The construction of a heat supply system installed in the floors of a house made of lumber is justified by a lot of compelling factors. Water or electrical equipment located under the finished floor does not affect aesthetic criteria and eliminates the need to install radiators and the pipes required to connect them. However, in order to install a heated floor in a wooden house, it is necessary to take into account the specific features of the wooden structure and comply with the rules for installing these heating systems in them. Today we will try to reveal these nuances.

The technical “warm floor” system in a wooden house completely copes with heating the building. With rational use and the presence of a thermal insulation layer, it can significantly reduce significant costs during the heating season. Refusal to install batteries and pipes makes it possible to fully use the useful internal space. The unique charm of the interiors of wooden houses is preserved, not spoiled by the presence of equipment that does not match the wooden surroundings.

Installing a “warm floor” system in a wooden house allows you to fully utilize the usable space

- 2 Technical requirements for the installation of an electrical system

- 3 Rules for installing the system in a wooden residential building

3.1 Laying the subfloor and installing a heated floor system

- 3.2 Laying the finished floor

Variety of heating systems

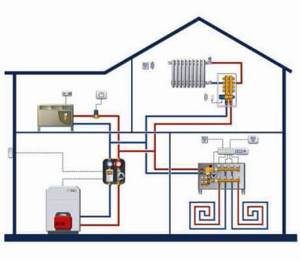

Almost every home uses autonomous equipment for heating. All heated floors can be classified according to various criteria :

- operating principle;

- type of boiler;

- coolant.

In individual houses a boiler can be installed , which uses for its operation :

- solid fuel;

- diesel fuel;

- gas;

- electricity.

In a heating system, the coolant can be :

- air;

- water;

- electricity.

According to the principle of operation, all heated floors can be of infrared or convective type.

Source stroyfora.ru

To make a film heated floor, a special film with heating elements glued to it is laid under the floor covering.

Each of the above types has its own advantages and disadvantages. All of them must be taken into account at the design stage. In doing so, experts take into account many different factors.

The most common, accessible and cost-effective in our country is gas heating.

When installing a heated floor, take into account the characteristics of the material from which the structure is made. For example, wood is characterized by a low thermal conductivity.

General principles

To decide what the floors will be like in a log house, we first formulate the conditions and requirements.

- In most cases, a relatively light wooden beam house is built on a light and inexpensive foundation - columnar, strip or pile. Therefore, the design feature of the house will be the presence of an underground floor. Hence the obvious conclusion: the floor will consist of a frame and flooring. We will not have a monolithic surface on which to lay an insulated screed.

However: on particularly weak and heaving soils, it is practiced, albeit rarely, to pour a slab foundation under a wooden house. In this case, the best solution is a reinforced screed over a layer of expanded polystyrene.

- Each extra crown means that the price per square meter of living space increases significantly. In principle, it is possible to lay joists on top of the beams and then lay the actual flooring on them; however, in this case we will lose extra centimeters of room height. A typical solution is to lay the plank floor directly over the beams.

- The insulation for the timber is protected from below by a vapor barrier, and from above by waterproofing. The vapor barrier film will protect the subfloor under the insulation from rotting, and at the same time prevent it from waking up; a layer of waterproof film on top is designed to protect the hygroscopic heat-insulating material. However, builders often do without it, relying on the impermeability of the final coating.

Installation of underfloor heating with liquid coolant

As we know, private homes often have a centralized gas supply. Many people install double-circuit boilers, which provide hot water in the pipeline. In this situation, it is better to choose water as a coolant. But if you do not live in a country house, but only come for the weekend, antifreeze will be the best coolant. In this case, you will not have to drain the water from the system and pipes every time.

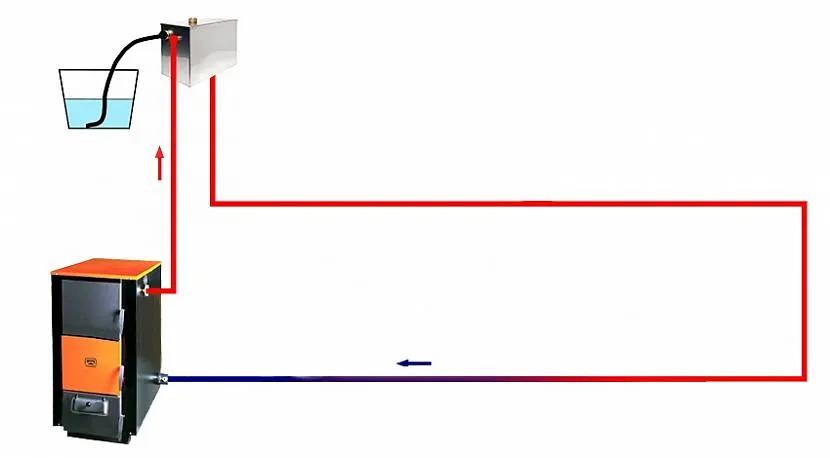

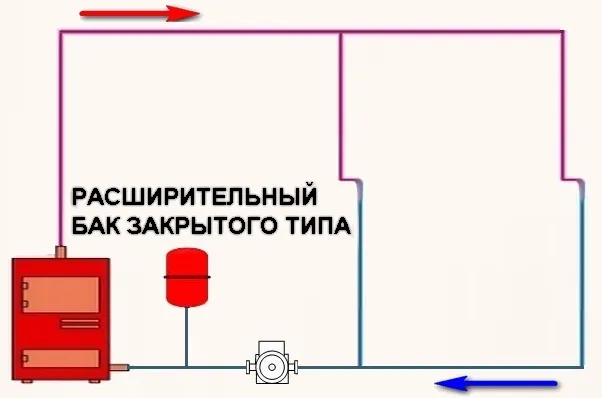

There are 2 types of liquid heating systems: open and closed loop. The difference between these types lies in the design of the expansion tank.

Source cabel-electro.ru

Open type expansion tank in the heating system

See also: Catalog of companies that specialize in insulating country houses.

An open loop system consists of a tank that is in direct communication with the atmosphere. During heating, the volume of liquid increases. It can be compensated in a simple way - add the required amount of water to the container. But the closed circuit system is characterized by a special design of the expansion tank.

Warm floors with liquid coolant include:

- boiler and circulation pump;

- expansion tank and Mayevsky tap;

- distribution unit and safety valve;

- pipelines.

The water in the heating system is constantly heated by the boiler, which monitors its temperature. The heated water enters the main collector, and then into the distribution unit. Here there is a uniform distribution of warm water through all pipes in all rooms. Thanks to this, the temperature throughout the house will be the same. The installation of water heated floors in a private house should be carried out by a specialist.

Source cabel-electro.ru

Closed expansion tank in the heating system

Automatic temperature control in the house

In the homes of thrifty Europeans, heating systems are necessarily initially designed, and then immediately built with an automatic temperature control system in the house. A German or a Pole knows and understands that without automation it is impossible to ensure economical gas consumption and an acceptable level of thermal comfort in the house.

In Russia, owners often begin to realize the need for automatic temperature control after the house is built, the heating system is already installed and working, and gas bills begin to arrive.

It turns out that outside the house the air temperature, direction and strength of the wind are constantly changing. Day and night, the outside air temperature, even during the day, often changes by ten degrees. The house sometimes blows through, sometimes not, the wind is changeable. The sun is inconsistent, sometimes it heats the house, sometimes it doesn’t. Heat loss at home constantly fluctuates by different amounts. In order not to bother with all this leapfrog several times a day, the owner of the house manually sets the temperature on the boiler to a higher temperature, so that the temperature in the house is warmer, with a margin. And at the end of the month he looks longingly at the gas bill and scratches his turnips.

The owner learns that in order to equip the house with automatic temperature control, it is necessary to throw out some things, replace and redo the heating system, and install additional equipment. And for this you will have to drill, chisel, and lay again. That all this automation would have been much cheaper if it had been installed immediately during the construction of the house.

three automatic temperature control systems: a heated floor based on the air temperature in the room with a limitation of the floor temperature;

radiators based on room temperature; boiler based on outside air temperature. As you know, a warm floor can be either “comfortable” or “heating”.

"Comfortable" heated floor

slightly warms the surface and provides a pleasant feeling when a person is on the floor. The main heat supply to the room is provided by radiators. For a comfortable heated floor, it is necessary to maintain a constant temperature of the coolant.

"Heating" heated floor,

In addition to comfort, it provides complete heating of the room.

The relatively small thermal power of a dry heated floor makes it most often suitable only for comfortable heating.

The room temperature sensor is located in the thermostat housing.

In a house with a comfortable dry heated floor, it is necessary to have three automatic control systems to control the temperature .

One system that regulates the operation of a warm floor must be controlled by the air temperature in the room until the temperature of the floor surface reaches a comfortable level. That is, in the off-season the house will be heated with the heat of the heated floor.

the automatic radiator control system comes into effect . Radiators will heat the air in the room, adding their heat to the heat that will constantly come from the heated floor.

The heating mode of the coolant by the boiler must be regulated by another automatic system that responds to the outside air temperature .

Considering that the underfloor heating system has a high inertia (it heats up slowly and cools down slowly), it is recommended to use weather automation to control its operation. Then the temperature of the coolant supplied to the system will be adapted to the outside temperature. Due to this, along with changes in outside temperature, the temperature of the coolant circulating in the floor changes.

When adjusted using a room thermostat, the temperature of the coolant in the system will not change until it begins to rise in the room (due to warming outside). Only after this the temperature of the coolant will begin to decrease, but due to the inertia of the system, the room will already become hot (i.e., waste of energy).

Therefore, in order for home heating to be economical, a weather controller must be used in the underfloor heating system to control it.

To regulate the temperature of the heated floor, it is necessary to select and install a manifold equipped with servo drives on the control valves.

A servo drive is a device that, when electrical current is supplied to it from the thermostat, acts on the valve, opening or closing it. The servo acts as a switch, completely opening or closing the valve. The surface temperature of the heated floor will be maintained with an accuracy of +/- 0.5 - 1 °C.

Pros and cons of using water floors

Compared to radiators and convectors, water heated floors have many advantages :

- comfort;

- economy;

- aesthetics;

- safety.

Warm floors allow you to evenly heat the entire area of the room, creating the ideal temperature for human health. There are no drafts on this floor and it is comfortable to play on with children.

Due to the low temperature of the coolant, energy consumption is reduced by 20−30%. By installing such a heating system in large rooms with high ceilings, you can save up to 60% by heating the air only 2.5-3 m in height.

This type of heating allows you to carry out various projects for remodeling the premises. There are no radiators here, which so often spoil the appearance.

The possibility of injury or burns upon contact with coolant is eliminated. Therefore, this heating system is safe even if there are small children in the house.

Source pikucha.ru

Warm floors can always be adjusted to a comfortable temperature

The disadvantages include:

- cannot be used on staircases;

- labor-intensive installation of the structure;

- the likelihood of a pipeline leak.

Floor without heat distribution plates

All design options for a dry heated floor can be made without laying heat distribution plates. The heating pipe is placed in the grooves, securing the pipe with clamps made from pieces of plastic tape and self-tapping screws.

In a prefabricated dry floor screed, the groove with the pipe is filled flush with gypsum mortar.

Due to the absence of a metal reflector - a heat distributor, the disadvantage of such a simple design of a dry heated floor will be some unevenness in the temperature of the floor surface. The floor will be underheated in the spaces between the pipes, and the thermal power will be lower - no more than 50-60 W/m2.

—>

In floors without heat distribution plates, it is recommended to reduce the pipe pitch to 150 mm. It is highly desirable to increase the flow through the pipes to a temperature difference of dt=5 °C, instead of dt=10 °C in the usual case.

This option is quite suitable for a comfortable heated floor, which slightly warms the surface and provides a pleasant feeling when a person is on the floor. Radiators provide the bulk of the heat in winter.

Types of pipes used

Metal-plastic and plastic pipes can be used to equip heated floors. Many plumbers have positively assessed cross-linked polypropylene pipes. They are characterized by a high degree of tightness, resistance to deformation and good thermal conductivity.

When choosing pipes for installing heated floors, carefully study their technical characteristics. In particular, pay attention to the suitability of the material for use in heating systems. Be careful, because some unscrupulous sellers may sell pipes intended for plumbing. As a result, the floor heating system will be ineffective. Therefore, pay attention to the markings on the pipes. Indicators that you should focus on when choosing pipes for installing heated floors:

- linear expansion (up to 0.025 mm/m);

- thermal conductivity (more than 0.43 W/m °C).

You can find out the required number of pipes, taking into account the diameter of the material and the pitch of its installation.

Source hydrost.ru

When selecting pipes for heated floors, there are a number of nuances, so it is better to entrust the choice to professionals

Types of insulation

In the process of floor insulation, materials play an important role, so their choice must be taken very responsibly. There are a large number of insulation materials that differ in both properties and cost. Let's take a closer look at how you can insulate the floor in a house made of timber.

| Sawdust

| It is considered the simplest, but at the same time popular material for insulation and for good reason: sawdust is an environmentally friendly product, has an affordable price, is easy to use, convenient for hard-to-reach places, but it also has disadvantages - it cakes over time, losing its beneficial properties, susceptible to rot, mold, mildew and insect attack. |

| Minvata | Due to the ideal price-quality ratio, mineral wool made from basalt fibers is becoming an increasingly popular material for thermal insulation in the modern construction market. Its main advantages are: high level of noise and heat insulation, resistance to various types of influences and fire safety. |

| Mineral slabs

| This material is almost identical to the previous one, except for the shape. Often this type of mineral insulation is more convenient - it does not roll, does not settle, does not compact for a long time, keeps its shape and is easy to use. |

| Styrofoam | A material that does not lose its properties over time. It is stronger than mineral wool, does not absorb moisture and has low thermal conductivity, the disadvantages are that it does not allow moisture vapor to pass through, does not breathe, and when ignited, releases substances harmful to health. |

| Expanded polystyrene | Lightness is one of the main features of this material, this applies to both light weight and ease of processing. It is an environmentally friendly material and resistant to biological influences; disadvantages include the lack of air circulation through it and instability to fire. |

| Polyurethane foam | A fairly popular material for floor insulation, due to its features: it provides a high level of thermal insulation, is not afraid of moisture and insects, has a high degree of sound insulation, is not flammable, the only disadvantage is the rather high cost. |

| Expanded clay | Very durable insulation, resistant to frost and high temperatures, wear-resistant and environmentally friendly. When using expanded clay as insulation, you should take into account the fact that it imparts load to the structure. Quite common as floor insulation due to its low cost. |

The variety of materials for insulation is very wide; the choice is made taking into account the structural features, as well as the personal preferences of the owner.

Electric heated floor installation

The essence of the operation of an electric heated floor is that the conductors that are under load are heated. And the level of temperature increase depends on the resistance of the material. At the moment, there are 2 ways to install such a heating system: cable and film.

Cable heated floors have much in common with water ones. Simply, instead of pipes with warm water, an electric cable is laid under the floor. It heats up by passing electricity through it. Managing such a heating system is simple - you just need to adjust the periods of power on and off. In other words, when the room reaches a certain temperature, the system will turn off, and when it cools down, it will turn on.

Dry installation on a solid surface

On a solid wooden floor used as a base, film heaters or cable mats are laid as one of the “sandwich” layers. Directly on the wooden covering (board, plywood, chipboard or OSB boards), if necessary, apply a waterproofing layer of some mastic that has the appropriate characteristics. A heat-reflecting coating is laid on it, which simultaneously plays the role of thermal insulation; most often it is foil-foamed polystyrene foam. Then the electric floor is laid, and the finishing floor covering is installed on it.

If necessary (for a laminated board, for example), a substrate is laid between the heating surface of the heated floor elements and the finishing coating - but this is done quite rarely: such a gasket conducts heat very poorly.

Foil cable mats are laid in a similar way, only they do not require a heat-reflecting “sandwich” layer - this role is played by the foil base of the mat. You just need to take into account that almost all manufacturers of electric heated floors produce all the layers necessary for laying the “sandwich” - and guarantee compliance with the declared characteristics of the heaters only when using branded materials and recommended installation technologies.

Pros and cons of electric heated floors

Electric heated floors in a private home have many advantages . The main ones:

- reliability (leaks cannot appear);

- noiselessness;

- aesthetics;

- long service life;

- uniform heating of the entire area;

- simple controls.

Instead of water pipes, electric heated floors use heating cables

Disadvantages of this heating system:

- the presence of weak electromagnetic radiation (harmless and safe for humans);

- high energy consumption.

Complicated method

Infrared heated floors

The system described above becomes more efficient, but also more difficult to install due to an increase in the number of functional elements.

It all starts with a heat-insulating layer, but the top is covered with aluminum foil. The use of this material increases the degree of heat reflection, which determines the concentration of the generated heat and its direction into the room. If it is not possible to cover the entire surface with a single sheet of foil, then you will need to additionally use double-sided adhesive insulating tape to connect the cut pieces.

Next, a metal mesh is laid, usually used to reinforce screeds on wooden joists, in order to strengthen the structure being created. A modern warm water floor on wooden logs involves the use of not only pipes, but also a heating cable. The use of this element in combination with polyethylene pipes is highly effective. Such a heating circuit can be heated much higher than the temperature of the coolant in the main heating system of the house. Also sometimes they make a heated floor on the ground in a private house, which is a pretty good option.

Autonomous control of the temperature of the coolant in the heating circuit of the heated floor is carried out using its own sensor, installed in a corrugated tube and connected in a specially designated place. In addition, the overall heating system has a number of different sensors. They concern not only the warm floor, but also the main heating circuit.

Features of installing heated floors in a wooden house

In a wooden house, underfloor heating should be installed correctly. After all, wood has its own characteristics that must be taken into account. Remember, the temperature of a heated floor in a wooden house should not exceed 30 degrees. Otherwise, the wood will dry out, which will lead to premature failure of the material.

A warm water floor in a wooden house, like an electric one, must be installed at the construction stage or during major repairs - otherwise the installation cost will be very high. All installation and connection work must be carried out only by specialists. Please note that the subfloor must be pre-insulated.

When installing an electric heated floor, it is recommended to use an armored cable with an outer metal braid. It should also be taken into account that the cable can be damaged by rodents. And such a braid protects the cable from various external influences.

Source hr.decoratex.biz

Only at the construction stage will installation of heated floors not result in additional costs

The electric underfloor heating system must be connected to an electrical network with the required parameters. Devices are first installed on them to protect electrical wiring from short circuits.

Having decided to install a warm water floor in a wooden house with wooden floors, you need to level the surface well. The heating pipes are placed in a special box, which is then covered with boards. The box is made of wood, drywall or other material that will absorb moisture well. Afterwards the laminate is laid.

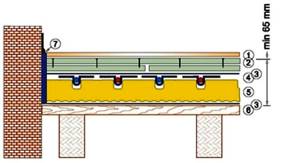

Dry warm water floor on polystyrene foam boards

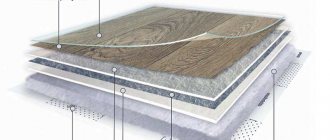

Another lightweight design of a dry heated floor is shown in the following figure:

1 – floor covering; 2 – prefabricated dry screed for the floor from gypsum fiber board sheets (see link to the article above); 3 – vapor barrier (polyethylene film 100-200 microns thick); 4 – heat-distributing metal plates with a heating pipe for a heated floor; 5 – polystyrene foam boards; 6 – subfloor; 7 – damper tape.

This floor can be installed on any flat surface, even over an existing floor when reconstructing a room.

The procedure for installing a “dry” heated floor is as follows:

- A hydro-vapor barrier is laid on the subfloor - a polyethylene film 200 microns thick, with an overlap at the joints of at least 10 cm and the joints are taped.

- A damper tape is installed on the walls around the perimeter of the room.

- Profiled polystyrene foam boards are laid on the floor.

- Heat-distributing metal plates are inserted into the profiles of polystyrene foam boards in straight sections.

- The heating pipe of the heated floor is placed in the prepared recesses.

- The entire laid system is again covered with a polyethylene film with a thickness of 100-200 microns.

- A dry prefabricated screed is mounted on top. The installation of a floor with a dry prefabricated screed is described in detail in the article at the link.

To install the screed, as in previous cases, it is better to use cement-bonded particle boards (CSP) or gypsum-bonded particleboards that are moisture-resistant (GSPV).

| Heat distribution plate made of galvanized iron or aluminum. The width of the plate is selected depending on the pitch of laying the heating pipe |

A factory-made dry heated floor system includes a set of materials: profiled polystyrene foam boards and heat distribution plates made of aluminum or galvanized steel. Sets of materials for installing dry heated floors of various modifications and manufacturers can be found on the construction market.

This system is by far the easiest floor heating solution. But the floor height will be slightly higher than that of a wooden system.

You can make profiled insulation boards for dry heated floors yourself.

To do this, smooth thermal insulation boards (expanded polystyrene, penoplex, etc.) are laid on the subfloor. A route for laying heating materials is drawn on the surface of the slabs. Then, using a special thermal knife, U-shaped channels are cut along these lines, into which thermal distribution plates are laid, and then loops of heating pipes.

How to make profiled insulation boards yourself, watch this video:

Frame house on stilts

The foundation can be made of piles. In this case, the base is well ventilated. In order for the floor in the house to be insulated, 4-5 layers of heat-insulating material are laid on the sheathing.

The “warm floor” in a frame house on stilts is installed from a liquid main or from electrical elements, but it is necessary to prepare the foundation for the heating system. What installation method is used for a frame house?

Concrete base

The forums are discussing the heating system in a house on stilts. It is recommended to raise the frame, make a strip foundation, sheathing and install the frame on the modified base.

Disputes arise due to the fact that all “warm floor” systems function effectively if they are laid on a screed and covered with concrete, but there is a risk that the wooden frame will not withstand heavy loads and will sag and deform. There is a danger that the sheathing will break. What recommendations do builders give?

- The logs are laid on the piles at a distance of 1.7-2 m. The length is 6-8 m. Experts advise making the laying step of the logs smaller, no more than 1.5 m, using short bars up to 4 m. In this case, the sheathing will be stronger. There is a possibility that it will withstand the load of the concrete coating.

- To insulate the foundation, in addition to mineral insulation, additionally use slabs of expanded polystyrene and extruded polystyrene foam. The materials are light and will not weigh down the foundation. The total insulation thickness can be up to 1 m.

- Rolled bitumen-based waterproofing material is laid on the joists, sheathing and insulation. It will not only protect all layers of insulation from moisture, but also from wind, which will reduce the cooling of the base for the “warm floor”.

- The depth of the rough screed is low, 4-5 cm. The finishing coating is 5-8 cm.

On a concrete surface, a liquid line is used as the main heating. For additional heating of individual small rooms, electrical systems are installed.

On the forums they suggest laying “warm floors” on joists. This technique is often used in a wooden house. Heating systems are installed without screed.

Wooden base

The floor is insulated with combined materials, mineral wool and polystyrene boards. Be sure to make a backfill of expanded clay. Carry out waterproofing measures. They make a rough wooden sheathing.

- GVL sheets are laid on the sheathing. The surface is leveled.

- Metal thermal distribution plates are installed on the sheets. They form a circuit for pipes or cables.

- The liquid line is connected to the communication comb. The cable is connected to the thermostat.

- For cable or carbon mats, a reflective screen is installed.

- The heating elements are covered with finishing sheathing. The floor covering is already being formed on it. It can be laminate, parquet, or leave the lining.

The “warm floor” in a wooden frame house is laid not only on logs, but also on boards. Grooves are made in them and foil material is placed. A water or cable line is placed in the grooves.

Mats are not used. A good option for underfloor heating is thermal film, but it is recommended to install it only as additional heating.

Underfloor heating systems have long been used in country houses. When calculating, not only the area of the room is taken into account, but also the type of foundation. In a frame house on stilts, the sub-base is carefully insulated and insulated from moisture.

In a wooden cottage, screeding is done using the dry method; heating systems are mounted on boards, on the surface of gypsum fiber sheets, which are laid between the joists.

YouTube responded with an error: Daily Limit Exceeded. The quota will be reset at midnight Pacific Time (PT). You may monitor your quota usage and adjust limits in the API Console: https://console.developers.google.com/apis/api/youtube.googleapis.com/quotas?project=268921522881

System design

- A boiler used for heating. If the choice fell on water floors, then it is possible to use a solid fuel, electric or gas equipped boiler. They are practical and quite comfortable. Their use implies the absence of a constant supply of fuel, which is used in wood and solid fuel boilers.

- If you plan to create a truly warm house, then it is recommended to use combined systems that will allow you to heat both the radiators and the floor layer. Its temperature regime may differ, since the temperature in radiators can reach 60°C, but for wooden coverings the maximum is 30°C. If this condition is not met, the tree will crack quite quickly.