Filling voids in the wall with polyurethane foam with your own hands.

Pouring polyurethane foam is an innovative method of thermal insulation, which consists of filling walls and their cavities in a building with this material. This technology is used for thermal insulation of buildings for various purposes - industrial enterprises, residential buildings and even offices.

Insulation of walls using polyurethane foam

Pouring polyurethane foam into interwall voids is used to insulate and strengthen the walls of a house under construction or an already in use building. When building houses, brickwork of 1.5 or 2 bricks is used. According to SNiP II-3-79, in order to provide adequate protection from the cold, the wall thickness must be at least 1.2 meters.

It is impractical to use such a number of bricks due to the load on the foundation and the complexity of installation, so the walls are made of two layers. They erect an internal and external one, leaving a space of 50 centimeters between them for free air circulation. This helps retain heat and prevent condensation. But this is not enough for complete insulation. It is difficult to thermally insulate the space between walls using rolled or soft materials. The method of filling voids with polyurethane foam allows you to evenly fill all the gaps inside and between walls.

How does the work happen?

Filling of polyurethane foam is carried out through the lower holes into which the material is supplied under pressure. As the voids fill and the foam hardens, the craftsmen move to the next level. The work continues until the specialists reach the ceiling openings.

Filling with polyurethane foam, in turn, provides a high level of protection against heat loss and cold ingress. Polyurethane foam is able to fill the smallest cracks, making the insulation absolutely airtight.

In addition, we provide waterproofing services for buildings.

12

Years of operation of the company

In the field of insulation and waterproofing

1920

Objects of varying sizes and complexity

190000 m2

Insulated and waterproofed area

4

Professional teams

99%

Satisfied clients

Features of using polyurethane foam for filling

After mixing components A and B, the polyurethane foam for pouring is a plastic mixture. After hardening, it becomes dense and rigid and has a cellular structure. The material is light and hard, does not deform or break.

The thermal conductivity coefficient of polyurethane foam is one of the lowest - 0.022 W/m·K. Therefore, even a small layer of a few centimeters is enough to protect the structure from the cold. Polyurethane foam has high adhesion and is attached to metal, glass, wood, and concrete. Penetrates into pores and cracks, fills them and maintains a uniform structure for 30 years.

Why is polyurethane foam the best among insulation materials?

What is this insulation? This is, in fact, foam plastic familiar to us from childhood, or rather one of its varieties. After hardening, polyurethane foam has a cellular structure, and inside each cell there is a gas bubble.

At the moment, polyurethane foam is significantly superior to its competitors in thermal protective properties, and in ease of use, as well. For example, to provide a level of thermal protection that can be provided by a five-centimeter thick layer of this insulation, you will need a layer eight centimeters thick of expanded polystyrene, nine centimeters of mineral wool and ten centimeters of polystyrene foam.

As a result, we get a lightweight, effective and fairly easy-to-use thermal insulator that can significantly increase the thermal protection of your home without complex work and serious material and labor costs. And in closed volumes, such as the voids in such walls, such insulation will serve for a very, very long time. In general, we can say that for insulation of inter-wall cavities, polyurethane foam is the optimal, if not ideal, choice.

Pouring equipment

To fill polyurethane foam walls, pouring complexes are used. Such equipment allows you to accurately dose the components to produce polyurethane foam, mix them until they are homogeneous, and pour them into the space between the walls. Installations come in high pressure (more than 100 atmospheres) and low pressure (4–10 atmospheres).

In high-pressure devices, mixing of components occurs due to penetration into each other. In low-pressure apparatuses, materials are mixed with a special mixer. Air does not participate in this process, because its bubbles lead to the formation of voids inside the matter. The polyurethane foam is applied to the surface using a spray gun.

Low pressure units usually weigh up to 100 kilograms. This makes it easy to move them in space when pouring polyurethane foam into the walls. They are easy to use and can be used at home. Disadvantages include the short length of spray hoses and higher material consumption compared to high-pressure installations.

The performance of high-pressure units allows you to fill large spaces, use hoses up to 120 meters, and avoid the formation of suspension near the spraying site. The disadvantages include the high cost of the equipment, weight more than 100 kg, difficulty of use - a specialist is required to work with the installation.

Features of lightweight brickwork

The walls of brick low-rise buildings are erected 2-2.5 bricks thick. This amounts to 510-640 mm. The parameters are calculated based on the ability of the masonry to conduct and retain heat, as well as calculations of autumn and winter temperatures typical for the area. This type of masonry is called lightweight or well.

The well masonry consists of 2 parallel walls that are connected to each other. Between them is a layer of air that performs thermal insulation functions. The thickness of the outer wall is half a brick, the inner one is 1-1.5. The air layer between them is about 120 mm. This type of masonry is more effective than solid masonry: brick consumption is 40% less, and the wall mass is 28% less. The thermal resistance of the structure increases.

IMPORTANT: well masonry is used exclusively for the construction of external walls of low-rise buildings, or the top floors of apartment buildings, since its strength is low for high-rise buildings.

Examples of high pressure installations:

- Polymer complex PK-60 - capacity up to 60 l/min, self-cleaning filling head, asynchronous gear motor, industrial controller with touch screen;

- Graco HGR - productivity up to 20 kg/min, hydraulic drive, filling controller, automatic determination of the accuracy of the component ratio. Watch the video to see how the Graco installation works using the example of Khimtrust SKZ-20 interwall fill:

- Hennecke - productivity up to 35 kg/min, hydraulic drive, built-in containers of 250 liters, filling head, automatic control of dosing accuracy.

Cost of spraying polyurethane foam

Density of polyurethane foam:

12 – 22 kg/m3

From 375 RUR/m2

- 5 cm - 450 rub/m2

- 10 cm - 800 rub/m2

- 15 cm - 1225 rub/m2

order

Density of polyurethane foam:

35 - 40 kg/m3

From 700 RUR/m2

- 5 cm - 750 rub/m2

- 8 cm - 1200 rub/m2

- 10 cm - 1400 rub/m2

order

Density of polyurethane foam:

60 - 75 kg/m3

From 1300 RUR/m2

- 5 cm - 1350 rub/m2

- 8 cm - 2120 rub/m2

- 10 cm - 2600 rub/m2

order

For any questions, call: 8 (968) 868-81-93 or leave a request:

PPU filling technology

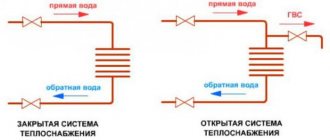

There are two approaches for thermal insulation of hollow walls by pouring polyurethane foam. If the building is at the construction stage, the material is poured from above between the outer and inner walls. To do this, choose polyurethane foam with a high start time - 30–45 seconds. For example, “Khimtrust SKZ-30 (slow).” The substance manages to sink down, and then begins to expand, filling all the voids and cracks.

How to fill with polyurethane foam if the building is already in use? To insulate a built house, polyurethane foam is poured between the wall and the cladding from the outside. Typically, a material with a low start time is used - 10–20 seconds. For example, Khimtrust SKZ-20. Holes with a diameter of 12–14 millimeters are drilled in the external wall of the house at the depth of the brickwork. The distance between the holes is 50–100 centimeters. They are placed in a checkerboard pattern. You need to fill the holes with polyurethane foam from the bottom up. This will allow the material to be distributed evenly, without voids inside. After filling, the holes must be closed with wooden dowels to prevent the material from leaking out. Polyurethane foam hardens in 1–2 minutes and forms a dense moisture-proof layer between the inner wall and the cladding of the building.

Video description

Pouring polyurethane foam using a household installation.

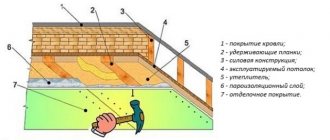

Insulation of attics and attics

You may have the impression that to fill polyurethane foam you definitely need space between two vertically constructed planes, but this is not so. If you have the right equipment, liquid thermal insulation can be poured onto exposed vertical and inclined planes, as shown in the top photo. After all, in essence, laying the foam substance here is no different from applying polyurethane foam, only there is no such powerful expansion effect. Therefore, to insulate an attic or attic, polyurethane foam is applied to the walls, roof and floor, and after drying it is covered with facing materials. When the foam hardens on the floor between the beams, you can even walk on it to lay the floor.

Note: pouring polyurethane foam for insulating houses has one drawback: this will require special equipment, and the foam itself must be ordered in containers, based on the volume of voids to be filled.

Advantages of filling walls with polyurethane foam

The method of pouring polyurethane foam between walls allows you to insulate a building at any stage of construction, as well as during operation, without disturbing the interior decoration of the premises. Polyurethane foam does not shrink, so you don’t have to worry about the integrity of the thermal insulation layer. Water resistance allows you to avoid the formation of cold bridges, condensation, and mold. Components for casting polyurethane foam have a thermal conductivity coefficient from 0.023 W/K to 0.03 W/K. "Himtrust SKZ-30" is suitable not only for heat insulation, but also for sound insulation of inter-wall spaces.

Watch the video for details of pouring polyurethane foam with the Khimtrust SKZ-30 component system.

Khimtrust products are available in 14 warehouses throughout Russia. When ordering components in the online store from a ton, cumulative discounts apply. Delivery throughout the Russian Federation and the CIS.

Application area

Polyurethane foam has excellent sealant properties, and therefore polyurethane foam is often used to fill voids with your own hands, as well as for processing thermal seams in panel houses, sometimes in road construction. In addition to this function, which is to create a thermal insulation effect, the use of polyurethane foam makes it possible to solve some other important problems for operation. With its help, it is possible to create high-quality sound insulation, and the wall receives an excellent protective coating that protects the coating from mechanical damage.

Quality is also important, since polyurethane foam can be used in places that cannot be insulated with other insulation materials due to the design of the building. For example, processing gaps where it is not possible to use roll and slab insulation, and to use granular materials will require dismantling the roof or part of the wall.

In addition, the use of polyurethane foam makes it possible to improve the appearance of the wall and get rid of defects, and due to the fact that the material is aesthetic, the layer will not crack when the structure shrinks and will retain its properties fully.

Advantages

Let us note the advantages of filling voids with polyurethane foam:

Among all similar materials, polyurethane foam has the lowest thermal conductivity coefficient.- The coating has a monolithic structure, in which there are no seams or cracks.

- Provides high quality noise insulation.

- The material has neutral biological indicators.

- Polyurethane foam is resistant to mold and various fungal formations, and also does not attract rodents.

- The material has a service life of 30 years.

- Can be used even in hard-to-reach places.

- Retains its thermal properties during the entire period of operation.

- It is vapor permeable and resistant to mechanical impacts.

- There is no shrinkage.

- Has high adhesion rates.

These are excellent characteristics for a thermal insulation material.