Principle of operation

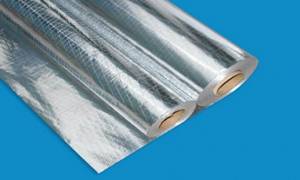

Foil materials are a complex product with a layered structure. The base here is polypropylene fabric, fiberglass, and lavsan. These are components that are resistant to explosive effects, biological and chemical aggression.

The use of a durable non-woven or woven polymer base allows you to create a reliable base for metal foil, which itself cannot boast of particular strength. At the same time, flexibility convenient for installation is maintained. This composition eliminates the possibility of fungal colonies settling and rotting.

Vapor barrier materials on the working side are backed with metallized film. The positive qualities of both aluminum foil and the polymer base are preserved. Vapor barrier with foil copes with three tasks at once:

- Insulation from precipitation and steam. The foil material protects the wall insulation system or roofing pie from steam penetration.

- Reflection of thermal radiation. The metal coating serves as a kind of reflector; it interrupts the flow of heat waves, redirecting the stopped heat within the house.

- Protection from ultraviolet rays and wind. Vapor barrier films are a durable barrier against wind. In the summer, they are able to reflect the sun's rays from the roof if they are installed with the working side facing outwards.

Methods of application

The structure of foil vapor barrier materials has significantly expanded the scope of application. Now they are actively used in insulated roofs , they are often placed on the inside of the roof pie, and in the south they are usually mounted above the insulation. If the house has an unfurnished attic, then foil protection is installed along with waterproofing.

They are often used as a substrate for floor coverings and underfloor heating systems, and for insulating frame wall structures. A foil vapor barrier is also installed in the form of a screen that reflects heat flows from any heating units.

The system must be installed correctly so that the foil materials can perform their reflex function. Between the ceiling of the steam room, the walls, the inner lining of the attic and the metal covering, you should always leave a non-ventilated air gap, the thickness of which should not be less than 2 cm.

If the material is used as a heat-reflecting screen for an attic or flat roof, then a ventilated gap of 3 cm is left . Here, everything that is reflected from the foil can easily be discharged onto the street along with the penetrated steam and condensate.

The necessary gaps are formed by installing a sheathing made of a metal profile or bar. The laths are installed taking into account the type of roofing, the calculated load on the structure, and the slope of the slopes is also taken into account.

What is the difference between vapor barrier and waterproofing

Vapor barrier films

Now this is an interesting question. In essence, in both cases we are talking about the effect of moisture, it’s just that in the first case an increased temperature is added to it. Therefore, it would be correct to use these concepts and related materials something like this:

- vapor barrier is done from the inside of the room so that water vapor that arises inside does not turn into condensation when faced with the cold of the external environment;

- waterproofing is done primarily to protect against moisture coming from outside, and it can be in the form of water vapor or precipitation.

When it comes to ceiling insulation, vapor barrier is the bottom layer, waterproofing is the top layer. However, if the bathhouse has a second floor with a residential attic, then the term “waterproofing” becomes somewhat arbitrary, because protection is carried out from the same vapors, only found in the insulation.

Hence, probably, the constant confusion that can often be found in descriptions.

Everything is clear with the roof: the layer located directly under the roofing material is waterproofing, because precipitation can seep into it, and the layer that is made from the inside on top of the insulation is a vapor barrier. See the article When is it necessary to insulate the roof of a bathhouse and when is there no point? Roof thermal insulation technology

REMEMBER! There is also a purely mechanical difference between the materials used for vapor and waterproofing. The vapor barrier does not “breathe” at all; it is designed not to let anything pass through it at all - neither air, nor steam, nor liquid. And waterproofing is preferably “breathable”, that is, capable of releasing water vapor in one direction, and in the opposite direction - preventing their penetration.

If you take this into account, do not make any mistakes either when steam or waterproofing the ceiling in the bathhouse. Here’s another video that will reinforce what has been said (advertising, of course, but you don’t have to watch it to the end):

Benefits of use

Insulating materials, where water-repellent material is combined with foil, have many advantages, which is why they are in high demand among craftsmen. These include:

- Minimum thickness. Laying does not affect the thickness of the roof pie. If materials with anti-condensation properties are used, then it is not necessary to install a distance gap.

- Lightness. This installation will not affect the weight of the structure. Therefore, there will be no need to carry out additional actions to strengthen the foundation.

- Flexibility. Installation is easy, even if you have to lay the material on complex forms. You can easily go around concave and convex corners, various rounded surfaces.

- Environmental Safety. Vapor barrier films are made from materials that are not harmful to human health or the environment.

- Manufacturability. The sheets are easy to cut with regular scissors, or you can use a construction knife.

- Zero porosity. Vapor barrier does not absorb moisture. Long-term use, even in a damp room, will not cause the foil to rot.

- Multifunctionality. The same film can be used to protect several adjacent structures, creating a continuous sealed barrier.

Installation technology

Most often, vapor barrier materials with foil are used to equip a cold attic and a warm attic. In the first case, the insulation system must be installed along the ceiling, in the second - along the slopes.

To install a vapor barrier correctly , you need to adhere to generally accepted construction rules:

- The vapor barrier of the slopes should be a continuous barrier that prevents the penetration of moisture. To do this, the canvases need to be sealed together with regular tape.

- Strips of vapor barrier material are usually laid strictly horizontally. The first panel is fixed at the ridge girder, the second is placed on top to cover the edge of the installed panel on the side of the room that is being finished.

- The canvas spreads from the attic side onto the wooden floor in strips, extending onto the walls along with vertical ceilings of 20 cm each. It turns out to be a kind of pallet with sides.

- Then the material is rolled out as if the roll was formed by the manufacturer himself. The installation side is indicated on the vapor barrier - it cannot be changed at your discretion.

- On pitched roofs, the material is stapled to the rafters from the inside. If they are fixed with a block, then a counter-lattice must be placed on top under further cladding.

- If you need to put a vapor barrier in a system with open rafters, then it is placed along the outer ribs, then rigid slab insulation is installed. The fabric is secured with a stapler.

- If you are installing a ceiling on the ceiling side, then you need to buy self-adhesive materials.

It is worth noting that accessories for foil insulation must be selected from the same manufacturer as the material. Of course, you can find universal tape on sale that is suitable for joining materials of any kind, but in the case of foil structures, you need to remember about tightness. Therefore, here it is better not to experiment with options for adhesive tape for gluing, but to take it from the same company that produces the foil sheets themselves.

Technology for laying vapor barrier membranes

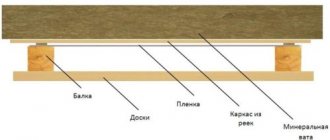

This section will discuss how to install a vapor barrier on a ceiling. Naturally, this process must be combined with the installation of heat-insulating material in the ceiling. In my case, we will talk about a wooden timber structure, in which the ceiling is made along supporting load-bearing joists. Therefore, it is very important to choose the type of vapor barrier when insulating the ceiling.

To insulate the ceiling in a wooden house with a vapor barrier, you need to perform several stages of work, which are shown in the diagram below.

Ceiling vapor barrier technology.

Now I’ll tell you how to make the necessary list of works at each stage.

Selection of vapor barrier, insulation and additional materials

First, let’s decide which materials are best suited for insulation (this also determines which vapor barrier to choose for the job). Considering that the work will be carried out in a wooden house, and this material belongs to the “breathable” category, it is better to thermally insulate it with products with high vapor permeability.

I advise everyone to use mineral mats based on basalt fiber for this purpose. These products have a huge number of advantages.

Now let's decide which vapor barrier is best for the ceiling of a wooden house. I don’t want to limit you in your choice of products in terms of strength and other characteristics. I will only note that you need to buy vapor barrier materials with high vapor permeability. It is desirable that this indicator should not be lower than the vapor permeability coefficient of mineral wool (0.56 mg/(m*h*Pa) and wood (0.32 mg/(m*h*Pa)).

Vapor barrier for a bathhouse is another matter. In this case, it is necessary to take all measures so that the insulation layer does not get wet from the huge amount of steam generated inside the room. Therefore, you need to choose an impermeable film with a foil heat-reflecting layer.

In the latter case, it is very important to know how to properly lay such a film, or more precisely, which side to attach the material to the insulating layer. But I'll tell you about this a little later.

So, everything is clear with insulation and vapor barrier. But you need to stock up on a few more materials and tools, without which it is impossible to complete the installation:

- Wooden boards 10 cm thick. They will be used to line the ceiling from the inside of the room and hold the insulation between the beams.

- Grooved floorboards. Suitable for arranging the floor on the attic floor (on the back side of the ceiling of a living space).

- Screwdriver. Useful for securing various cladding parts.

- Stapler with staples. You will learn its purpose when you read about how to attach a vapor-permeable film to the ceiling.

Well, now you can go directly to work.

Ceiling preparation

Any specialist you ask about how to properly install vapor barrier and insulation will tell you that the work needs to start with preparing the ceiling. To do this I perform the following operations:

- I am repairing ceiling beams. If the house has already been used, you need to check the integrity of the supporting elements of the shelf, clean them of dust and debris, and remove traces of mold and mildew. If defective areas are detected, part of the beam (or all of it) must be replaced. Otherwise, it is impossible to guarantee any long service life of the insulating layer.

Schemes for repairing damaged floor beams.

- We treat the supporting elements of the ceiling with a fungicide and fire retardant. To do this, you can use some universal liquid such as Guardian-2 or “Fire Bioprotection”. This treatment will destroy microorganisms living on the surface of the wood, and will also increase the fire safety of the ceiling.

Fire-retardant composition for wood processing.

- I am installing utilities in the ceiling. This must be done before laying insulation and installing waterproofing membranes. All electrical wires in a wooden house must be laid in metal or polyvinyl chloride fireproof ducts, and ventilation pipes must be insulated with polyethylene foam shells.

Installation of electrical cables in a wooden ceiling.

- I'm making a box for the chimney to pass through a wooden ceiling. It is necessary to ensure that heat from the pipe is not transferred to the ceiling. To do this, I recommend constructing a box from tin, which is secured to the beams, and then filled with expanded clay or covered with mineral wool.

The place where the pipe passes through the ceiling.

After such preparation, you can safely proceed to laying the vapor barrier membrane.

Ceiling vapor barrier

The technology for installing the vapor barrier film itself will not cause you much difficulty. As a material, I suggest using Izospan B membrane or a similar one produced by another manufacturer.

Laying is done from inside the living space. The scheme is like this:

- I mount the first canvas on the floor beams. To do this, I simply roll out a roll of film and attach it to the bottom of the beams with staples from a construction stapler. You can also use nails with wide heads. There are several points here:

- The canvas must be secured so that there is a slight overlap of the membrane on the walls of the home. Otherwise, cracks will form there, through which water vapor will penetrate to the insulation and lead to its getting wet.

- If the work is carried out in the hot season at high air temperatures, the film should not be fastened tightly, but with a slight sag - about 2 cm per meter. This is necessary so that when the temperature decreases (and, accordingly, the size of the canvas), the vapor barrier layer does not tear due to strong tension.

Installation of a vapor barrier membrane on the ceiling beams from below.

- I secure the second and subsequent vapor barrier sheets. You need to proceed similarly to the scheme described above. The edges of the films should overlap each other at a distance of 10-15 cm to ensure greater tightness. For convenience, Izospan membranes are already marked with appropriate markings that you just need to follow.

Markings on the film for ease of installation.

- I seal the seams of the vapor barrier layer. For this, various adhesive tapes are used, which I discussed in the corresponding section above. Please note three points:

- First, the seams between the canvases are sealed. To do this, you need to bend the overlap and glue a strip of adhesive tape. After this, remove the protective anti-adhesive film from its surface and secure part of the second sheet. As a result, the adhesive tape will end up inside, forming a completely sealed seam.

- Then you need to seal the junction of the film with vertical enclosing structures (walls and partitions). Izospan tape will also help with this, as it adheres well to vapor barriers and other building materials. You need to leave a margin in this place so that the film does not tear due to the displacement of the base.

- After this, all that remains is to cover the box, which serves to pass the chimney through the wooden ceiling. Izospan brand adhesive tape can withstand surface temperatures up to +100 degrees, so it will not come off during operation of the stove or boiler. As a result, you should have a dense, sealed surface similar to the one shown in the photo.

- I sew up the ceiling from the inside with decorative material. Considering that I used a “breathable” membrane on which moisture does not condense, there is no need to create a ventilation gap. Therefore, I will lay the lining directly on the vapor barrier, securing the parts with clamps on the floor beams. The result will be the design shown in the photo.

Vapor-insulated and insulated ceiling, lined with clapboard.

It’s a different matter when you use a material with a reflective foil layer for vapor barrier. Then a gap is necessary and the decorative material is attached as follows:

- brackets for the galvanized frame (the so-called “pawns”) are attached to the floor beams from the bottom directly through the layer of reflective vapor barrier;

- load-bearing profiles or wooden blocks of a suitable cross-section are attached to them (by the way, at this stage you can additionally level the surface of the ceiling if the floor beams were installed unevenly);

- lining or sheet material (plasterboard, plywood, etc.) is attached to the rack-mount supporting parts.

Ceiling sheathing using reflective vapor barrier.

There must be a gap between the sheet material or lining and the vertical enclosing structure to allow moisture to escape from the ceiling.

Installation of insulation

I have already written more than once about the installation of insulation, in my case mineral wool, and those interested can find detailed information in one of my articles on this site.

Laying insulation boards on the outside of the ceiling (the vapor barrier membrane is clearly visible in the photo).

Therefore, here I will mention only a few features that are very important to remember:

- The width of the insulation boards used should be 1-2 cm greater than the distance between the support beams. Then the thermal insulation material will become ineffective and will not form cold bridges.

- To install an insulation layer 100 mm thick, it is better to use slabs 50 mm thick. They are laid in two rows with alternating layers to prevent the appearance of cold bridges in the transverse seams.

- The top of the insulation must be protected from moisture with a waterproofing layer. I will tell you how to do it in the next section.

Ceiling waterproofing

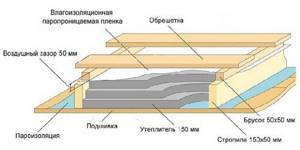

To protect the thermal insulation layer from getting wet from the attic (or attic) side, you need to use a reliable membrane that will not let water through if it leaks through the roofing. Installation is done as follows:

- I lay the film over the insulating material. It is necessary to ensure that the membrane is distributed freely over the surface, but does not form strong sagging. Otherwise, the air flow inside the ventilation gap will create an unpleasant rustling sound.

- I attach the film to the beams. To do this, I use the same construction stapler with staples.

- I seal the seams. This process is no different from the technology described above. Adhesive double-sided tape is used.

- I install the counter-lattice bars. To do this, wooden parts with a cross section of 5 by 5 cm are fixed to the floor beams. Self-tapping screws are used that are screwed directly through the waterproofing film.

- I'm installing flooring. The floor boards of the attic or attic are attached to the bars. The end result should be a cake similar to the one shown in the photo below.

Scheme of a vapor-insulated insulating pie of the interfloor floor.

Leading foil products

To install a ceiling or attic, you need to select a suitable and reliable vapor barrier film. Therefore, you should first find out what proven and popular product options are available on the construction markets.

Energy saving film DELTA®-REFLEX

These products have proven themselves well in roof construction and have an impeccable reputation among roofers. The reflective coating on the working side is created by spraying. Then a polyester film is applied over it, which protects the aluminum layer from shedding and damage. The reflection coefficient of this product is about 50%.

At sub-zero temperatures , the film does not lose its flexibility; it is used to provide protection against steam from inside and outside the house. Can be used in different rooms with high humidity. If you find a version of a similar film, but where the word PLUS is added to the marking, then there will be a self-adhesive tape along the edge of such films - it makes the work of installers much easier, which is why it is what is most often purchased, despite the high cost of the product.

Reflective material “Izospan FD”

In terms of price, this is a more humane option, but it is also less resistant to the realities of adversity. This is a two-layer composition made of polypropylene fabric, with an aluminum coating applied on top.

In terms of strength indicators, it is inferior to the first option, but is able to outperform in terms of energy-saving characteristics: the coefficient of thermal reflection is about 90% . It usually attracts installers with its affordable price; in addition, these products are easy to find in many hardware stores. It is worth noting that in the technical data sheet of the film, a separate line indicates the temperature range, which ranges from -60 to +80 degrees.

Do-it-yourself vapor barrier for the walls and ceiling of a bathhouse

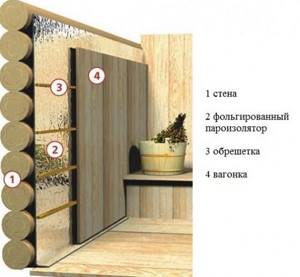

When building a bathhouse on your own, you need to take into account many factors. Starting from the choice of the location of the foundation, the material for the walls and roof, ending, at first glance, with such little things as hydro and vapor barrier of the bathhouse. Let's consider an example. Let's take as a basis a bathhouse built from timber 150 mm thick, where the wall decoration is wooden lining:

- if there is insulation and vapor barrier in the bathhouse, heat loss per 1 sq.m. walls will be 28 W/sq.m.

- without the use of thermal insulation materials, heat loss will be equal to 52 W/sq.m.

Thus, if thermal insulation is not used, additional energy costs are required to heat the bath and maintain the desired temperature inside the steam room.

Foundation waterproofing

The foundation is one of the main vapor barrier zones. Saturated with groundwater, the soil freezes in winter, creating the danger of deformation of the structure and the appearance of foundation cracks. To avoid this, waterproofing is necessary.

Foundation waterproofing scheme A layer of waterproofing mastic is laid on the concrete blank. The base of the mastic is high-quality insulating bitumen, which includes a corrosion inhibitor and antiseptic. There are no toxic solvents. It is used in conditions of weakly and moderately aggressive soils. Main characteristics of the mastic:

- Water absorption per day – no more than 0.4% by weight

- Average consumption with a layer thickness of 0.5 mm – 0.5 l/m2

- Drying time for one layer – no more than 24 hours

The use of waterproofing mastic extends the service life of the foundation. Once the waterproofing is completed, it is necessary to insulate the “sole” of the building. The most advantageous option is to use polystyrene foam. We cover the base with sheets of thermal insulation 5 cm wide in a checkerboard pattern.

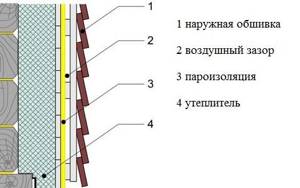

Vapor barrier of bath walls

The main task of a steam room in a bathhouse is the ability to retain heat. After all, in winter, the bathhouse must be guaranteed to have a high temperature inside the room. If there is no vapor barrier, then the steam accumulated in the room escapes through the walls. If the bathhouse is not insulated, then the steam, passing through the wooden paneling, condenses between the wall and the cladding. As a result, drops of accumulated water contribute to the processes of rotting and mold formation. IMPORTANT! Only professional installation of insulation and vapor barrier will preserve the structure of the bathhouse

Bath vapor barrier diagram

Insulation of walls from the inside

To insulate the walls, thermal insulation material is placed on the inside between the wooden frame and the wall. The main thing is to choose wisely which vapor barrier material is best for a bathhouse. Remember! glass wool, mineral wool, basalt are not used as insulation for bathhouse walls!

- Polyfoam - not afraid of moisture, durable, fireproof. Qualitatively insulates any structures, even brick buildings. It is easy to use and can be easily cut with a knife. The most versatile material.

- Fireproof plates "Minerit". The Minerit LV slab belongs to the class of absolutely non-combustible materials and can withstand high temperatures of up to 150 degrees. They are moisture-resistant, impact-resistant, and do not contain harmful or toxic substances. The stove works great in conditions of high humidity. The material absorbs and releases water practically without deformation, which makes it possible to install the slabs end-to-end.

Thermal insulation materials are placed in the space between the racks made of wood or metal profiles. The fastening of the plates is carried out with special glue or plastic dowels. If the sheets are larger than the opening between the bars, then a tighter fit will ensure high-quality insulation of the room. If necessary, fill the gaps with construction foam. Foil is attached to the planks on top of the insulation, with an overlap of 10-15 cm. The joints are taped with aluminum tape for tightness. The foil prevents the escape of heated steam, thereby retaining heat in the room. But due to the high thermal conductivity of aluminum, some of the heat passes further, where it is retained by the insulation. So, this design: insulation + foil insulator is the best option for vapor barrier of a bathhouse. But there is a more profitable solution from an economic point of view. This is the use of foil material that combines insulation and vapor barrier at once. Foil thermal insulation does not absorb, but reflects thermal energy and can be used to enhance the “thermos” effect. Thermal insulation material prevents cold air from penetrating into the room and sends warm air into the steam room. There are many foil materials, here are some of them:

- Penolon - suitable for protection in areas with high humidity. It is a two-layer polyethylene foam, one of the surfaces of which is covered with aluminum foil. The material is resistant to high temperatures up to 120 degrees, hydrophobicity 99%, low vapor permeability coefficient 0.001 mg/m h Pa, low thermal conductivity coefficient 0.031-0.040 (W/m°C) and low density 26-45 kg/m³. Foil Penolon is the thinnest of thermal insulation materials (thickness - 8-10 mm).

- Reflective insulation PenoPremium NPP LF is specially designed for vapor barrier and insulation of baths and saunas. The insulation is made from NPP foamed polypropylene, followed by lamination with high-quality aluminum foil. It has high temperature resistance up to 150 degrees, moisture absorption occurs in 24 hours - 0.74%. Thermal conductivity is Kf – 0.034 W/m*°C. The coefficient of thermal reflection of the surface is 90%. NPP is an eco-material made using ozone-saving technology; freon is not used in production. There is no unpleasant odor when the material is heated. Does not cause allergic reactions.

When installing reflective insulation, it is necessary to leave an air space between the film and the finishing of the room. To do this, use a sheathing on top of the “mirror”.

Bath ceiling vapor barrier

Thermal protection of the ceiling is extremely important. Hot air easily rises and goes out. To prevent heat loss, the surface is insulated using an open or closed method. The open method is intended for a bathhouse without a “working” attic. The wooden sheathing is waterproofed with a reflective film and then covered with a thermal insulator. A layer of sawdust and a layer of dry earth are used as backfill; expanded clay is also used for insulation, with a layer thickness of at least 25 cm. With a closed vapor barrier method, it is possible to use the attic as an additional room. The “pie” is installed according to the standard scheme: vapor barrier membrane + mineral slab + waterproofing membrane. Then they are covered with boards attached to the joists. Hydro and vapor barrier membranes are used as a water barrier. Membranes are designed to protect against the penetration of water vapor from inside the room and from exposure to moisture from the external environment.

Membrane vapor barrier for a bath

Yutafol vapor barrier is a membrane consisting of 3-4 layers with micro-perforation.

It is based on a polyethylene reinforcement mesh, onto which several layers of polyethylene film are applied. The microscopic perforation present in the film creates a vapor barrier effect. There are several types of membranes; one type has an additional foil layer. All Utafol membranes have a long service life and are manufactured according to the standards required for vapor barrier. Double-sided lamination of the film greatly improves its insulating properties. During installation, the film is laid so that its aluminum surface is directed inside the room. The membranes are connected to each other with special aluminum tape. Waterproofing membranes "Megaspan" - area of application: protection of insulation and internal roof elements from wind and rain. The waterproofing agent helps remove water vapor from the roof space and insulation, helping to extend the service life of the insulation and the entire structure as a whole. The membrane is laid on the outside of the insulation under the roof covering.

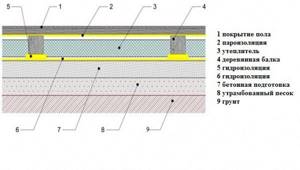

Floor insulation

Wooden covering is the most common flooring option. Insulation of the ceiling is only possible for a water-resistant wooden floor. The heat insulator is laid between the finished and subfloors. They protect the insulation from water with a vapor barrier on the inside of the room and a hydrobarrier on the ground side. Rigid mats made of mineral wool or polystyrene are used as insulation. For example, the Megaspan D waterproofing membrane is a two-layer, high-strength polypropylene woven fabric used as a layer when laying floors on concrete bases. In a steam room with a concrete floor, a “warm floor” system is not required. It is enough to place wooden gratings around the perimeter. But in the washing room, installing floor insulation will give convenience and comfort to visitors.

Specifics of foil vapor barrier: characteristics, conditions of use, installation

To create a fully functional vapor barrier in rooms with unstable temperature and humidity levels, it is necessary to use appropriate materials tailored to specific specifications. Similar conditions are formed in buildings such as bathhouses, attics, unheated cottages and extensions. Considering the features, a good solution would be to install a fabric such as a foil vapor barrier. But in order to ultimately obtain a fully functioning protective layer, many factors should be taken into account.

Why do you need foil vapor barrier ↑

As mentioned above, a vapor barrier layer with a metal aluminum coating is used in special cases and only in certain types of buildings, why is this necessary?

Firstly, the most important function of a foil vapor barrier is the ability to protect structures from excess moisture entering them. But, unlike other films and membranes, analogues with an existing metallized coating still perform the work of a heat reflector. That is, foil layers of vapor barrier are primarily needed where it is worth increasing energy saving.

2 Secondly, in rooms such as baths and saunas, the use of conventional films and membranes is impractical, since high temperatures will quickly render the protective layer unusable. And in conditions of high humidity, a protective layer is simply necessary.

Also, a good solution would be to use a vapor barrier with a layer of foil in the premises of dachas, outbuildings, balconies and attics, which are poorly or not heated at all. This will both protect structures from condensation and reduce the overall heat loss of the room.

Why do you need a roof vapor barrier?

In the interior of the house, a variety of economic and household activities are carried out, accompanied by the release of steam: we are engaged in cooking, wet cleaning, hygiene procedures, washing dishes, watering indoor plants. Even while at rest, we emit water vapor through breathing, not to mention intense physical activity.

Do you know how much moisture a person releases into the surrounding air? At 25 degrees Celsius per day, one person at rest throws 1.5 liters of moisture into the room, and with little activity up to 4.5 liters! Moisture evaporates through the skin and through breathing through the lungs

The vapor in the air is not visible to the naked eye. However, it is this that causes windows to fog up in cold weather, and after taking a shower we can see drops of condensed steam on the mirror in the bathroom. That is, steam is constantly in the air around us, and when it comes into contact with cold objects, it settles on them in the form of condensation. The more steam in the air and the colder the surrounding objects, the more condensation will fall.

During the cold season, the same water vapor settles in the form of small droplets in the structure of the insulated attic floor (ceiling) or in the roofing pie of an insulated roof. As a result, it causes dampness, the formation of fungus and the proliferation of pathogens. This happens if a vapor barrier was not created during construction, which is why fumes from the premises easily penetrate the layers of insulation and are absorbed into the wooden rafters and beams.

The lack of a vapor barrier in the attic floor resulted in steam leakage into the attic. During the cold season, steam condensed on the cold roof elements and turned into water and frost. Due to constant contact with water, the wooden elements of the roof have become infected with fungus and will soon become unusable. If you do not prevent steam from getting under the roof with a vapor barrier film, the roof will soon have to be replaced

During the cold season, the inside of the insulation and beams is warm, as it is heated by the internal air from the room. And their outer part is cold, because it is constantly exposed to the cold air of the street. Moving through the insulation and wood, water vapor at a certain moment cools to such a state that it can no longer be steam and turns into drops of water (dew point). This water wets the insulation and wood. The first loses its thermal insulation properties, and the wood begins to rot. Moreover, if the temperature drops further, the moisture accumulated in building structures will freeze. It is no secret that when water hardens, it greatly increases in size, and in our case this will lead to micro-tears and damage to the insulation and wooden elements.

In wooden houses, this problem is especially acute, since problems with excessive humidity directly affect the load-bearing capacity of structures and the sanitary condition of the house. Therefore, vapor barrier in a house with wooden floors or rafters is an urgent need, and not a marketing fiction.

Video about why vapor barrier of roofs and ceilings is needed

Types of foil insulation and regulations for their use ↑

In addition to wall materials, the use of vapor barrier is regulated by its type, or more precisely, by the material from which it is made.

The panel has two layers - the base and the actual metallized coating. The vapor barrier base can be of two types:

- Made from kraft paper. Quite a simple and cheap material, but it is subject to mechanical stress and less resistant to moisture. Made from polymer materials. This base is resistant to damage, humidity, and temperatures.

The metal coating of insulating panels also comes in two types:

- Aluminum spraying. The layer thickness can be 0.3 microns or more. However, thin metallized films play the role of a heat reflector much worse. Aluminium foil. Such vapor barrier materials have a metal layer of 10 microns, which makes them resistant to corrosion, and the degree of reflection is about 97%.

You should select foil insulation based on two factors: the type of room, and the types of film itself. Cloths coated with metal foil on a polymer base are best suited for wet bath conditions. And for dry rooms, you can purchase a cheaper option for spraying on paper. Also, the first option, covered with foil, goes well with heated floors.

Advantages of foil vapor barriers ↑

A metallized layer on a vapor barrier base significantly improves the properties of the barrier and gives it tangible advantages over conventional films.

- Low weight. With decent functional properties, foil vapor barrier is lightweight, which does not create large loads on the load-bearing structures of the building. Slight thickness. The layer laid on the attic ceiling or ceiling does not in any way affect the volumes or height of the room due to the minimum thickness of the base and the metallized coating itself. Ease of use. Vapor barriers with foil can be easily installed on curved contours of buildings and in hard-to-reach places. In addition, it is very easy to make a workpiece of any shape by simply cutting the panel with scissors. You also do not need to have specialized tools and skills to install the insulating layer. Temperature stability. The presence of a foil layer makes the vapor barrier less susceptible to high temperatures. And in combination, the film provides maximum protection to structures from high humidity. Cleanliness of materials. The production of such insulation does not require toxic materials and compounds that can be released under the influence of heat. Versatility. Using the same type of panel, you can insulate various building elements adjacent to the installation site.

Manufactured assortments of reflective vapor barrier can be selected for any room based on the price-quality factor. It will equally have vapor barrier protective properties. And long-term use in conditions of even excessive humidity (typical of a bathhouse) will not lead to the formation of mold and mildew.

But, you can get a fully functioning vapor barrier in a room only taking into account its specifics, and most importantly, compliance with the installation rules.

The main functions of the attic vapor barrier layer

To answer the question of which vapor barrier to choose for the attic, you need to know its purpose. When warm and cold air flows combine, steam and condensate always form, the accumulation of which certainly leads to a decrease in the performance characteristics of any, even the most reliable building material.

Wood rotting reduces the strength of the entire structure, which becomes the reason for repair or complete replacement of the main parts of the structure. In addition, high humidity promotes the formation of mold and fungi, which release toxic substances. As a result, a person may experience malaise and headaches, and even allergies.

The joint work of insulation and vapor barrier not only prevents the penetration of steam, but also retains maximum heat in the attic room.

Features of installation of foil vapor barrier ↑

The main task of a vapor barrier is to protect the insulation and walls from moisture penetration inside. This function is the starting point when installing panels in different rooms.

- When assembling a “cold” roofing pie, metallized strips of material are mounted in the ceiling (recommended for the ceiling), from the inside of the room with the foil down.

- If installation is carried out for a house in the attic, then the foil vapor barrier is laid with the metal side inside the room on top of the laid insulation on the inside of the roof slopes. Fix the film with a stapler and counter-lattice slats. In the bathhouse, foil vapor barrier is installed on all planes, on the floor, walls and ceiling. The foil surface is turned inside the room.

When installing layers, you should adhere to the technological laying rules:

- All wooden parts of rafter systems and other building elements should be carefully inspected for protruding sharp edges or fasteners to avoid damage to the film during installation. Before you begin installing the insulation, you should treat all wooden parts of the structure with an antiseptic. This will extend the life of the material and is guaranteed to eliminate problems such as the formation of fungus and mold. Vapor barrier layers on any planes (roof slopes, walls, interfloor ceilings) must be continuous. The porous structure does not require ventilation gaps. The mounted panels are connected hermetically using foil tape. Laying of vapor barrier is carried out only in a horizontal position, according to the scheme from top to bottom. That is, the first strip is mounted near the ridge, the second lies lower, overlapping the first. When laying sheets of material, releases are made on walls and other nearby areas. The width of such strips should be at least 150-200 mm. Fastening in attics, attics and ceilings is carried out with a stapler. Additional fixation is performed with sheathing slats, which can later be used as a base for the internal cladding. All joints of the panels are taped with foil tape.

How to install a vapor barrier on a ceiling

The vapor barrier layer is laid on the inside of the ceiling, located inside the room.

In cases where the ceiling separates the interior from the cold attic, and the ambient temperature can be quite low, the insulation should be vapor-proofed on both the inside and outside (from the cold attic side).

Installation of the vapor barrier layer is carried out before laying the insulation, and the film materials must be installed without sagging or folds. The overlap of the vapor barrier strips should be 10–15 cm, which will ensure the required strength of the connection, and the use of special adhesive tapes of the appropriate width will ensure the required tightness.

The use of narrow tapes, 5.0 cm wide or less, is one of the mistakes that leads to peeling and, accordingly, depressurization of the installed vapor barrier layer.

When laying various types of material, it is necessary not to make a mistake with the sides of the vapor barrier, like this:

- polyethylene films of various types are laid on the insulation on either side;

- anti-condensation films are laid with the smooth side facing the insulation, and the fleecy side towards the vapor formation;

- foil vapor barriers are laid with a metal layer inside the room;

- The method of arrangement of membranes must be looked at according to the manufacturer’s recommendations, because different types are arranged differently.

When securing the vapor barrier layer by using a construction stapler equipped with fastening brackets, it is necessary to place a gasket made of cardboard, thin plastic or other durable material under them in order to prevent damage to the vapor barrier coating. If there is a rough ceiling covering, the vapor barrier is attached to its surface using wooden blocks with a thickness of 20.0 - 25.0 mm or a galvanized metal profile used for fastening plasterboard and other sheet cladding materials.

Vapor barrier with foil

Heating your home costs more and more every year. Winters are getting colder. Many people have found a solution: installing insulation for walls, ceilings, and floors. But a large difference in air temperature inside and outside leads to the occurrence of condensation precipitation. They, in turn, negatively affect the insulation material. Thus, you most likely will not be able to save money. Either you will pay a lot of money for electricity consumption, or spend money on a new insulation system every year.

The only way out is a vapor barrier. This is an auxiliary layer that prevents condensation precipitation from damaging the insulation layer.

Materials for vapor barrier can be:

- plastic film (not a reliable barrier);

- reinforced polyethylene film (due to its structure it is not a reliable material for vapor barrier);

- fabric for bags (better suited for roof vapor barrier);

- combined spunbond fabric (better suited for roofs);

- foil fabric (great for vapor barrier of all surfaces).

Thanks to its unique properties, practicality, reliability and economy, foil film is the most optimal option for creating a barrier.

The texture of the foil is solid and smooth. These indicators create an ideal barrier.

- About the thickness of Penofol

- FLOORING CONSTRUCTION USING PENOFOL

- More information on the topic:

Membrane "TechnoNikol" for the ceiling

The leading position among vapor barrier materials is occupied by the TechnoNikol membrane. Her brand “Optima” is excellent for vapor barrier of the ceiling in a house with wooden floors. The structure of this material contains three layers, two of which are made of polypropylene, the middle layer between them is a high-tech functional vapor-permeable film. Membranes of this brand are in most cases presented in roll form up to 1.5 meters wide and 50 meters long. The material is the best option when creating a vapor barrier layer on any type of floor. Can be used both indoors and to protect the external surfaces of a building.

Installation of a vapor barrier on a wooden ceiling is carried out according to the following scheme:

- The membrane should be laid on top of the thermal insulation, with the smooth side facing the inside of the room.

- The stripes can be located in a parallel or perpendicular direction relative to each other.

- The strips are installed with an overlap of 10-15 cm.

- To fasten the membrane, it is recommended to use galvanized self-tapping screws with a wide head or special brackets that have an anti-corrosion coating.

- The joints of the canvases are hermetically sealed with mounting tape with a self-adhesive side.

- The edges of the membrane sheet must be placed on the wall by 15-20 cm and secured with a wooden strip or metal profile.

- The perimeter of the vapor barrier layer is also taped with mounting tape.

- In areas where the membrane will come into contact with beams, pipes and ventilation ducts, care and attention should be exercised. It is important that the vapor barrier does not have folds or sagging.

- A gap of about 3-4 cm should be left between the vapor barrier membrane and the decorative ceiling for ventilation.

In addition to the main listed brands, there are other materials on the market for ceiling vapor barrier. Their quality characteristics and efficiency are also at a high level.

Advantages of foil vapor barrier

Foil is a material that creates the maximum barrier, preventing precipitation from entering the insulating material by 100%. This is what is most often used to decorate a bathhouse.

Many people use regular foil, but it is quite fragile and can break under the slightest pressure.

Manufacturers have taken care to eliminate this drawback. They created a two-layer material. It consists of a flexible and durable material and aluminum foil coating. This tandem brings maximum benefit, reducing negative indicators to a minimum.

This type of vapor barrier material can retain over seventy percent of thermal mass. It is easy to attach to the wall or any other surface. It is fixed to a wooden base using a stapler. For concrete and other surfaces, mounting tape is used. This film can be easily divided into the necessary elements. It tolerates very high temperatures well - more than plus one hundred degrees, low temperatures - below forty. Therefore, it is often used for baths.

Disadvantages of this material

Foil film for vapor barrier is divided into three types:

- with a layer of foil;

- with aluminum coating;

- with aluminum foil.

If you choose a film with a layer of ordinary foil, you must be prepared for the occurrence of corrosion processes. Simply put, the foil layer can become rusty.

Film coated with aluminum and aluminum foil are not subject to such processes.

It is important to fill the joints between film elements with an adhesive composition that forms the film. Otherwise, all positive effects will be lost.

It is important to protect material coated with aluminum from overheating. Otherwise, it may damage the finishing layer.

If you buy aluminum-coated film, remember that it does not retain heat well. In general, aluminum foil film is the most useful option.

Vapor barrier in a bathhouse with aluminum foil is shown

Laying process

Most often, foil vapor barrier is used for bathhouses. In this room, more moisture is located inside. Also, the inside is subject to sudden temperature changes. That is why the vapor barrier layer is laid on the inside.

Useful picture for work

Usually the bathhouse is built of wood. And it tends to collapse under the influence of moisture. To prevent this from happening, it is important to use a vapor barrier material. It is this layer that will ensure quick and high-quality heating of the room, with minimal consumption of resources. To be most effective, it is important to follow the instructions exactly when installing the vapor barrier.

Stages of work:

- prepare a layer of insulation;

- for reliable vapor barrier, it is important to make the previous layer as even as possible;

- prepare wooden boards: thin and low;

- divide the foil film into strips;

- fasten strips of material using wooden boards and nails, staples;

- elements of the material must be superimposed on each other, with an overlap of twenty centimeters;

- You can connect the strips together with adhesive or tape with foil elements;

- Tape the joints of the material with the wall, ceiling, floor, and windows with tape.

Important Tips:

- ensure the tightness of the vapor barrier layer;

- leave a gap for air between the vapor barrier layer and the decorative layer, about two centimeters, the height of the boards for fastening will help with this;

- Do not stretch the material; when heated, it will deform; leave a sag of two centimeters.

You can buy vapor barrier film at any hardware store. The price per square meter of such film with aluminum foil starts from twenty-five rubles per square meter. It can withstand about one hundred and forty degrees Celsius with a “+” sign, and is capable of reflecting about ninety percent of heat. Environmentally friendly.

You can buy tape with a metal element in the same store. The price for it ranges from one hundred rubles per fifty meters, fifty-five millimeters wide.

Good luck with your renovation!

We would be grateful if you share this article on social networks with your friends.

The main types of materials for ceiling vapor barrier

To install a vapor barrier layer when installing a ceiling, various materials are used, differing in their technical characteristics, possible places of use and, of course, cost. When choosing a vapor barrier, the criteria that determine the type of material used are:

- Technical characteristics - vapor permeability and strength to mechanical stress, as well as temperature conditions for installation and operation.

- Geometric dimensions and weight.

- Environmental and fire safety.

- Service life.

- Reliability.

- Possibility of installation on certain building structures.

- Personal preferences of the user (developer).

- Price.

Polyethylene films

The most affordable material used when installing vapor barriers is polyethylene film, which can be of the usual type, as well as reinforced or perforated types.

For reinforced grades, the film web is strengthened by making a polyethylene reinforcing layer.

These films come in perforated and non-perforated types. Perforated stamps have microholes on their surface that allow substances to pass through in a vapor state, but retain them in liquid form. The advantages of polyethylene films are:

- Low cost.

- One hundred percent vapor tightness (for non-perforated brands).

The disadvantages of this material, when used as a vapor barrier, are:

- Low strength to external mechanical influences.

- Not long service life.

- Difficulty in performing installation work.

- Formation of condensation on the inner surface, which requires an air gap between the film and the insulation layer.

Brands of reinforced polyethylene films have slightly better performance in terms of strength and service life, so they are more preferable for vapor barrier of building structures, however, they are somewhat more expensive than their counterparts without a reinforcing layer.

To fasten the film to the ceiling surface, a construction stapler and nails with wide heads are used, and for reliable fastening, wooden slats are used, mounted on wooden structures.

In difficult places, the vapor barrier is attached using double-sided adhesive tapes, as well as special adhesives. The film strips are overlapped and secured with adhesive tapes, both single-sided and double-sided, depending on the location of the joints.

Reinforced polyethylene film

Polypropylene films

Polypropylene films are also used for vapor barrier construction of ceilings and other building structures. This is a more durable material than analogues made on the basis of polyethylene.

Anti-condensation films are made on a propylene basis, consisting of two layers, of which one, polypropylene, is smooth, and the second, made of cellulose, is fleecy. Anti-condensation polypropylene films have the following advantages, such as:

- Strength to mechanical stress such as tensile and tearing.

- Reliability.

- No condensation formation.

A feature of the installation of anti-condensation films is their location in relation to the insulation. The fleecy side is located inside the room, where moisture can penetrate, and the smooth side is located on the side of the insulating layer.

Foil materials

Foil-coated materials are materials that have a layer of foil applied to their surface.

They are made on a film base, as well as on a foamed polymer layer (penofol, isospan). The advantages of this type of vapor barrier are:

- Strength.

- Ease of installation work.

- Increased ability to retain heat indoors, because a layer of foil reflects currents of warm air, preventing them from leaving the room.

The main disadvantage is the high cost in comparison with various types of films. When installing foil materials, the strips are connected end-to-end, using special aluminum tape.

Vapor barrier foil materials on a film base

Diffusion membrane

This material is a multilayer coating and comes with varying degrees of vapor barrier, which is determined by the presence of a certain amount of perforation on the surface of the membrane, as well as layers in its structure.

A distinctive feature of diffusion membranes is that when used, it becomes possible to install the membrane directly on the insulation layer. Thus, the internal space of the room is used more efficiently and labor costs for installing the “pie” of interfloor or other ceilings are reduced.

These indicators are due to the fact that there is no need to create a ventilation gap and, accordingly, install the sheathing that creates this gap.

Diffuse vapor barrier membrane

Other materials

The group of other materials that are used to create a vapor barrier layer when installing a ceiling includes: glassine, roofing felt, as well as special mastics and varnishes.

Glassine is a fairly popular material when installing the “pie” of interfloor ceilings, the reason for this is its advantages, such as:

- Environmental Safety.

- Ease of use.

- Relatively low cost.

Liquid materials that are made on the basis of bitumen are also used when performing such work.

Their advantages are the absence of the need to pair individual vapor barrier elements (strips or sheets), as well as ease of application to the surface to be treated using hand-held painting tools or spray devices.

Glassine is an inexpensive and easy-to-use insulating material

Foiled penofol for frame housing construction

This article describes the technical characteristics and distinctive features of Penofol insulation. Which can be used for frame house construction, made using wooden house-building technologies or LSTK technologies. Insulation in frame houses is used to insulate the house from external weather conditions. Insulation materials are usually produced in flexible versions, as well as in the form of slabs or rolls. Penofol is available in roll form, which is convenient for insulating corners, roofs and walls of frame structures.

It should be borne in mind that Penofol, due to its small thickness, does not retain heat very well and cannot be used as the only insulation. Penofol is equivalent to stone masonry five centimeters thick.

Penofol - reflective thermal insulation - a new generation of insulation. Unique thermal insulation properties with low thickness.

Penofol is a highly effective vapor and heat insulation based on foamed polyethylene covered with aluminum foil. Penofol - combines the heat-insulating properties of “trapped” air bubbles with the high heat-reflecting ability of pure aluminum (99.4%), thus being a unique product that stops heat in all three ways of its propagation: thermal conductivity, convection and radiation.

Foil vapor barrier will save your money

Heating your home costs more and more every year. Winters are getting colder. Many people have found a solution: installing insulation for walls, ceilings, and floors. But a large difference in air temperature inside and outside leads to the occurrence of condensation precipitation. They, in turn, negatively affect the insulation material. Thus, you most likely will not be able to save money. Either you will pay a lot of money for electricity consumption, or spend money on a new insulation system every year.

The only way out is a vapor barrier. This is an auxiliary layer that prevents condensation precipitation from damaging the insulation layer.

Materials for vapor barrier can be:

- plastic film (not a reliable barrier);

- reinforced polyethylene film (due to its structure it is not a reliable material for vapor barrier);

- fabric for bags (better suited for roof vapor barrier);

- combined spunbond fabric (better suited for roofs);

- foil fabric (great for vapor barrier of all surfaces).

Thanks to its unique properties, practicality, reliability and economy, foil film is the most optimal option for creating a barrier.

The texture of the foil is solid and smooth. These indicators create an ideal barrier. The absence of seams, cracks, allows you to reliably retain moisture. The reflective effect retains heat by reflecting warm air and bringing it back inside.

Among other things, this material is not susceptible to mold and bloom. They are convenient for covering surfaces. You do not need to use special equipment for this. Affordability is also an advantage of this option. A fairly low price makes it accessible to everyone.

Installation of vapor barrier

The next step in the attic insulation scheme is the installation of a vapor barrier, for which purpose foil film made of polypropylene is most often used. Less commonly used are polyethylene, glassine or roofing felt. The foil material provides reliable protection of surfaces from evaporation, and at the same time improves thermal insulation by reflecting heat back into the room.

The foiled polyethylene film is secured to the rafters using a construction stapler, placing the shiny side inside the attic. The vapor barrier material should not only cover the entire insulated surface, but also extend beyond it by about 5-10 centimeters on each side, where it is then glued with aluminum tape or tape. The film tension should be moderate - not too strong and not weak, without sagging.

Advantages of foil vapor barrier

Foil is a material that creates the maximum barrier, preventing precipitation from entering the insulating material by 100%. This is what is most often used to decorate a bathhouse.

Many people use regular foil, but it is quite fragile and can break under the slightest pressure.

Manufacturers have taken care to eliminate this drawback. They created a two-layer material. It consists of a flexible and durable material and aluminum foil coating. This tandem brings maximum benefit, reducing negative indicators to a minimum.

This type of vapor barrier material can retain over seventy percent of thermal mass. It is easy to attach to the wall or any other surface. It is fixed to a wooden base using a stapler. For concrete and other surfaces, mounting tape is used. This film can be easily divided into the necessary elements. It tolerates very high temperatures well - more than plus one hundred degrees, low temperatures - below forty. Therefore, it is often used for baths.

Disadvantages of this material

Foil film for vapor barrier is divided into three types:

- with a layer of foil;

- with aluminum coating;

- with aluminum foil.

If you choose a film with a layer of ordinary foil, you must be prepared for the occurrence of corrosion processes. Simply put, the foil layer can become rusty.

Film coated with aluminum and aluminum foil are not subject to such processes.

It is important to fill the joints between film elements with an adhesive composition that forms the film. Otherwise, all positive effects will be lost.

It is important to protect material coated with aluminum from overheating. Otherwise, it may damage the finishing layer.

If you buy aluminum-coated film, remember that it does not retain heat well. In general, aluminum foil film is the most useful option.

Vapor barrier in a bathhouse with aluminum foil is shown

Which material to choose?

To achieve the maximum effect from vapor barrier in the bathroom, it must be performed in combination with waterproofing and insulation.

And since all this work is carried out using the same type of materials, the choice will be based only on the ratio of price and quality. Most often, for the vapor barrier of Ondutis ceilings, they use: ordinary polyethylene film or polypropylene, foil, special waterproofing and vapor barrier membranes.

The main advantages of using polyethylene film:

- affordable price;

- you can lay the film yourself without additional knowledge or outside help;

- additional strength is achieved when used in conjunction with reinforced mesh.

But the film creates a not very comfortable indoor climate and may not last as long as other vapor barrier materials.

Polypropylene film:

- more durable material than standard polyethylene;

- has an additional moisture-absorbing cellulose layer;

- Condensation removal is achieved by ventilating the space between the waterproofing and insulation.

The use of foil polyethylene film allows you to simultaneously create an excellent vapor and heat insulation layer, thanks to the foil and metal mesh. This film has quite good characteristics for long-term use in any residential area and works much better, in contrast to standard one-sided polyethylene.

Membrane hydro- and vapor barrier film is today considered the most advanced material that fulfills its duties 100%. Thanks to the special design, it allows the entire room to “breathe”, which creates very comfortable conditions for people. The cost of membranes is, of course, higher than that of polyethylene, but this difference in price is completely justified.

Additionally, such membranes can be divided into three more types:

- Membranes with limited hydropermeability allow you to remove all excess moisture from the room. The percentage of moisture extracted is controlled due to the specific design of the material.

- Membranes with variable permeability are a more advanced design that begins to allow a greater amount of moisture to pass through, depending on its current concentration in the room.

- Foil membranes are very widely used in the construction of bathrooms, swimming pools, saunas and baths. Thanks to their design based on a metal mesh, they allow not only to control the level of humidity, but also to return a certain percentage of heat back into the room.

The complex Izospan system is used in the construction of not only floors and roofs, but also walls. Regardless of the manufacturer, it is an almost universal set of materials that can replace both individual elements of thermal, hydro and vapor barrier, and all together. Each roll of such material of any brand of the Izospan system has a convenient installation diagram and instructions for use. Buying such material is also not difficult - today it is a fairly common type of building materials. For information on how to properly insulate a ceiling, see here.