Features of Siberia gas boilers: review of floor-standing units

Siberia floor-standing appeared on the market not so long ago, but have already earned good reviews from customers and specialists.

The Siberia boiler is a product of the famous Russian enterprise “Rostovgazoapparat” (Rostov-on-Don), whose history dates back to the end of the 19th Century. This Rostov company became known thanks to the legendary AOGV gas boilers, which heated the private homes of millions of residents of the former USSR. But time does not stand still; all competitors on the market are constantly improving their products. Rostovgazoapparat also did not stand aside, presenting to the consumer a modern gas heating unit - the Siberia gas boiler.

We will talk about this device today, having examined in detail the double-circuit and single-circuit models with an atmospheric burner presented in stores, their technical characteristics, features and internal structure according to its operating instructions (passport).

Having analyzed all the parameters of the Siberia gas boiler 11, 17, 23, 29 and 35, we will leave our review based on the advantages and disadvantages of this device for heating a private home, and also watch a video about possible malfunctions: why it does not light up and does not heat the water.

Model range of Siberia boilers

On the domestic market, the Rostov enterprise is represented by two types of floor-standing gas boilers of the Siberia series:

— with a steel heat exchanger; — with a cast iron heat exchanger.

Boiler Siberia 11 with SIT automation

All boilers have a modern appearance, in contrast to the models of the “Soviet” AOGV series, the necessary set of functions and a reliable security system. All devices are completely energy-independent and operate at low gas pressure, i.e. adapted for Russian operating conditions.

In addition, the Rostovgazoapparat enterprise offers customers different types of its devices:

— single-circuit gas boilers Siberia, intended only for heating; - double-circuit gas boilers that already perform two useful functions: heating and hot water supply.

The most popular, judging by consumer reviews, are single-circuit models of Siberia boilers. They are produced in different capacities: 11, 17, 23, 29 and 35 kW. Only boilers with a steel heat exchanger are produced as double-circuit ones, and with a cast iron one - only for heating.

Siberia gas boilers with a cast iron heat exchanger are characterized by high reliability and long service life of the device, thanks to the material of its manufacture. They are produced with a nominal power of 16 to 50 kW, are capable of heating a room up to 500 m2, and are marked as follows:

— Siberia Ch16 (KCHGO 16); — Siberia Ch25 (KCHGO 25); — Siberia Ch40 (KCHGO 40); — Siberia Ch50 (KCHGO 50).

“H” is a cast iron boiler, and the number indicates the power of this heating apparatus. “KCHGO” is a cast iron gas heating boiler.

Floor-standing gas boilers Siberia

— Siberia 16E; — Siberia 25E; — Siberia 40E; — Siberia 50E.

Gas boiler Siberia: design and automation

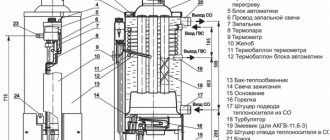

Like most floor-standing gas boilers, heating devices of the Siberia brand consist of a housing, a heat exchanger for heating the coolant (water jacket), a gas burner and automation.

The Siberia gas boiler is equipped with a steel or cast iron heat exchanger, Italian SIT automatic equipment (gas valve, thermostat, piezo ignition and boiler safety system), a Polidoro gas burner made of stainless steel, as well as a layer of foil thermal insulation with basalt fiber.

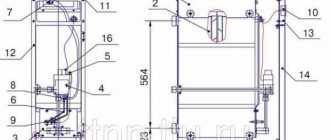

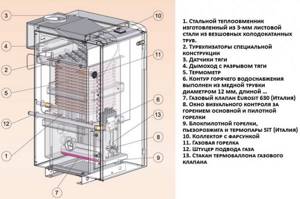

Let's take a closer look at the internal structure of the Siberia single-circuit gas boiler according to the instruction diagram.

Siberia boiler design

Gas boiler Siberia: technical characteristics, dimensions, connection

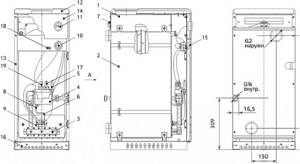

The Siberia boiler has compact dimensions, and depending on the model, its dimensions are only 850/280/560 or 850/380/560 mm. The fittings for connecting to the heating system have a diameter: for a device with a power of 11 kW - 1 1/2′, for others - 2′.

The gas connection to the boiler is made using a bellows hose with a diameter of 3/4′, for a device with a power of 11 kW - 1/2′. And for domestic water - also 1/2′ for all dual-circuit models. Boiler chimney diameter: on Siberia 11 and 17 units - 125 mm, on more powerful models - 140 mm. Other technical characteristics, gas consumption and productivity are described in the table.

Siberia boiler: technical characteristics

— time-tested manufacturer; — compact dimensions; — modern Italian automatic equipment is installed on all models; — quiet operation; — efficiency of at least 90%; — wide model range; — reasonable price for the boiler and spare parts.

Disadvantages of Siberia boilers:

- low hot water productivity for dual-circuit models; — Russian assembly; — the network of service centers throughout the country is poorly developed.

So, we have examined Siberia floor-standing gas boilers , customer reviews of which are increasingly found on the Internet: on forums and stores. We reviewed the technical characteristics according to the instructions, features and internal structure of heating devices produced by the Rostovgazoapparat enterprise. We identified the main advantages and pointed out some disadvantages of Siberia boilers. Let's watch a video review from the buyer about the experience of using the device.

Despite the enormous popularity of foreign household appliances, the domestic industry also produces high-quality equipment. For example, Siberia gas boilers have many advantages and high quality. This equipment can be used to heat not only residential but also industrial premises.

Heater parameters

The high efficiency of the AOGV - up to 92% - means that the installation of this equipment will bring maximum heating efficiency, and this is due to the original design of the jacket. Boilers can operate in heating systems with forced or natural circulation of coolant, provided that the pressure in the system is at least 1.4 Atm. Such conditions can ensure a liquid temperature of +40/+90C.

The disadvantage of this equipment can be considered to be too much power - even the lowest-power boiler produced by the Zhukovsky plant is designed to heat an area of at least 200 m2, which means that in small houses its installation will be impractical and costly.

The burner in any modification and brand of boiler is made of stainless steel, so its durability is guaranteed. The jacket for hot water supply is made of copper, the body of the unit is coated with polymer or powder paint. Standard automation has temperature sensors and regulators to control the temperature of the coolant and prevent overheating of the boiler. The package also includes a thermocouple that controls gas flow and an air flow stabilizer, which serves to compensate for differences in air pressure during gusts of wind, and shuts off the gas in calm weather. Certificate of conformity for gas boiler AOGB

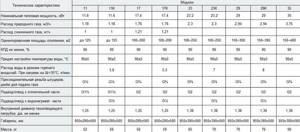

| Names | AOGB-11.6 | AOGBK-11.6 | AOGB-17.4 | AOGBK-17.4 | AOGB-23.2 | AOGBK-23.2 | AOGB-29 | AOGB-35 | AOGBK-35 |

| Indicators | |||||||||

| Rated power, kW | 11,6 | 11,6 | 17,4 | 17,4 | 23,2 | 23,2 | 29,0 | 29,0 | 35,0 |

| Consumption of main or bottled gas | |||||||||

| Main, m3/h | 1,19 | 1,19 | 1,75 | 1,75 | 2,32 | 2,32 | 2,95 | 3,56 | 3,56 |

| Balloon, kg/h | 0,865 | 0,865 | 1,215 | 1,215 | – | – | – | – | – |

| Heated area, square meters | 120 | 120 | 100-200 | 100-200 | 100-250 | 100-250 | 150-300 | 150-400 | 150-400 |

| Efficiency ≥ 90% | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 |

| DHW consumption when heating water at 35°C, liters per minute | – | 3,5 | – | 3,5 | – | 7,0 | – | – | 10,0 |

| Thread on fitting, inches | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| Inlet/outlet | |||||||||

| To the heating system | 1/2 | 1/2 | 1/2 | 1/2 | 2 | 2 | 2 | 2 | 2 |

| To the DHW system | – | 1/2 | – | 1/2 | – | 1/2 | – | 1/2 | – |

| Diameter of gas outlet pipe, ≥ decimeters | 1,15 | 1,15 | 1,25 | 1,25 | 1,38 | 1,38 | 1,38 | 1,38 | 1,38 |

| Dimensions, cm | |||||||||

| Height | 86,5 | 86,5 | 86,5 | 86,5 | 85,0 | 85,0 | 85,0 | 85,0 | 85,0 |

| Width | 41,0 | 41,0 | 41,0 | 41,0 | 33,0 | 33,0 | 38,0 | 38,0 | 38,0 |

| Depth | 41,0 | 41,0 | 41,0 | 41,0 | 55,0 | 55,0 | 55,0 | 55,0 | 55,0 |

| Weight, kg | 43,0 | 47,0 | 49,0 | 52,0 | 56,0 | 72,0 | 65,0 | 80,0 | 82,0 |

| In models with a power of 23.2 29 and 35 kW - rectangular housing |

Single-circuit unit AOGV - design and dimensions

Product advantages

Gas boilers "Siberia" have the following advantages:

- Almost complete independence of ignition from the electrical network, since it is carried out using piezoelectric elements.

- High quality equipment.

- Ease of use.

- Long service life.

- Great looks.

- Variety of models.

- The different power of boilers makes it possible to choose the appropriate option.

- Automatic control. Thanks to this, the operation of the product is completely safe.

- Low fuel consumption.

- It is possible to purchase models with which you can additionally heat water.

- Burner resistance to high temperatures. Thanks to the stainless material that has undergone special treatment, you don’t have to worry about premature burnout of the element.

- High structural strength.

- Some models provide hot water to several points of intake at once.

- Acceptable cost: from 15,600 to 24,000 rubles.

As you can see, Siberia gas boilers are practically in no way inferior to foreign competitors.

Device Features

So, Siberia gas boilers have the following operational features:

- The size of the flame is adjusted automatically, and this is done very smoothly.

- The device has a very high level of efficiency - up to 90%.

- The device is capable of heating rooms whose area ranges from 100 to 500 square meters. m.

- The heat exchanger can be open or closed, it all depends on the model of the device.

- The temperature of water and heating is regulated separately, which allows you to use the Siberia gas heating boiler as a boiler in the summer. The heating system remains switched off.

- Availability of additional functions: anti-blocking of the circulation pump, resistance to contamination and freezing.

User manual

Operating Siberia boilers is not difficult at all . The owner’s only task is to maintain the cleanliness of the unit and the absence of soot, soot or ash inside the unit. Changing the mode is done by turning the knob to the desired position.

In order to light the boiler, you need to press the handle, pushing it all the way, while simultaneously pressing the piezo ignition button.

Hold in this position for some time (up to 1 minute) until a flame appears on the pilot burner.

Then the control knob is switched to the desired operating mode, which will cause the flame on the main burner to light up and heating of the coolant will begin.

The system is filled with water with the make-up tap open. The process lasts until water flows from the signal pipe, after which the tap is closed.

Specifications

The Siberia gas boiler (reviews about it are mostly positive) has the following technical parameters:

- Warranty duration: 25 years.

- Power: 11-35 kW, although devices rated at 50 kW are used to heat industrial premises.

- The total weight of the product is 52-90 kg.

- Efficiency - no less than 90%.

- Possibility of converting the device for liquefied gas.

If you want to buy a Siberia gas boiler, reviews will help you find out more about it than the manufacturer says. For example, buyers note the high efficiency of the equipment. The unit is able to quickly heat water, even if there are several points of intake in the house. The device copes well with the task, even if it is installed in a house with several floors. An undoubted advantage is piezo ignition, so you can start the boiler even in the absence of light.

Types of devices

The Siberia gas boiler, the characteristics of which we have already reviewed, is manufactured in different modifications. For example, all manufacturer’s products can be divided into 3 types:

- Floor-standing single-circuit. Their feature is a cast iron heat exchanger, which is characterized by increased power. This device is most often used for large houses or buildings consisting of several floors.

- Floor-standing dual-circuit devices. They are equipped with a heat exchanger made of high-quality and durable steel. Such devices are intended not only for heating the room, but also for producing hot water.

- Wall-mounted. These devices are lightweight, compact in size and have high performance.

Choosing the right boiler

The most important characteristic that influences the choice of a floor-standing boiler is the power, which must correspond to the area of the heated room. The calculation is done in specialized organizations that charge quite large sums for their services. In fact, you can estimate how much power of a heat generator is needed to heat a particular room on your own without complex calculations: to heat a 10 m2 room you need 1 kW of boiler plant power. The formula is correct for rooms with ceiling heights of up to 3 m. As practice has shown, for normal operation of the boiler unit, you need to add 30% to the resulting value.

Note! For poorly insulated rooms, the power of the boiler installation should be calculated: 2 kW per 10 m2 of area. For warm buildings located in the southern regions of our vastness, this figure is 0.5 (0.7) kW/10 m2

The second characteristic that you should pay attention to when choosing a floor-standing boiler is the number of circuits. If you want to use the installation not only for heating the room, but also to obtain hot water for household needs, then pay attention to dual-circuit models

They are designated by the letter “K”. Depending on the performance, each such boiler can produce a certain amount of hot water per unit of time.

At a water temperature of 35°C, the nominal flow rate is:

- 11 K – 3.8 l/min;

- 17K – 5.5 l/min;

- 23K – 7 l/min;

- 29K – 8 l/min.

The third selection criterion is the heat exchanger material. Above we indicated all the advantages and disadvantages of devices with steel and cast iron heat exchangers.

Line of models

The Siberia floor-standing gas boiler is most often used for heating large buildings. However, you should consider all product lines of the presented manufacturer:

- AKGV and AOGV. These devices are installed on the floor. Their power ranges from 11 to 35 kW. The heat exchangers in them are often made of carbon steel. AKGV models are double-circuit, and AOGV are single-circuit. The presented equipment is capable of heating rooms with an area of 125-400 square meters. m. At a heating temperature of 35 degrees, you can consume 3.8-8 liters of hot water per minute.

- KCHGO. The line of these devices is distinguished by high power: 16, 25, 40 and 50 kW. Such boilers are intended for heating very large houses, industrial or warehouse premises. The heat exchanger in this equipment is made of cast iron.

- Top Line. These are wall-mounted devices with a power of 24 kW. They are equipped with biometric copper heat exchangers. They are capable of serving several water intake points. Most often they are used in those houses whose area does not exceed 200 square meters. m.

- Aqua. These devices are intended, rather, for heating water. Their power ranges from 18-23 kW. The speakers have piezoelectric or electronic ignition.

Advantages and disadvantages of the model

The advantages of Zhukovsky AOGV 23 boilers are:

- Reliability, simplicity of design.

- Independence from the power supply system.

- Simple and intuitive controls.

- Designed for use in Russian conditions.

- Designed to work in harsh climatic conditions.

- The service life is 14 years (or more).

- The cost of boilers is much lower than that of European analogues.

The disadvantages of the units should be considered:

- The heat exchanger of the units is made of steel, which is inferior in thermal conductivity to cast iron.

- The appearance of the boilers is inferior to European models.

- The mechanical automation of the boiler is quite weak.

- The dimensions and weight of the unit require installation in a separate room.

NOTE!

Most of the shortcomings are, to one degree or another, common to all atmospheric models, so they can be attributed to a specific design feature.

How to choose the right equipment?

The Siberia floor-standing gas boiler (you have already read the reviews) is very efficient and economical. However, you need to choose exactly the option that is suitable for your structure. The following parameters should be taken into account:

- Device power. The higher it is, the larger the area it can heat. Naturally, the more power, the more fuel you will need. This parameter is always specified in the model name. For example, Siberia-11 has a power of 11.6 kW.

- The size of the heated room. It can be found in the technical plan of the house. Calculating the power of the device is not difficult. For every 10 sq. m of area requires 1 kW of energy. However, the equipment should not be used to its limits to reduce the likelihood of wear on its parts. Therefore, it is better to increase the resulting power result by a third.

- Climatic conditions.

- Decorating the house. This parameter is also of great importance. For example, you can use facing material with additional insulation.

- Availability or need for hot water supply.

- Device type. If you want to install equipment in an apartment, it is better to give preference to wall-mounted models. For the home, the floor option will be the best.

- Heat exchanger type. Experts advise giving preference to a cast iron product, as it is stronger and more durable.

Equipment installation rules

Siberia floor-standing gas heating boilers must be installed by a specialist licensed to carry out such work. It is better not to do this on your own. Moreover, you will still have to obtain permission to install.

So, equipment installation has the following features:

- First you need to obtain a permit from the gas service.

- The installation must be carried out by specialists who have a special license to work with heating equipment.

- Since the expansion tank and circulation pump are not included with the equipment, these parts will have to be purchased separately.

- Since you will have to install the boiler against a wall, it is necessary to provide a gap between the device and the base. This distance is at least 3 cm.

- To install the floor unit you will have to make a foundation. Most often it is made of brick. The wall-mounted version must be fixed very firmly.

- The equipment should be connected very carefully so that no gas leaks are detected. That is, all connections must be carefully insulated.

- Please note that when you first start up the equipment, condensation may occur on the heat exchanger. However, this phenomenon is temporary, since after the unit warms up it disappears.

If you want to install a Siberia gas boiler, the installation and operating instructions must be followed strictly.

Reviews about Siberia 11

Thank you, your review will appear on the site soon.

Autonomous heating systems demonstrate the greatest efficiency if they are based on gas boilers.

It is customary to classify the products of European companies as the highest quality and most reliable units, although there are serious complaints about them regarding the excessive sensitivity and fragility of some important components.

Recently, significant competition for these models has come from gas boilers from domestic manufacturers who have managed to find their own approach to creating heating equipment.

The driving idea was the exclusion of unreliable elements from the design, the rejection of all components without which the unit is capable of operating.

Let's look at floor-standing gas boilers from the Russian company Siberia, which have managed to provide a serious alternative to imported models.

Rules for using the equipment

So, heating equipment will last longer if you follow the operating rules:

- You cannot turn on the unit if its burner is faulty or the chimney has not been cleaned.

- The boiler body must be grounded.

- If you want to use antifreeze instead of water as a coolant, then it must be certified. The liquid must not contain ethylene glycol.

- Do not bring the water in the system to a boil (heat more than 95 degrees).

- If the boiler is installed near a wall lined with flammable materials, it should be protected with a gasket made of steel or asbestos sheet.

- You can turn on the equipment only after the system is filled with coolant.

- It is imperative to clean the chimney, filters, check the tightness of connections, and flush the burner once a year.

Siberia floor-standing gas heating boilers are a domestic competitor to foreign devices, which can be bought cheaper and will last longer.

Currently, there are a large number of heat generators from different manufacturers on the heating equipment market, among which the leading positions are occupied by German and Italian boilers. However, domestic producers are not giving up their positions. In the article we will look at what the Siberia gas boiler is and note its main characteristics.

The most common problems and breakdowns

It is clear that there is no perfect equipment and it breaks down or does not work as it should. In most cases there are specific reasons for this. Based on the operating experience of Siberia boilers, we can identify several characteristic problems that owners often encounter:

- Low heating of water for domestic hot water supply by Siberia double-circuit floor-standing boilers. There's nothing you can do about it - it's not their strong point. If you look at the technical specifications, the maximum hot water flow is very small. And this is at normal gas pressure. If the pressure is low (which usually happens in cold weather), then the water will be slightly warm.

- The water at the boiler outlet does not heat up to the stated 90°C (if you turn the regulator even to the very last, 7th position). There are several possible reasons. The first is low gas pressure. When the pressure drops below 130 mm. water the column's power decreases proportionally. When you call the gas service (they are responsible for the nominal pressure), ask them to clean the inlet filter. If it is clogged, the pressure will be low. The second possible reason is a burner clogged with soot and dust. It needs to be cleaned once a year. If this is not done, the efficiency decreases and the Siberia boiler heats worse.

- The pilot burner does not ignite the working burner. Again, there may be several reasons. And the first is low gas pressure in the pipe. But this time it is below 50mm. water pillar At this pressure the boiler does not start. The second reason is a clogged gas valve. The third is a smoked burner. In all cases, we clean the valve and/or burner. Fourth, the thermocouple sensor is located too far away (you can see it visually, if it doesn’t reach the flame, that’s the reason). In this case, you need to loosen the thermocouple mounting nut and move the contacts a little closer. Fifth - weak traction.

- After a summer of inactivity, it is difficult to start the boiler. During downtime, air collects in the gas supply pipe. Until it is “corroded”, it will not be possible to light the boiler. When igniting for the first time, open the window/vent and monitor your health. Take a break between launch trials. During this time, the burner will be ventilated and the Siberia floor-standing gas boiler will start up faster.

As you can see, there are a lot of problems, but most of them are related to the peculiarities of the work of public utilities in our country. Of course, there are reasons in the equipment. But this is a small part of the total number of cases of non-working equipment. In order for the Siberia floor-standing gas boiler to work without problems, it is worth fulfilling all installation requirements and carrying out regular maintenance.

About the manufacturer

The owner of the Siberia brand is Rostovgazapparat CJSC. This is a large company that produces gas equipment. The company began its activities in 1988 in Rostov-on-Don.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery throughout the Russian Federation and CIS countries.

It was the first in the USSR - in 1959 - to begin producing gas boilers AOGV-80. Currently, the plant is a model of automation and robotization of production processes. Products manufactured by Siberia have a service life of 20 years.

Design and principle of operation of the Siberia gas boiler

The design of the Siberia gas boiler includes:

- the heat exchanger is made of carbon structural steel;

- automatic Sit unit is constructed of a magnetic valve, a modulating thermostat for on/off, a thermoelectric device that is responsible for controlling the flame;

- there is a re-ignition and fuel pressure stabilizer, piezo ignition and a gas filter;

- atmospheric burner, which is made of heat-resistant steel. Can function in low pressure conditions;

- body with powder protective coating;

- foil heat insulator designed to reduce heat transfer and increase productivity;

- capillary thermometer.

The unit is activated using piezo ignition. The spark ignites the burner while it is still functioning. The main burner, the atmospheric burner, is ignited by the igniter. The radiator begins to heat up, and with it the coolant heats up.

The thermostat determines the temperature, and when the water temperature reaches the set value, the automation will automatically turn off the flame. When, in the process of lowering the temperature, it reaches a critical point, the temperature sensor sends a signal to the valve - the fuel supply begins again and the fire is ignited. And the procedure is repeated.

Design and principle of operation

The main idea used by the creators of Siberia is to develop a completely energy-independent floor-standing gas boiler Siberia. It can work in difficult situations without requiring electricity. This approach became correct, and the low cost of the units created great consumer demand.

The Siberia gas boiler is made with an open-type atmospheric burner, which places increased demands on air exchange in the room where it is located.

Smoke removal is carried out in a natural way; for this reason, drafts or a sudden change in air movement are dangerous, since they contribute to an emergency situation due to the separation of the gas flame from the burner or smoke in the room.

An internal highly efficient heat exchanger, made of steel or cast iron, makes it possible to heat water with an efficiency of 90%, which corresponds to the performance of many popular Western analogues.

Design of floor-standing gas boilers Siberia:

- Internal heat exchanger of the heating circuit, for single-circuit devices.

- Secondary heat exchanger for heating DHW, for dual-circuit devices.

- Multifunctional three-way valve for adjusting coolant flows.

- Set of gas elements: shut-off valve, torch combustion stabilizer, fine filter.

- Automatic piezo ignition.

- Gas burner device in the form of two burners - main and ignition.

- Automatic regulation and protection system.

The basic functions of the Siberia gas boiler are performed by the burner device and heat exchangers, where the water coolant is heated. The heated water directly enters the three-way valve for single-circuit modifications or flows through the secondary boiler, heating the water for domestic hot water.

In the mixing unit, the coolant acquires the specified temperature and enters the heating circuit. The movement of streams occurs by gravity, under the influence of natural circulation of layers of water.

Similarly, using the natural circulation of air layers, smoke combustion products are discharged into the atmosphere.

Advantages

Siberia boiler logo

According to the manufacturer, the Siberia gas floor-standing boiler is a new generation heating device that is used not only to heat a house, but also to supply it with hot water. If we compare these devices with foreign-made analogues, we can note the following advantages:

- a wide range of models, each user will be able to choose the best option based on the required functionality and funds;

- fully automated control system that ensures simple and safe operation;

- the units are highly economical;

- ensures uninterrupted operation of the device even in harsh operating conditions;

- availability of service support;

- acceptable price.

Models

Main modifications of gas boilers Siberia:

- AOGV. Floor-standing design for rooms up to 400 square meters.

- KCHGO. Powerful units with cast iron heat exchangers for heating large areas.

- Top Line. Wall-mounted modifications with copper heat exchangers to serve multiple points on site.

When choosing, it is important to consider the power and size characteristics. The larger the power parameters, the larger the area the boiler is designed to heat. Depending on the availability of free space in the room, the dimensions are selected. Wall-mounted models are more compact. Siberia floor-standing boilers are more powerful.

Gas boiler Siberia 11

Type of heating boiler: gas, convection Number of circuits: single-circuit Max. thermal power: 11.60 kW Burner: gas 1

RUR 20,860

Gas boiler Siberia 11K

Heating boiler type: gas, convection Number of circuits: double-circuit Max. thermal power: 11.60 kW Burner: gas 1

RUB 22,897

Gas boiler Siberia 17

Type of heating boiler: gas, convection Number of circuits: single-circuit Max. thermal power: 17.40 kW Burner: gas 1

RUR 22,199

Gas boiler Siberia 17K

Heating boiler type: gas, convection Number of circuits: double-circuit Max. thermal power: 17.40 kW Burner: gas 1

RUR 24,506

Gas boiler Siberia 23

Type of heating boiler: gas, convection Number of circuits: single-circuit Max. thermal power: 23.20 kW Burner: gas 1

RUB 26,040

Gas floor boiler 40 Siberia KCHGO

Price: RUB 63,176 Buy Quick view

Gas boiler Siberia 35

Type of heating boiler: gas, convection Number of circuits: single-circuit Max. thermal power: 35 kW Burner: gas 1

RUR 37,014

Series of gas boilers Siberia

The manufacturer of gas boilers for heating private houses, Siberia, offers three series of these devices:

- Premium Topline-24. These models are designed for heating small rooms. They have two circuits, so in addition to heating they perform the function of heating water for domestic needs. A distinctive feature of this series is electronic ignition. There is ionization control of fire and exhaust gases. There is also an anti-scale function. Boiler performance is high, efficiency reaches 90%.

- Comfort Siberia. Models - 23, 29 35, 40, 50 (these values indicate the power of the device). Boilers of this series are available with both one and two circuits. Designed for heating large areas.

- Economy Siberia. These units began to be produced in 2005. There are four main modifications, differentiated by the number of circuits and power - 11; 6 and 17.6 kW. “K” in the marking indicates that the boiler is double-circuit. If desired, the operation of the equipment can be switched to liquefied gas. The body of the device is covered with enamel, which protects it from mechanical damage.

Execution options

Siberia gas boilers are available in the following modifications:

- The Siberia gas floor-standing single-circuit boiler is equipped with a cast-iron heat exchanger, which provides high power to the unit. Based on the power of the heating device, it can be used to heat private houses and buildings with several floors;

- The Siberia double-circuit floor-standing gas boiler has a steel radiator. The device is used both for heating and for supplying the premises with hot water for domestic needs;

- The Siberia wall-mounted gas boiler is characterized by its light weight, compact size and high performance.

Let's look at the distinctive features of mounted units:

- First of all, it is worth noting that such devices are very popular among users, because they are practical, small in size and have wide functionality;

- bithermal radiator, made of copper;

- the burner is made of alloy steel;

- there is an anti-freeze function;

- There is a liquid crystal display that displays all the information and error codes that appear during failures.

If you connect a room thermostat, you will reduce fuel consumption. Features of floor-standing boilers:

Available with two types of radiators: cast iron and steel. Double-circuit ones have a steel radiator and are connected to the hot water supply circuit. The Sit autocontrol unit includes:

- modulation thermostat;

- magnetic valve;

- pressure stabilizing device;

- gas filter;

- thermoelectric device with a fire control sensor and piezo ignition.

- the use of such devices is highly economical;

- have a reasonable price;

- characterized by reliability and durability;

- have a compact size;

- non-volatile, that is, their operation does not require electrical energy;

- wide range of products.

The most reliable models

All Siberia gas boilers have a good trouble-free operation period of more than 10 years.

The most popular model lines:

- Single-circuit floor heating with power from 11 to 35 kW: Siberia 11, Siberia 17.

- Double-circuit gas boilers with simultaneous heat supply for heating and hot water supply: Siberia 17K, Siberia 23K.

- Models with increased power and cast iron heat exchanger: Siberia KCHGO-40, Siberia KCHGO-16.

Installation rules

In order to create an autonomous heating system and install equipment, you must have a project and permits that are prescribed by the gas company. According to the manufacturer's requirements, the installation of Siberia floor-standing boilers must be carried out in accordance with SNiP standards and the requirements of GOST and SanPin, only by certified specialists who have permission to conduct such activities.

After you buy the equipment and have the permit in hand, you need to take care of additional devices. You need to purchase an expansion tank, a circulation pump, which is responsible for the forced movement of the coolant along the heating circuit. This equipment must be purchased separately, because It is not included in the boiler package.

The next stage is preparing the boiler room. Floor-standing boilers can be installed in a kitchen or in a specially designated non-residential premises that has a supply and exhaust ventilation system and a waste gas removal system. Utilities must be installed in the firebox.

Next, we pay attention to the location of the boiler unit - you need to choose an area near fireproof walls. Be sure to place the floor heating device on the foundation.

You can connect the pipeline and heating circuit yourself, without the help of specialists. Gas industry employees must connect the installation to the gas main.

Popular models of Siberia boilers

Let's consider the main models of domestic gas heaters Siberia.

Gas boiler Siberia 17K

Gas boiler Siberia 17K

The unit is designed for floor installation. The design is very simple with minimal functionality. It is in wide demand among users due to its technical characteristics and low price. This boiler is a double-circuit boiler. Power is 17 kW. The device is capable of effectively heating a room up to 200 m². Productivity is high, efficiency reaches 90%.

The combustion chamber is open. Fuel consumption is 1.21 kg/hour and 1.76 m³/hour of liquefied and natural gas, respectively. Control is mechanical. Protection - gas control. Weight is 59 kg, width is 28 cm, height is 85 cm, depth is 56 cm.

These parameters are standards for Siberia brand boilers. Also a popular model is the Siberia 23K gas boiler. Its technical characteristics are similar to the described unit, only the power is higher - 23 kW.

Siberia KCHGO-25

This is a single-circuit floor-standing convection boiler that can heat an area of up to 270 m². The heat exchanger is made of cast iron, the power of the device is 25 kW. Natural gas consumption is 2.45 m³/hour. The control is mechanical, the weight of the device is 115 kg.

AOGV-17.4

Gas boiler AOGV 17.4-3 Universal

The unit is floor-standing. It does not respond to pressure changes in gas pipes and is dependent on electrical energy. There is a heat insulator with basalt fiber, the control is automatic, the radiator is made of steel.

The device can cope with heating a house with an area of 180 m². The equipment includes a magnetic valve that tolerates dirt well, as well as piezo ignition.

TopLine 24

Gas boiler Siberia TopLine 24 C

The unit is wall-mounted with a copper heat exchanger. Productivity 12 l/min at 25 °C - as the temperature increases, productivity decreases.

Based on the power of a particular device belonging to this model range, the device will be able to heat a room from 30 to 200 m².

Characteristics

BasicType BurnerNumber of circuitsMax. thermal power Non-volatile Combustion chamber Heated area KPD Control Installation Primary heat exchanger material Built-in circulation pump Built-in expansion tank Fuel Natural gas consumption Liquefied gas consumption Max. coolant temperatureComfortFunctionsSafetyProtectionConnectionGas connection pipeHeating circuit connection pipeChimney diameterDimensions (WxHxD)Weight

| gas, convection |

| gas |

| single-circuit |

| 17.40 kW |

| Yes |

| open |

| 200 sq.m |

| 90 % |

| mechanical |

| floor |

| steel |

| No |

| No |

| natural gas, liquefied gas |

| 1.76 cu. m/hour |

| 1.21 kg/hour |

| 90 °C |

| thermometer |

| gas control |

| 3/4″ |

| 2″ |

| 125 mm |

| 280x850x560 mm |

| 56 kg |

Siberia