Technology and installation nuances

According to reviews from experienced builders, it is easiest and fastest to lay polystyrene boards in a continuous layer, so we will consider this method.

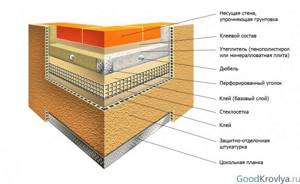

For insulation, you will need to buy a special facade adhesive for polystyrene foam - frost-resistant and solvent-free. In addition, disc dowels and foam for sealing seams will be useful. The work order is as follows:

- Remove the remains of the old finish from the facade, level the walls as much as possible, plastering all cracks and depressions deeper than 15 mm.

- Attach a horizontal stop at the bottom - a metal corner that will not allow the foam sheets to slide off until the glue has set. The width of the shelf is selected in accordance with the thickness of the insulating layer, the step of fastening to the wall is about 30 cm.

- Treat the base with a deep penetration primer with antiseptic additives.

- Prepare the adhesive mixture and apply it to the façade polystyrene foam. Along the perimeter of the slab, the layer must be continuous; point distribution is allowed in the center.

- Press the foam sheet against the wall and hold it there for half a minute; immediately remove any excess glue that appears.

- Using the same technology, glue the next slab in the row, trying not to leave seams thicker than 2 mm. When one wall of the facade is completely insulated, all joints must be sealed with polyurethane foam.

- After setting, the protruding excess composition is cut off, and a second layer of foam is mounted on top, ensuring mutual overlap of the seams.

- When the adhesive solution has completely hardened, the slabs on the facade are fixed with disc-shaped dowels.

Installation features

Thermal insulation of walls will be done efficiently if you take into account a few simple points. First you need to choose the right material. You should not purchase polystyrene foam that is stored outdoors. Expanded polystyrene should be white, without stains or faded areas. The plate is elastic and soft. Its balls are approximately the same in diameter.

The slabs are mounted on previously prepared surfaces. So, the walls need to be leveled and treated with a primer that will protect against mold (and mildew). Glue is used to attach the boards. The sheets are laid according to the principle of brickwork, that is, between the three sheets the seams form the shape of the letter “T”. The glue should dry within a few days (depending on the weather).

After the glue has completely dried, the polystyrene foam is attached using “umbrellas” (dowels with a very large head). Initially, holes are prepared into which dowels are inserted. “Umbrellas” are driven inside. Dowel umbrellas are chosen to be plastic, since metal ones allow the cold to pass through. This stage of work is carried out in order to increase the reliability of the connection between the wall and the foam.

The next stage involves gluing the reinforcing mesh. This is done using an adhesive that completely covers the mesh. The mesh is rolled out over the entire surface of the wall. Its individual parts are overlapped

Particular attention is paid to the corners. The glue should completely hide the mesh

After it dries, the wall is sanded using sandpaper. The surface must be flat.

Next, a layer of putty is applied. After it dries, the wall is primed. At this point, the surface is considered ready for application of the topcoat. This can be paint, wallpaper and any other materials.

Expanded polystyrene PSB-S 35 can be considered a universal material that has found its use as a heat and sound insulating layer in the construction of buildings and structures for various purposes. The material is used in regions with different climatic conditions.

Related Posts

- Which is better: polystyrene foam or polystyrene foam?

- Finishing the facade of the house with foam plastic

- DIY foam cutting

- Harm of polystyrene foam to human health

- Do-it-yourself insulation of walls with polystyrene foam - detailed instructions

- How to glue foam together

- GOST 15588-2014 polystyrene foam thermal insulation boards. technical specifications (edition with amendments)

- Insulating the attic with foam plastic

- Penoplex or technoplex: which is better to choose and how do they differ?

- Different ways to attach foam to the wall

- How to properly insulate a garage outside and inside with your own hands step by step

- Equipment for the production of penoizol with your own hands: nuances of assembly and production of insulation

- House made of polystyrene foam: how to make it yourself

- Insulating a balcony with panoramic glazing: useful to know

- Description and technical characteristics of xps insulation

- Which penoplex plaster is better? overview of mixtures and plastering technologies

- Foundation insulation technology with foam plastic

- Insulation of a veranda in a wooden house

- How to insulate metal garage doors from the inside

- Insulation of the base, grillage and blind area of the foundation

- "technoplex" 50 mm: characteristics, reviews

- Houses made of permanent formwork

- Fum tape technical characteristics, how and how much to wind on the thread

- Foil insulation: types, properties and possibilities of use

- Insulation of a house made of 150x150 timber from the outside

Read with this

- Which is better: polystyrene foam or polystyrene foam?

- Finishing the facade of the house with foam plastic

- DIY foam cutting

- Harm of polystyrene foam to human health

- Do-it-yourself insulation of walls with polystyrene foam - detailed instructions

- How to glue foam together

- GOST 15588-2014 polystyrene foam thermal insulation boards. technical specifications (edition with amendments)

- Insulating the attic with foam plastic

- Penoplex or technoplex: which is better to choose and how do they differ?

- Different ways to attach foam to the wall

Features of the material

Polystyrene foam is white sheets with low weight. If we talk about pressless PSB-S, it looks like small balls connected to each other. It contains up to 98% air. Despite this, the technical characteristics of the PSB-S 35 remain at their best.

The abbreviation is deciphered as follows. The letters "PS" stand for "polystyrene". The letter “B” is “pressless”, “C” is “self-extinguishing”. The numbers indicate maximum density. In this case, the specific gravity of the material is in the range of 25-35 kg/m3.

PSB-S 35 is capable of withstanding high loads. In this case, the slab does not sag or move. Polystyrene foam does not absorb water. Due to this, it does not change its size and shape. The mechanical, thermal insulation and technical characteristics of PSB-S 35 do not change throughout the entire service life.

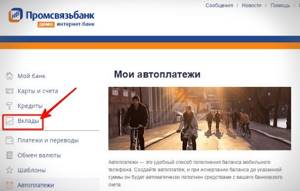

Data Security

When developing services, Promsvyazbank uses modern technologies to protect customer data and funds. All software products are tested and certified for compliance with security requirements. But clients also need to follow a number of simple rules when using online services:

- You cannot enter your personal account through other people’s devices or public networks in cafes and hotels;

- It is recommended to install anti-virus software on devices used to work with online banking;

- password, SMS codes, CVV code of the card are prohibited from being transferred to third parties.

Polystyrene foam with brick finish

These facade expanded polystyrene foams belong to a separate type and are called “brick-like” imitation. This reinforced insulation consists of two layers: expanded polystyrene and a coating of polymer concrete.

Available in the form of square slabs, already decorated on the outside. For this reason, additional processing of the material is not necessary. All that remains for the customer is to mount the products on the walls, securing them with special glue.

The role of the outer layer is to decorate the facade of the house and protect the 25F foam from mechanical and atmospheric influences. Reinforced brick-like layers are made from: sand, cement, water and polymer additives. This makes the foam façade resistant to frost, fire and moisture.

The texture of the brick is perfectly conveyed by the smooth concrete surface. Additional façade foam is not required. The slabs are mounted using glue or special anchors. This type is popular because it reduces the time spent and the cost of exterior finishing of the house.

Personal account functionality

Your personal account provides the opportunity to perform almost any transaction directly from home. The user has access to all information on active products, opening deposits, making payments, transfers and other operations via the Internet.

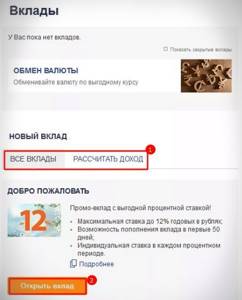

Deposit management

In the PSB personal account, you can open and manage deposits with special rates. To view information about active deposits, select the “Deposits” link in the left menu.

The page immediately prompts you to look at the bank’s current offers, calculate profitability and open a deposit. Funds are transferred to it from the account in the PSB.

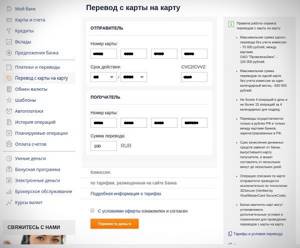

Money transfer

Your personal account allows you to quickly transfer money to other accounts and cards. To make a transfer to a card of a third-party bank, select the “Transfer from card to card” section in the service, indicate the card details of the sender, recipient and the amount of the transaction.

Checking the balance on your account or card

In the “Accounts and Cards” section of your personal account, information about the balance of all active products is available. By default, card information is shown. To go to account data, select the appropriate tab.

Loan or mortgage balance

Information about the balance of debt on a loan, mortgage, as well as data on upcoming payments is available in the “Loans” section of your personal account. To go to it, just click on the corresponding link in the left menu.

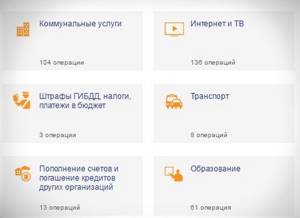

Payments

In your personal account you can pay for communications, utilities, the Internet, repay debt on loans from any banks and make almost any other payments. For the convenience of users, the “Payments” section contains a catalog of ready-made templates for paying for the most popular services.

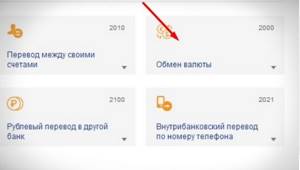

Currency exchange

In online banking, currency conversion occurs at a favorable rate. To make an exchange, go to the “Payments and Transfers” section, and then click on the “Currency Exchange” button and follow the system prompts.

Why do buyers choose this brand of foam?

Packaging of self-extinguishing polystyrene foam PSB-35.

I will not list the advantages of polystyrene foam as insulation. Those interested can familiarize themselves with them in my other articles on the site. I would like to highlight the differences specifically in the 35th PSB-S.

Another example of PSB-S products.

In short, we can say that this is in a sense a universal material that will suit:

- for wall insulation;

- will not be “afraid” of the foundation or septic tank;

- and can also be used to insulate floors inside an apartment or house.

This is a kind of substitute for an extrusion machine, but cheaper.

Do-it-yourself thermal insulation of the base.

The strength of these sheets is sufficient for use in the construction of heated roads and parking lots, runways, protection of soils from swelling, strengthening of slopes, etc. The instructions allow you to use PSB-S of the thirty-fifth series for these purposes, although personally I would play it safe and buy a PSB-S-50.

In regions with harsh climates, the material can be used on walls.

Types of polystyrene foam for insulating house facades, floors and foundations: Step-by-step instructions + Photos and Videos

Polystyrene foam is an insulating material with a foamed structure.

Due to its qualities and low price it has become widespread. Polystyrene foam, photos of which can be found on various Internet resources and manufacturers’ websites, has both significant advantages over other insulation materials and disadvantages. For the production of polystyrene foam material, polystyrene is used, which is famous for its resistance to sub-zero air temperatures and also perfectly withstands high humidity. If exposed to high temperature, it can take on a variety of shapes.

To make polystyrene foam, polystyrene is foamed in a special way, and the granules are treated with steam. Thus, manufacturers are trying to reduce the density of polystyrene and reduce weight.

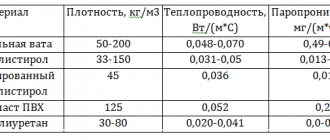

Thermal conductivity and density of foam

Moreover, the value increases at intervals of 50 mm. The width is mm, pitch is 50 mm. The material thickness varies in 10 mm increments and is in the mm range. One of the main parameters that provides a wide range of applications is the ability of foam to retain heat. The popularity of expanded polystyrene is explained by its cost and ease of use, but these are far from the only advantages.

The main advantages can be expressed as follows: No chemically active substances are used in production, therefore PSB belongs to the category of environmentally friendly products. After installation, it increases vapor permeability, which prevents the development of wall mold and mildew.

The material is easy to process: the sheet can be cut with an ordinary stationery knife. Therefore, PSB can be used to insulate buildings with complex geometry.

The cellular structure helps reduce the weight of the sheet, so installation can be easily done by one person. After installation, polystyrene foam does not rot, even with prolonged contact with a damp environment.

The sheets do not collapse, which completely eliminates subsidence of the insulation. Long service life: PSB does not lose its original properties for 30 years from the date of manufacture. By the way, three detected thermal insulation defects are unable to cover the main advantages. The following are considered significant disadvantages:

When melted, harmful substances are released into the atmosphere that pose a threat to human health. Knowing these nuances, you can better understand the scope of application of the SIS and avoid possible misunderstandings.

Despite its excellent resistance to bacteriological influence, polystyrene foam can become a medium for the development of fungi. This appears as patches of green or black mold. If you decide to purchase PSB-S 35, you should not take it from open storage areas. Unexposed polystyrene foam is white and free of stains and faded areas. Material grades The production of material of various fractions is made possible through the use of special chemical components and manufacturing technologies.

Application PSB foam plastic is used mainly when it is necessary to insulate building structures that are not susceptible to significant loads and intense exposure to environmental factors. PSB S Medium density polystyrene foam boards. What kind of insulation is not chewed by mice. Features of Technoblock insulation.

Rockwell basalt insulation boards. List of characteristics of Penoflex insulation.

Definition and properties

Polystyrene foam is an insulating material that has excellent heat and sound insulation properties.

The cost expression of polystyrene foam boards is much lower than for other insulation materials. The use of expanded polystyrene slabs in construction work helps reduce operating costs for heating or cooling residential or commercial buildings by tens of times.

There are several points of view that are associated with the concept of density. The unit of measurement for this parameter is kilogram per cubic meter. This value is calculated from the ratio of weight to volume. It is impossible to measure with one hundred percent accuracy the qualitative properties of polystyrene foam, which are associated with its impermeability and density. Even the weight of this insulation does not affect its thermal insulation capabilities.

When thinking about the question of which insulation to buy, customers are always interested in its density. Through this data, it is possible to evaluate the strength of the material, its weight and thermal conductivity. The density value always refers to a specific range.

When producing expanded polystyrene boards, the manufacturer sets the cost of the products. Based on the formula for finding density, the mass of the insulation will affect the indicated value. The greater the mass of the material, the more dense it is, and therefore its sum is higher. This happens because polystyrene foam as a raw material for heat insulation boards is important. It is approximately 80% of the total cost of finished products.

Insulation of various surfaces with polystyrene foam

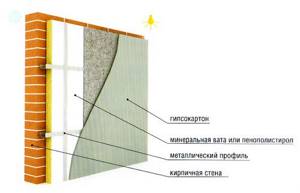

The opinion that polystyrene foam is not suitable for insulating, for example, roofs or walls, is unfounded: in order to mitigate the disadvantages and evaluate all the benefits of using polystyrene boards, thermal insulation from them must be correctly installed. According to GOST, their scope of application is limited to the middle layer of building enclosed structures, so that the material cannot come into contact with air and, especially, with open fire.

Flat roof insulation

After insulation, the attic space turns into an excellent living room. The use of polystyrene foam allows this to be done at relatively low cost. Denser grades (35 and 50) are used for flat roofs, including inversion roofs. In this case, film or liquid waterproofing must be laid on a polystyrene foam layer about 70 mm thick.

Thermal insulation of the roof from the inside

Pitched roofs can also be insulated with polystyrene foam boards, the joints of which are sealed with polyurethane foam. However, it is much more rational to use them to insulate the attic floor, since this will not create cold bridges. The insulation is secured with dowels (preferably), cement mortar or glue, if the unevenness on the surface does not exceed 1 cm.

You can cover the walls with foam plastic both from the outside and from the inside, but, following fire safety recommendations, a non-flammable heat insulator, for example, mineral wool, should be installed around the perimeter of all openings (windows, doors, ventilation) at a distance of 50–80 cm

When installing foam plastic boards as an internal heat insulator, special attention should be paid to the ventilation system of the internal space

Scheme of thermal insulation carpet on the wall

The thickness of the slabs must be calculated based on the thickness and material of the walls, as well as the standard heat transfer resistance for a specific climatic zone. The density of the material should be different: for external work it is better to use denser slabs (grades 25 or 35), and for internal work the PSB-S 15 brand is quite suitable.

It is optimal if the base of the building is insulated during the construction process. Those whose house has already been built, but the thermal protection of the foundation has not been thought through, will have to dig it deep into at least the width of the sheet (1 m). The prepared surface must be treated with bitumen mastic and, after it has dried, polystyrene foam sheets must be glued.

Thermal insulation of the base of the house

If the foundation of the house is level with the ground, the foam plastic needs to be completely covered (when backfilling it is better to use expanded clay), and it does not need finishing. In all other cases, insulation boards must be finished with plaster, brick, siding, ceramic tiles or aluminum profiles. These materials are non-flammable and, in addition to their decorative function, create a protective barrier.

Thus, polystyrene foam boards are a completely economical material, the insulation of which increases the energy efficiency of the building by 3–5 times. Along with this, there is no reason to fear that polystyrene foam is not environmentally friendly and poses a threat to human health. A sufficient condition for ensuring your own safety is to give preference to well-known brands when choosing products, and to adhere to construction requirements during installation.

Results

A complete or partial change in color indicates poor quality material. There is black foam on sale, this indicates that the material contains graphite. Manufacturers claim that this improves heat retention properties.

When buying foam plastic, inspect it from all sides; there should be no signs of crumbling. A high-quality foam board will spring back under pressure while maintaining its density. Also, the granules should fit tightly to each other, and there should be no gaps between them that exceed their size.

If you notice that balls fall off when transporting or moving polystyrene foam, it means you bought poor quality material. Armed with all the knowledge and recommendations for choosing foam, you can be sure that the material will serve you for a long time.

Article rating:

What does the foam marking mean? Link to main publication

Related publications

- How to connect polystyrene foam together?

Technical specifications

| Brand | Sheet strength, kg/m2 | Dry thermal conductivity at 25 °C, W/(m K | Flammability group | Water absorption, no more than % of volume | Vapor permeability, mg/m*h*Pa |

| PSB-S-25F | 16-18 | 0,039 | G3-G4 | 0,4 % | 0,05 |

| PSB-S-35 | 25-26 | 0,039 | G3-G4 | 0,4 % | 0,05 |

| PSB-S-50 | 35-36 | 0,039 | G3-G4 | 0,4 % | 0,05 |

1. Use temperature.

All types are used only at temperatures from -40 to +80 degrees: if this limit is exceeded, toxic styrene may be released from the sheets. Therefore, expanded polystyrene is not recommended for insulating the facades of baths and saunas. You should also not leave regular polystyrene foam in direct sunlight, as it does not tolerate ultraviolet radiation well.

2. Flammability.

The material is assigned flammability group G3 (normally flammable). Compared to wood, it is much less susceptible to fire, so in the event of a fire in an already finished house with furniture, polystyrene foam will not aggravate the situation. According to GOSTs, the burning time does not exceed 4 seconds, but many modern manufacturers have improved this figure by 2 times.

3. Durability.

The frost resistance of the material reaches 100 cycles of alternating thawing and freezing, which has been tested by Russian and Canadian scientists. To create difficult conditions, the foam was cooled and heated in a 4% sodium chloride solution. This proves that the sheets can be used to insulate foundations even in salt-saturated soils, with high groundwater levels and for the facades of houses in northern climates.

4. Moisture absorption.

Polystyrene foam is a waterproof material: it hardly changes its properties even in a humid environment. Thanks to this, it also serves as waterproofing for the facade of the house. Due to its low vapor permeability, it is recommended to mount it on the wall on the street side to prevent moisture from accumulating indoors.

Price

The table contains information from the websites of major manufacturers. Prices shown are current as of March 2021.

| Brand | Strength, kg/m2 | Dimensions | Price per sheet | Price per cubic meter |

| PSB-S-25f | 16-18 | 1000x1000x50 | 135 | 2 700 |

| PSB-S-25f | 16-18 | 1000x1000x70 | 189 | 2 700 |

| PSB-S-50 | 35-36 | 1000x1000x100 | 300 | 4 500 |

| PSB-S-15 | 10-12 | 1000x1000x20 | 110 | 2 200 |

| PSB-S-35 | 26-27 | 1000x1000x70 | 220 | 3 500 |

The cost of one sheet is higher than packaging, and when purchasing from 10 m2, most suppliers make favorable offers to customers.

Before you buy products, check the quality of the foam according to the following criteria:

- Smooth surface.

- No smell.

- The granules are the same size.

- Brand marking on the packaging or on the sheet itself.

- Compliance with material dimensions.

Advantages and disadvantages of polystyrene foam

As experience shows, to date no materials have been invented that would not have disadvantages. They also exist on foam plastic facades.

Despite the huge number of positive characteristics, there are also negative ones. Let's try to understand both of them.

Positive characteristics:

- excellent thermal insulation;

- economical use (when compared with other insulation materials);

- foam does not absorb moisture;

- no vapor barrier required;

- durability and reliability;

- resistance to fungi, mold and rot;

- ease of installation and operation.

Negative qualities:

- does not burn, but during the melting process it emits toxic smoke;

- does not “breathe”, therefore it is not recommended for use for insulating a wooden house;

- easily spoiled by mice and rats.

General information

Polystyrene foam manufacturing process

After secondary foaming, the material is sent to dry. This is done in the open air, due to which the granules are filled with oxygen and acquire their final structure. The material is then molded and the end result is the white slabs we are all too familiar with. After all the manipulations, the finished foam is cut.

A very important point in the production of polystyrene foam is maintaining the room temperature at +18ºС. If this nuance is not observed, the material will crumble. Often, finished foam is cut into blocks of 100 x 500 mm. In addition, product sizes of 2000 x 1000 mm are often found.

Note. Polystyrene foam is very popular as insulation due to its low cost and ease of installation.

Types of foam

- Unpressed;

- Pressed;

- Extrusive.

Unpressed foam has a loose structure and is a rather fragile material. In pressed material, the granules are held together by pressing, which in turn makes the material much stronger. The extrusive type of foam is made under high temperatures, as a result of which the granules are firmly connected, forming a single substance.

Thermal conductivity coefficient of foam plastic boards

Insulation of a house can be done in various ways, for example, using polystyrene foam, which has high performance characteristics. These include: practicality, environmental friendliness, light weight, ease of installation, immunity to temperature changes, as well as an affordable price. But the main advantage is the low thermal conductivity of polystyrene foam, which allows for excellent energy saving.

What determine the characteristics of the material?

The ability to conduct heat is influenced by many factors, in particular:

- Layer thickness. Sometimes, in order to achieve high-quality energy savings, it is necessary to use a large amount of insulation. For example, the thermal conductivity of 5 cm foam plastic boards will be lower than 1 cm with the same density.

- Structure. The porous structure leads to increased insulating properties, because the cells contain air that perfectly retains heat.

- Humidity. During storage, slabs must be protected from moisture. This is due to the fact that liquid does not have a very favorable effect on the characteristics of thermal insulation foams: the more it accumulates, the worse it is.

- Average layer temperature. Its increase leads to a deterioration in the efficiency of the insulator.

Types of foam plastic and their indicators

There are a huge number of insulation boards on the construction market. In general, polystyrene foam has low thermal conductivity, but this varies depending on its type. Examples: sheets marked PSB-S 15 have a density of up to 15 kg/m3 and a thickness of 2 cm, while the described indicator is up to 0.037 W/(m*K) at an ambient temperature of 20-30 °C. Its value for sheets 2-50 cm marked PSB-S 35, with a density of no more than 35 kg/m3 and 16-25 kg/m3 marked PSB-S 25 of the same size is 0.033 W/(m*K) and 0.035 W/ (m*K) respectively.

The dependence of the thermal conductivity of foam insulation on its thickness is best seen when comparing it with various materials. Thus, a sheet of 50-60 mm replaces twice the volume of mineral wool, and 100 mm is equivalent to 123 mm of expanded polystyrene foam, which has approximately similar characteristics. Basalt wool also loses greatly. But the thermal conductivity of Penoplex is slightly lower than that of polystyrene foam: in order to obtain normal temperature conditions in the room, you will need 20 and 25 mm, respectively.

How do you know which sheets to buy?

In order to most effectively apply this or that insulation method, it is necessary to select the correct dimensions of the material.

Expanded polystyrene

Expanded polystyrene is one of the best insulation materials with an extremely low thermal conductivity coefficient. It consists of polystyrene granules, which swell and stick to each other under the influence of temperature. During foaming, the volume of polystyrene increases approximately 40-50 times, accumulating air in the pores (up to 98%), which is the best natural heat insulator.

PRICE FOR FOAM:

PBS-S 25 F (100*100*30) — 95 rub. for 1 sheet.

PBS-S 25 F (100*100*50) — 170 rub. for 1 sheet.

PBS-S 25 F (100*100*100) — 320 rub. for 1 sheet.

PSB - S stands for Expanded Polystyrene Suspension Non-Shrinkable - S - self-extinguishing (i.e., when the fire supply stops, it stops burning) according to the classification of the State Fire Service of Russia.

Expanded polystyrene PSB S is divided into 4 grades (according to GOST 15588-86) 1. PSB S 15 with a density of up to 15 kg/m3 2. PSB S 25 with a density from 15.1-25 kg/m3 3. PSB S 35 with a density from 25.1-35 kg/m3 4. PSB S 50 with a density of 35.1-50 kg/m3

Expanded polystyrene PSB S 25 is a material used in the production of SIP panels as insulation, heat and sound insulator. In a SIP panel, it plays the role of a “filling” - insulation, located between two plates and attached to them using polymer and pressing.

This white, lightweight product is an environmentally friendly, heat and sound insulating material. It consists of 98% air and 2% polystyrene foam. The pentane fraction of hydrocarbons is used as a foaming agent, which is then converted into carbon dioxide and water.

Expanded polystyrene PSB S 25 is resistant to water, mineral oils, alkalis and acids, and to temperature changes. At the same time, it is vapor-permeable, thanks to which a house built from SIP panels “breathes.”

Structure of the material PSB S.

Expanded polystyrene PSB S 25 is very durable. It does not contain substances harmful to humans, is odorless, does not generate dust and does not support combustion. In addition, it is not susceptible to rotting and mold and generally cannot be a breeding ground for microorganisms and fungi. If the ambient temperature does not rise above +90°C, then no changes occur in the material. It begins to deteriorate only with prolonged exposure to sunlight, from which it is reliably protected by a protective and decorative coating.

Properties: Environmentally friendly. For the production of expanded polystyrene, styrene is used - a substance harmless to humans and the environment. The use of this material is approved throughout the world both in construction and in food containers. Low thermal conductivity. The thermal conductivity of expanded polystyrene, regardless of the manufacturer and brand of raw materials, ranges from 0.037 to 0.041 W/(m*K). Low thermal expansion. The stability of the structure at any temperature makes the use of PSB-S in construction possible at temperatures from -180°C to 80°C. For a short time, this material can withstand temperatures of 110°C. High strength at low density. High level of waterproofing. The closed pores of PSB S 25 do not absorb moisture and steam, so even if placed under water, the absorption of moisture by the material will be insignificant. High level of sound insulation from impact noise due to the low rigidity of the material. Fire resistance. When producing sandwich panels, a fire retardant is added to polystyrene foam, which makes the material difficult to burn and gives it the property of rapid self-extinguishing. Corrosion resistance. Unlike most similar materials, polystyrene foam is extremely resistant to exposure to various substances, including sea water, salt solutions, lime, cement, gypsum, anhydride, alkalis, diluted and weak acids, soaps, salts, fertilizers, bitumen, silicone oils, alcohols , adhesive, water-soluble paints. Non-biological origin, which excludes the appearance of fungi, bacteria and other microorganisms in this material. Durability. The “shelf life” of this material under the most unfavorable influences is at least 100 years. Ease of gluing with other building materials, ease of processing.

Advantages and disadvantages

The popularity of expanded polystyrene is explained by its cost and ease of use, but these are far from the only advantages. The main advantages can be expressed as follows:

- No chemically active substances are used in production, therefore PSB belongs to the category of environmentally friendly products.

- After installation, it increases vapor permeability, which prevents the development of wall mold and mildew.

- The material is easy to process: the sheet can be cut with an ordinary stationery knife. Therefore, PSB can be used to insulate buildings with complex geometry.

- The cellular structure helps reduce the weight of the sheet, so installation can be easily done by one person.

- Neutral to any external influence, does not react with other types of building materials.

- After installation, polystyrene foam does not rot, even with prolonged contact with a damp environment. The sheets do not collapse, which completely eliminates subsidence of the insulation.

- Long service life: PSB does not lose its original properties for 30 years from the date of manufacture.

- Does not support combustion: the flame does not spread across the sheet; it dies out, melting the edges.

Of course, it was not without some drawbacks.

By the way, three detected thermal insulation defects are unable to cover the main advantages. The significant disadvantages are:

- Loses properties upon direct contact with solvents and bitumen.

- Attracts rodents.

- When melted, harmful substances are released into the atmosphere that pose a threat to human health.

Knowing these nuances, you can better understand the scope of application of the SIS and avoid possible misunderstandings.

Despite its excellent resistance to bacteriological influence, polystyrene foam can become a medium for the development of fungi. This appears as patches of green or black mold.

Types of foam

The raw material for the manufacture of the material is polystyrene and its derivatives. The following types of pressless foam are distinguished:

- PSB – ordinary;

- PSB-S – self-extinguishing.

A distinctive feature of PSB S 25F is its surface with high adhesive properties. Thanks to its even and smooth structure, painting and plastering work is easier. This variety is made from smaller granules, compared to the PSB-S 15 and PSB-S 25 brands.

The production method of the material is different, which is why the products are divided into two large classes. For the production of the first (non-press) ones, high temperature is used, leading to sintering of the granules. For the second (press) granules are kneaded at elevated temperatures, adding a special foaming agent to the composition. The final stage of production is removal from the extruder.

Two letters are used as markings - PS. Pressless varieties are designated as PSB. The most common brands:

- PSB-S-15. Due to its low density, it is more suitable for insulating those places that do not require high mechanical strength. Demanded for insulation of: attics, roofless roofs, containers, carriages. Among the advantages: high moisture resistance, environmentally friendly and not “afraid” of the influence of microorganisms;

- PSB-S-25. The most popular and versatile brand. It is used to insulate: walls, floors, loggias, facades. The advantages are the same as the first type;

- PSB-S-35. This expanded polystyrene is used to insulate foundations and underground communications. Good because it is suitable for regions with unfavorable climate;

- PSB-S-50. The difference is the highest density. It is used in situations where it is necessary to achieve high mechanical strength. Areas of application: construction of roads in wetlands, construction and insulation of interfloor floors, garages, industrial zones.

There are even more types of foam, each with its own properties and characteristics.

Classification of expanded polystyrene

According to the production method, this material is figuratively divided into 2 large classes, which have very different properties. The first is done at high temperature by sintering granules. The second involves mixing the pellets at very high temperatures with the future addition of a special blowing agent and removal from the extruder.

The first class is called pressless; it can be easily installed by eye. The material looks like balls interlocked together, somewhat similar to a beehive. We need to remember the polystyrene foam in which any household appliances (microwave, refrigerator) were supplied. The second class is called press, because the granules are connected to each other much more tightly. It is much harder to break or crumble. Accordingly, different brands are distinguished.

Application area

Due to its technical characteristics, expanded polystyrene PSB-S 35 is ideal for use in regions with severe climatic conditions. It is used to insulate the foundation, ground floor, basement, pipelines (and other communications located underground), roofs (both flat and gable). But the main area of application is thermal insulation of walls and floors (including with a heating system).

The material is used in a wide temperature range - from minus 200 to plus 85 degrees. In areas with very high temperatures, the use of polystyrene foam is prohibited.

Foam is easily cut with a regular knife in any direction. In addition, it reduces vibration levels during transportation, thereby protecting the goods. Therefore, it is widely used as packaging material. It is used for packaging breakable goods (glass, ceramics), electronics, and so on.

Read and understand

Expanded polystyrene foam, pressless, self-extinguishing. This is exactly what the abbreviation stands for – PSB S. Popularly it’s just polystyrene foam. Let's break down the terms of the name by bone:

P: based on a material widely used for the production of insulation, polystyrene foam. Expanded polystyrene granules are filled with carbon dioxide, pentane or isopentane (derivatives from natural gas production).

C: these granules are obtained as a result of suspension polymerization of styrene in a gas environment.

B: the slab is formed without using pressure. Sintering of granules occurs under the influence of high temperature steam. At the same time, a 50-fold increase in the volume of the component occurs due to the expansion of the gas inside the granules.

C: when foam is exposed to open fire, the material spontaneously extinguishes.

Characteristics and applications of polystyrene foam

Brand PSB-S-15, or “foam plastic with 15th density” is used for insulating areas of buildings and structures in which mechanical impact on the thermal insulation layer is completely eliminated:

- When laying walls in the space between the load-bearing wall and the facing layer.

- When insulating interfloor ceilings, it is mounted in the space between the joists.

- When insulating a suspended ceiling.

It is widely used in industry for insulating cabins, carriages, containers, etc. Thermal conductivity of this brand is λ=0.043 W/m*K, strength 0.04 MPa, density 10-12 kg/m3.

“25-density foam plastic”, or brand PSB-S-25, occupies a leading position in sales volume in the Russian Federation. This product owes its popularity to its wide range of applications:

- Can completely replace the previous sample

- When arranging “wet facades”

- When insulating floors

- When insulating roofs of any type

- When insulating balconies and loggias

The density of this brand is 17 kg/m3, thermal conductivity λ=0.041 W/m*K, compressive strength 0.08 MPa.

The PSB-S-35 grade has a high strength of 0.14 MPa, so it is used for insulating structures subject to mechanical stress:

- Insulation of flat roofs

- Insulation of exploited floors

- Insulation of floors with increased loads, for example, in a garage

- Insulation of foundations and basements. In this case, it is necessary to perform waterproofing, since the material is hygroscopic and, when absorbing moisture, partially loses its properties

- In the manufacture of multilayer panels

The thermal conductivity of PSB-S-35 is lower than previous samples λ=0.038 W/m*K, density 27 kg/m3. It is not advisable to use when performing a “wet facade” due to cost.

There is also a super-strong grade PSB-S-50, but it is used extremely rarely in civil engineering. It is used for insulation of floors in industrial premises, warehouses, barns, installation of heated paths and in the construction of highways on moving and soft soil.

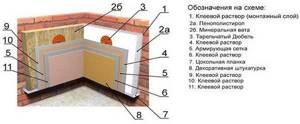

Installation features and tips for buyers

1. If you decide to purchase PSB-S 35, you should not take it from open storage areas. Unexposed polystyrene foam is white and free of stains and faded areas. Its balls are approximately equal in diameter, and the entire slab is both elastic and soft.

2. When choosing, the sheets must be placed side by side and compared: all characteristics, length, width, and especially thickness must be respectively identical to each other. On the foam itself there is a marking for decoding.

3. There are several features during installation. Thus, the work is carried out on leveled walls, coated with an antifungal primer. After drying, glue is applied to them and insulation is installed. The seams between three sheets of polystyrene foam should be T-shaped (masonry bonding). To completely harden the PSB-S binder, leave it alone for a couple of days.

4. Then, if the joints are more than 4 cm wide, then they are sealed with strips of polystyrene foam with the same characteristics; if less, then with polyurethane foam followed by gluing. Holes are drilled through the foam in the wall for plastic dowels, which are driven in there. In turn, plastic nails with a very large head are driven into them. Their goal is to make the connection more reliable.

5. Next, a reinforcing mesh is glued onto the polystyrene foam, so that it does not protrude anywhere from under the fastening agent. The dried glue is smoothed with sandpaper, the surface is puttied and primed for wallpaper, paint or other coating.

Cost of PSB-S 35

For all calculations, such as prices per sheet, square meter, entire insulated surface, the basis is the cost of 1 m3 of polystyrene foam. It depends on the density, since the production of different brands will not require the same amount of raw materials, board parameters, location and volume of delivery, and prices for the use of transport. In addition, each manufacturer and seller may have different financial policies. Most often, the price fluctuates throughout the country in the range of 3200-4000 rubles per 1 m3.

Knowing the dimensions of the slab and the cost per unit volume, it is easy to calculate how much the required amount of polystyrene foam will cost. For example, for 3200 rub/m3:

| Parameters of sheet PSB-S 35, (mm) | Thickness, mm | Pieces per 1 m3 | Panel price, rubles |

| 1000x1000 | 200 | 5 | 640 |

| 190 | 5,26 | 610 | |

| 180 | 5,55 | 580 | |

| 170 | 5,88 | 540 | |

| 160 | 6,25 | 510 | |

| 150 | 6,66 | 480 | |

| 140 | 7,14 | 450 | |

| 130 | 7,69 | 420 | |

| 120 | 8,33 | 380 | |

| 110 | 9 | 350 | |

| 100 | 10 | 320 | |

| 90 | 11,1 | 290 | |

| 80 | 12,5 | 260 | |

| 70 | 14,28 | 220 | |

| 60 | 16,66 | 190 | |

| 50 | 20 | 160 | |

| 40 | 25 | 130 | |

| 30 | 33,3 | 96 | |

| 20 | 50 | 64 |

Application of expanded polystyrene

1. Sound and heat insulation of walls, both internal and external.

2. Production of multilayer panels.

3. Construction of parking lots, access areas, heated paths.

4. Waterproofing of underground communications.

5. Thermal protection of balconies and loggias, attics and roofs, foundations and pipes.

6. Drainage of waste water, strengthening of slopes when laying out a pool, saving soil from freezing and swelling.

7. Arrangement of sports grounds, laying out lawns.

8. Foam plastic is easily cut in any direction, therefore, for example, PSB-S-35 board 100 mm and thicker is used for packaging breakable goods or stuffed with electronics, since the material dampens vibrations.

Characteristics, properties and scope of application

To determine the harm of polystyrene foam as insulation, it is necessary to consider its properties, composition and manufacturing method

Special attention should be paid to the area of application, since it is the decisive factor in identifying the impact on humans.

Structure of the material on a cut

Insulation

Foam plastic is almost irreplaceable as a material for protection against cold.

- Its porous structure can significantly reduce thermal conductivity.

- The polystyrene foam holds its shape perfectly, something that not one of the insulation materials in this price category can boast of.

- It is more than 90% air, so it does not burn and does not support this process.

- In its production, a minimum amount of styrene-containing substances is used, which is considered a decisive factor in determining environmental cleanliness.

- The maximum service life of foam plastic exceeds 50 years. This is evidenced by the installation instructions and the quality certificate included with most products made from this material.

Use as external insulation of houses, amateur photo

Release of toxic substances

It is believed that polystyrene foam, when burned or subjected to strong heating, releases styrene, which is very harmful to the body and in its pure form can become a real poison. However, the harmfulness of basalt insulation is sometimes much higher, especially if violations were made during its manufacturing process, which leads to the decision to use a less dangerous material, although it emits unnecessary substances.

The use of this material was approved back in the Soviet Union, taking into account the relevant GOST

Thus, it becomes clear that it is quite safe to insulate a loggia or other premises using polystyrene foam. In the same cases where it will emit harmful substances, there are many other materials, in the form of vinyl wallpaper and plastic interior items, that can cause more harm.

Rodents really like this material. What may indicate lack of toxicity

Application area

When determining the degree of harmfulness of a given material, it is necessary to consider the places where it is used.

First of all, it is worth understanding that polystyrene foam is used indoors only when insulating plastic windows or entrance doors. In all other cases, cheaper materials are used. Therefore, its impact on humans is minimal. Separately, it is worth noting the insulation of walls in contact with the street. The fact is that it must be done only from the outside (see also the article Insulating facades with foam plastic: we do external thermal insulation with minimal time and money)

Otherwise, condensation will appear between the insulation and the wall, mold and mildew will form. When plasterboard partitions are erected, it does not matter at all whether the basalt insulation is harmful or whether styrene foam releases. In this case, both of these materials are placed in such conditions that their use is not only the most optimal solution, but also environmentally friendly. The only unsafe place to use this insulation is considered to be a metal roof. However, taking into account the fact that foam plastic is separated from the immediate area of incandescence by a layer of waterproofing, and from the living space by a vapor barrier film, then using it for these purposes is quite acceptable.

However, taking into account the fact that foam plastic is separated from the immediate area of incandescence by a layer of waterproofing, and from the living space by a vapor barrier film, then using it for these purposes is quite acceptable.

Houses in Japan made entirely of foam plastic

Technical characteristics of polystyrene foam

Thermal conductivity

The undeniable advantage of polystyrene foam is its unique thermal insulation abilities. This is explained by the fact that the polystyrene cells in the form of polyhedrons measuring 0.3-0.5 mm are completely closed. The closed cycle of air cells reduces heat transfer and prevents the penetration of cold.

Windproof and soundproofing properties

Walls insulated with foam plastic do not require additional wind protection. Moreover, the sound insulation of buildings and structures is significantly increased. High sound insulation properties are also due to the cellular structure of the foam. For high-quality insulation of premises from external noise, it is enough to lay a layer of material 2-3 centimeters thick. The thicker the foam layer is used, the better sound insulation can be achieved in the room.

Low water absorption

Compared to other materials, foam is characterized by low hygroscopicity. Even when directly exposed to water, it absorbs a minimal amount of moisture. This is explained by the fact that water does not penetrate through the walls of the foam cells, but only seeps through separate channels through interconnected cells.

Strength and durability and foam

Foam plastic slabs do not change their physical properties for a long time. They withstand significant pressure, but do not deform or collapse. A good example is the construction of runways, where polystyrene foam has found widespread use. The degree of strength is determined by the thickness of the polystyrene foam board and its correct installation.

Resistance to biological and chemical influences

Expanded polystyrene boards are resistant to aggressive environments, including solutions of salts, alkalis and acids, sea water, lime, gypsum, cement, bitumen, silicone and water-soluble paints. Substances containing animal and vegetable oils, as well as gasoline and diesel fuel can have a certain effect upon prolonged exposure.

When using polystyrene foam as a building material, avoid its contact with aggressive chemical compounds, including:

- organic solvents (paint thinners, turpentine, ethyl acetate, acetone);

- saturated hydrocarbons (alcohols) and petroleum products (kerosene, gasoline, diesel fuel, fuel oil).

The cellular structure, which is the basis of the foam, when in contact with the listed compounds, is disrupted and can completely dissolve in them.

Polystyrene foam is an unfavorable environment for microorganisms. However, if it is significantly contaminated, harmful microorganisms may appear and multiply on its surface.

Easy installation and ease of use

Polystyrene foam slabs are distinguished by their unusually low weight, which makes them easy to handle and their installation does not cause difficulties. They are cut into pieces of the required sizes using conventional tools.

Expanded polystyrene is recognized as an environmentally friendly material and does not emit harmful substances. Therefore, builders working with it do not require personal protective equipment. The material is non-toxic, does not generate dust, does not irritate the skin and has no odor.

Fire safety

High-quality building materials must meet all fire safety requirements and be resistant to open fire. Polystyrene foam does not support the combustion process and flares up at a temperature that is twice that of wood. Moreover, when burning polystyrene foam, the energy released is 8 times less than when burning wood. This means that the fire temperature when burning foam is much lower.

Expanded polystyrene can only ignite during direct contact with an open flame. When the exposure stops, the foam self-extinguishes within four seconds. These indicators characterize it as a relatively fireproof building material. Although manufacturers and sellers claim that it is absolutely fireproof.

To purchase material, place an order through the shopping cart or call us.