The use of gas boilers for heating private houses or apartments is becoming common.

Homeowners do not want to indulge the appetites of the owners of resource companies, who are constantly increasing housing and communal services tariffs.

Some villages are located in remote areas, their networks are not able to provide new subscribers.

These reasons have caused an increased demand for heating equipment, which is represented not only by European, but also by domestic manufacturers.

Consider gas boilers from Ochag.

Gas boilers from Ochag

, which is the owner of the Ochag brand, is located in Ulyanovsk. The beginning of its activities is considered to be 1993.

Today the company produces a wide range of heating equipment and individual components for it of its own design . There are many standard sizes and designs of gas boilers in production, capable of heating rooms from 70 to 1000 V. m.

The company carries out its activities based on the principles of simplicity, reliability, and stability of its equipment. The main advantage of Ochag boilers is their low cost, which makes them preferable and accessible to the mass buyer.

At the same time, the functionality and quality of the boilers are at a high level, which confirms the high demand and positive user ratings.

The boilers are non-volatile, which for the Russian user is a guarantee of reliability and continuous operation of the heating system.

Features of ignition of different models of gas boilers

Different models have their own ignition features. For example, before lighting a gas boiler Aton or Danko, you should set the regulator to the icon with an asterisk and hold it there for 5-10 seconds. After this, you need to press the button next to it.

How to light a gas boiler AOGV? When the boiler is turned off, the control knob is in the “dot” position. To ignite, it is switched to the “spark” mode and held in the pressed position until it stops. At the same time, activate the piezo ignition button until the burner ignites. If necessary, press the piezo several times. After the flame appears in the burner, hold the handle for about 10 seconds until the thermocouple warms up.

Another option is how to light a Lemax gas boiler. It has a main burner and a pilot burner. Initially, the handle is in the “dot” position. To light the boiler, turn the handle to the “spark” position and hold it for 10-60 seconds. At the same time, press the piezo ignition button until fire appears in the pilot burner. If after releasing the handle the flame goes out, you should repeat the manipulations again, but hold the handle longer. To immediately turn on the main burner of the Lemax boiler, you need to turn the knob to position 1.

Kinds

The Ochag company produces different structural types of boilers:

- Floor-standing . They do not require any special installation as they can be placed directly on the floor. This expands installation options compared to wall-mounted models.

- Wall mounted . They require hanging installation on strong, preferably load-bearing walls. Temporary or plasterboard partitions are not suitable for this. The specifics of the installation require reducing the weight and reducing the size of the boiler, which affects power and performance.

- Parapet . They can be used both as part of a heating circuit and as an independent heat source.

By functionality:

- Single-circuit . Designed only to supply the heating circuit with hot coolant.

- Dual-circuit . Capable of simultaneous heating of coolant and preparation of hot water (DHW) for domestic needs.

By type of combustion chamber:

- Atmospheric (open) . Smoke removal occurs through a common house chimney using a stove-type draft, and combustion air is taken directly from the room.

- Turbocharged (closed) . Smoke removal and air supply are carried out by a special turbocharging fan. Possible only on energy-dependent models, but independent ones can also be modified using an external turbo nozzle.

There are many design options for Ochag boilers; the user can choose the most suitable option for his or her purposes.

How to choose?

Options for the material of manufacture of the heat exchanger - the container where the coolant is heated:

- Steel. Good ductility, minimizing the likelihood of cracks due to thermal stress. Used in budget models. The service life is short due to susceptibility to corrosion.

- Cast iron. Heavy weight. They cost more than steel ones. Minus - they react to temperature changes. They don't rust - a plus. They serve for about half a century.

- Copper. They weigh little. Corrosion resistant. They are usually found in wall-mounted versions.

Series and models

The Ochag company produces several model lines:

- Premium . The series is represented by single- and double-circuit floor-standing models AOGV and AKGV with a power from 8 to 29 kW. There are models with different types of automation - Italian SIT or the company’s own development.

- Standard . A series of floor-standing single- and double-circuit gas boilers. The power of the models is in the range of 7-20 kW. EUROSIT or SABK-AT automation was used.

The most common models are KSG 7, 10 and 15.

They have a power of 7, 10 and 15 kW, respectively, which makes it possible to provide thermal energy to rooms with an area of 70, 100 and 150 m2, which allows heating private houses of the most common sizes.

These are non-volatile floor-standing boilers, designed in a modern compact style and fit perfectly into the interior of any room . There is a possibility of conversion to liquefied gas.

A durable stainless steel burner is used.

IMPORTANT! All models of Ochag boilers are manufactured in accordance with the requirements of the European standard ISO 9001-2011.

Model overview

Characteristics of the most popular modifications of the Hearth equipment:

- Boiler KNG 24. Compact wall-mounted unit, double-circuit. The modern design allows it to be installed in a residential area and operates silently. Maximum productivity 24 kW, gas consumption 2.5 m3/hour, efficiency 90%.

- Model KSG-11. Floor-standing, steel heat exchanger, capacity 11 kW, gas consumption 1.34 m3/hour, efficiency 90%. The design allows the use of automation EUROSIT 630, SABC-AT.

- Boiler KSTG-16. The simplest single-circuit floor-standing unit, power 16 kW, runs on coal and gas, efficiency 74%, not equipped with automation. Designed for heating rooms up to 160 m2.

- Model KSG-10 AT. Underfloor heating installation with a power of 10 kW. It runs on natural gas; you can change the nozzles for heating with liquefied gas. Compact, lightweight, equipped with SABK-AT automatic control devices.

- Boiler KSG-7 E. Budget, choice of functions is limited, unit power 7 kW, efficiency 85%. Heats a room of 80 m2 area. Single-circuit, floor-mounted, operates stably at low network pressure. Small dimensions, modern design, low cost make it popular when choosing for heating small buildings.

- Parapet modification. Hangs on the wall. Smoke removal is carried out through a pipe included in the delivery set. Available in two types - single-circuit KSGZ and double-circuit KSGZV. The boiler body is covered with a layer of mineral wool insulation, which can be removed to clean the heater from scale. Productivity 85%.

Ochag brand boilers are not the best among modern heating equipment. Their advantage is low cost, simple design and maintenance. You can purchase units with a wide range of equipment and capabilities, with full control automation, at a higher price. This budget option does not require long-term use; the service life of the brand is 10-15 years.

Technical characteristics

Let's consider the parameters of gas boilers Hearth:

| Options | Values | ||

| KSG-7AT | KSTG-16 | KNG 24 | |

| Boiler type | Gas heating convection | ||

| Fuel type | Natural gas with the possibility of conversion to liquefied gas | Natural gas with the possibility of using solid fuel | Natural gas with the ability to convert to liquefied gas |

| Functions | Heating | Heating | Heating and hot water supply |

| Installation method | Floor | Floor | Wall |

| Efficiency | 85 % | 75 % | 90 % |

| Power | 7 kW | 16 kW | 24 kW |

| Power supply | Absent | Absent | 220 V 50 Hz |

| Life time | 15 years | ||

| Guarantee | 36 months | ||

Boiler marking Ochag

The boiler brand has letter designations, which are deciphered as follows:

- K – boiler;

- C – heat exchanger material steel, CH – cast iron;

- T – used for working on solid fuel;

- G - equipped with gas burners;

- B – has a water heater in its design;

- M – heating elements and an expanded firebox can be mounted to it;

- The number indicates the power of the boiler, the first number is for solid fuel, the second is for gas.

For example: KSG-7AT is a boiler with a steel heat exchanger, equipped with a gas burner with a power of 7 kW, and has SABK-AT automation. Modification KCHTG-16: a boiler with a cast iron heat exchanger, runs on gas and solid fuel, with a power of 16 kW without installing automation.

Advantages and disadvantages

The advantages include:

- Durability, reliability, stable operation of boilers.

- A wide selection of models allows you to obtain the optimal design and power of the boiler.

- The energy independence of the units ensures uninterrupted operation of the heating system in all situations.

- High performance boilers.

- Simplicity of design, ease of management and maintenance.

- Low fuel consumption.

- Attractive appearance, compact size.

- Low price.

The disadvantages of Ochag boilers are::

- Difficulty igniting.

- The need to ensure a slope of the system to ensure coolant circulation.

- For more stable operation, the use of external devices is required - a circulation pump and a turbo nozzle.

For non-volatile boilers, these disadvantages are quite typical and are, rather, design features.

Advantages of boilers from ServiceGaz

Automation makes using boilers from the Ulyanovsk plant comfortable. Heat consumers completely shift the task of maintaining a given mode to the electronics. Advantages of all modifications of “Hearth”:

- Economical gas consumption. The developers have included a stabilizing device in the design to equalize fuel pressure. Thanks to the stabilizer, gas consumption is reduced by 30%.

- Environmentally friendly. Minimal emissions of harmful substances. In this regard, the equipment from ServiceGaz is not inferior to its European counterparts, which is quite unusual for domestic gas equipment.

- Precision temperature control.

- Three levels of security:

— protection against unexpected flame extinction in the burner;

— shutdown in the absence of traction;

— protection against lack of gas in the system.

- Steel heat exchanger. High efficiency.

- Simple but stylish design. Fits well into modern interiors, does not look like a foreign body, bulky or ugly.

- The design uses innovative technologies. High technical equipment.

- Low price. Simple and cheap maintenance.

- No additional energy sources are needed.

- High quality build. Multi-level quality control.

- Adaptation to domestic gas supply conditions.

- Italian automation EUROSIT.

- Compactness.

- Temperature adjustment.

- Remote control system. Can be controlled using a mobile phone. An electric horn and the ability to connect to a “smart home” system are also provided.

- The package includes a passport and instructions.

Operation and setup

Operation of gas boilers Hearth occurs almost without human intervention, in automatic mode.

The owner is only required to:

- Filling and draining water from the system.

- Switching the boiler to summer/winter mode.

- Periodically clean the housing from dust and dirt.

The operating mode is configured during installation and initial startup. Boilers are sold already configured and adjusted .

At startup, only adjustments are made to the factory settings for the most efficient operation under the given conditions.

The setup must be performed by a specialist from the service center with the appropriate approval and qualifications.

Any independent intervention in the boiler design automatically terminates the warranty agreement . In addition, an inexperienced user with his actions can permanently damage the boiler.

Commissioning of a wall-mounted boiler

For installation and initial start-up of a wall-mounted gas boiler, it is better to contact the organization of the specifics in question. The presence of all approvals and appropriate qualifications for the installation of water heating equipment on the part of the service center will allow you to purchase a warranty, as well as extend it with proper operation in subsequent years. All this must be accompanied by documentation in the form of an act or card with a stamp and signature.

In addition to the provided warranty, when contacting specialists, another advantage is the safe installation and adjustment for economical operation of the gas boiler. Safety means the absence of gas leakage and the risk of unwanted ignition.

Installation features

According to SNiP requirements, the heating boiler must be connected to the gas main using a copper pipe or a stainless steel bellows hose. The presence of a gas shut-off valve is mandatory. It is also possible to use various types of adapters and fittings for connection. We must not forget about the presence of gaskets and sealing materials at the joints.

Gas boilers can only be mounted on fireproof walls at a distance of at least 2 centimeters. Otherwise, a fireproof material (plaster, metal or ceramics) must be placed between the boiler and the wall. The distance to the wall should be more than 3 centimeters, and the sheet area should exceed the dimensions of the heating installation in width and height.

Another important condition for placing a gas boiler is the presence of a hood and a window with elements of free air access. After installing the heating boiler, it is necessary to check for gas leaks using an electronic device or a soap solution.

Commissioning

The sequence of actions when starting a wall-mounted gas boiler may differ slightly and be as follows:

- The mains voltage is measured. If there is a large “drawdown”, operation of the water heating installation is possible with the additional inclusion of stabilizing devices;

- Check the tightness of the expansion tank using a pressure gauge (preferably before filling the heating system with water). The pressure in a diaphragm-type tank should be slightly less than in the heating system. Air pumping is possible (with water drained from the boiler);

- The circulation pump is being prepared. To do this, unscrew the screw representing the plug and located in the center. The engine rotor rotates to avoid unwanted blocking (jamming as a result of long-term storage) and subsequent failure. The cover screw is screwed back in;

- All taps open (including the “feed” tap);

- After filling the heating system with water and reaching a pressure of 1.2 - 1.5 bar, the “make-up” tap is closed;

- The power cord is connected;

- The plug of the automatic air valve on the circulation pump is opened;

- Using the control unit, the forced operating mode of the pump is activated. At this time, the heating system is “de-aired” (air is bleed through the radiators);

- Check the pressure in the gas line (if possible);

- The operation of a gas heating boiler is checked in all modes (hot water supply and heating) at different temperature setpoints;

- Temperature is monitored using indicators;

- The gas supply, maximum temperature of the heating circuit and hot water supply are adjusted based on the criteria of efficiency and durability.

How to light a boiler

The procedure for igniting a gas boiler with automatic SABK-AT:

- Open the gas tap.

- Place the gas block handle in the “Ignition” position.

- Press the “Start” button, hold it for about 10 seconds, then press the piezo ignition button 2-3 times until it clicks (ignition is possible through the viewing window using a burning match).

- Hold the “Start” button for another 20-30 seconds to warm up the thermocouple. The gas valve can then be held open by a magnetic plug.

- Turn the gas block knob to position 5 and make sure the burner flame is stable.

- Set the desired temperature on the gas block.

To ignite the burner of boilers with automatic EUROSIT, the same steps are performed, only in step 5 the handle must be turned to position 7.

Download instructions Download instructions

for the gas boiler Ochag

.

Gas boiler Hearth

The gas boiler Ochag KGS is part of a wide range of products. The Russian manufacturer produces gas burners, control units and gas burners. The Ochag KGS boiler is the result of the implementation of innovative strategies combined with the technical experience accumulated by the largest specialized plant over many years. Just imagine, 63 types of boilers this company can offer!

Don’t be alarmed, our review today will only cover the standard and premium versions of boiler equipment from the Ulyanovsk plant:

Boiler Hearth standard

Specifications

| OCHAG FLOOR FLOOR GAS BOILERS KSG-STANDARD SERIES | |||

| Name | Heating area | Dimensions/weight | Natural/liquefied gas consumption |

| Single-circuit heating only | |||

| KSG-7 S/E | 80 m2 | 244*470*710 / 46 kg. | 0.78 / 0.64 m³/hour |

| KSG-10 S/E | 100 m2 | 244*470*710 / 46 kg. | 1.11 / 0.88 m³/hour |

| KSG-12.5 S/E | 120 m2 | 300*470*710 / 49 kg. | 1.39 / 0.97 m³/hour |

| KSG-16 S/E | 160 m2 | 300*470*710 / 49 kg. | 1.78 / 1.1 m³/hour |

| KSG-20 S/E | 200 m2 | 376*470*710 / 60 kg. | 2.22 / 1.41 m³/hour |

| Double-circuit with DHW | |||

| KSGV-12.5 S/E | 120 m2 | 300*470*710 / 50 kg. | 1.39 / 0.97 m³/hour |

| KSGV-16 S/E | 160 m2 | 300*470*710 / 49 kg. | 1.78 / 1.1 m³/hour |

| KSGV-20 S/E | 200 m2 | 376*470*710 / 61 kg. | 2.22 / 1.41 m³/hour |

The gas boiler Ochag KSG is operated in automatic mode. Maintains the temperature of the coolant in the heating unit at the same level set by the consumer. Provides multi-level protection in case of emergency situations. In particular, the sensor system monitors the flame attenuation on the ignition burner and monitors the occurrence of a lack of draft situation - in each case, the gas supply is immediately blocked.

Boiler Hearth Advantages

- Laconic design;

- High efficiency up to 92%;

- Gas blocks of own design of the ServiceGas concern;

- Completely non-volatile. There is no need to connect to the electrical network;

- Possibility of conversion for further operation on liquefied gas;

- Stable operation of the device in case of low gas pressure;

- Heat-resistant stainless steel burner.

- The gas pressure and draft stabilizer is built into the Hearth boiler;

- Regular maintenance using easily removable turbulators in gas passage channels adds ease of operation;

- Easy installation with a choice of one of two gas connection options.

- Thermocouples serve as additional protection against operational breakdowns;

- Service maintenance due to the special mounting of the smoke collector does not interfere with convenient work with the flue part;

- Small pipe diameters = 1.5 inches contribute to reducing financial installation costs;

- Service life of at least 15 years;

- Warranty period from the manufacturer is 2 years.

The floor-standing gas boiler Hearth KSGV serves as a heat supply device for rooms with an area of up to 160 m2, taking into account that the ceiling height does not exceed 2.7 m. Higher ceilings will most likely require a more accurate calculation of heating equipment. The two-circuit model provides the consumer with heat in combination with hot water supply, as indicated by the “B” index.

Explanation of the abbreviation KSGV S -12.5 AT

The letter designations that the Ochag boiler has are intuitive and not difficult to decipher: “K” – boiler “C” – steel “G” – gas “B” – possibility of supplying hot water (a water heater coil is installed) “12.5” – boiler power in kilowatts “A” – a – possibility of operation as a solid fuel “E” – EUROSIT automation “C” – SABK-AT automation

The device uses a gas pressure stabilizer designed to regulate the network pressure and ensure a uniform and stable flame on the main burners without changing thermal performance. A new heat-resistant stainless steel burner of atmospheric type is used. It is installed at the bottom of the heat exchanger, maintaining a uniform thermal zone in the combustion unit. The design has a uniform placement and prevents zonal overheating of the heat exchanger and its failure.

The built-in draft stabilizer balances the pressure at the entrance to the ejector of the main burners and at the exit from the slot grooves. This ensures constant discharge and stable combustion of the gas-air mixture in the firebox without additional regulation.

Boiler Ochag Premium

Consider the Premium series AOGV and AKGV. This line has a power from 10 to 35 kW, and serves as a heating device for a residential building up to 300 square meters. The devices are characterized by high performance and reliability. The manufacturer provides for the equipment to operate on natural or liquefied gas. In case of planned connection to a liquefied gas cylinder, it will be necessary to purchase an additional set of nozzles with subsequent adjustment of the equipment.

Specifications

| OCHAG FLOOR FLOOR GAS BOILERS AOGV PREMIUM SERIES | |||

| Name | Heating area | Dimensions/weight | Natural/liquefied gas consumption |

| Heating unit Gas water heating, one circuit and works only for heating. | |||

| AOGV – 8 C/E | 80 m2 | 350*450*760 / 38 kg. | 0.81 / 0.63 m³/hour |

| AOGV – 8 11.6 C / E | 100 m2 | 350 450 850 / 57 kg. | 1.18 / 0.91 m³/hour |

| AOGV – 17.4 C/E | 160 m2 | 350 450 850 / 61 kg. | 1.76 / 1.36 m³/hour |

| AOGV-23.2 S/EM | 210 m2 | 430 565 850 / 66 kg. | 2.35 / 1.82 m³/hour |

| AOGV-29 S/EM | 260 m2 | 430 565 850 / 82 kg. | 2.95 / 2.28 m³/hour |

| AOGV-35 S/EM | 320 m2 | 430 565 850 / 96 kg. | 3.6 / 2.79 m³/hour |

| AOGV-45 S / EN | 400 m2 | 500 650 930 / 102 kg. | 4.6 / 3.54 m³/hour |

| Combined Gas Water Heating Unit, two circuits, one for heating the room, the other for heating hot water. | |||

| AKGV – 11.6 C/E | 100 m2 | 350x450x850 / 57 kg. | 1.18 / 0.91 m³/hour |

| AKGV – 17.4 C/E | 160 m2 | 350 450 850 / 62 kg. | 1.76 / 1.36 m³/hour |

| AKGV – 23.2 C/EM | 210 m2 | 430 565 850 / 68 kg. | 2.35 / 1.82 m³/hour |

| AKGV – 23.2 C/EM | 210 m2 | 430 565 850 / 68 kg. | 2.35 / 1.82 m³/hour |

| AKGV – 29 C/EM | 260 m2 | 430 565 850 / 86 kg. | 2.95 / 2.28 m³/hour |

| AKGV – 35 C | 320 m2 | 500 640 930 / 96 kg. | 3.6 / 2.77 m³/hour |

Boiler Hearth device:

Structurally, the Hearth boiler is designed in such a way that it can be integrated into any heating system. The front door can be adjusted according to need and opens either on the left or right side. Two return lines, on the side and behind, make it possible to supply coolant from a convenient installation side.

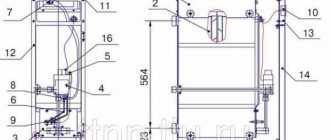

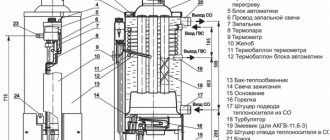

The Hearth boiler consists of:

- Boiler body

- Automatic control

- Heat exchanger

- Second circuit (if the boiler is double-circuit)

- Safety system

In the lower part of the body, there is a combustion chamber, closed on the sides and rear by sections of the water jacket. A heat exchanger is located above the combustion chamber. High efficiency of heat transfer and heat exchange between flue gases and coolant is achieved due to the developed convective part of the heat exchanger, consisting of “flame” pipes.

At the top of the heat exchanger there is a smoke collector with a built-in draft stabilizer. In the front part of the smoke collector there is a draft sensor, in the upper part of the smoke collector there is a boiler outlet pipe. When installing a boiler into a chimney, it is necessary to coordinate the diameter of the outlet pipe with the cross-section of the chimney. The technical parameters of the chimney must correspond to the technical parameters specified in the operating manual.

In the middle part of the smoke collector, there is a partition plate to ensure stable operation of the device regardless of weather conditions. The heat exchanger, complete with a smoke collector, ensures efficient operation of the boiler without consumer intervention and without requiring manual adjustments. The stabilizer draft contributes to stable operation of the boiler during unstable draft.

A gas burner device manufactured in Russia by the Service Gas company is installed in the combustion chamber of the apparatus. It consists of a front panel, burner pipes, safety sensors (flame sensor and draft sensor), and the SABC AT control unit.

An easily removable distribution grid is mounted below the burner pipes. Designed to supply secondary air for combustion. It is very important when installing the Hearth boiler in a room to ensure free access of air through the lower part of the boiler through the distribution grid to the burner pipes.

The boiler must be installed with clearance at the height of the legs relative to the floor. The Hearth boiler is connected to the gas main on both the left and right sides. This can be done by the design of the SABC AT block. A temperature sensor is installed on the front panel, which indicates the room temperature.

How to light a boiler?

In order to ignite the Hearth boiler, you need to turn the control knob clockwise until the point is opposite the pointer. Then press and hold the start button. Press the piezo ignition button until you hear a characteristic click. At this time, the igniter lights. We continue to hold the start button pressed while the thermocouple heats up. The gas block operates automatically on the igniter. Next, turn the knob counterclockwise to the required temperature.

The Hearth boiler achieves high efficiency due to efficient combustion of fuel and high heat transfer from flue gases through “flame” pipes to the coolant and a developed firebox. The manufacturer guarantees a service life of at least 15 years. Factory warranty for the product is 24 months.

Watch a video on how to light a gas boiler with Eurosit630 automation

Why does a gas boiler go out?

The extinction of a gas boiler flame can be caused by external or internal reasons.

External reasons include:

- The occurrence of reverse thrust . The most difficult case, almost impossible to eliminate by conventional means. Sometimes eliminating drafts and opening or closing some doors or windows helps.

- Strong gust of wind outside . Cases of flames being blown out by the wind are frequent; they are the result of an unsuccessfully located chimney or low height above the roof surface.

- Drafts in the room . This situation is completely solvable, the main thing is to determine the source of the draft and close it.

Internal problems may be:

- Stopping the gas supply to the mains.

- Gas valve failure, problems with gas equipment.

- Burner nozzles are clogged with soot and combustion products.

If such problems occur, you should call the gas service and clarify the reasons for the lack of gas. The fuel supply valve must be closed before doing this.

Call a specialist from the service center and entrust him with the repair of gas equipment.

It is prohibited to try to repair the gas block yourself; this can cause very dangerous and even fatal consequences.

Preparation for installation of gas equipment

Those who are sure that the installation of a gas heating device begins with its purchase are greatly mistaken.

We start with collecting permits. Simultaneously with obtaining the necessary papers, you should begin to select and prepare a site for installing the heating unit, while taking into account the following regulatory requirements:

In order to obtain permission to install heating equipment, you need to go through several stages:

Step No. 1: Obtaining Technical Specifications and Permits.

It is necessary to find out whether it is in principle possible to install a gas boiler in a particular apartment or house. To do this, an application is submitted to the gas service with a request to carry out such a procedure. It must indicate the estimated annual volume of gas consumption.

The document will be reviewed and as a result the applicant will receive permission to install along with the Technical Specifications or a justified refusal.

Step #2: Creating a project for the future installation.

To begin with, it is advisable to decide on the brand of meter and boiler, but you should not purchase them yet. After which an installation project is ordered. It is carried out on the basis of a previously obtained permit for specific equipment.

READ How to install the spider game on your computer for free

The document must indicate equipment connection diagrams and the laying of the main line inside the building from the gas communications connection point. Only a licensed company has the right to engage in the project.

Step No. 3: Obtaining approval from the gas service.

The new project must be agreed upon with the gas service that services the area on which the house is located. The procedure usually takes a maximum of three months and a minimum of a week.

At this stage, you can already purchase gas equipment, because in addition to the project, you must provide the following documents for approval:

It is very easy to obtain these documents. The manufacturer must include them with its products. At the end of the verification procedure, the applicant receives an approved project, which in this case will be stamped with a special stamp.

If the document is not agreed upon, a list of activities must be drawn up to adjust the project. After they are completed, re-approval is carried out.

Rules for arranging a combustion room

According to current SNiPs, a gas boiler is installed only in a specially equipped room called a furnace room.

This rule cannot be neglected, since a gas boiler belongs to the category of potentially dangerous equipment and should be handled with extreme care. Otherwise, penalties will inevitably follow and emergency situations may arise.

First you need to calculate the power of the gas boiler, then determine the location for installing the boiler. The instructions allow the placement of single-circuit heating devices with a power of no more than 60 kW in any room of the building. Most floor-standing gas units are single-circuit, because... Designed for servicing heating systems only.

Dual-circuit models of any power cannot be installed in the kitchen. These are miniature boiler rooms with a built-in safety group and their own expansion tank. A furnace room is set up for them. If the total power of the equipment does not exceed 150 kW, it can be installed on any floor.

More powerful installations or groups of devices can only be installed on the ground floor or in the basement. In any case, gas heating boilers are prohibited from being installed in living rooms, bathrooms and toilets.

The room intended for the furnace must have certain dimensions. Its minimum volume can be calculated by the formula: 0.2 m³ multiplied by 1 kW of device power, but not less than 15 m³.

In addition, there are a number of requirements for the premises:

These requirements are strictly required to be met in the case of arranging a combustion room for a boiler with an open combustion chamber. For units with a closed chamber, the area of the room is not important and the ventilation requirements are less stringent, since for their operation they do not use air from the room, but take it from the street.

A gas duct is installed in the combustion chamber. Its horizontal section within the premises should not exceed 3 m.

In this case, the number of turns cannot be more than three. The vertical outlet of the chimney is raised above the level of a flat roof or a pitched ridge by at least a meter. The materials from which the structure is made must be resistant to aggressive thermal and chemical influences.

Multilayer materials, for example, asbestos-cement pipes, can only be used in areas more than 5 m from the exhaust pipe.

There should be no cavities or niches formed by horizontal surfaces in the combustion room. Combustion products can accumulate here, which is very dangerous for humans.

The space in front of the heating device must be free. The floor in front of it is covered with a metal sheet, the minimum size of which is 1x1 m. It is prohibited to use asbestos cement for these purposes, since it wears out quickly and is harmful to human health.

Preparing the premises for installation

Before starting the installation of the heating device, you need to complete all work related to the arrangement of the heating system, installation of radiators, distribution of water supply and warm water floors, if present. In addition, electrical and plumbing must be fully installed.

READ How to install diesel fuel heating

The boiler room should also be ready. A strong floor based on cement screed is laid under the gas boiler or a separate foundation is prepared.

The last option is considered not the best. Ceilings, floors and walls, if they are decorated with flammable coatings, must be additionally protected from possible fire.

For this purpose, non-combustible linings are used, made of roofing sheet steel laid on a fire-resistant layer, for example, asbestos. The thickness of the latter sheet cannot be less than 3 mm.

In this case, the insulation must protrude beyond the dimensions of the device body along the entire perimeter by at least 100 mm. The minimum distance from the heating device to a wall made of non-combustible materials must be 100 mm.

The distance from protruding pieces of fittings, burners and automatic control devices to the opposite wall is also regulated. It must be at least 1 m.

If the floor is made of flammable material, it should be protected from possible fire. For this purpose, a platform made of concrete blocks is used. Its height must be at least 100 mm.

The top of the elevation is covered with a steel sheet, the thickness of which is at least 0.8 mm. It is possible to arrange a site for installation of the device from special fire-resistant slabs.

In addition, it is advisable to install auxiliary equipment, otherwise the boiler will interfere with this. It is optimal to complete the layout of its placement in advance in order to think through all the nuances of the arrangement.

According to this diagram, mounting holes are marked on the walls and floor, after which the necessary devices are installed. The heating device is installed and connected last.

Basic faults

The main malfunctions of gas boilers Hearth are problems with the burner - weak flame, extinction after a few seconds of burning, frequent flame failures for unknown reasons.

There can be many reasons for the malfunction of gas equipment; to eliminate possible problems, you need knowledge of the design and operating features of the equipment.

All work must be carried out by service technicians who are certified to work with gas equipment.

The only possible independent procedure may be to clean the burner nozzles from soot.

Installing a floor-standing gas boiler with your own hands: technical standards and work algorithm

An autonomous heating system is the dream of many homeowners. Most of them choose gas heating, a significant disadvantage of which is the mandatory installation of equipment by certified specialists. However, control over the actions of invited workers is still necessary, don’t you agree?

Here you will learn how, according to building regulations, a floor-standing gas boiler should be installed. We will tell you how to prepare a room for installing a heat generator, and how to properly organize the removal of combustion products. Our advice will help you build a safe and effective system.

The information presented for review is based on regulatory documents. To optimize the perception of a difficult topic, the text is supplemented with useful illustrations and video instructions.

How to light it?

The ignition sequence is carried out by turning the control knob clockwise. Further procedure:

- You need to turn the knob until the mark is pointing towards the pointer.

- Next, press and hold the “Start” button.

- The piezo ignition button must be pressed until it clicks. The igniter lights.

- Keep “Start” pressed - waiting for the thermocouple to warm up. On the igniter, the gas block operates in auto mode.

- Turn the knob counterclockwise to the required temperature.