Do-it-yourself DUGA® P1 equipment

The need to insulate your own home, cottage, garage with high-quality durable material with a high thermal insulation coefficient, the absence of cold bridges, a simple and reliable method of fastening/application, as a result of considering all options, often leads to the decision of self-spraying polyurethane foam. After choosing polyurethane foam as thermal insulation, there is a need to purchase ready-made equipment for spraying it, or a desire to make equipment for polyurethane foam with your own hands .

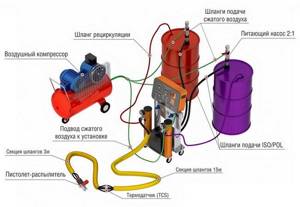

Considering the unreasonably high cost of so-called “one-time installations” for spraying polyurethane foam with the impossibility of subsequent use, a reasonable choice would be to purchase an inexpensive ready-made installation, with which you can spray polyurethane foam not only on a specific object today, but also to use it in the future, or even try assemble the equipment for the power supply unit with your own hands. Technically, at first glance, an installation for spraying polyurethane foam is really not anything complicated: a drive, pumps, a sprayer. However, often numerous attempts to make equipment for PPU with your own hands lead to unplanned results: the components “press” each other, a stable required ratio is not ensured, pumps that are not intended for pumping PPU components leak and jam, the sprayer requires a lot of air and does not provide high-quality mixing and sprayed foam onto the surface. In addition to wasted money and lost time, an installation assembled from unsuitable components not only does not fulfill its direct task, but also discredits the very idea of thermal insulation with polyurethane foam due to total savings and the lack of the required technical knowledge and experience necessary when designing any equipment. For those who want to assemble equipment for the PPU with their own hands and, thereby, reduce the cost of insulating their home, the Vladimir Construction Equipment Plant offers a choice of two solutions:

1. kit for self-assembly of equipment for DUGA ® P1 power supply unit:

The cost of such a kit, due to reduced production costs, is lower than the price of a finished installation and amounts to 56,920 rubles including VAT . The kit includes all products and parts that are used to assemble the DUGA ® P1 equipment, in addition, the kit includes hoses for sampling and supplying components, remote control, spare parts, instructions for assembling and using the installation, a passport, technological instructions for polyurethane foam.

By purchasing a factory kit for assembling equipment for the do-it-yourself power supply unit DUGA ® P1, you receive:

- Guaranteed quality of all parts used when assembling the DUGA ® P1 at the factory.

- Components developed by our design department and made according to our drawings, intended specifically for PPU equipment.

- Ready-made factory PPU equipment at a price lower than the retail factory price list.

It is also necessary to understand that the quality of assembly and configuration of the equipment, ensuring the production of polyurethane foam with the necessary characteristics in this case, lies entirely with the buyer. The factory warranty valid for finished DUGA ® does not apply to the purchased kit for the reason stated above.

2. Do-it-yourself household installation for applying polyurethane foam ARC ® P0

This option seems optimal for most people who want to independently insulate their home, garage, bathhouse, extension, etc. with polyurethane foam. By purchasing such an installation, you receive a complete set of high-quality factory equipment for applying polyurethane foam yourself, including: supply hoses, a pumping unit, supply hoses for components and compressed air, a professional spray gun, detailed instructions for working with equipment and polyurethane foam. The unit has a full factory warranty - 1 year, is equipped with high-quality gear pumps of our own production, designed to work in an environment of PPU components. You can watch a video of our clients insulating their homes using the DUGA ® P0 installation on our YouTube channel. You can learn more about the installation on our website: household installation DUGA® P0.

"VZSTO" Design and production of innovative equipment for construction, road and repair work, as well as work related to construction chemicals, including waterproofing and thermal insulation

Process Basics

Many believe that it will be cheaper to insulate your home with polyurethane foam with your own hands. But in practice, everything turns out to be not so simple, because you need to have not only theoretical knowledge, but also practical skills. In addition, specialized equipment and materials are required. Before starting work, you should properly configure the equipment.

When a person understands the operation of the system, but does not have his own equipment, he can rent it, but it is quite expensive. In this case, it makes sense to invite a specialist with equipment who will quickly perform thermal insulation procedures, saving the owners from many problems.

If a person decides to independently carry out the insulation process, then he needs to take into account some features. Among them:

How to insulate a house yourself. DIY polyurethane foam spraying

If you are faced with the task of insulating your home, and hiring a team of professionals is too expensive, then there is a way out - to do the insulation yourself. In this article, we will, of course, consider the option of insulation only with polyurethane foam, as one of the best insulation materials today.

Why polyurethane foam?

- Polyurethane foam has one of the lowest heat transfer coefficients, it is 25 times warmer than brick, 4 times warmer than mineral wool and 3 times warmer than polystyrene foam

- PPU is durable, service life more than 30 years

- Polyurethane foam can be used in the temperature range from minus 100 to plus 100 degrees Celsius;

- Resistant to microorganisms, mold and fungi;

- High adhesion (sticking) to any surface and seamlessness - add advantages compared to traditional insulation (mineral wool, polystyrene foam, extruded polystyrene);

- It does not emit anything, does not accumulate dust and microbes, and does not itself turn into dust particles, so it is widely used in our lives - it is used to insulate all refrigerators, pillows and mattresses are made from it, and much more.

Internal insulation of house walls

Most often, city apartments are insulated from the inside with polyurethane foam, and not all of their space, but only the walls facing the road or corner walls, as well as loggias and walls separating two adjacent apartments. In this case, polyurethane foam acts not only as insulation, but also as a reliable sound insulator.

Due to its low water absorption coefficient, polyurethane foam can be rationally used as insulation for walls and floors in the bathroom, kitchen and toilet. But in these rooms, characterized by high humidity, even for polyurethane foam it is desirable to create additional vapor barrier, which is not required at the natural level of humidity.

Scheme of insulating walls from the inside with polyurethane foam.

Before you begin insulating the interior, you need to make sure that it is free of furniture, carpets, plumbing fixtures and household appliances. A special protective film must be glued to doors, window sills and windows. These measures are very important because... the insulation itself is sprayed onto the walls of the house under high pressure, and its splashing cannot be avoided.

Possessing increased adhesion, foamed polyurethane foam can stick almost tightly to any type of surface, and after hardening it will be impossible to remove its splashes without leaving a trace. Therefore, it is necessary to initially take all necessary protective measures to prevent splashes of insulation on other objects.

You need to remove the facing material and finishing from the walls, reaching their base. Facing materials must be removed carefully so that upon completion of the spraying process they can be reused for finishing. Immediately before spraying, the frame must be treated with a wide damp brush to remove as much dust as possible.

Reusable cylinders with polyurethane foam for do-it-yourself insulation

The NST company offers an excellent solution for insulating polyurethane foam with your own hands. Household kits with liquid polyurethane foam in 10 liter cylinders. Portable device PENA-mini for spraying insulation.

The prototype for PENA-mini was the American household PPU Foam Kit . They appeared in Russia in 2011 and quickly became popular.

Foam Kit cylinders from Convenience Products USA are not unique in their kind. In the USA, we counted 4 more companies, the most famous of which is Dow Chemical, plus we discovered a plant in Canada and another in South Korea.

From 2011 to 2014, NST actively traded FoamKit cylinders. We offered our industrial PU foam installations to professionals and builders, and we sold American household PU foam devices Foam Kit Touch and Seal to those who like to work with their own hands.

The dollar exchange rate of 28-30 rubles, combined with the construction boom, made this product in demand in Russia. Such cylinders with polyurethane foam were in good demand until approximately August 2014, when the ruble began to weaken.

The current rate of 62-67 rubles per 1 USD automatically multiplied the price of each FoamKit by 2, which also automatically reduced the attractiveness of goods made in the USA by 2 times. It became obvious that it would not be possible to sell American PU foam cylinders in large quantities as before.

Well, if the mountain does not come to Mohammed, then Mohammed himself will go to the mountain. In other words, we decided to create a domestic analogue of American household cylinders for self-insulation. And, strictly speaking, - Yes we did it, i.e. Yes, we did it.

By June 2015, the NST company had developed and began mass production of portable household devices for do-it-yourself foam insulation. The new product is called PENA-mini B2 .

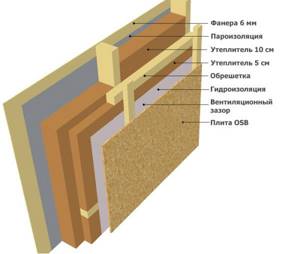

Pie wall

The main condition for applying polyurethane is the construction of a lathing made of wood or a metal profile on the wall surface. The insulation will be applied to the space between the sheathing guides . The lathing not only creates “cells” for applying polyurethane foam, but also performs a leveling function.

Separate vapor and waterproofing is not needed if polyurethane foam with a closed structure is used, since its moisture-proof properties are very high. Open cell material requires the installation of a vapor barrier layer.

wall pie

For external insulation, it is installed between the thermal insulation and the wall structure. The most popular vapor barrier material is polyethylene , which is laid with an overlap under the sheathing over its entire area.

Waterproofing and windproofing is always installed between the polyurethane foam layer and the external finish of the wall.

PENA-mini B2 Russia vs PPU Foam Kit USA cylinders

We planned for our PPU household device, like the American one, to work on the “ Touch and Seal ” principle, i.e. " Touch and isolate ." But it was not possible to copy the Yankees 1 to 1.

In fact, there are three differences. One is negative and two are positive. Read on and decide for yourself what is better to buy for thermal insulation of polyurethane foam with your own hands: American or Russian cylinders.

PENA-mini B2 is inferior to the American Foam Kit in that imported cylinders do not require a source of compressed air. Containers with components A and B are already under pressure. Therefore, to get started, just connect the sprayer, open the valves on the cylinders and spray. The “Touch and Seal” principle in the truest sense of the word.

Our device requires compressed air, i.e. small household compressor. It is needed to create excess pressure in the cylinders. Americans pump gas into cylinders with polyol and isocyanate and seal them somewhere in Florida or California. And to a Russian in Samara or Barnaul who decided to a balcony, garage, etc. with PPU with his own hands. no compressor needed. That's a plus.

If suddenly there are not enough components in the cylinders, then you need to go to a gas station. The closest ones to Samara are located in Florida, Georgia and South Carolina. California or Arizona will be more convenient from Barnaul. Or, without leaving Russia, you can always buy another new Foam Kit kit.

FOAM-mini B2 is superior to imported Foam Kit in that our installation is REUSABLE. PENA-mini B2 cylinders are filled with PU foam immediately before work, on the balcony of a house in Samara or a garage in Barnaul.

From one canister we pour component A into the first cylinder, from the second - component B into the second. And now, to get to work, you need to create excess pressure in the cylinders. This function is performed by the compressor.

Yes, a domestic product requires a source of compressed air, but the components can be added to the cylinders and used repeatedly. American cylinders are disposable.

FOAM mini is also better because it is cheaper. Domestic cylinders and components for refilling them are cheaper than imported Foam Kits.

American cylinders are expensive and can only be used once, i.e.: sprayed and thrown. Therefore, the motto Touch and Seal in relation to Russia can be clarified: Touch, Seal and Threw.

The NST company offers a reusable device PENA-mini B2 for insulating polyurethane foam with your own hands and raw materials for self-refilling.

Negative aspects of using foamed polymer

Most brands of foam have flame retardant additives. But this does not mean that the polymer is absolutely safe in fires. Like any organic substance, at high temperatures foam releases large amounts of toxic gases, which are most often caused by fires.

The second negative side is the intense destruction of the polymer under the influence of solar radiation. Often, to lose the properties of polyurethane foam, it is enough to expose the material to the open sun for a couple of weeks. Therefore, the insulation layer must be covered with sheet plastic or fiberboard.

The worst sin in carrying out work on applying a layer of foamed polyurethane foam is violating the proportions of the components used. If the mixing chamber and flow rate are set incorrectly, for example with too much isocyanate, the foam will be very weak and hard. If it is deficient, we will get the opposite effect - the foamed polymer will not harden, will be soft, and will gradually lose its bubble structure.

Household device PPU FOAM-mini reusable

According to the NST price catalog dated March 23, 2021:

- the price of a refilled (10 kg of component “A” Izolan A-131 and 10 kg of component “B” isocyanate) household kit for self-spraying polyurethane foam is 30,060 rubles.

- You can buy an unfilled (empty) FOAM mini B2 to fill the raw materials later for RUB 23,580.

- We offer a double refill kit in the amount of 20 kg of isocyanate (component B) and 20 kg of polyol (component A) at a price of 12,588 rubles.

Basic delivery set of unfilled PENA-mini B2 for do-it-yourself insulation with polyurethane foam:

- sprayer with spare parts kit;

- Cylinder “A” and cylinder “B” with flow and pressure regulators;

- Hoses “A” and “B” 3m each;

- Compressed air supply hose from the compressor, 3m;

Additionally, a small household compressor with a capacity of 150 l/min is required. It’s not difficult to buy or get one now. Perhaps friends, neighbors, or relatives have such a compressor.

Due to the pressure of compressed air entering through the regulators into the containers with the components, they are dosed and supplied to the sprayer. Both components then enter a static mixer. Thanks to the complex internal geometry of the mixer, the raw materials are well mixed while passing through it.

The mixed system is then atomized using compressed air through a special static mixer tip. Polyurethane foam expands quickly and forms a seamless thermal insulation coating.

Household device PENA-mini rechargeable . After the components run out, you just need to add raw materials to the container and continue working. Do-it-yourself insulation of 1 m 2 with a thickness of 50 mm takes 1 minute!

Characteristics of the resulting polyurethane foam coating

- density - 35 kg/m3;

- thermal conductivity coefficient - 0.02 W/m;

- at least 98% of closed cells;

Application of household reusable polyurethane foam cylinders PENA-mini

For self-insulation:

- verandas, attics, walls and roofs of country houses and dachas;

- balconies, loggias;

- metal containers, garages and small shopping pavilions;

- gaps, cracks, cavities and joints in all construction applications;

- along the perimeter of windows and doors, at the junction of walls and ceilings;

- in the manufacture and repair of yachts, boats, trailers and refrigerators;

- for insulating and sealing channels and connections;

- for replacement or repair of insulation of refrigeration chambers;

- as a sealant when laying utility lines;

- In other cases, when it is necessary to quickly and efficiently do sealing and/or insulation with polyurethane foam with your own hands.

To solve professional insulation problems, we offer equipment for spraying polyurethane foam of the PENA series.

Technical characteristics of PENA-mini:

Balcony insulation technology

Insulating the balcony with polyurethane foam

Insulating a balcony with polyurethane foam will not take much time due to the small area of the room. Do-it-yourself thermal insulation is carried out from the inside of the balcony, since special equipment is required for external work.

During the insulation process you will need:

- aluminum profile for sheathing;

- screws and plastic dowels;

- level;

- drill;

- spray installation;

- insulation components.

Step 1. Surface preparation

Peeled or loose coverings are removed from the ceiling and walls of the balcony, and the corners and joints around the perimeter of the windows are checked. If there are deep cracks, they can be filled with pieces of foam plastic and sealed with putty. All small gaps and seams will be filled during the spraying process. There is no need to level or sand the surfaces.

Step 2. Making the sheathing

An aluminum profile is screwed to the walls and ceiling in vertical rows. Next, strengthen the sheathing with horizontal jumpers in increments of about half a meter. Be sure to screw the profile around the perimeter of the window and doorway. It is recommended to cover the window, door frame, and communication pipes with plastic film, since the insulation quickly sets and is very difficult to clean.

Step 3. Spraying insulation

Open the box of polymers and thoroughly shake the components. Connect hoses and a gun to them, select a nozzle with a narrow torch. First, polyurethane foam is blown into the cracks, the seams between the walls and ceiling are sealed, and the joints around the openings are treated. Then the nozzle is changed to a wide one and the insulation is sprayed onto the ceiling. Application should be uniform, the gun should be held at the same level and moved smoothly along the surface to be treated.

After insulating the ceiling, they move on to the walls; if there are noticeable defects, depressions, polyurethane foam is applied in a thicker layer, leveling the working plane. On smooth walls, the insulation layer should be as uniform as possible. After spraying, carefully remove excess material from the sheathing.

Step 4: Finishing

Drywall, plastic or wooden panels are attached to the profile on top of the heat-insulating layer. If finishing with decorative plaster is planned, a reinforcing fiberglass mesh is attached to the surface, on top of which the plaster is applied.

Do-it-yourself insulation with polyurethane foam: features of the material

Polyurethane foam (PPU) is a type of plastic . In construction, the formation of rigid polyurethane foam . As a result of the combination of two liquid components, a chemical reaction occurs with the formation of a porous, quickly hardening substance, which has increased thermal insulation qualities. The popularity of the material as insulation is explained by its reasonable cost and the possibility of self-application using special equipment. PU foam differs in technical characteristics, areas of application and method of coating.

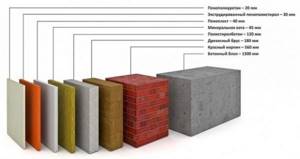

Choosing high-quality insulation for walls

Material characteristics

Polyurethane is a two-component material that is formed by combining a polyol and an isocyanate.

It has high wear resistance and good insulating properties, making it widely applicable in industry.

It is used to make sealants, elastic forms (including shoe soles), implants and other products.

Polyurethane comes in both liquid and solid forms. In private construction, a liquid material is used, which is applied to the walls by spraying and immediately turns into foam due to contact with air.

The material can be sprayed not only on vertical, but also on horizontal surfaces, which will allow it to be used for insulating ceilings, floors, and basements.

Polyurethane in its original state is vulnerable to moisture, but the foam it forms is resistant not only to water, but also to gasoline, ethers, alcohols and most other aggressive liquids.

Polyurethane foam (PPU) is available in two main varieties: with open cells (“soft foam”) and with a closed structure (“hard foam”) . A material with a closed structure has better vapor barrier properties, but its price is higher than that of “soft foam”.

The average thermal conductivity coefficient of polyurethane foam is 0.025 W/(M*K).

Advantages:

- High adhesion. Polyurethane adheres well to any surface, even rough and uneven, and fills all recesses, providing complete and continuous coverage of the wall over its entire area.

- Quick application and hardening (1 hour).

- Resistant to rot and mold.

- Lightness: polyurethane does not weigh down the structure.

- Non-flammability.

Flaws:

- Relatively high price.

- Self-installation of polyurethane foam is difficult.

- Contact with fire does not cause the material to ignite, but it does begin to emit smoke containing toxic substances.

- Polyurethane quickly deteriorates when exposed to direct sunlight - ultraviolet protection is required.

Comparison of thermal insulation characteristics of materials

Filling with polyurethane foam

This method is used to insulate rooms with hollow spaces between walls that are filled with foam. The process of insulating an already operating facility is as follows.

- Technical holes of about 10 - 15 mm in size are made in the surface of the wall reserved for pouring. They are made using a grid method, with a distance of 60 cm between each other.

- Using special equipment, polyurethane foam is poured, starting from the bottom row

- The entire cavity is filled in stages, sequentially, with foam. The result is a monolithic, insulating layer.

Pouring polyurethane foam has many positive characteristics:

- Due to its location in the space between the walls, the material is not exposed to negative environmental influences.

- Insulation work can be carried out without the need to dismantle existing coatings.

- Filling involves filling as much as possible all cracks, crevices, voids, even in hard-to-reach places.

- Greater thermal conductivity compared to other methods.

- Minimum investment of time and effort.

When insulation is carried out at the stage of hollow-core construction (masonry with an air gap, well masonry, etc.), polyurethane foam is poured during the construction of the structure every 1 - 1.5 meters. When swelling, the foam reliably fills the entire possible volume.

Technology and basic circuits

Work on insulating polyurethane foam begins with choosing its density, taking into account the load-bearing capabilities of the structures and the thickness of the future layer according to the climatic conditions of the region. When doing it yourself, it is recommended to adhere to the following scheme of actions (using the example of a facade):

Surface preparation: applied to stable, clean and dry structures, heated if necessary.

Evenness does not play a special role, but there should be no peeling pieces of the old coating. Installation of sheathing (recommended). Theoretically, a frame is not needed, but installing guides helps control the level and facilitates the finishing process. The height of the sheathing is selected taking into account the future thickness of the insulation. Application of polyurethane foam: in a thin layer (no more than 5 mm) in the direction from bottom to top.

If necessary, the process is repeated. Upon completion of the polymerization process, excess foam is cut off along the guides and external finishing is carried out. To plaster polyurethane foam, a chain-link mesh must be placed (similar to polystyrene foam, secured to the sheathing or material). The easiest way is to cover the facade with siding, clapboard, or, if you have an unlimited budget, to cover it with brick.

This guide is also suitable for roofs or floors on joists; experienced operators use up raw materials without leaving a trace, even without lathing.

It is allowed to use polyurethane foam in systems with heating elements (both pipes and cables); it is believed that such insulation reduces space heating costs. When insulating pipelines, containers or metal walls, the preparatory stage includes the removal of old flaking paint and rust. A mandatory step in any scheme is sealing and hiding from ultraviolet radiation.

Spraying polyurethane foam

The method allows for insulation of structures inside and outside buildings. This method of insulation has a number of advantages that distinguish it from all others:

- PPU firmly adheres to any surface, regardless of the material. The geometry of the surface does not matter.

- No preliminary preparation of the spraying object is required. It is enough to remove dirt and dust.

- Not afraid of seasonal temperature fluctuations.

- Unaffected by precipitation.

- The lightness of the material means that there is no additional load on the object, which allows you to spray polyurethane foam everywhere without restrictions.

- This insulation option further strengthens the structure.

- The absence of seams and joints that can reduce the thermal insulation properties.

- Due to technical features, it does not require additional transportation costs.

- High environmental safety.

Spraying of polyurethane foam is carried out using special equipment. There are many varieties of such construction equipment for use on an industrial scale and for personal use.

Choosing the right insulation for siding

Calculation of the thickness of the polyurethane foam layer

Heat transfer resistance is a standardized characteristic that is set separately for each region.

The thickness of the polyurethane foam layer must be calculated in accordance with this parameter.

The standards indicate the values of the total heat transfer resistance related to the entire wall structure.

For this reason, the calculations take into account not only insulation materials, but also the parameters of the insulated structure.

Self-calculation formulas are complex and cumbersome, but there are a large number of online calculators that find the required insulation thickness based on user-entered data (region, wall material, its thickness, insulation materials and additional finishing).

The average thickness of the polyurethane foam layer is 10-30 centimeters.

Ready-made kit for spraying polyurethane “Foam Kit”

A disposable system for insulating polyurethane foam, Touch*n Seal Foam Kit, manufactured in the USA, is presented in the following configuration:

- 2 cylinders, sufficient for private use, filled with polyurethane foam.

- Hose – 4 m.p.

- Spray gun - “pistol”.

- Nozzles 8 pieces - 4 each, for flat and round pressure.

Hoses are connected to the cylinders, a suitable nozzle is put on the gun, and the gun is mounted to the hose. Several disposable attachments allow you to take breaks while working. The kit is usable for a month, from the first opening. The layer hardens in 1 – 2 minutes. Excess will be removed after hardening.

Properties

The characteristic properties of polyurethane foam include:

- Low thermal conductivity and high density. Depending on the amount of material and quality of raw materials, the thermal conductivity of the polymer ranges from 0.019 to 0.035 W/m*C, which is considered one of the lowest values among all polymers;

- The expansion coefficient is 1:40, that is, after exposure to air and the start of the reaction, the volume of the polymer will increase 40 times. In a practical sense, this means that a small volume of substance will be required to insulate the walls of a building or insulate the floors;

- The vapor permeability of the material is low, only 0.02-0.05 mg/m*h*Pa, and the density is high. This means that polyurethane foam does not accumulate moisture, and condensation does not accumulate on the surface of the polymer itself and the wall underneath it. Low vapor permeability allows thermal insulation of almost any surface, since the vapor permeability of almost any building material is less than the vapor permeability of polyurethane foam, which means that moisture will freely escape;

- Another characteristic of the material is associated with vapor permeability - moisture absorption. For polyurethane foam, the moisture absorption coefficient is 1-3%, that is, the polymer does not absorb water more than 3% of its volume;

- The sound insulation of polyurethane foam is also higher than that of insulation with a similar density, and therefore spraying can be used both for insulating private houses and for insulating the floors of office buildings.

You can use polyurethane foam for external thermal insulation of walls, and for internal insulation of floors, attics and ceilings between floors. You can thermally insulate walls using a polymer coating not only from the outside of the building, but also from the inside of the wall.

The mixture is poured into the voids between the foam blocks or the space between the walls of the building if the house is built using the Sandwich technology.

In other words, if a house is built from two partitions parallel to each other and closely located on the same foundation, then polyurethane foam or similar materials are poured between the walls as insulation and sound insulation.

What is polyurethane foam

The first samples of the material were obtained in the 30s of the last century. By mixing polyol and polyisocyanate under various conditions, the researchers obtained:

- elastic and flexible samples with low density, called foam rubber;

- solid, durable, but non-flexible samples are the prototype of modern polyurethane foam and polyurethane foam insulation.

The cellular structure of the material serves as a barrier to the penetration of cold. Foamed and hardened polyurethane foam consists of 80-90% carbon dioxide, enclosed in thin, randomly located plastic bridges.

Do not confuse polyurethane foam with expanded polystyrene for wall insulation. Expanded polystyrene is a common foam made by polymerizing styrene with the addition of pentane as a blowing agent. The high thermal insulation properties of polystyrene foam allow it to be used for wall insulation, but there are such disadvantages as:

- solubility upon contact with technical liquids and their vapors;

- toxicity at high temperatures;

- fragility,

limit areas of application.

Foamed polyurethane does not have these disadvantages; its thermal insulation capacity is higher, so its use is more justified. The material is presented in molded form and liquid, two-component. To insulate non-linear structures and hard-to-reach places, it is advisable to use sprayed polyurethane foam.

Varieties and details about polyurethane foam

Several types of insulation can be applied using the spraying method:

- carbamide-formaldehyde foam - penoizol (KPF), which requires a foam generator. The composition is mixed with water, forming foam, and when it hardens, it becomes similar to polyurethane foam;

- ceramic liquid insulation in the form of a suspension, which is suitable for all types of surfaces (brick, concrete, wood, metal, plastic, etc.). Safe, tolerates painting, wallpapering, plastering;

- jellied foam, which is suitable for insulating any premises; It is odorless, and after hardening it takes on a cellular structure and retains heat well. Durable and suitable for high-rise buildings.

Sprayed polyurethane insulation is a type of foam. Such gas-filled plastics are obtained through the process of foaming and subsequent hardening of certain liquid mixtures. The cells of the resulting substance are filled with carbon dioxide, air, and sometimes other gases are used.

About 98% of the volume of this insulation is gas, solid matter accounts for only 2%. This circumstance determines the main feature of gas-filled plastics of this kind - low specific gravity.

Operating principle of the equipment

Equipment for pouring polyurethane foam is divided into 3 categories according to the method of application.

According to this criterion, installations are divided that during operation perform:

- Low pressure.

- High pressure.

- Foam generators.

Models that operate at high pressure do not use compressed air during application.

Equipment of this type has a number of advantages:

- High performance.

- The dosage is accurate.

- Operation is simple.

- Mixing of components is carried out perfectly, which has a good effect on the quality of the resulting material.

- You can spray polyurethane foam in small portions.

- Due to the airless application method, the formation of fine particles in the room is minimized.

Disadvantages include difficulty in maintenance and high price of materials. Low pressure models use compressed air.

The advantages of such installations are as follows:

- Reasonable price for components.

- Easy to maintain.

- Simplified design.

Among the disadvantages, we highlight the high consumption of polyurethane foam and not entirely accurate dosage. And a separate category is the foam generator, which mixes components using air, which is supplied using special compressors.

Application conditions and surface preparation

Insulation with polyethylene foam can be carried out from the inside of the room, but the optimal method is external spraying. Internal insulation is a necessary measure, which is justified only if external work is impossible. Applying polyurethane foam from the inside reduces the usable area of the rooms and requires vapor barrier. The foam from the inside insulates the walls from the heat of the room, which leads to freezing and a shift of the dew point inside the external walls. Moisture in building envelopes leads to the formation of mold and mildew. At subzero temperatures, moisture that gets into the walls freezes, gradually destroying them.

Preparing for work

The insulation process is completely within the capabilities of any owner. Spray insulation will require two components:

- a prepared mixture of foaming agents, polyester components, foam regulators and fire extinguishing additives;

- a substance based on isocyanate.

Shake the first ingredient thoroughly. Usually a mixing mechanism is used for this; doing it yourself may not provide the required accuracy. The isocyanate is carefully checked for the presence of foreign impurities. If they are detected, the second ingredient is heated to 700°C and mixed. Before use, strain the mixture through a metal sieve. The components are used in a 1:1 ratio.

It is important to remember that the ingredients should not come into contact with water, steam or moist air; It is unacceptable for foreign objects to get into them. Containers containing insulation components must be tightly closed.

All ingredients are best used within a short period of time, immediately after preparation.

Spray equipment

The entire process of applying insulation foam is carried out using low-pressure machines. In addition to machines, you will need:

- protective glasses;

- overalls and shoes, rubber or cotton gloves;

- additional equipment: gas mask, thermometer and respirator.