Types of mineral wool and their differences

Mineral wool has a fibrous structure of various orientations, which can be:

- horizontal;

- vertical;

- corrugated (wavy);

- combined (mixed).

Thanks to the thin cross-section of the fibers and the air mass, it is light and convenient for transportation and installation. The small diameter of each thread helps slow down heat transfer, so behind a small layer of 50-100 mm it will be warmer than behind brickwork of the same width. The range of application of the material starts from insulation of walls, floors and ceilings, to insulation of lines with liquid carriers, industrial containers.

Among the well-known manufacturers of mineral wool are:

Rockwool.

Knauf.

Izovol.

Isover.

Paroc.

Ursa.

In addition to mineral wool, popular names include “basalt”, “stone”, “slag” and “glass wool”. Some buyers, trying to figure out which is better - stone wool or mineral wool, turn to sellers at the market or in the supermarket with similar questions, and inevitably bring a smile to their face.

It’s worth clarifying here: mineral wool refers to all materials that have a similar fibrous structure and are used for sound and heat insulation. That is, stone or basalt, as well as glass wool - these are all types of mineral wool. It makes no sense to talk about the advantages of mineral wool, since this is the general name for a group of fleecy insulation materials. Let's look at what they are separately and what are the features of each of them.

The materials used for insulation of vertical and horizontal surfaces, as well as sound insulation, are prescribed in GOST 52953-2008. They are divided into three types: glass wool, stone wool and slag wool. The latter is made from molten slag, which is a by-product of blast furnaces. Due to its weak structure and high tendency to absorb moisture, it is not very suitable for insulating rooms and will not be considered in this comparison.

Glass wool (glass wool)

The production of glass wool is similar to the production of glass. For the base, sand, borax, limestone and soda are taken. Broken glass can be used, which is the use of recycled materials and provides even greater savings in the cost of the process.

The substances are mixed and fed into the hopper. The composition is heated to a temperature of 1400 degrees, due to which it melts, turning into glass. But they don’t let him freeze. The liquid hot substance is passed through dies into a special centrifuge. Due to the high centrifugal force and the action of steam, the material is divided into multiple thin glass threads.

In order for the fibers to better hold together, polymer substances are added to the composition, acting as binders. Often these are formaldehyde resins, the amount of which can reach 4% of the total mass. In the glass wool of recent years of production, there are new developments where a petroleum composition is used, which has increased the strength of the final product.

The combined mass is dried at a temperature of 250C, which consolidates the polymerization. During this process, the fibers harden and become yellowish in color. After final cooling, it is cut and packaged for sale. The product can be supplied in slabs or rolls of different thickness and density, which is important to pay attention to when choosing.

The thickness of the resulting fibers can vary from 5 to 15 microns, and the length of the threads from 15 to 50 microns. When thousands of similar fibers are woven together, this gives sufficient strength and does not allow the material to fall apart. But individually, each thread is fragile, so it is easily damaged by impacts. The consequence of this is itching and irritation on the skin when invisible fragments dig into bare areas of the body.

Glass wool in a roll.

Basalt (stone) wool

To produce basalt insulating slabs, rock (most often of volcanic origin, frozen on the surface) is used. Hence the second name stone wool. The raw materials are melted in furnaces to a temperature of 1500 degrees and fed into a centrifuge. Rotation at high speed helps separate thin threads from the total mass.

The resulting fibers are immediately subject to the addition of binders (the same formaldehyde resins and petroleum compounds). Under high air pressure, the materials are pushed into the chamber, where it cools and compacts, forming a fleecy substance. Using mechanical cutting, it is given shape and size.

Basalt wool in slabs.

Basalt wool is produced in the form of rolls or slabs. The thickness of an individual fiber is 3-5 microns, and the length does not exceed 16 mm. Therefore, the material has low thermal conductivity and is more durable. Due to the production from stone, the threads are not so brittle and do not dig into open areas of the body.

Having obtained a general idea of the methods for producing types of insulation, you can move on to the details. To find out which is better - stone wool or glass wool, we will consider the key characteristics of each material and highlight the leader by position.

What to choose: basalt wool or glass wool

In the building materials market, mineral insulation materials account for ½ of the total sales of products in this category.

Their advantages over organic-based insulation materials have ensured their popularity and high rating in the field of construction work. The most common types of insulation are glass wool and stone wool (basalt wool). Today we will tell you about the properties of these products, the pros and cons of their use, and which insulation is best suited for a particular type of construction.

Glass wool

The starting material for these products is broken glass (80%), natural sand, limestone, borax, dolomite. The raw material, melted at a temperature of 1500 degrees, is placed in a centrifuge in a chamber and inflated with steam. After treatment with a polymer aerosol, the fibrous mass enters the conveyor for the leveling procedure.

The further process is polymerization of the material at a temperature of 250 degrees and cooling. The finished insulation is cut, rolled into rolls and sold.

- fire safety level is 400-700 degrees, after which the material begins to fuse and loses its performance qualities;

- insulation resistant to aggressive environments protects metal surfaces of structures from corrosion;

- the long fiber of glass wool makes it flexible and elastic, which allows it to be used for geometrically complex structures;

- high level of sound insulation;

- small volume and the ability to restore shape after compression simplifies the transportation process; affordable cost.

Among the disadvantages is the tendency of the material to shrink due to crystallization of the fibers. But this process begins after a long period of time from the start of operation. Working with insulation requires full compliance with safety rules, since microparticles from brittle fibers can cause irritation of the skin or mucous membranes.

https://youtube.com/watch?v=eHT165_JaYA

Basalt wool

Insulation obtained by melting basalt rock. The production technology is similar to the production of glass wool. The material obtains certain properties thanks to special binders and additives.

- fire safety level 700-1000 degrees;

- service life up to 50 years with preservation of all operational properties;

- the vertical arrangement of some of the fibers protects the material from shrinkage;

- insulation fibers allow water vapor to pass freely without absorbing them;

- the material is chemically passive and helps protect structures from corrosion;

- the technological process allows us to produce insulation with different hardness, these can be rolls with soft material and slabs with increased rigidity;

- the insulation has good heat and sound insulation properties.

The disadvantages of the material include the fact that it cannot be compressed like glass wool rolls during transportation.

What to choose?

These mineral insulation materials have many similar characteristics. But there are also differences. Products based on basalt stone have a longer service life. A building with such insulation does not shrink, and will maintain excellent thermal insulation for several decades without the need to replace the material.

When constructing buildings in noisy areas of the city and near highways, the question arises of reducing the noise level in the room. The ideal value for our body is 25 dB. According to sanitary standards, the daytime indicator should be within 45 dB, and the nighttime value should not exceed 35 dB. Stone wool absorbs noise better, so it is more suitable for areas with heavy traffic or entertainment centers.

According to its characteristics, stone wool is in a more advantageous position, but in terms of cost, it is much more expensive. Therefore, in terms of recommendations, we can give advice - be guided by the purpose of insulation and the period of operation of the premises.

For temporary premises and country houses, cheaper glass wool is suitable. It will cope with all functions perfectly, and its service life will come to the end of the building’s life.

It is better to insulate residential premises - apartments and houses - with basalt wool. Its durability, the ability to be used for any area of the house from floor to ceiling, technical characteristics are more suitable for such premises. Its safety is also important - the absence of particles that cause injuries to the skin and eyes. When carrying out repair work on insulated areas, you will not have to worry about the health of your loved ones.

«>

Thermal conductivity

Thermal conductivity is the ability of a material to transfer thermal energy from a warm part of the material to a colder part. When it comes to insulating walls or floors, the lower the indicator, the longer the external cold will not be able to penetrate the room, and therefore heating costs will be reduced. In the summer heat, thermal conductivity has the opposite effect and helps keep the inside of the house cool.

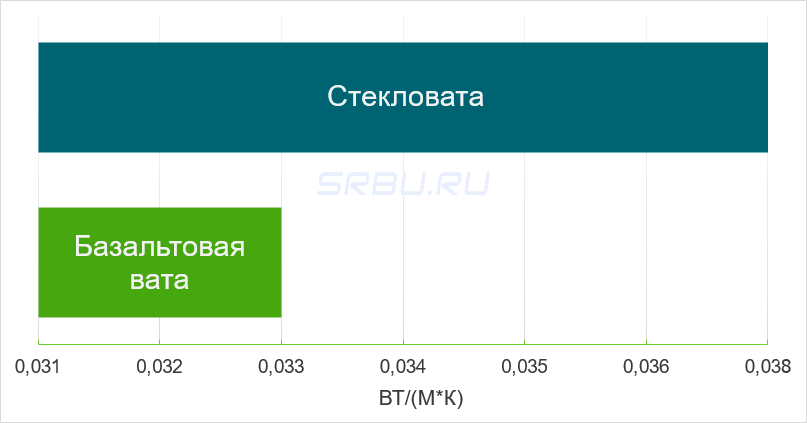

Due to its fibrous structure, heat transfer through mineral wool depends on the thickness of the threads. Glass wool with fibers of 5-15 microns has a thermal conductivity index of 0.038-0.046 W/(m*K). And basalt wool, with fibers with a cross-section of 3-5 microns, begins its minimum value from 0.033 W/(m*K). Since insulation made from a basalt base has thinner threads, heat transfer through them takes longer, which makes it a leader in this characteristic.

Results

Both materials can withstand high temperatures and belong to the flammability group NG (non-flammable). The cost is approximately the same. According to the manufacturers, these insulation materials do not harbor mice, but this is not true. Rodents take root almost everywhere.

Today we figured out what is better: mineral wool or stone wool. By mineral wool, we (like everyone who asks such questions) mean glass wool. Having compared the characteristics, we determined that glass wool is environmentally cleaner, does not generate dust during installation and does not chip. It is better for interior work. If we are talking about laying thermal insulation under screed or plaster in places with high humidity, then basalt thermal insulation is preferable. It does not absorb moisture so much and retains its thermal insulation properties even when wet.

Density and mass of materials

Density affects the mass of a material. The denser the slab, the more weight it will have on the insulated structures. Glass wool has a density from 11 to 200 kg/m3. Stone wool is produced with a density of 15-220 kg/m3.

With the same roll sizes, stone wool is denser and is clearly in the lead, but this victory has a second side - weight. In the case of a ceiling, second floor floor or walls, basalt slabs will exert greater pressure on the structures underneath, which must be taken into account at the design stage.

What is the difference, list of differences, difference in characteristics

Price

The cost of materials and the price of work (if the installation is not carried out by the buyer’s own efforts) is an important characteristic . The previously presented list of advantages demonstrates the high quality of insulation, so the price of materials cannot be low. We will not give specific values, since the cost of materials from different brands and from different suppliers may differ.

Basalt insulation IZOVOL L-35. Photo source here

We only note that the price of basalt insulation exceeds the cost of materials based on glass and slag by 20 and 50-60% , respectively. The cost of the work is the same and does not depend on the type of materials, especially since the installation can be done with your own hands. Manufacturers also supply installation instructions along with thermal insulation materials. There is a lot of advice and recommendations from experts in the public domain.

Durability, service life

Service life is an important characteristic. Insulation of buildings for various purposes is carried out for a long time, so owners need reliable and durable materials. The service life of the insulation and the ability to maintain its own properties depend on the quality, cost and manufacturer. Experts say that materials made from artificial fibers will not last more than 35 years. After this, they dry out and collapse, losing their thermal insulation properties. Insulation materials based on natural raw materials can last a longer period of time. Manufacturers and experts provide the following information:

- the service life of basalt wool is 40-50 years, some sources call the number 80 years;

- glass wool retains its properties for 8-10 years, its service life can reach 25-40 years, but the material at this time ceases to fulfill its intended purpose;

- Slag wool can also last a long time - up to 50 years, but subject to certain conditions, in particular, the absence of exposure to moisture and high temperatures.

Thermal conductivity

Thermal conductivity is one of the key characteristics of materials used for insulation. The parameter is represented by thermal conductivity coefficient , which represents the amount of heat that a material can conduct per unit time. Thus, the lower the value, the less heat the material conducts and the less cold air will enter the room, which will save on heating costs. The coefficient is denoted by the Greek letter lambda and is measured in watts per meter-kelvin - W/(m K).

Basalt insulation Isoroc Super Warm 100 mm 3.05 sq.m. Photo by Leroy Merlin

It should be remembered that the indicator depends on the thickness of the fibers and density; as a result, the thermal conductivity coefficient of mineral materials is:

- basalt wool - 0.032 to 0.048 W/(m K);

- glass - 0.038-0.052;

- slag - on average 0.46-0.48.

Thus, all materials have a low thermal conductivity coefficient and perfectly fulfill their intended purpose. As a result, when comparing the three types of materials, you should pay attention to other characteristics.

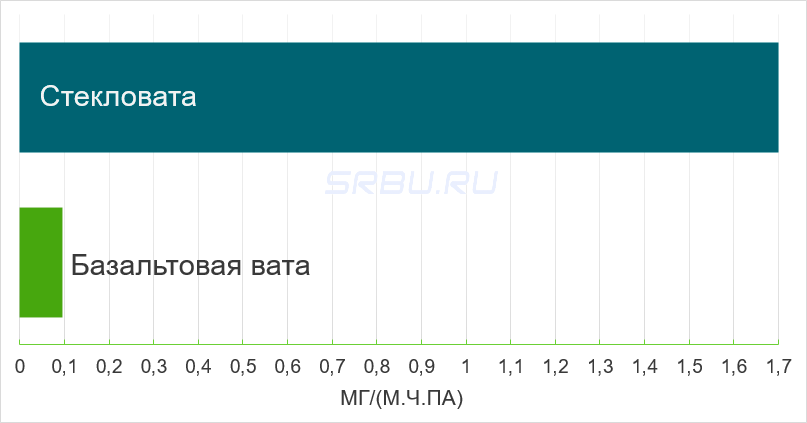

Vapor permeability

Vapor permeability - the ability of walls with insulation to “breathe” - is an important property for insulating materials. It is this characteristic that makes it possible to avoid the appearance of condensation between the layers of the wall sandwich, which in turn can lead to the formation of mold, mildew, and unpleasant odors. In accordance with this indicator, basalt wool is inferior to glass wool, 0.4-0.7 m·h·Pa versus 0.3. However, in this case the digital values do not play any role. Another important conclusion is that both materials are vapor permeable. It will not be possible to provide an indicator for slag wool; there is no information in open sources.

Water absorption

In accordance with this indicator, the record holder is basalt wool. Materials based on rocks of volcanic origin have practically zero hygroscopicity , which allows their use without restrictions on environmental humidity. The fibers do not absorb moisture, and the binding components (resins) act as a water repellent and repel water.

Basalt insulation 1.2 x 0.6 m, thickness - 10 mm. Photo Teplomarket

As a result of the experiments (basalt wool mats were immersed in water for 24 hours), only about 0.095% of water was absorbed . The water absorption coefficient of stone wool (when it is in a damp room) does not exceed 2% . Thus, stone wool is excellent and is actively used for insulating baths and sanitary facilities, facades, and foundations.

Glass and slag wool cannot boast of such characteristics. Materials quite actively absorb moisture from the air , which leads to deterioration and loss of thermal insulation properties; under these conditions, insulation is susceptible to shrinkage. Sorptive moistening per day of glass and slag wool is 1.7 and 1.9%, respectively.

Chemical resistance

All three analyzed mineral insulation materials tolerate contact well with chemical compounds , including those contained in plaster and installation mortars, and paints. If we talk about specific indicators, it is possible to give the following values:

- chemical resistance in water for slag, glass and stone wool is 7.8; 6.2 and 4.5% weight/mass loss;

- in an alkaline environment - 7; 6 and 6.4%;

- in an acidic environment - 68.7; 38.9 and 24%.

Thus, basalt wool in accordance with these characteristics (in two out of three) is the best option.

Density and mass

These characteristics are closely interrelated. The denser the material, the more weight it exerts on the insulated structures, but at the same time it has better strength, sound and heat insulation properties. Manufacturers offer a wide range of insulation materials with different densities to solve any problem.

Basalt insulation Paroc eXtra Smart 50x600x1200 mm 7.2 sq.m. Photo Petrovich

Materials with certain values are suitable for insulating specific structural elements of buildings, for example, basalt materials with a density of at least 60 kg/cubic meter are suitable for insulating walls.

The density of basalt insulation varies from 15 to 300 kg/cub.m. ; glass wool - 11-200 ; slag - 75-400 . However, with the same dimensions of the product, stone wool has greater density and weight; in comparison with mineral insulation, the value is twice as high.

Fire resistance

In accordance with fire resistance, materials are divided into several classes: from non-flammable (NG marking) to highly flammable or capable of igniting themselves (G4). Mineral insulation (three types) are non-combustible materials. But stone wool can withstand higher temperatures - up to 1000 degrees (different sources offer different indicators, since the value depends on several factors, in particular, on the manufacturer / brand), without changing the structure and properties.

Alternative options based on glass and slag do not contribute to the spread of fire, but without losing their own characteristics they can withstand less significant temperatures - 450 and 300 degrees, respectively.

Shrinkability

Shrinkage implies caking, sliding, reduction in volume and size of the material after a certain period of time due to exposure to moisture, vibration, wind, compaction under its own weight, etc. If the material is subject to shrinkage to a high degree, then you should expect the formation of voids in the wall “pie” and deterioration of the building's thermal insulation.

Fireproof basalt material OBM-50 1500x500x50mm. Photo by Maxidom

Basalt wool, due to the random arrangement of fibers, is not subject to shrinkage . The same cannot be said about glass wool. With proper installation, the insulation will last a long time, but will still shrink over time. Exposure to moisture on slag wool leads to the formation of mold and mildew, so the likelihood of shrinkage is not such an important problem.

Environmental friendliness

Both basalt and glass wool are completely environmentally friendly materials ; they do not contain harmful components and/or allergens. Binding components - resins - can pose a danger to the respiratory system. The materials contain two types of resins - arbolo-urea , which is absolutely safe for human health, and formaldehyde , when heated, it releases a small amount of substances that can cause harm, as a result the body does not notice them. Thus, both materials can be used to insulate any element of a house or apartment.

But the composition of slag wool contains phenol-formaldehyde resins , which have toxic components (phenol and formaldehyde), but their concentration is minimal (if we consider high-quality materials). However, the attitude towards binding components of this type is ambiguous, and even when comparing slag wool with analogues, the composition of the former is clearly inferior in terms of safety for humans.

Resistance to mold, mildew, rodents

Basalt and glass wool are not the basis for the development and growth of microorganisms : mold and mildew. Slag insulation (if used correctly) is also not susceptible to rotting and fungus formation. But the relationship between materials and rodents is complex. Despite the assurances of some sources about the ability of mineral insulation to resist rodents, this is not true. Rodents do not breed in insulation materials, but they make passages and homes in the materials. Therefore, when insulating foundations and basements, it is recommended to pay attention to alternative options.

Soundproofing properties

Mineral materials effectively solve the problem of not only heat but also sound insulation. There are two terms to describe basalt wool and its analogues:

- Sound absorption is an indicator demonstrating the amount of reduction in the energy of a sound wave when interacting with a material, expressed in the sound absorption coefficient - aw, which takes values from 0 to 1, the closer to unity, the higher the efficiency. The coefficient depends on the thickness of the product and the tightness of the material to the base. Thus, the coefficient for basalt wool ranges from 0.75 to 0.95, glass wool - 0.8-0.92 , slag wool - 0.75-0.82.

- Sound insulation is a characteristic measured in decibels that demonstrates how much the sound level will decrease when passing through a surface with insulation. Basalt wool absorbs up to 57 dB of noise , the airborne noise insulation index of glass wool is 47 dB.

Elasticity

Elasticity is an indicator that depends on the bending strength of the material. For basalt and slag wool, this parameter is low; when trying to insulate raised surfaces, the materials will break and crumble . Therefore, to insulate pipes, manufacturers produce cylindrical basalt insulation. But glass wool is characterized by flexibility and elasticity, so it can be successfully used when working with any structural elements. As a result, glass wool has no competitors among mineral insulation materials when working with surfaces with complex geometries.

Ease of installation, causticity and skin irritation

The technology for laying mineral insulation differs depending not on the type of material, but on the type of “processed” surface. Cutting insulation is equally easy ; you can use a knife or hacksaw. So it's hard to pick a favorite here.

Thermal insulation of the pipe using basalt (stone) wool. Photo of SuperOven

However, when performing work with basalt wool, it is recommended to use protective equipment due to the small particles released into the air, with glass and slag wool - this is a prerequisite , a respirator is required for the respiratory system, glasses for the visual organs, open areas of the body must be covered with a thick cloth, protect your hands with gloves. This is due to the caustic nature of the materials, which can cause allergic reactions and cause injury. Thus, self-installation of any of the mineral materials requires caution , but to a lesser extent when working with stone wool.

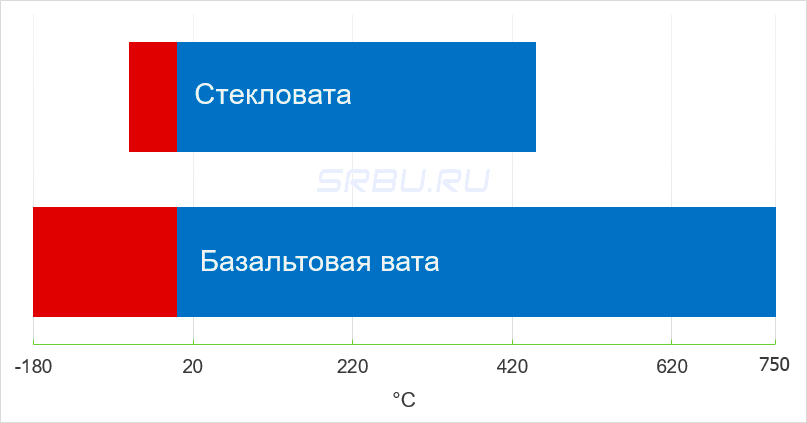

Operating temperature range

This parameter affects the areas of application, which structural elements can be insulated, for example, surfaces located next to the heat source, equipment, radiators, boilers. Operating temperature range:

- for basalt wool it ranges from -270 to +900 degrees;

- glass wool - from -60 to +450, at +500 the fibers begin to sinter and lose their properties;

- the maximum temperature for slag wool is +250; at values higher, the material begins to melt and also loses its thermal insulation properties.

As a result, the leader in this aspect is stone insulation.

What is better to choose and in what cases

After familiarizing yourself with the pros and cons, the characteristics of materials, it is possible to determine which material is the optimal solution in different situations. It is recommended to use glass wool to insulate building elements operating in dry conditions. The material is suitable for insulating attics, balconies and loggias, apartment walls, the density should be from 11 to 30 kg/cub.m.

Basalt wool for baths

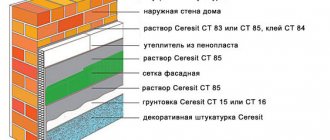

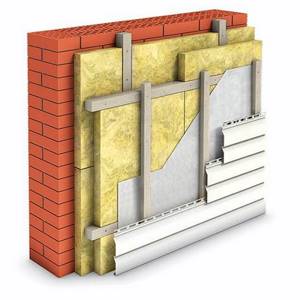

Basalt wool is intended for working with roofs, density - 100-120 kg/cub.m.; facades of buildings and walls of baths - from 20; special foil materials are relevant when creating an obstacle in the event of a fire - from 200.

The choice of materials is also made easier by manufacturers who offer materials with special purposes, i.e. to solve specific problems. The range of enterprises also includes universal materials.

Water absorption

If there is a possibility that the structure in which the insulation is embedded may come into contact with water, then the water absorption indicator is important, indicating how quickly the insulating layer will get wet. When wet, its properties deteriorate significantly, so when choosing insulation for entrance doors or filling walls in a bathhouse, you should give this priority attention.

The water absorption of glass wool is 1.7% by weight after 24 hours of direct contact with water. Basalt slabs have a value of 0.095%, making it twice as good in this category.

Advantages and disadvantages

The raw materials used, production technology, equipment used are parameters that affect the positive and negative parameters of each material. Basalt wool has the following advantages:

- resistance to open fire, chemicals, clumping and caking,

- low level of water absorption,

- long service life,

- low thermal conductivity coefficient,

- ease of installation,

- light weight,

- ease of transportation,

- environmental cleanliness,

- versatility.

The disadvantages of stone insulation include high cost and the need to be careful when installing, since particles released during cutting and installation, getting on the skin and mucous membranes, can cause allergies and irritation, the use of protective equipment is necessary; connection seams formed during installation, after some time, contribute to a decrease in thermal insulation properties; Rodents can make their home in the insulation.

Basalt insulation ISOBOX ExtraLight-31 100Х600Х1200 mm/4.32m2/0.432m3/6pcs. Stroylandia Photos

The main advantages of glass wool include:

- excellent thermal insulation properties,

- environmental friendliness,

- versatility,

- low water absorption coefficient,

- non-toxic,

- non-flammability,

- ease of transportation and installation,

- resistance to fungus and mold,

- low specific gravity,

- safe for human health.

Glass wool has more disadvantages than its basalt-based counterpart : high hygroscopicity, short service life (no more than 10 years, after which the material ceases to provide thermal insulation properties due to shrinkage), installation must be carried out using protective equipment, low resistance to impact chemical components, attractive to rodents.

Slag wool, actively used in the Soviet Union, is now used quite rarely. The unpopularity is due to a number of disadvantages:

- high percentage of residual acidity of the slag,

- low resistance to temperature changes,

- good moisture absorption,

- coarseness and fragility of fibers,

- limited scope of application, it is not recommended for use in rooms and buildings with high levels of humidity, in wooden buildings, since when wet the material undergoes rotting.

As a result, slag materials are now being used in temporary buildings.

Thermal insulation Ursa Geo M-11F 12500x1200x50mm foil based on fiberglass. Photo by Maxidom

But slag wool also has positive properties:

- low cost,

- high sound absorption coefficient,

- ensuring good thermal insulation,

- ease of installation,

- long service life, but provided there is no exposure to moisture and high temperatures.

Thus, fibrous materials have both similar and different characteristics. Some parameters should be considered in detail, indicating specific values, which is done below.

Operating and maximum temperature range

This parameter affects the location of operation, especially if the insulation will be installed on the roof or next to a heat source (boiler, heating radiators). Glass wool has a temperature range of -60 to + 450 °C. Stone wool will withstand even greater temperatures from -180 to + 750 degrees. Here, stone wool is definitely superior to its counterpart.

Rating of mineral fiber insulation

| Photo | Name | Rating | Price | |

| #1 |

| Basalt wool | ⭐ 96 / 100 70 — votes | Go to material description |

| #2 |

| Glass wool | ⭐ 75 / 100 9 — votes | Go to material description |

| #3 |

| Slag wool | ⭐ 42 / 100 9 — votes | Go to material description |

Which fibrous mineral insulation would you choose?

Take the survey

Now let’s try to analyze this rating in more detail, with justifications.

Shrinkability

Shrinkage involves sliding or caking of the insulation after some time. If the tendency of the material to shrink is high, then voids without insulation may form and the thermal insulation of the building will deteriorate.

Here, the difference between basalt wool and mineral fiberglass wool lies in the improved structure of the first. Some of the basalt wool fibers are located vertically, which prevents caking throughout its entire service life. The same cannot be said about glass wool, which, if properly installed, can last for a long period, but will still shrink over time. Glass wool placed in horizontal structures is subject to shrinkage the most, where, in addition to caking, sliding of the material can occur.

Basalt wool

Basalt thermal insulation is made from gabbro-basalt ore. The maximum temperature that basalt insulation can withstand is +1200°C. There are a large number of sizes, densities and shapes of this insulation.

Advantages

Since basalt wool is made from stone, it is non-flammable. Due to this and the high maximum operating temperature, it is used in places where it is necessary to protect the structure from the effects of high temperatures. For example, basalt is excellent for insulating places where a chimney passes through the attic floor.

Basalt insulation does not shrink and also has excellent vapor permeability. Therefore, it is recommended to use it for wooden structures. In addition, basalt thermal insulation does not absorb water from the air and rodents do not eat it.

Flaws

Basalt insulation cannot be considered environmentally friendly, although it is made from natural components. To improve consumer qualities, chemical additives are added to it, which at high temperatures can release harmful volatile substances.

Thermal insulation from gabbro-basalt ore

Rodents are not interested in basalt as food, but they can live in it. As a result, it is necessary to install additional protection against their penetration inside.

Basalt wool does not absorb moisture from the air, but when water hits the surface, it quickly draws it in. Therefore, it cannot be used for insulating foundations, basement floors and blind areas. Also, basalt cannot be considered a good sound insulator, since it only retains airborne noise and allows shock to pass through.

For insulation with low density, wind protection is required, since they are blown. It can also be blown out at the joints, so the slabs must be laid staggered. If it is necessary to lay thermal insulation with a layer of 100 mm, then it is better to do this in 2 layers of 50 mm each.

Basalt insulation does not fit tightly in places where it cannot be positioned at an angle of 90°. Therefore, it is not considered the best option for domes or similar frame structures. When working with basalt wool, you also need to use protective equipment, as it emits dust.

https://youtube.com/watch?v=ivHaQo3exks%3F

Ease of installation

Both materials cut equally well. The degree of compression allows them to be conveniently placed between rafters or posts, even if cut to a slightly larger size. But glass wool is highly prickly due to the vitreous fibers, which injures the skin. Even with protective gloves, it penetrates between the threads of the fabric and causes harm.

Stone wool is softer and does not leave itching, but it creates more dust in the air (the fibers are thinner and lighter). But since you need to work with both types in a respirator, due to its less causticity, the stone one is clearly more convenient.

Let's put the definitions in order!

In order to have a truly meaningful conversation with the reader, it is necessary to clarify the further use of terminology. And judging by the title in the title, it is very far from correct.

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

I wonder what answer you would find, for example, if you were asked the following question: “what is better – a car or a passenger car?” Or, let’s take an even more paradoxical one: “Which do you like better – trees or birches?” Surely you will look at the person who asked such a question with some wariness and, perhaps, “twist your finger at your temple.”

Meanwhile, these formulations of the question are no more absurd than the one in the title of the article! Don’t believe me, do you think that the author just decided to “get smart”? Well, let's turn to the source and go through the chain of definitions to the points that interest us.

In this case, the primary source will be GOST 31913-2011 .

A document that brings order to definitions in the field of use of thermal insulation materials. By the way, please note that the standard is not just state, but even interstate.

The standard has interstate status, or more precisely, it can be considered a Russian-language version of the European standard EN ISO 9229:2007 . And for the basic terms used in it, even in the Russian edition, the accepted international name (in English) is indicated.

So, let's look:

Clause 2.1.13 - it combines all types of fiber insulation.

“Thermal insulating material consisting of natural or artificially obtained fibers.” In the English version – “fibrous insulation”.

It is clear that natural fibers (cotton, linen, cellulose, etc.) are not of interest to us in this case. But mineral ones - they are negotiated separately.

Clause 2.1.15 – under the collective image of mineral fiber (English – “mineral fibre”) all fibers of inorganic nature are hidden, with the exception of metallic ones.

It also includes subclause 2.1.15.1 - about artificial mineral fiber (English: “man-made mineral fiber”, which includes what is obtained in industrial conditions from glass melts, rocks, slag, clay, metal oxides, etc.). P.

But now we come close, that is, literally verbatim, to our problem.

Clause 2.1.16 directly talks about the concept of “mineral wool” (English: “mineral wool” or abbreviation MW). This term refers to fibrous thermal insulation materials obtained from molten glass, rocks or slag. And then there are three subparagraphs that completely reveal the whole picture:

2.1.16.1 - glass wool (English: “glass wool”) - obtained mainly from melts of broken glass or natural quartz sand.

2.1.16.2 - rock wool (English: “rock wool” or “stone wool”) - from rock melts of volcanic origin.

2.1.16.3 - slag wool (English: “slag wool”) - obtained from blast furnace slag melts.

Here we can put an end to the dispute - so which is better, mineral or stone (basalt)? Are there still any ambiguities about the incorrectness of the question?

And if we carry out a “showdown”, then rather in this vein - which of the mineral wools is better to use for home insulation: stone wool, glass wool, or slag wool?

But here, it must be said, the “leadership” of one of the listed insulation materials is clearly visible. This can be displayed with this kind of rating.

Summary table comparing stone wool and glass wool

| Basalt (stone) wool | Glass wool (glass wool) | |||||||

| Thermal conductivity, W/(m*K) | 0,038-0,046 | 0,035 – 0,042 | ||||||

| Specific density, kg/m3 | 15 to 220 | 11-200 | ||||||

| Weight | heavier | easier | ||||||

| Vapor permeability, mg/(m.h.Pa) | 0,3 | 0,4-0,7 | ||||||

| Water absorption, % by weight for 24 hours | 0,095 | 1,7 | ||||||

| Operating and maximum temperature range, 0C | -180 to + 750 | -60 to + 450 | ||||||

| Shrinkability | not susceptible | susceptible | ||||||

| Ecological cleanliness | pure material | pure material | ||||||

| Flammability | non-flammable material, can withstand temperatures up to 750 0C | non-flammable material, can withstand temperatures up to 450 0C | ||||||

| Durability, years | 50 | 20-50 | ||||||

| Chemical resistance | high | average | ||||||

| Sound absorption coefficient | 0,75 — 0,95 | 0,8 — 0,92 | ||||||

| Installation | more convenient | less convenient | ||||||

| Price | higher | less | ||||||

Description of what these materials are

Before you begin to analyze the properties and characteristics of insulation, you should determine what the materials are. Buyers planning to compare basalt and mineral wool often do not realize that they are formulating the question incorrectly. Since the concept of “mineral wool” according to GOST 31913-2011 includes basalt wool, as well as glass and slag wool, each of the materials is produced from a certain type of raw material using a specific technology:

- Basalt (stone) wool is a universal heat and sound insulating material, the initial raw material for which is the melt of mountain gabbro-basalt rocks, the fractions of which are melted in furnaces at a temperature of about 1500 degrees, the resulting mass is cooled and mixed with binding components, their role is played by resins .

- Glass wool is a popular material intended for thermal and sound insulation; to produce glass fiber, the same raw materials are used as for making glass (quartz sand, lime and soda), or waste from glass production; as a result, the insulation is distinguished by its relatively low cost.

- Slag wool - the material is used for insulating buildings for various purposes, smooth and rounded surfaces, it is produced by processing blast furnace slag, which is waste from the metallurgical industry in the production of cast iron, into microfibers. Recently, the material has been inactively used, as it is inferior in properties to its analogues.

TeploKNAUF mineral wool for roofing. Photo Pilomaterialy.rf

Next, we will try to provide information about three types of fiber insulation, despite the obvious differences between slag wool and the other two varieties, which sets it apart. In addition, potential buyers of thermal insulation materials should know and remember that some experts and clients themselves mean glass wool by the term “mineral wool”.

Bonus: Express assessment of the required insulation thickness

The effectiveness of certain insulation materials is best assessed, so to speak, quantitatively. That is, an indicator of which layer of thermal insulation will be sufficient. And if at the same time there is an opportunity to make a comparison with other materials, then it turns out great.

We will provide you with this opportunity. Our online calculator will help you perform similar calculations and, if desired, make comparisons. Below we will give some explanations on working with it.

Express calculation calculator for insulation thickness.

Go to calculations

Explanations for working with the program

For starters, why express? Yes, simply because, without pretending to be completely professional, this algorithm allows you to very quickly “estimate” the thickness of the future insulating structure. And at the same time, with a fairly high degree of accuracy - the discrepancies with the final results of more advanced pro programs that take into account a lot of different nuances ultimately amount to a few millimeters. So, let's move on to sequentially indicating data in the fields of the calculator

- In the list of insulation materials, mineral wools are placed in the first positions - simply because our publication is dedicated specifically to them. But if you wish, you can carry out calculations for other materials from the proposed list - this helps many to determine the best option.

- The next point asks you to indicate the normalized value of heat transfer resistance. Where and how to get this indicator?

Where - it's easy! In the proposed map-scheme, having found your region of residence on it.

Map-scheme of indicators of normalized heat transfer resistance for building structures (by regions of Russia).

Be careful though! The values for different parts of the house structure are different:

- for walls - indicated in purple numbers;

- for floors (floors, ceilings) - indicated in blue numbers;

- for coverings (in particular, roofing, and this also includes the attic wall, which are, in fact, the reverse sides of the roof slopes) - indicated in red numbers.

- Next, it is proposed to indicate the features of the insulated structure - what it is made of (select a material from the list), and what its thickness is (in mm).

There is a nuance. In some cases there will be nothing to indicate. For example, insulating the roof from the inside, the roofing material itself is not taken into account. Or, say, a frame wall. Thin cladding on both sides can also hardly pass for a “major structure.” And so on - it’s not difficult to figure out. In such situations, regardless of the material specified in the list, it is enough to leave the thickness of the insulated structure equal to zero.

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

It is possible to specify two more layers. For example, internal and external cladding of the wall, front surface of the floor, lining of the flow and attic floor - for the ceiling, internal cladding of the slope-wall for the attic, etc. The approach is the same - the material from the list and its thickness in millimeters. If there is no such layer, or there is no desire to take it into account in the calculations, simply leave the thickness equal to zero.

That's all - all you have to do is press the "CALCULATE" button and get the finished result in millimeters. This is the minimum thickness, and is usually reduced to standard insulation thicknesses, rounded up.

An example of two-layer wall insulation with mineral wool - cold bridges are reduced to a minimum.

And it’s even smarter to use two-layer insulation. For example, the result is shown at 138 mm, and it probably makes sense to place 100 mm thick mineral wool slabs as the first layer. And then, as a second layer, lay out another 50 mm ones, so that they completely cover the joints between the blocks of the first one. This way, cold bridges are almost completely eliminated!

We deal with each type personally!

Slag wool

Metallurgical technologies require huge deposits of blast furnace slag - practically empty melted rock. Terricons of such slag are almost the “calling card” of large metallurgical plants. The problem of recycling this waste is largely solved by the production of various building materials, including fiber insulation.

To do this, the slag is melted in special furnaces. And then thin fibers are drawn from the melt, which are subsequently formed into blocks or mats using binders. The output is the same insulation, which is called slag wool.

To be honest, I’m not completely sure that the illustration shows exactly slag wool. Information about her, I must say, is very vague...

They say that it once completely prevailed among fiber insulation materials, as it was used extremely widely. But now her popularity is approaching zero, and it’s hard to even imagine that someone would let her into their apartment building.

What’s interesting is that they write a lot of negative things about this material (apparently, rightly so), but even “admiring” such cotton wool is a whole problem. The picture above looks like it, but I came across the same one with the caption that it is basalt insulation.

Anyway. There is no point in wasting too much time on slag wool - for the simple reason that it is of little use for home insulation.

Let's look at the advantages and disadvantages:

pros

- The only advantage of slag wool is its low cost. By the way, there will be another small remark on this topic below.

Minuses

- Slag wool, due to the high fragility of the fibers, quickly cakes, loses volume, and therefore loses insulating qualities.

- Slag wool is very hygroscopic and requires reliable protection from moisture. Once wet, it simply ceases to be insulation - just like a wet rag.

- The slag from which insulation is produced usually has very high acidity. Contact of slag wool with metal parts of a structure can dramatically intensify corrosion processes. And in general, an unclear and unstable chemical composition is not what is needed for a residential building.

- Slag wool contains the maximum amount of formaldehyde group binders. And probably no one is fighting for its environmental friendliness...

- By the way, blast furnace slags are not always good in terms of background radiation.

- In terms of working with it, slag wool is inconvenient - the fibers are brittle and thorny. The use of reliable personal protective equipment is mandatory. Otherwise, skin irritation, or even worse, eyes and mucous membranes, will be guaranteed!

We can remember more, but what has already been said is probably quite enough. Let’s put a “fat cross” on this insulation!

And - the promised remark. It was supposed to complete the subsection about slag wool with a Yandex Market widget in order to prove its only advantage - the most affordable cost. But, sorry, it didn’t work out - there are no offers on Ya-Market!

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

I specifically called all the leading construction stores in my city - there is no such cotton wool anywhere. Glass wool - please, basalt - there are also several brands to choose from. And slag materials were never even imported. Another argument about the “popularity” of this insulation among private consumers.

The only place where offers were found on the Internet was Ali Express, wholesale deliveries. And even there one cannot rule out “difficulty of translation”, since in many ways the proposed insulation is more like basalt.

So, we are left without an exact guideline on the issue of cost.

Glass wool

The raw material for the production of this insulation can be either natural material - quartz sand, or glass waste. Everything is melted down with the addition of special additives that give the thin fibers drawn from the melt in centrifuges a certain elasticity and reduce fragility. Then, from the resulting fibrous mass, webs with a certain fiber orientation are first formed. This is followed by the processes of pressing and cutting into mats and slabs of certain sizes, and other necessary technological operations.

As a result, packaged insulation materials in various release forms are sent to the consumer. The most characteristic color of glass wool is a variety of shades of yellow. However, there are exceptions - even snow-white.

High-quality modern glass wool for universal use “ISOVER Warm Home”.

As already mentioned, it is behind glass wool that there is a trail of rumors associated with its increased allergenicity, causticity, and ability to cause persistent serious irritation of the skin and mucous membranes. Surely this is not out of nowhere, and many of us remember the results of our childhood “experiments” at construction sites.

It is possible that such glass wool is still in use. But modern insulation materials with increased elasticity and elasticity of fibers, using absolutely safe acrylic resins as a binder, are much more popular today.

One of the examples of modern brands of glass wool is “PureOne” from

The use of optimally selected raw materials that have undergone a special cleaning cycle, and the use of advanced production technologies allow many companies to produce effective insulation materials, which are associated with the old familiar glass wool more by name than by performance qualities.

Nevertheless, let's go over the advantages and disadvantages of the material.

pros

- Glass wool traditionally has high thermal insulation efficiency.

- Glass itself, unlike slag, is a chemically inert product and will not emit any harmful fumes into the indoor atmosphere. Binders are a different matter; here you need to be on guard (this has already been discussed).

- There is a lot of talk about the fact that rodents do not like glass wool. Perhaps this is true to some extent. Half jokingly, if mice have a choice between living in glass wool or basalt wool, they will most likely choose the latter. But, unfortunately, even in glass wool insulation they make excellent passages and make nests. Moreover, in a timely manner, which in its physical qualities is very close to stone.

- Glass wool is light and elastic, and if the precautions are followed, it is quite convenient to work with.

- High vapor permeability will prevent stagnation from forming - if the insulation is positioned correctly, it will be effectively ventilated.

- The cost of glass wool is considered more affordable than that of its main competitor - basalt insulation. However, this difference is becoming more and more blurred in our time.

Minuses

- The fragility of the fibers inherent in many brands of glass wool, which has already been mentioned more than once.

- Due to the fact that glass itself is not considered absolutely solid, but an amorphous material, that is, it gradually “flows,” glass wool also tends to gradually lose volume and cake. But, we repeat, by introducing special mineral additives, manufacturers have learned to combat both the “fluidity” and the fragility of fibers.

- Rumor has it that glass wool is not doing well with hygroscopicity. But this also now largely depends on the quality of the product - some brands have achieved almost hydrophobicity - they do not absorb moisture at all. Well, when installing an insulating structure, hydro- and vapor barriers are definitely mandatory, and regardless of which type of mineral wool is used.

The most well-known manufacturers of thermal insulation based on glass fiber remain the companies URSA and ISOVER . The reader can follow the links to special articles on our portal devoted specifically to these insulating materials - there he will certainly find a lot of interesting information.

Mineral wool URSA

Video: Impressions from working with URSA glass wool

Basalt wool

There seems to be some kind of contradiction in the name itself - “stone wool”! Meanwhile - all this must be taken almost literally - stones are the raw materials for the manufacture of such insulation. Not all, of course, but some rocks belonging to the gabbro-basalt group. However, these rocks are extremely common throughout the planet, so there is no shortage of raw materials, at least today.

It seems incredible, but from such rough stones the output is a fibrous, air-filled structure, reminiscent of elastic felt.

The finest fibers drawn from the melt of such rocks differ from glass or slag in higher flexibility and elasticity, that is, they do not break under compressive load. And because of this, the insulation acquires a structure that is very similar in appearance and tactility to natural felt. But despite all this, it remains a mineral material, not subject to getting wet, rotting, or other biological damage.

The elasticity of the fibers is also confirmed by the fact that some brands of mineral wool, after removing the packaging, are capable of expanding, increasing in volume several times! A huge plus in terms of organizing the storage and transportation of the material, without losing its insulating qualities!

In principle, all the advantages of mineral stone wool, which distinguish it from its “competitors,” flow from the increased strength and elasticity of the fibers.

Interestingly, basalt wool can be produced in a very wide range of densities. And many “heavy” insulating boards can fully cope with the loads under a floor screed or in a flat roof structure. And what’s really remarkable is that this doesn’t even particularly affect the insulation capabilities of the material.

Insulation of a flat roof with blocks of high-density basalt mineral wool.

So, the yet unnamed advantages and disadvantages of stone wool.

pros

- This type of cotton wool is the most comfortable to work with (so to speak). And during further operation, if really high-quality material was used, you don’t have to worry about the appearance of fine dust from breaking fibers.

- Judging by the characteristics, it still has the lowest thermal conductivity coefficient.

- We can safely say that such insulation is the most durable among fiber insulation - manufacturers guarantee several decades of “flawless service”. Compared to others, it is the most “stress-resistant”, that is, capable of withstanding various negative influences, for example, vibration, without losing its forms and qualities

- The hygroscopicity of basalt wool is reduced to such a minimum that we can rather talk about the hydrophobicity of the material. And this quality is complemented by high vapor permeability, which guarantees ventilation of the insulation.

- The elasticity of the fibers is an excellent quality for effective noise absorption - sound vibrations simply “drown” in this structure.

Minuses

- Fibers are fibers, but some brands of stone wool are still far from environmentally friendly. Simply due to the presence of a harmless phenol-formaldehyde binder. That is, if the owner is really fighting for a healthy atmosphere in his home, he will have to look for brands of insulation with harmless binders. There are many of these, but they are, of course, more expensive.

- Stone wool does not prick, it is comfortable to work with... Believe me, mice also appreciate this very much, and willingly make their nests there! So you will have to come up with some kind of “mechanical barriers” to prevent rodents from penetrating the insulation - metal mesh, expanded clay backfill, etc.

- The cost of basalt mineral wool is the most sensitive. However, some brands of modern glass wool, as already mentioned, are located very close in the “price scale”.

There are a lot of manufacturers of high-quality basalt wool. On the pages of our portal there are detailed reviews on insulating materials from the companies “ROCKWOOL” , “BASWOOL” , “KNAUF” .

Mineral wool ROOCKWOOL