in a groove on the wall and placed on the mounting box of the device. This sequence of installing water floor sensors is not an easy task, but if the device breaks down, it can be changed quickly and easily.

In the case where a floor heating system was used, the installation method is similar. In this case, the corrugated hose must be attached to the system and not be pinched.

Three-way valve connection diagram

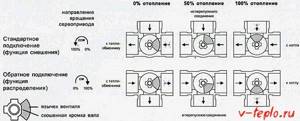

Depending on the direction of flow, the thermostatic valve is available in two models.

- T-shaped or symmetrical design. With this connection, hot and cold water enters through the side holes, and after mixing, the liquid flows out through the central passage.

- L-shaped or asymmetrical design. In this case, hot water comes from one side, and cold water from below. Subsequently, the mixed flow exits from the second side passage.

A mixing tap equipped with a thermostat is installed if it is necessary to ensure a stable temperature of the coolant.

Considering the mixing unit, we can distinguish the following components in it:

- Check Valve;

- temperature sensor;

- circulation pump;

- three-way mixing valve.

Diagram of a mixing unit for heated floors

The connection diagram includes a circulation pump mounted on the supply. Then a temperature sensor is installed, which is necessary to determine the degree of heating of the incoming water. After this comes the thermostatic valve. A check valve with an outlet is mounted on the “return”, which is connected to a pipe with circulating cooled liquid directed to the mixing valve.

With a similar connection diagram, the coolant moves along the following route.

Serial connection type

- Pumping hot water using a circulation pump into the equipped heated floor system. The coolant temperature can reach 80°C.

- Mixing with cold water through a three-way valve. As a result, the desired temperature is achieved.

- Distribution of coolant through underfloor heating pipes.

- The return of the cooled water to the “return”, from where it is taken into the three-way valve for subsequent mixing with the hot liquid.

With such a connection, the temperature sensor regulates the degree of heating of the water entering the water circuit. There are other ways to control. The most ineffective is the manual method, when you need to change the flow by turning the handle. There is a control option using a servo drive, commands to which are received from the controller in accordance with signals received from sensors.

Diagram of components based on three-way mixing and thermostatic valves for heated floors

The thermostatic tap plays an important role when installing a water heated floor. By preventing the coolant entering the pipes from overheating, it saves fuel. In addition, safety is ensured during the operation of a rather complex heating system and the trouble-free service life is extended.

Additional components of the mixing unit

Not only does the three-way thermostatic mixing valve for underfloor heating ensure efficient operation of the system in each individual room. The node includes:

- Thermal head. Ensures continuity and automatic operation of the auxiliary air heating system. If the purchased two- or three-way faucet is already equipped with a thermostatic element, then there is no need to install it additionally.

- Servo. They produce electrical and mechanical devices, as well as equipment with remote control. The device is designed to physically influence the thermo-mixing valve for a heated floor, sending a command to open and close the damper. Thanks to it, it is possible to supply coolant with different temperature characteristics to different rooms of the house.

DIY connection and installation

When connecting, take into account the direction of the coolant; there should be an arrow-shaped indicator at the top of the case.

The valve is installed in a vertical or horizontal direction; its location does not matter:

- In multi-storey buildings

, the working fluid is supplied to the tap through the heating element, then to the pump, into the heating system. The input is designated “A”, the output is designated “AB”. - Next, the supply of cooled water enters the boiler

at the valve assembly at inlet “B”. To ensure that the pressure in the boilers is stable and a certain temperature is maintained, the individual characteristics of the boiler are taken into account; the installation of the device in a particular case may differ. - The units are installed depending on the variations in

their connections with other parts of the pipeline. Typically a valve is installed with a threaded connection.

Step by step installation guide:

When installing, it is important to avoid mistakes, which could damage the pipeline or set the temperature to sudden changes. The factory product must have arrows marked by which you can determine the direction of the moving flow and install the device yourself. Do not allow the tap to overheat.

The installation location must be easily accessible.

When installing a faucet in a coolant containing impurities, additional filters will be required.

Decide on the valve connection location depending on the direction of coolant flow.

Install the valve vertically or horizontally.

Install the lever at an angle within a radius of 90 to 180 degrees. The valve serves to mix cold and hot flows, prevents cold flow from entering the pipeline, otherwise condensation will form, the system will be deformed, cracks will appear at the joints, or become completely unusable

The valve serves to mix cold and hot flows, prevents the cold flow from entering the pipeline, otherwise condensation will form, the system will be deformed, cracks will appear at the joints, or become completely unusable.

Thanks to the mixing tap, the liquid at the entrance to the boiler will be at least 50 g, which eliminates sudden temperature changes; cold water does not have a negative effect on the pipes.

Mixing tap task

— prevent coolant from entering the pipeline at high temperatures. The average range is -75 - 85 degrees.

Valves classification

Without lengthy introductions, we note that the device can be of two types according to the principle of operation. It could be:

- dividing;

- mixing.

The features of each type of action are clear from their names. The mixing device consists of two outputs and an input. In other words, it is necessary to mix fluid flows, which may be required in order to reduce its temperature. By the way, this is the most optimal option for setting the desired mode in the “warm floor”.

The procedure for adjusting the temperature regime is extremely simple. You just need to know about the current temperature indicators of the incoming liquid flows, accurately calculate the required proportions of each of them so as to obtain the required indicators at the output. By the way, this device, subject to proper installation and adjustment, can also function for flow separation.

But the separating valve divides one flow in two, therefore, it is equipped with one inlet and two outlets. This device is used primarily to separate the flow of hot water in hot water systems. Although quite often it is found in the piping of air heaters.

Externally, both options are almost identical. But if you look at their cross-sectional drawing, their main difference is immediately visible. The rod, which is installed in a mixing-type device, has one ball valve. It is located in the center and blocks the main passage.

As for separating devices, the stem has two such valves, which are installed at the outlets. They function according to the following principle: one of them is pressed against the saddle, closing the passage, and the other, in parallel, opens passage No. 2.

According to the control method, modern models can be:

- electrical;

- manual.

In most cases, a manual device is used, which in appearance resembles an ordinary ball valve, but is equipped with three outlet pipes. But electric models with automatic control are used mainly in private homes, namely to distribute heat. For example, the user can set the temperature regime by room, and the working fluid will flow in accordance with the distance of the room from the heating device. As an option, you can combine it with a “warm floor”.

Video - Device in a boiler group

Three-way valves, as well as other devices, are determined in accordance with the pressure in the system and the diameter of the inlet. All this is regulated by GOST. And if the requirements of the latter are not met, this will be regarded as a gross violation, especially when it comes to the pressure indicator in the line.

Brass Fittings and HDPE Piping

We advise you to read our guide to the selection and installation of brass fittings for HDPE pipes, all

Kinds

There are several types of such devices:

- With hydraulic drive.

- With pneumatic drive.

- Electrically driven.

A motorized three-way valve, such as the ESBE model, will have a slightly different operating principle. The electric drive performs the function of a conventional thermostat, which allows you not only to mix flows, but to maintain a given temperature. When the temperature decreases/increases, the drive automatically changes the position of the shut-off valves, increasing or decreasing the cross-section of the hot water flow. At the same time, the cross section at the point of inlet of the cold flow also changes. The result is water with a constant temperature. The ESBE crane does not require any human intervention. Its operation is regulated automatically.

Equipped with electric actuators and thermostats, ESBE valves are equally suitable for use in heating and hot water systems. In principle, the valve can be installed in any pipeline where it is necessary to mix two liquid streams with constant temperature maintenance. No matter how high-quality and reliable a three-way valve with a thermostat is, it will have one drawback that is characteristic of absolutely all devices of this type.

This disadvantage is the strong narrowing of the entrance points. The narrowed cross-section of the inlet point, in turn, increases hydraulic resistance.

Such a faucet will work well in water supply systems. ESBE valves are suitable for installation in underfloor heating systems, but require a special connection diagram. In addition to the designs described above, three-way thermostatic valves are available on the market. These devices are often confused with each other, but they are still completely different. Thermostatic models have a thermostat with a remote sensor, but they differ not only in this element, but also in the principle of operation. Unlike conventional models, in thermostatic taps the flow is regulated at only one point, the remaining two are open and their cross-section does not change. When choosing such a design, you need to check whether there is any narrowing at point 2, otherwise hydraulic resistance will lead to difficulties in the operation of the device. It may be necessary to install a mixing valve in an alternative ring to minimize the problem.

Purpose of using the collector

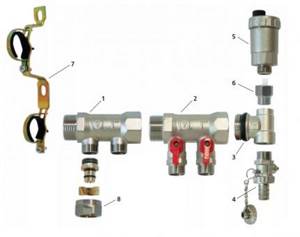

A collector is a device with which the coolant flow is distributed over individual circuits of the water floor and then returned back for heating. The collector unit looks like two pipes with holes to which the system circuits are connected.

The presence of a distribution manifold in the heated floor arrangement makes it possible to control the volume of coolant flow. One of the collector pipes is the supply pipe; hot water flows into it and the inputs of the water floor circuits are connected to it.

The return circuits are connected to the return pipe of the collector. The openings to which this connection is made are usually equipped with threaded, fitting or other connections.

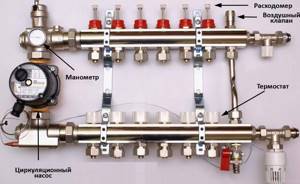

The collector consists of a number of elements such as the collector itself (1 and 2), an adapter for the Mayevsky tap (3); drain valve (4); air vent (5); valve (6); bracket (7); Eurocone (8)

Various devices are also installed here with which you can regulate the coolant flow rates. The simplest version of an industrial manifold is a pipe with a connector called a Eurocone. This is a completely convenient and reliable unit, but it does not allow you to control the flow of water.

To effectively use such a device, you will have to additionally purchase and install a number of elements.

The manifold made in the DPRK is a little more complicated. In addition to the connections at the outlets, valves are installed here; no automatic means of regulating the flow are provided. This is an excellent and inexpensive option for a water floor in a small area with two or three contours of the same length.

Such a system does not require complex management. But on large areas, this type of collector will have to be supplemented with automation.

In addition, the center-to-center distance between the feed and return sections of Chinese devices does not meet the standards adopted in Europe, which can cause problems when connecting it to European-made devices.

Ball valves in such devices are sensitive to low-quality water, and over time they begin to leak. To fix the problem, it is enough to replace the O-rings, but you must take into account the fact that the need for such repairs will arise periodically.

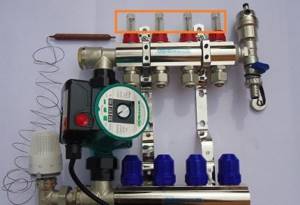

If the operation of the water floor system is intended to be automated, it makes sense to purchase at least a manifold with control valves.

Servo drives can be installed on such valves, connected to thermostats in the rooms. This will ensure automatic control of the coolant flow in accordance with data on the air temperature in a particular room.

To automate the operation of a water heated floor system, flow meters are installed on the collector supply (indicated by a frame), and connectors for servo drives are installed on the return (blue caps at the bottom)

It is most difficult to control a water floor system in which the individual circuits vary markedly in length, but in complex systems this is usually the case. In such a situation, the optimal choice would be a manifold with flow meters installed on the supply, and sockets intended for mounting servos on the return.

Using flow meters, it will be possible to adjust the intensity of the coolant flow, and servo drives in conjunction with thermostats allow you to set the appropriate temperature on each circuit.

If there is no need for automatic control, you can purchase a supply manifold with flow meters, and a return manifold with conventional valve taps.

It happens that it is not possible to choose a collector with the number of connection sockets that corresponds to the project. Then you can take the device “with a reserve”. And the extra holes are simply closed with plugs.

This solution may be useful if you later need to add a couple more loops to the water floor system.

Temperature adjustment

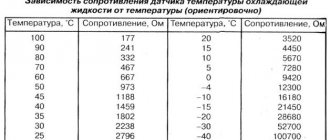

The operating temperature of the underfloor heating fluid may vary depending on the quantity, length of circuits and general operating conditions of the system. The main value is the temperature in the circuits; its value is accepted as the most comfortable in the range of 35-45 degrees (up to 55 if the loops are long).

When supplied from the network, the temperature of the medium is too high, such values are unacceptable for pipelines and high-quality regulation is simply necessary. In some cases, it is necessary to install an intermediate heat exchanger, which heats a separate coolant in the underfloor heating system to acceptable values.

When the system is powered by its own boiler, it is possible to initially set the supply temperature, which simplifies the operation of the mixing unit and makes the system operating mode less aggressive.

Constant control of the coolant temperature is the prerogative of sensors working in conjunction with the system control unit (it is often mistakenly called a thermostat, which is not entirely true). A warm floor is a very inert system that reacts to any impact with a delay. Therefore, constant monitoring of small fluctuations with immediate temperature correction is necessary to avoid significant changes in operating conditions.

Adjustment can be carried out on a simple mechanical principle - like a thermal head - to a complex system of temperature sensors located directly next to the heated floor pipes and collecting information on a common control unit, which, using servo drives, regulates the operating parameters of the system and displays the data.

Three-way valve for heating with thermostat: principle of operation and purpose

Thermostats are installed on radiator passage plugs. If necessary, these devices completely or partially block the coolant flow. The same function is performed by a faucet, however, if you have a thermostat, you set the necessary parameters once, after which the thermal valve maintains the set temperature on its own. Electronic thermal valves provide the greatest accuracy and functionality.

It is important to understand that the thermostat is not capable of changing the initial power of the heat source, but it allows you to wisely manage thermal energy and create comfortable conditions in the room

The principle of operation of the thermostat

The temperature regulator is a two-way device consisting of two main parts:

- valve ("valve");

- thermal head.

Thermostat device:

| Element | Function | Device | Operating principle |

| Valve | Locking mechanism | Consists of a seat, cone and stem. | The operating rod retracts, reducing the distance between the seat and the cone and thereby reducing the flow. As the distance between these parts increases, the flow, on the contrary, increases. |

| Thermal head | Rod control | A heat-sensitive substance is enclosed in a “bellows” (special cylinder). | The operating principle is based on the expansion of gas and liquids when heated. Under the influence of hot coolant, the substance in the bellows expands, pushing the spring-loaded piston. It acts on the rod with a cone in the direction of the seat. When the coolant flow decreases, cooling occurs and, accordingly, the volume of the active substance decreases. The spring returns the piston, cone and rod to their place, and the flow increases. Repeating the cycle allows you to regulate the degree of heating of the radiator with high precision. |

Types of thermostats for radiators

There are several types of classification of thermostats for three-way valves.

Classification of thermostats according to the method of setting the temperature and controlling the temperature regime:

| Thermostat type | Peculiarities |

| Mechanical thermostats | Presetting the device is done using a handle with divisions. The rod is driven by a bellows and a return spring. |

| Manual thermostats | The operating principle is similar to a regular faucet. This model can be easily replaced with a regulator for automatic operation of the valves under changing conditions. |

| Electronic thermostats | They have a digital panel. The energy source is batteries. The temperature of the coolant is taken into account. Allows you to program the mode by time. |

Manual and mechanical thermostats can be divided according to the type of active substance in the bellows. Liquid or gas can be used as a heat-sensitive substance in the bellows; accordingly, thermostats are:

- liquid;

- gas.

Thermostats are also divided according to their purpose. Depending on the features, thermostats are designed:

- for two-pipe distribution systems;

- for single-pipe distribution systems.

According to the connection method, thermostats are:

- corner;

- straight.

Factors for choosing a mixing device for heated floors

Before you begin installing a three-way valve on a warm floor or any other device, you need to consider a number of factors. In particular, the heated area is of great importance.

The least expensive from an economic point of view will be standard valves, but they are used only for small rooms. At the same time, to equip a small room, bathroom or toilet, for example, there is no need to spend a lot of money on a mixing unit. Installing three-way valves will be slightly more expensive, but they will allow you to automatically regulate the temperature.

Of course, devices with built-in thermostats will cost a little more. Although the difference between two-way and three-way valves will not be too big. The mixing unit will cost much more.

Alternatively, if the price of a mixing unit for a large room seems prohibitive, you can assemble it yourself if you have the necessary experience and technical knowledge. If desired, you can find many schemes for installing regulators for heated floors, which are easy to do yourself. In any case, independently assembling a unit from individual elements will allow you to save significantly.

Comb selection

When choosing a comb, you need to know the need for its functionality and performance; it must have a reserve so that it can withstand sudden changes in pressure.

In addition, you need to consider:

- Material: Available in brass, plastic and stainless steel. The budget comb is made of plastic, but it is not durable. A welded stainless steel product is durable, but susceptible to corrosion. Brass manifolds are the highest quality and most reliable, but they are expensive.

- The number of valves for connecting the floor circuits - it is better to install a comb with a number of outlets equal to the floor branches. If there are more taps, then the extra ones will have to be plugged.

- Level of automation - There is now equipment that connects to thermostats and programmable controllers. They simplify the process of adjusting and monitoring temperature and coolant flow.

When purchasing a distribution unit, it is better to take a product from a well-known company, even if its price is higher - it will pay for itself during operation. Availability of appropriate warranty documentation for the product is mandatory.

Simplified mixing elements with temperature lock

An autonomous three-way valve of a simplified type can be installed in simple heating systems of country houses, where heat is obtained from a TT boiler. To function, it does not require a thermal head with a temperature sensor, and there is no rod there.

The thermostatic element, which is installed inside the housing, is adjusted to a certain temperature of the coolant at the outlet, for example. 50 or 60 °C (must be marked on the body).

The mixing valve of this sample always maintains the set temperature of the coolant at the outlet; this setting does not change. This gives rise to positive and negative aspects when using such fittings:

- advantage - cheaper, unlike a unit with a thermal head. The difference is about 30%;

- disadvantage - there is no possibility of adjusting the heating of the exiting coolant. If the factory settings are set to 55°C, then it will constantly supply water at this temperature ±2°C;

- Before purchasing a valve of a simplified design, carefully study the documentation for the solid fuel boiler; it usually indicates the minimum return temperature.

A thermostatic three-way valve is a rather useful thing in the heating system of a private home, which makes it possible to efficiently use the heated liquid, and thereby save fuel. Moreover, this part allows you to increase the service life of solid fuel boilers, and also plays the role of a safety element. On the other hand, you should not sculpt the valve just anywhere; it is always better to consult with a specialist who is well versed in this.

How is the price determined?

This is due to the fact that the price for a specific plot will be much lower. This is due to the mechanism for setting the price for a specific plot.

So, if there is a paid acquisition of land, its cost will be determined based on a similar cadastral value. At the same time, you need to know that in each specific case the calculation of the value will be carried out based on the purpose for which the land is being purchased.

So, for example, if it is used for individual housing construction, its value can range from 3 to 100% of the same cadastral value (in the event that a house on such a plot has not yet been built).

In the event that we are talking about the use of a land plot for organizing agricultural production (if it is impossible to develop the plot free of charge), then the price here cannot be more than 3% of the cadastral value of a specific plot.

In the case of purchasing a plot at auction, the value will be calculated from the cadastral to the average market value for a specific type of plot.

Mixing unit

Installation of a warm water floor.

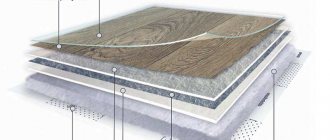

The mixing unit is needed exclusively for water-based floor structures, since they contain the same coolant as in heating radiators. In most cases, the heating system is organized as follows: a boiler, a coolant for heating, the design of high-temperature radiators, the required number of circuits.

The boiler will heat the water to the temperature required for the radiators. In most cases, this is 95 ° C, but sometimes radiators with a temperature of 70-80 ° C are installed. According to sanitary standards, the floor base should not heat up more than 31 ° C. If you take into account the thickness of the screed in which the floor structure pipes are laid, as well as the type of coating base of the floor, the liquid in the tubes should be heated to approximately 40-55 ° C. It should be understood that liquid cannot be sent directly from the boiler to the heating system, since its temperature is high. To cool the liquid at the entrance to the circuit, you should use a heated floor mixing unit. It will mix the hot coolant and the cooled coolant from the return pipe of the heated floors. As a result, the average temperature will become lower, after which the liquid will flow into the circuit. As a result, all available heating devices will work correctly: hot water will be supplied to the radiators at a temperature of 95°C, and to the heated floor circuit at a temperature of 55°C.

It is possible not to use a mixing unit if the heating in the entire apartment or private house is carried out using low-temperature circuits, while the heated liquid will heat the coolant exclusively for the heating system to the required values. An example of such a design is an air pump. If the heat source will heat water not only for heated floors, then a mixing unit should be installed.

How to make initial floor adjustments

The initial launch of a newly installed floor heating begins with adjustment, and it is necessary to carry it out correctly. This is important not only for the system itself, but also for the operation of the floor covering, which should not be subject to overheating.

Water pipes can also be mounted on a dry screed, but most often they are laid in a monolith due to the greater heat transfer of such a pie. Regardless of its design, the initial start-up of the system is carried out before the finishing cladding is carried out.

The initial launch is carried out before installation of the decorative coating

At the same time, residual moisture evaporates from the screed, which is very important when construction is not carried out during the hot season and the cold forces you to hurry. In this case, you can only set the temperature to room temperature (about +20), increasing it by only 1 degree per day.

On a note! Forcing events is inappropriate - gradual heating will eliminate the occurrence of cracks in the screed due to sudden linear expansion.

The system must operate in this mode for at least 2 weeks. During this time, the concrete will dry perfectly, which has a beneficial effect on most finishing materials that do not like moisture.

Table 2. Adjusting the heated floor

| Photos, steps | Explanation |

Step 1 – fill the system with water | To start the system for the first time, you first need to fill it with water and bleed the air. To do this, you should open those taps that are supposed to be open when the floor is working. These are: 1. Flow meters or valves on the manifold. 2. Three-way valve (if it has a thermal head, then the value on it should be the maximum possible). 3. Shut-off valves on supply and return. 4. Air vents. |

Step 2 - bleeding air from the circuits | Water will begin to fill the pipeline, whistling sounds will indicate that it is displacing air. When everything calms down, all taps can be closed, except for the supply to one circuit. This is done so that the pump pressure concentrates only on it and squeezes out the remaining air. Thus, you will have to crimp each loop, and then turn off all the taps. |

Step 3 - Setting up the 3-way valve | In this case, the 3-way valve must be closed or at a minimum. |

| Step 4 - adjusting flow meters | Now you need to distribute the water flows along the contours, taking into account their length. As you can see, there is a scale on the flow meter body that indicates l/min. You should know the length of the circuit and the pump performance too. Divide one by the other, you get l/hour, then divide by 60 minutes, you get l/min. Underestimate the result by 0.2 (by the hydraulic resistance), and set it on the flow meter. |

Step 5 – manifold with tuning caps | If there are no flow meters, and you have manifolds with adjusting caps, open them according to the instructions for the required number of revolutions. In any case, equal heating of all circuits should be achieved. |

Step 6 - turn on the pump | After setting, turn on the circulation pump at minimum speed, then add another revolution (medium). Hot water will begin to gradually displace cold water, which will take about 3 hours. |

If, before starting to warm up the floor, the flow meters were set to maximum values, or they turned out to be different on each circuit, now is the time to adjust them to achieve uniform heating. When the system has an electronic thermostat, which was described above, you set it the desired temperature - and it will adjust it itself.

Prices for heated floors Caleo

heated floors Caleo

Video - A simple way to adjust the temperature of a heated floor

How to choose

Installing a heated floor, even in a private house, is a rather complex engineering system with ambiguous results. If the adjustment is poor, all the benefits may disappear, so you cannot save on the manifold assembly and control valves. Good three-way valves are not cheap, and there is a high probability of purchasing low-quality products on the market or on the Internet.

Usually they buy products made of brass. Stainless steel valves are more expensive and less commonly sold. Silumin is not even worth considering - products made from it do not tolerate constant opening and closing, and the control valves cost a lot.

When purchasing in a store, you need to inspect the valve to ensure there are no chips, cracks, or jams. You need to try to look inside the valve - on brass products without coating, the inside should be golden (and not white-silver, like silumin). You can navigate by weight. Silumin products weigh much less than brass ones - the density of brass is approximately three times greater than that of silumin.

Popular manufacturers

In first place in terms of quality are the products of the Swedish company ESBE. The company has been producing pipe fittings for various purposes for over a hundred years. The second place is occupied by the American company Honeywell. Fittings from HEIMEIER, HERZ, Navien, Danfoss, Mut, Oventrop, Siemens are common. The cost of these products outstrips the quality. The products of the joint Italian-Russian manufacturer Valtec have a more reasonable price.