Is it necessary to insulate the basement?

From the description above, it becomes obvious that yes, it is better to insulate the basement. Let's give a few more arguments for those who doubt:

- effective use of usable area;

- the appearance of fungi and mold in the basement, which are a source of unpleasant odors and deterioration of the microclimate on the lower floor of the house, is excluded;

- the temperature in the insulated basement does not drop to below zero;

- insulating the basement in a house makes it possible to protect the foundation from dampness and deformation due to soil heaving;

- the rate of destruction of the building foundation is reduced;

- the consumption of electricity or gas for heating the house is reduced.

Note. If the basement is not insulated, according to GOST 9561-91 “Reinforced concrete floor slabs” it is necessary to insulate the floor that separates the floor of the first floor from the non-insulated area. The same requirement is specified in SNiP 2.08.01-85

For your information, the technology for insulating a cellar is similar, but has some differences.

General characteristics of the premises

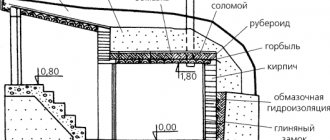

A cellar is a storage area for workpieces. This is a free-standing object or buried in the ground. It can be located on the site or in the basement of a house, garage or barn. Usually, its construction is planned in advance or a house is purchased with a ready-made storage facility.

The walls of the storage area can be soil, cement or brick. Floors made of compacted soil or concrete. The ceiling can be wooden or concrete.

The temperature in such a room is constant, but in the cold season it can freeze. This will lead to crop loss.

Pros and cons of internal insulation

Most often, answers to the question of how to insulate a basement are sought by owners of private houses, who in this way want to reduce heat loss in the house and change the purpose of the room. The main disadvantage of this solution is cold bridges in the area where the basement wall meets the floor slab, which are very difficult to get rid of.

An advantage can be considered the absence of the risk of damage to the insulation by groundwater. Nevertheless, it is extremely difficult to achieve a protective layer that does not allow moisture to pass through foundation walls. To prevent the risk of damage to the insulation material under the influence of moisture, it is additionally waterproofed, including with bitumen, and groundwater drainage is practiced using special methods.

Another significant advantage of internal insulation is the ability to carry out work at any time of the day, regardless of the outside temperature and time of year.

Features of the cellar microclimate

Regardless of whether the cellar was located under a private house or built separately (like Angela Olegovna’s), in my opinion, it requires good insulation. This operation affects not only the formation of an acceptable microclimate inside, but also the service life of the building.

The walls in an improperly insulated cellar will become moldy.

If certain measures are not taken, the walls will quickly become unusable and collapse from the destructive effects of external factors: high humidity and significant temperature fluctuations.

But the most important thing is the optimal temperature for storing food. My auntie told me that soaked apples are obtained only if the air is not heated above 4 degrees Celsius and not cooled below 2. This can only be achieved if the cellar is thermally insulated both inside and out.

If the temperature in the cellar is too low or high, the products will deteriorate.

In this case, the walls of the cellar will not let warm air inside in summer and cold winter.

Another important point that many people rarely pay attention to. Many times I have encountered situations where moisture condenses on the walls and ceiling inside the cellar. This is one of the consequences of improper insulation (or its complete absence).

To reduce humidity levels, insulation measures are not enough. It is also necessary to design ventilation that will regulate the content of water vapor in the room.

And, of course, I advise you to immediately think about waterproofing, without which the thermal insulation material will get wet and work worse, and the walls themselves will quickly collapse.

However, let's return to our sheep. Before describing the process of insulating a cellar, I want to devote a few lines to the problem of choosing a suitable material.

What surfaces are insulated in the basement?

To understand how to insulate a basement, including in a private home, you need to know about all the ways to establish and maintain the indoor microclimate. If everything is done correctly, then in the end you will be able to create a warm, comfortable and cozy room, suitable also for arranging a living room.

Current methods of internal basement insulation are insulation:

- walls;

- ceiling;

- floor.

And it doesn’t matter, you need to find out how to insulate a cellar or basement for equipping a workshop in a private house. The main thing is to adhere to the work algorithm and select the necessary set of tools. For insulation you will need:

- Insulation.

- Bitumen mastic.

- Plastic mesh.

- Glue.

- Cement mortar for screed.

- Brushes and rollers.

Correctly carried out thermal insulation will eliminate the formation of dampness in the basement, significantly increase the temperature, and reduce heat loss.

How to choose the thickness of insulation?

To reduce heat loss and ensure an acceptable temperature in the premises when insulating, the thickness of the walls, their heat-insulating properties, type of foundation, climate of the area and prevailing wind loads are taken into account. If the walls are thick enough, made of materials with high heat-insulating properties (for example, made of brick or logs), insulating the facade is not necessary.

The thermal insulation of a house assembled from cinder blocks should be maximum - this material is not capable of retaining heat for a long time. When calculating the thickness of the walls, the thermal conductivity coefficient of the insulation itself is taken into account. The best characteristics are provided by materials such as polyurethane foam, polystyrene, and mineral wool.

For example, a 50 mm layer of polyurethane can retain heat in the same way as 1720 mm of brick.

Thermal conductivity of materials

Professional builders use quite complex formulas to calculate the thickness of insulation. When choosing a heat insulator for a private home, it is convenient to use online calculators. You only need to indicate your region of residence, the size of the building, the types of basement and attic floors, the thickness and material of the walls, and the type of roof.

Even with significant wall thickness, a small layer of insulation along the facade is still worth laying. After all, upon contact with cold air and temperature changes, cracks form on their surface over time, leading to premature destruction.

Veranda attached to the house - expanding the living space: projects, tips on how to create it yourself (200 original photo ideas)

DIY basement insulation technology

Let's look at how complex basement insulation is carried out using penoplex (the technology will be similar for polystyrene foam and expanded polystyrene). Note that comprehensive thermal insulation includes external and internal insulation (in particular walls, floors, ceilings).

In addition to insulation for work you will need:

- material for interior decoration;

- polyurethane foam;

- reinforced polymer mesh;

- waterproofing material (bitumen mastic);

- adhesive solution;

- concrete or external plaster;

- tool.

In order for the insulation of the basement from the inside to be sufficient for the minimum level of heat loss, the thickness of the insulation should be:

- 10 centimeters for polystyrene foam;

- 8 centimeters for polyurethane foam.

But it is recommended to increase this value by 40 - 50% if the basement is supposed to be heated and maintain a temperature of 20 - 25 degrees in order to reach the recommended level of thermal insulation.

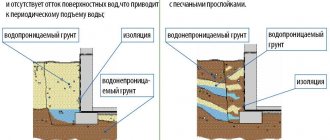

If water penetrates, then it is unacceptable to insulate from the inside.

Insulating the basement from the inside is a necessary measure when external insulation is impossible or not cost-effective. Internal insulation of the basement can only be carried out on dry foundation walls. But this poses a risk of increasing the rate of destruction of the foundation due to its freezing.

If water penetrates into the basement from the ground through the foundation walls, then laying insulation on the inner side surface of the foundation is strictly prohibited.

Internal insulation will cause even greater moisture in the foundation, and will also lower its temperature in winter, since there is no external insulation.

The freezing area inside the foundation will increase significantly, which, coupled with increased humidity, will very quickly damage the foundation.

How to drain and drain water

Eliminating water penetration into the basement from the ground is either difficult or impossible. More often it is necessary to install a drainage system around the house or repair the existing one.

In this case, it is necessary to tear off the foundation from the outside. In this case, talking about internal insulation loses all meaning, since the foundation walls become free for external insulation and for additional waterproofing.

There may be other drying options. Sometimes the issue is resolved comprehensively for a group of houses or an entire village, by opening a drainage ditch.

Sometimes the basement can only be drained by installing a well with a pump. Although pumping out a spring under a house is an extremely thankless task, what should you do? This source of water can serve the purpose of water supply to the house, so not all the work of the pump will be “wasted”.

Insulation from outside

Insulating a cellar from the outside is quite a painstaking task, as it involves performing a mandatory series of actions.

Basic work process:

- Removing excess soil.

- The insulation is being installed (polyurethane foam can be applied).

- Removing irregularities and roughness from the surface (if any).

- Dry all surfaces.

- Roofing felt is laid on top of the ceiling.

- Insulation of the cellar with polystyrene foam.

- The top of the roof is covered with a pre-prepared mixture (if the basement is bulk).

- Filling the gaps with polyurethane foam (good insulation for a cellar).

Having fulfilled all the above conditions, the thermal insulation of the cellar can be considered completely completed.

How to insulate a basement ceiling

Expanded polystyrene or EPS

It has low hygroscopicity, low thermal conductivity and no vapor permeability. There are many modifications of this material, with different densities and methods of implementation. When insulating basements, PPS with a density of 35 kg/m3 and a panel thickness of at least 10 cm is used.

In this video you will learn more about wall insulation:

Important! The material is flammable, so for construction work it is recommended to purchase polystyrene impregnated with fire retardant, which significantly increases its fire resistance.

Penoplex

An improved version of PPS insulation. It is characterized by higher density, lower thermal conductivity and increased wear resistance. With a relatively small panel thickness (maximum 10 cm), it provides good thermal protection. It costs more than PPP, but less than PPU. For insulating basement walls with penoplex, the “Foundation” brand is recommended.

Polyurethane foam, or PPU

Liquid insulation, which has a number of obvious advantages over panel materials:

- quickly applied;

- saves space due to the thickness of the coating;

- does not require vapor and waterproofing, as well as additional mechanical devices and chemical compounds for fastening;

- the material is applied without gaps, which improves the quality of insulation.

The disadvantages include the need to use specialized equipment designed for applying insulation to the surface.

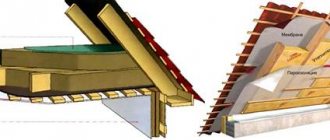

The procedure for installing panel or roll materials does not depend on the choice of insulation.

Algorithm for performing the work:

- Prepare the surface.

- Secure the vapor barrier material (the joints should overlap by less than 10 cm to ensure sealing).

- Lay insulation.

- Treat the joints of the thermal insulation panels with sealant to avoid the appearance of “cold bridges”; if necessary, secure the moisture-proofing membrane.

- Install exterior trim.

You can insulate the floor in the basement from the inside using the same materials as the ceiling and walls, but for this you must first install logs made of wooden beams or metal profiles. Place the outer joists along the walls, and make the distance between them identical to the width of the insulation so that there are no large gaps. After processing, the procedure is carried out according to the algorithm indicated above, with the difference that the waterproofing and vapor barrier materials are swapped.

After installing the insulation, you can make a concrete screed or flooring from floorboards, which must be installed perpendicular to the joists.

We follow the instructions for insulating walls

A private house

Insulating the basement from the inside in a private residential building begins from the ceiling. You need to think about thermal insulation of the floor outside at the construction stage. If the basement has self-leveling concrete floors, they can only be insulated from the inside. Wooden flooring can be opened and external insulation can be made using expanded clay or other thermal insulation materials. The insulation algorithm for all surfaces of the basement is the same.

Since the basement floor line is below the dangerous depth of soil freezing, there is no point in using expensive insulation with low thermal conductivity. Any budget material will cope with this task.

Garage

Features of insulating a basement in a garage depend on the functionality assigned to the room. If the basement will be used for storing workpieces, then thermal insulation should be approached with full responsibility. The garage is not a living space, and therefore is not heated in winter, so to maintain a positive temperature in the basement, you need to organize high-quality insulation.

Apartment house

Insulation methods applicable to private cottages may not be suitable for multi-apartment municipal buildings. In this case, to carry out any work you will need permission from the administration, to obtain which you will have to collect a package of documents. The list of required papers can be obtained from the housing and communal services department, which controls the improvement of the house. It is possible that permission from a fire inspector will be required, who will definitely not approve the use of flammable PPS and PPU.

When insulating the floor of an apartment building, it is recommended to pay attention to materials such as mineral wool or foam glass. Both materials have a number of advantages:

- environmental cleanliness;

- high levels of noise and heat insulation;

- waterproof;

- resistance to chemicals;

- free air exchange;

- fire resistance;

- long service life.

Against the background of the listed advantages, the disadvantages of cotton wool are not so significant:

- high vapor permeability;

- with humidification of only 2%, the thermal insulation qualities drop by 10%;

- very dusty.

Foam glass has its disadvantages:

- high price;

- fragility;

- impossibility of resuscitation in case of damage.

However, if there is a need to insulate the basement of an apartment building, and you do not know how best to insulate the pipes in the basement, you should not do it yourself, but submit an application to the housing and communal services service.

In a private house

It is not difficult to do the insulation of basement walls in a private house with your own hands. The main thing is to choose the right material and follow the instructions.

If heating or water supply systems pass through the basement floor, but there is no external thermal insulation of the perimeter, the pipes must be insulated. Basic requirements for insulating heating pipes in the basement:

- ease of installation;

- low thermal conductivity;

- resistance to wet environments;

- self-extinguishing ability;

- environmental cleanliness.

You can insulate pipelines in the basement with the following materials:

- Rolled mineral wool. The most inexpensive and inconvenient material to use. Installation is carried out in the following order:

- cut a piece of material of the required size;

- wrap the pipe with insulation;

- secure the thermal insulation with a nylon rope.

- Shell made of polyurethane foam or polystyrene foam. Such materials are produced in different formats, so when purchasing, you need to consider the diameter of the pipe. Installation is carried out in several stages:

- fix the shell halves on the pipe;

- secure the insulation with tape;

- Attach the following insulation elements with an overlap of 10-20 cm so that there are no gaps.

- Foamed polyethylene tube. This type of insulation can be used when installing a water supply system, then the insulation will be seamless. The main advantage of this material is that it does not need waterproofing. Installation is carried out as follows:

- if the system is already installed, the material must be cut to length and wrapped around the pipe;

- secure the insulation with plastic clamps and seal the joint with aluminum adhesive tape.

After such insulation, you don’t have to worry about the pipeline even in the most severe frosts, but insulating the walls in this situation will not be superfluous.

In the garage

Not long ago, an innovative insulation technology using heat-insulating paint appeared on the building materials market. The thickness of such a coating is only 5 mm, which is a definite plus when insulating rooms with a small cubic capacity), but it can replace 1.5 m of brickwork. Insulating paint is also unique in that it not only does not allow heat to pass through itself, but also plays the role of a reflector. This material is ideal as insulation for a garage basement.

If until now the question was how best to insulate the basement in the garage, now the answer is obvious.

In an apartment building

Heating networks, as a rule, pass through the basement floors of municipal buildings. Thermal insulation of pipes in the basement of an apartment building, as well as protection from the cold of the entire building, are under the control of housing and communal services.

Information on how to insulate a basement in a private residential house, garage or cellar is not a military secret. More detailed materials on this topic can be found on the Internet. Making thermal insulation of a basement with your own hands is not so difficult, especially if you have the skills to use the necessary tools.

Material selection criteria

In order for the basements of the house to be properly insulated, you need to choose the right material.

Criteria for choosing insulation:

- high heat retention capacity;

- moisture insulation;

- not susceptible to rotting and fungal attack;

- fire resistance;

- environmental friendliness;

- tightness.

It is advisable to take into account the thermal requirements given in the tables. The main parameters and requirements for thermal insulation are specified in SNiP 02/23/2003 Thermal protection of buildings. If it is impossible to select the material yourself, it is better to involve a specialist.

Dependence of the thermal conductivity coefficient of insulation and its thickness for internal basement insulation

Dependence of the thermal conductivity coefficient of insulation and its thickness for external basement insulation

If self-assembly is preferred, the possibility of its implementation is added to the selection criteria. The cost of materials is also important, which will depend on the requirements for quality and insulated area.

What do you need to get in the end?

The main “enemies” of the basement (and the entire structure as a whole) are low temperature and moisture. Therefore, the work carried out should completely eliminate their negative impact, resulting in dryness and the desired temperature inside.

The dampness that reigns inside the basement (no matter how thick its walls are) very quickly renders almost all insulating materials unusable. The problem can be partially solved by the use of waterproofing coatings applied in several layers. However, the slightest violation of the tightness of such a layer will very quickly lead to the fact that the insulation will begin to deteriorate. As a result, he will cease to fully cope with his task.

It is for this reason that only those materials that are not afraid of moisture and will not allow it to get inside the room should be used to insulate the basement.

How to properly insulate a basement

Having understood the variety of materials, we move on to installation. Of course, its type will depend on the material, but we will try to combine the information, placing emphasis along the way.

Surface preparation

We start by inspecting the basement walls - you need to understand what protection they already have, and what needs to be added.

Treatment of walls against mold is carried out first.

- If the walls are covered with mold, this is a signal of a high level of humidity, which means that the walls do not have external waterproofing, or it is faulty. You can also talk about freezing, but this practically never happens underground.

- The mold needs to be removed. The most effective method is to coat them with chlorine-containing substances, the same “Whiteness”.

- Next, the walls are cleaned of dirt and dust. Priming is carried out - the type of composition is selected depending on the material that will be mounted on top.

Penetrating coating waterproofing

- Since we don’t have access to the concrete walls from the outside, all that remains is to make the concrete itself waterproof. For this purpose, penetrating compounds are used, which penetrate deep into the structure of the material and endow it with the appropriate properties. By the way, such coating will be an excellent primer for plaster.

To enhance the effect, it is recommended to cover the walls with roll waterproofing with a mandatory overlap of 10 cm at the seams.

Wall insulation

Further actions will depend on the type of heat insulator, future finishing and the surfaces to be insulated. Let's start with the walls.

Insulation of a basement in a private house

- We can use rigid board insulation and sprayed materials on the walls. The former can be placed inside the frame (this applies to soft wool) and mounted using adhesive or mechanical methods.

- The frame is set according to the type of material. For example, drywall is used. We make a grid under it with cells 60*50 cm. We cut the insulation as needed and insert it inside.

- It is better to do insulation in two layers in order to cover the seams between the slabs, which will become cold bridges.

- For adhesive and mechanical installation, we attach the slabs directly to the wall using the chosen method. In the first case, we use polyurethane foam, and in the second, special umbrella dowels.

Materials for thermal insulation of cellars and their characteristics

A variety of insulation materials can be used as heat-insulating materials:

- Expanded polystyrene can be in the form of regular polystyrene foam or penoplex. The material is durable, insulates any surface well, and is safe – it does not emit harmful substances. The disadvantages of polystyrene foam are that it is flammable and does not allow air to pass through. Penoplex retains moisture well and is easy to install. The thickness of the foam varies from 20 to 150 mm, it does not wrinkle.

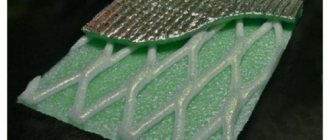

- Penofol. High-quality thin insulation with a foil layer. The environmentally friendly material is resistant to temperature fluctuations, does not allow moisture to pass through and is easy to install. Thanks to its reflective properties, it retains heat perfectly. Its thickness is from 2 to 10 mm.

- Liquid PPU insulation. A two-component mixture of isocyanate and polyol. Pros: adheres well to any surface, applied in a layer of any thickness, moisture resistant. Disadvantages - Requires a pressurized installation.

- Mineral wool. Available in the form of roll material, slabs of different thicknesses. The density of mineral felt is 100-150 kg/m3, slabs - from 100 to 400 kg/m3. Depending on the manufacturer, there are different thermal conductivity options. From Isover - from 0.032 to 0.044 W/mK, URSA - from 0.032-0.044 W/mK, Knauf - from 0.032 to 0.047 W/mK, Rockwool - from 0.035 to 0.045 W/mK.

Mineral wool adheres well to any surface, repeating design features, wear-resistant and non-flammable.

- Basalt wool. It has high resistance to heat and moisture retention, and is fireproof. Shelf-life Unlimited. It is stronger than mineral insulation.

Sand and expanded clay are traditionally used to insulate floors.

A good method of action when insulating basement walls

We will exclude from this description a detailed study of preparatory work, but we will note those that need to be done first:

Firstly, treatment of wall sections covered with thermal insulation. It should be done using modern deep impregnations with the addition of antiseptics that prevent the formation of mold and fungi.

Secondly, perfect leveling of the walls when working with extruded polystyrene foam is not required. However, cracks should be repaired, significant protrusions and depressions should be smoothed out, and other major imperfections should be removed.

Thirdly, it is necessary to prepare channels for ventilation of the basement in advance in the structure. To make it easier to regulate the flow of clean air, you can choose devices with bimetallic drives. They automatically open/close holes when the temperature changes, and perform all their functions without power supply or additional settings.

Fourthly, at this stage it is necessary to install a soil water drainage system. To create drainage, pipes made of specialized membrane fabric are used.

Main types of foundation insulation

The foundation of a house can be insulated in three main ways: from the outside, from the inside, and from both sides at the same time. External insulation is the most preferable, since it is this method that allows you to move the dew point beyond the boundaries of concrete structures, which protects against steam condensation inside them, as well as, as a result, freezing and premature destruction. Internal and double-sided insulation are used in exceptional cases.

External one-sided

External insulation is the most effective method of creating thermal insulation for a basement, as it allows you to move the dew point beyond the load-bearing structures, which ensures their reliability and extends their service life. It is often believed that this method is applicable only during the construction of a house, after the formation of the foundation. However, there are no obstacles to the use of this insulation technology at the final stages of construction, as well as after its completion.

It is necessary to install heat-insulating materials to the depth of soil freezing. Therefore, the first stage is excavation work. Near the foundation, it is necessary to make a trench from one to one and a half meters wide along the entire perimeter; the vertical size should correspond to the foundation, if it is shallow, or to the freezing of the soil, in other cases.

Next, the foundation is cleaned, primed, and after it dries, waterproofing is applied. This can be either hydrophobic mastic or a special sheet material. Then it is necessary to install thermal insulating boards made of extruded polystyrene. Particular attention should be paid to the joints; it is best to fill them with polyurethane foam, this will prevent the formation of cold bridges. When insulating using the polyurethane foam spraying method, the question of sealing joints does not arise.

The insulation boards must protrude above the ground to a height of at least 50 cm. They can be mounted using either adhesives or special fasteners. When installing, do not disturb the waterproofing layer that was previously applied to the foundation.

At the last stage, the thermal insulating boards can be protected with a layer of plaster, covered with decorative plastic or metal panels, or improved in another way. After all work is completed, the trench around the perimeter of the house is filled with soil. It tightly clamps the insulation and also becomes an additional obstacle to the penetration of cold.

Internal one-sided

It is easier to thermally insulate the basement from the inside than from the outside if we are talking about an already built house with a basement. This insulation option is also used if ground-based buildings that cannot be dismantled, or any underground communications, prevent access to the foundation from the outside. Internal insulation is used if the house is on a pile foundation and it is necessary to arrange the space under the floor, or if the underground is not equipped.

The disadvantages of the method include the fact that the insulation reduces the usable space of the basement; it is difficult to eliminate cold bridges - in order to completely thermally insulate the basement, you will need to spend a large amount of material, because all the bridges will also have to be insulated.

When installing insulation from inside the basement, ventilation becomes important. The penetration of moisture and cold into the room will occur regularly and it will actually be impossible to get rid of dampness in the insulation. This means that in order to ensure the removal of moisture and drying of the premises, it is necessary to organize good ventilation of the basement.

It is much easier to insulate the basement if we are talking about the subfloor of a house on a pile foundation. In this case, you will need to make a simple wooden or metal frame. Install thermal and waterproofing on the inside along the perimeter of the building. Next, decorative panels are mounted on the outside space on the frame. Also in this case, the base can be made of brick, then the order changes and the insulation is installed secondarily - after the masonry is completed.

Types of polystyrene

As already mentioned, penoplex and polystyrene foam are types of polystyrene, which differ slightly in characteristics and production technology. Very often you can find the terms foamed and extruded polystyrene foam, where the first means foam plastic, and the second penoplex.

Foamed polystyrene foam is produced without forced pressure injection. The resulting material is quite fragile and is able to absorb moisture. In addition, when using it in basements, there is a possibility of encountering vermin such as rats and mice. However, the material has a wide range of applications due to its low cost.

To create penoplex it is necessary to use high pressure and temperature. This material has low vapor permeability, but is characterized by high density, which allows it to be used as insulation in structures that are subject to high mechanical loads. Despite its density, penoplex is very easy to process, which greatly simplifies the installation process.

Options for basement insulation with polystyrene foam and penoplex are considered the most acceptable and common; the choice will depend solely on the customer’s budget.

polystyrene type

Properties and types

kulirka-s-laykroy-2 kulirka-s-laykroy-1

A cooler with lycra has the same hygienic and physical properties as a classic one made of pure cotton:

- hygroscopicity. Capable of absorbing an amount of moisture equal to 15-20% of its own weight;

- breathability. In products made from this material, the body “breathes”;

- hypoallergenic. The material is made from environmentally friendly raw materials and does not cause allergies.

kulirka-s-laykroy-3 kulirka-s-laykroy-4

Physical properties:

- softness. Very pleasant to the touch and does not cause skin irritation;

- strength and durability. Products made from it do not tear and last a long time;

- firmness and elasticity. It stretches well and returns to its original shape, practically does not wrinkle.

Thanks to the addition of elastane fibers, the mechanical strength and elasticity of the fabric increases; items made from it are shape-resistant: they stretch and completely restore their shape without stretching, and do not shrink after washing.

The disadvantages of the material include a strongly curled edge, which usually causes inconvenience when cutting and sewing; the edges of thin knitwear need to be processed in a special way.

Sometimes a certain percentage of polyester is added to cotton and elastane fibers, which reduces the hygroscopicity and softness of the fabric, adding strength and wear resistance to it. This material is cheaper than natural material. When choosing products, it is recommended to take into account the composition and choose those in which the polyester content does not exceed 20%.

The canvas fabric lends itself well to dyeing, prints perfectly on it, and can be plain-dyed or printed.

Depending on the length and quality of the threads used, there are several types:

- singing - made from threads 35-70 mm long and is the most expensive and high-quality. This material does not form pills, it does not shrink, and printed designs fit perfectly on it;

- cardier or ring - has a coarser texture than pene, made of threads of shorter length (up to 35 mm);

- Open end knitwear is made from the shortest threads and is considered the lowest in quality. Pellets may form on the surface.

Preparing the ceiling surface for insulation

First of all, you need to prepare the base ceiling. The surface is cleaned of dust and cobwebs, cracks are covered, unevenness and other defects are eliminated. Since foam plastic can only be glued to a flat surface, it is worth checking the height difference on the ceiling. If it is significant, then foam plastics are also mounted on a supporting frame.

To eliminate defects and unevenness on a wooden base ceiling, wood putty is used, and when working with concrete surfaces, cement-based leveling mixtures are used. When the repair mixture has dried, the surface is sanded and impregnated with antiseptic primers, as well as deep penetration compounds if an adhesive installation method is used.

Practical tips for creating high-quality insulation

The quality indicator of the insulation work performed will depend not only on the type of insulator used, but also on the technique of its installation. The maximum effect when laying mineral wool can only be achieved if the following conditions are met:

- The rough coating layer, consisting of a mixture of sand and cement, must be laid as evenly as possible and compacted thoroughly.

- The material for waterproofing can be roofing felt or polyethylene film.

- If the insulation boards are located in the same horizontal plane, without noticeable gaps between them, additional sealing of the joints will not be necessary.

- It is necessary to place a thin layer of screed on top, reinforce it with a galvanized mesh and fill it again with concrete mixture. You can use foam concrete, since it has less weight compared to the standard composition.

- Laying the flooring can only be done after the concrete has completely gained strength and dried.

Depending on the foundation

Heaving soils pose a particular danger to the integrity of the foundation. As the seasons change, they tend to change their volume due to the freezing and thawing of the moisture that permeates them. The soil, as a result of freezing, can have a destructive effect on the supporting structures of the building if they are located above the freezing depth or do not have the necessary thermal insulation.

Each type of foundation has its own insulation methods. For example, the peculiarity of a shallow foundation is that it is entirely located in the zone of soil freezing. Therefore, both vertical and horizontal insulation (thermal insulation of the blind area) should be used for it, which will avoid freezing of the soil directly under the foundation itself.

For columnar and pile foundations, a so-called fence is created around the perimeter - a type of plinth - and insulated. This design does not allow the soil under the building to freeze. If the space under the house is large enough, then by making high-quality insulation, it can be put to good use by organizing a dry warehouse or habitable space there.

Insulation of a monolithic foundation is carried out from the outside around the perimeter. For this, both polystyrene foam boards and polyurethane foam can be used, which are evenly sprayed onto the outer side surface of the foundation.

Strip foundation

The most common type of foundation is strip foundation. The popularity is due to high reliability and versatility with relatively low (compared to a monolithic foundation) material costs.

The strip foundation can be insulated both from the outside and from the inside.

If it is planned to make a basement under the floor of the first floor, then it is necessary to thermally insulate the perimeter and lintels using polyurethane foam, extruded polystyrene foam or polystyrene foam. If a basement is not needed, then it is enough to fill the space under the floor with a good and inexpensive heat insulator, such as, for example, expanded clay.

External insulation of a strip foundation begins with the creation of a trench around the perimeter of the building and is carried out using polystyrene foam boards, polyurethane foam, and polystyrene foam.

Waterproofing of the entire outer side surface of the foundation is required. PPU allows you to provide a continuous, sealed layer of heat insulation - there are no gaps, joints or cracks. Application of this insulation is quick and simple, compared to other types of heat-insulating materials. However, the price may make many people refuse to use it.

Such insulation, such as extruded polystyrene foam boards TEPLOFOM+ with a waterproofed surface, have increased protection against moisture and good mechanical strength, and are also a better heat insulator than polystyrene foam and mineral wool. They can be mounted either using polymer or cement-based adhesive or using special fasteners.

The final stage of work - backfilling with soil - should be done gradually by 30-40 cm, carefully compacting each layer.

Calculation of insulation thickness

Determining the thickness of the heat insulator for organizing the insulation of foundations is calculated based on the parameters established by regulatory documents. For each region of Russia, heat transfer resistance coefficients are specified for different types of buildings and types of buildings. With their help, as well as knowing the thermal conductivity coefficients of all materials included in the wall structure - load-bearing part, insulation, finishing and others - you can calculate the required thickness of a particular type of heat insulator.

Construction companies in different regions use a set of pre-calculated parameters for the most typical situations. For example, for warm basements with a concrete wall thickness of 500 mm, the following values for the thickness of insulation (extruded polystyrene foam) are established:

| Region | R, m2x°K/W | Heat insulator thickness, mm |

| Moscow | 3,13 | 80 |

| Krasnodar | 2,34 | 50 |

| Murmansk | 3,63 | 90 |

| Anadyr | 4,72 | 130 |

The values indicated in the table are estimates. For more accurate calculations, it is necessary to take into account that R - the heat transfer resistance coefficient is set for individual elements of the building structure, as well as for certain operating conditions - it should be selected correctly. In addition, the calculation will require the thickness of all layers of the insulated structure and their thermal conductivity. Then the calculation can be made using the formula:

R=s1/k1 + s2/k2+ s3/k3+.. sn/kn;

This is a general formula for a structure with n layers, where n is determined on a case-by-case basis. R – heat transfer resistance coefficient; s, s1, s2.. sn – thickness of the corresponding layer; k, k1, k2.. kn – thermal conductivity coefficients.

All necessary thermal calculations must be carried out when designing a house. They can be ordered separately from the relevant construction or design organizations. It is also permissible to contact the company that produces the insulation for clarification. Employees will answer questions and provide consultation on the correct use of the heat insulator.

Selection of materials

The selection of the type of heat insulator depends on the climatic characteristics of the area, the type of soil, the type of insulated material, and the planned construction budget. The main types used for insulating the base:

- Expanded clay;

- Mineral, basalt wool;

- Styrofoam;

- Polyurethane foam (PPU);

- Extruded polystyrene foam.

You can insulate with expanded clay both inside and outside the building. On the room side, it is used when there is space to fill, that is, in the case of using a strip or pile foundation. To use expanded clay when insulating a strip foundation from the inside, you do not need a binder - just pour the material between the lintels.

But for external use of expanded clay, you need a binder, which is most often used as concrete. Since concrete conducts heat well, the resulting mixture will be a poor thermal insulator.

Basalt, mineral or glass wool is a good thermal insulator, but tends to absorb moisture, which impairs its properties. Application requires additional hydro- and vapor barrier, which significantly complicates and increases the cost of work.

Foam insulation can be used to thermally insulate foundations. The material retains heat well, practically does not absorb moisture, but is attractive to insects and rodents that like to live in it. To prevent their penetration into the insulation, a metal mesh is installed directly on the foam.

Polyurethane foam is a good insulator, and its application by spraying provides additional advantages:

- The surface is smooth, without seams, gaps, cracks;

- The material has good adhesion to almost any surface;

- PU foam easily penetrates into any cavities and reliably isolates them.

The material perfectly protects from moisture and retains heat well. Its disadvantages include its high price, the need to use expensive equipment for its application, and degradation under the influence of ultraviolet rays.

Extruded polystyrene foam, like polyurethane foam, is an excellent heat insulator and is not afraid of moisture. The material is more affordable in price than polyurethane foam. However, its installation is more labor-intensive than spraying polyurethane foam. To install polystyrene foam boards, it is necessary to cut the boards to size, apply glue, and also seal the joints of the boards.

TEPLOFOM+ panels based on extruded polystyrene Styrofoam are resistant to corrosion and have high impact strength due to the polymer-cement layer. They are characterized by increased mechanical strength due to the presence of fiberglass mesh in the structure. They are not destroyed by ultraviolet radiation. Therefore, they are more preferable for outdoor use than polyurethane foam.

Vertical or horizontal insulation

When insulating the foundation from the outside, you can install thermal insulation vertically, horizontally, or in both ways at once. Vertical insulation involves installing thermal insulation on the base or side surface of the foundation. This makes it possible to maintain the temperature without allowing it to drop excessively.

Horizontal insulation allows you to both additionally protect the foundation itself from cooling and prevent freezing of the soil around it and under it (in cases where the foundation of the house is shallowly buried).

Installing thermal insulation of the blind area (horizontal insulation) does not allow the soil to freeze and swell, which means the foundation is not subject to the destructive effects of frost heaving forces that occur when the soil expands when the water that impregnates it freezes.

Simultaneously with the insulation of the blind area, its waterproofing is organized. This allows excess water to be drained away from the foundation, thereby preventing its destruction.

The use of both vertical and horizontal insulation at the same time makes it possible to create effective thermal insulation, which will better retain heat inside the house and will have a positive effect on the durability of the load-bearing structures of the house.

Vertical insulation

Vertical insulation of the base is a measure of increasing the strength and durability of the foundation, which is the key to a high service life of the entire building. In winter, an uninsulated foundation becomes a powerful conductor of cold, which, while simultaneously contacting the external environment and structures adjacent to heated rooms, will significantly reduce the temperature of living rooms. This means you either have to put up with the low temperature in the house, or you’ll have to spend extra money on heating.

In order not to have to endure inconvenience and incur extra costs, it is necessary to make vertical insulation of the foundation. This effective measure will prevent unwanted heat loss and also prevent premature destruction of the foundation.

Horizontal insulation

Insulation of the blind area - horizontal insulation - is used to effectively prevent the interaction of moisture and the buried part of the foundation, as well as to prevent freezing of the soil near the foundation and directly under the house. Polystyrene foam boards are best suited for thermal insulation of blind areas. They are effective as a heat insulator, they are the easiest to work with, and they do not require the rental of expensive equipment for installation.

Work on insulating the blind area is carried out both in conjunction with vertical insulation and independently of it. At the first stage, the layer of soil next to the foundation is removed. The width of the trench should be 1-1.5 meters, the depth depending on whether it will be only horizontal insulation, or whether it will be combined with vertical insulation. For horizontal, a depth of 5-6 centimeters is enough. For vertical, next to the foundation, additional depth is made to the depth of soil freezing.

The resulting trench is filled with a layer of crushed stone, which acts as drainage. The thickness of the layer depends on the type of soil. It is advisable to compact the ground under the crushed stone layer in advance, tilting it away from the house - this will create an additional system for draining water from the foundation.

Then insulation boards are laid; it is preferable to use extruded polystyrene foam - this is a durable material with high resistance to mechanical stress, good resistance to moisture, and excellent thermal insulation properties. A layer of thermal insulation is placed on top of the insulation. At the end, finishing is done by concreting the blind area or laying decorative material.

Stages of work

To ensure effective thermal insulation, reduce heat loss, and extend the life of the foundation, it is necessary to strictly follow the installation sequence of the insulation:

- It is necessary to dig a trench around the perimeter of the building. Near the foundation it should be buried at least to the extent of soil freezing. Or, if we are talking about a shallow foundation, then to its lower edge;

- The side surface of the foundation is cleaned of dust, dirt, and debris. Cracks, potholes, ditches must be sealed, protruding parts must also be eliminated. It is desirable that the entire surface is flat, so that the insulation can be installed as tightly as possible to the foundation, which will improve the heat-insulating properties of the structure;

- The vertical surface is primed or a bitumen-based waterproofing primer is applied to it. The layer should be such as to completely cover the surface from the base of the foundation to its upper edge;

- Then the waterproofing is glued or fused. It is performed with an overlap at the bottom and top of the foundation. Overlapping is also necessary at the joints of adjacent sheets. Particular attention should be paid to gluing the corners. Only carefully completed work on installing waterproofing will protect the foundation from moisture;

- When the installation of waterproofing is completed, it is necessary to proceed to the installation of thermal insulation panels. They are attached using a special adhesive on a cement or polymer base. It can be purchased either dry or in liquid, ready-to-use form;

- Covering the foundation with polystyrene panels starts from the bottom edge moving upward. For small private houses, it is enough to install one panel about 120 cm long. Approximately half the length will be below ground level, the other half above this level.

- Each panel is equipped with a stepped recess. This is necessary so that when joining the slabs, through gaps do not form, leading to the appearance of cold bridges. The main measure to eliminate them is to fill cracks and gaps with polyurethane foam;

- Polyurethane foam can decompose due to moisture penetration, so it is recommended to coat the seams with bitumen mastic. It is acceptable to use branded foams from insulation manufacturers. They do not require additional processing;

- After completing the installation of thermal insulation panels, it is recommended to protect the material from direct interaction with the ground. To do this, a reinforcing mesh is placed on top of the insulation, and then a layer of plaster is applied. As a solution, you can use an adhesive composition or a special waterproofing mixture. You can also cover the insulation with some kind of rolled material that can provide protection against moisture penetration. Ruberoid works well.

- The final stage is backfilling the trench with soil. It is recommended to carry out the process in several stages, at each of which it is necessary to compact the poured layer.

When the thermal insulation of the foundation is completed, you can move on to the next stage of work, for example, finishing with decorative materials.

Pile foundation

Insulation of a pile foundation can be done either with or without arrangement of space under the floor. In each case, thermal insulation will require different measures. If the space between the floor and the ground surface is small, then it is necessary to form insulation of the floor using expanded clay backfill or a sand and gravel cushion.

If it is intended to create an insulated subfloor, then the space under the house is insulated along the entire perimeter, and then a fence is formed using brickwork or through the installation of decorative panels from siding, lining, and corrugated sheets. To ensure reliable removal of moisture in the underground, vents are installed that allow the space to “breathe,” which prevents the development of fungus and mold. It is recommended to close the vents during the winter period.

If it is necessary to insulate only the floor and leave the subfloor unheated, a layer of heat insulation is introduced directly into the floor structure. This is done at the construction stage. The insulation is placed between the subfloor and the decorative finishing floor. As a rule, the heat insulator is installed in two layers to ensure that cold bridges are eliminated.

Read more: Insulation of foundations on screw piles.

Features when working with acrylic paints

Acrylic paints are an inexpensive material that is easy to work with and dries relatively quickly. But the disadvantage is the narrow palette of colors, so you need to create the desired shade manually. You can get burgundy, lilac, turquoise, sand, wenge, lilac, and others by mixing colors.

Mixing colors

There are some rules when working with acrylic:

- The surface to be painted must be smooth, clean, free of oil and grease stains. It must first be cleaned of the previous finish. It is not recommended to apply a new coat of paint over an old one;

- Before painting, the walls need to be leveled with putty, and then several layers of primer must be applied. The primer is used for better adhesion of paint and for less paint consumption;

- Before use, acrylic must be diluted with water or special solvents, but it is better to do this in a separate container with a portion of paint. This is necessary in order not to spoil the entire volume at once, but to use only as much as needed.

- After use, used rollers and brushes must be rinsed thoroughly with water, otherwise they will become unsuitable for further work. You also need to wash other tools that were used. The top of the paint bucket needs to be wiped down so that the lid can be opened in the future.

- Most often, painting occurs in 2-3 stages, and for an effective result, this must be done in one direction. To simplify and speed up the work, you can take a spray bottle.

Important! Also, do not forget about precautions; before work, it is better to cover or seal all places and objects that will not be painted. You can work with the material at a temperature not lower than 5 degrees and not higher than 27 degrees

Another main rule of application is to use paint first on a small area or a completely separate surface. When creating the desired shade, it is better to try it on a draft. You also need to wait until it dries completely, as after that the color becomes a little darker or lighter, depending on the type of paint. And if the color matches the expected desired result, then you can start painting the surface or decorating objects.

Useful tips

If you decide on external thermal insulation of the basement, a few tips will be useful for you that will help increase the efficiency of the measures taken:

It is better to carry out insulation in dry and clear weather. Especially if instead of EPS you use regular foam, which is less resistant to moisture. Never neglect waterproofing

This operation not only prevents damage to the insulating material, but also protects the foundation and walls of the basement from destruction. When choosing a mastic with which you are going to glue foam or EPS, pay special attention to its hydrophobic properties. And do not apply it pointwise (as I described for interior work), but in a continuous layer

Then it will play the role of another waterproofing agent. The edge of the glued insulation material must rise above the ground level (after backfilling) by at least 50 cm.

A basement like this is everyone’s dream.