Autonomous heating systems for a private home, created on the basis of gas boilers, are considered the most efficient and economical.

They allow you to solve heating problems in the absence of the ability to connect to centralized networks, and in some cases, users themselves prefer to create their own independent system.

The number of manufacturers producing heating gas boilers is large and constantly growing.

European companies are recognized leaders in this area, but the developments of companies from the countries of the former USSR are beginning to squeeze them out in the market.

The reason for increasing competitiveness is our own conceptual approach to the manufacture of gas boilers, which can be considered using the example of Danko floor-standing models.

Floor-standing single-circuit gas boilers Danko

Danko is a brand owned by PJSC Agroresurs, which is based in the Ukrainian city of Rivne.

The company creates heating boilers, guided by the principles of equipment availability, resistance to weather and climatic conditions, technological features of gas and water supply.

The main direction that allowed us to successfully promote our products on the market was the exclusion from the design of all minor and unused parts and assemblies, of which there are too many on European models.

This not only reduces the price, but also reduces the risk of boiler breakdowns or failures, which can become a very serious problem in winter. The company's products are aimed at the mass consumer; the boiler power level is optimal for use in small and medium-sized private homes.

There are non-volatile models that increase the reliability of the heating system, but require some changes in the configuration of the pipelines to ensure natural circulation of the coolant.

Solid fuel boilers for private homes

Of course, the most common fuel is gas, but there are a number of alternatives - for example, solid fuels such as wood, coal and coke.

There are two types of solid fuel devices:

- Universal. Quite popular and expensive designs that can operate on any type of solid fuel - and this greatly simplifies the process of preparing fuel for the boiler.

- Operating on a single type of fuel. Such equipment is not universal, but focusing on a specific type of fuel allows you to optimize the operation of the device and increase its efficiency.

The main disadvantage of solid fuel boilers is the inability to operate in autonomous mode. The problem is the need to constantly add fuel, which requires a considerable investment of time and effort. In addition, fuel must be stored somewhere - and this can cause additional complications if there is not much free space.

Types

Danko floor-standing boilers can be divided into two groups:

- Single-circuit. They are intended only for supplying coolant to the home heating system.

- Dual-circuit. Capable of preparing hot water for domestic needs simultaneously with the supply of coolant.

Most users believe that double-circuit boilers are much more convenient and efficient than single-circuit boilers. However, this statement is only true for families with a relatively small need for hot water.

The boiler's performance allows for limited hot water consumption; with large water consumption, the temperature will drop, which is inconvenient and uncomfortable for users. Therefore, many people prefer to install single-circuit models and connect an external indirect heating boiler to them.

This addition allows you to significantly increase DHW performance and stabilize the operating mode of the system as a whole.

Why are the reviews positive?

Positive reviews are associated with a wide range of models, which allows the buyer to choose the appropriate option specifically for his heating system. Quality and low cost also play an important role. Another advantage is the ease of connection.

Every user knows that to connect such equipment, you usually have to hire professionals who have the appropriate license. Therefore, the cost of such services varies from 250 to 600 dollars, which is not always acceptable given the average salary.

That is why Danko has done everything possible to simplify the task of connecting and installing equipment. Thus, each man will be able to independently fix the boiler on the wall and connect water and electricity. Of course, the help of an inspector is required to check and open the gas valve, but this is much cheaper than hiring specialists for installation.

Advantages and disadvantages

The advantages of Danko floor-standing boilers include:

- The design of the units is optimized for maximum efficient and economical operation in all conditions.

- Boiler components and parts are made of high-quality materials using modern equipment.

- Fuel consumption is reduced by one and a half times compared to products from other companies.

- The units are designed for a long service life.

- Attractive appearance, compact size.

- Relatively low price.

The disadvantages of Danko boilers can be considered:

- Demanding requirements for water quality, the need to use softening filters.

- Requires annual inspection and maintenance.

- There are often cases of random flame extinction due to the backdraft effect.

NOTE! The disadvantages of Danko boilers can partially be overcome through proper installation, and are partially a specific design feature.

Model overview

If communications are connected to your home, you can always provide it with heat and hot water. More than 50% of boilers installed by domestic consumers are gas. Among them, ServiceGaz products are not the least important.

KSG-7AT

If you are looking for the cheapest option, pay attention to the non-volatile single-circuit device KSG-7AT. Its estimated cost is 10,600 rubles

Material of manufacture – steel

Floor-standing option Simple and convenient operation. Saves fuel. Capable of heating 80 square meters. Specifications:

Manufacturing material – steel. Floor-standing option Simple and convenient operation. Saves fuel. Capable of heating 80 square meters. Specifications:

- Maximum power - 7 kW.

- High efficiency – 85%.

- Water pressure – 0.1 MPa.

Stable operation even at the lowest pressure in the gas pipeline. Equipped with a gas block. There is a built-in pressure and draft stabilizer. Compact heat exchanger made of steel. Burner material is heat-resistant stainless steel. Convenient to maintain - the lining can be easily removed. Gas connection - on either side. There is a device that collects condensate.

According to users, the model has excellent characteristics. If you replace the burner nozzles, you can use liquefied gas as fuel.

KNG 24

Approximate price 25,000 rubles. Dual-circuit. Wall. Compact device with stylish design. The latest technical advances have been implemented. Absolutely silent operation - can be installed directly in the room, it will not disturb the residents in any way. The front panel has an LCD screen to display current settings. The boiler can be used for heating rooms equipped with a water heating system and for heating water. Technical specifications:

- Efficiency – 90%

- Can heat rooms with a total area of 220 square meters.

- The maximum heating power is 4.6-24 kW.

- There is automatic ignition.

- Gas consumption - 2.6 m3/h.

You can connect a heated floor. Closed combustion chamber type. Capable of operating on natural or liquefied gas. There are several stages of automatic protection. Weighs 36 kg.

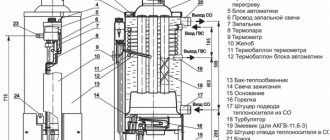

KSG-11

Purpose – heat supply of premises for various purposes. Design Features:

- Convenient installation - gas can be connected from any side.

- Floor.

- The door can be reinstalled on the user-friendly side.

- Condensate collection device.

- Steel heat exchanger.

- Thermal insulation – 30 mm.

- Combustion type: low flare.

- Quiet operation.

- It is possible to use the EUROSIT 630 or SABC-AT control unit.

Technical specifications:

- Heating capacity 11 kW.

- Heating area – 125 sq. m.

- Efficiency – 90%.

- Gas consumption – 1.34 m3/h.

- Weight 48 kg.

KSTG-16

Combined single-circuit boiler with a maximum heating power of 16 kW. Can run on coal or gas. Designed for heating 160 sq. m. Floor installation. Without auto-ignition and flame modulation. Efficiency – 74%.

KSG-10 AT

Floor installation. heating capacity 10 kW. Heats an area up to 100 square meters. m. Fuel consumption - 1.11 m3/h. Price – 11,000 rubles. It is possible, by replacing the burner jets, to burn with liquefied gas - 0.88 kg/h. Consumers note the compactness of the device, its dimensions are 25x47x75 cm. Weight is 48 kg. Tank capacity – 18 liters.

KSG-7 E

Floor. Single-circuit. It features stable operation at low pressure in gas supply pipes. Approximate price – 11,900 rubles. Efficiency 85%. Consumers are attracted by compactness, efficiency and stylish design. Heats up to 80 sq. m. Weighs 37 kg. Open combustion chamber. No auto-ignition. There is no flame modulation. Budget version with a limited set of functions.

Parapet modifications

Their distinctive feature is the absence of a chimney. Smoke removal is carried out through a pipe supplied in the kit. Installation – wall. A hole is made in the walls in advance - the chimney pipe is inserted into it. The heater can be mounted on a wall facing the street. Two modifications of the parapet type are available:

- KSGZ - with one circuit;

- KSGZV - with two circuits.

The body is thermally insulated with mineral wool and can be easily removed to access parts of the heater that need cleaning. 89% efficiency. The heat exchanger is protected from salts and scale.

Type

What series and models are floor-standing

The range of Danko floor-standing boilers is wide and includes several series.

Household models include the following lines:

- Danko SR or VSR . This is a series of single- and double-circuit domestic heating boilers with a 3 mm thick steel heat exchanger. Includes models with a power of 8, 10, 12, 15, 18, 20 and 24 kW. They are capable of heating houses with an area of 80 to 250 m2, which corresponds to the usual size of a private house.

- Danko SN and VSN . The units of this series have increased power, ranging from 30-48 kW. The main design features are the same - single- and double-circuit gas boilers with a steel heat exchanger.

There is also a series of Danko gas boilers with a cast iron heat exchanger. They are more massive and heavier due to the dimensions of the cast iron container, and have increased efficiency.

The ability of cast iron to transfer heat is higher than that of steel, which makes boilers more efficient and powerful.

There is a series of boilers for use in large industrial or public premises, the power of which reaches 96 kW. They are capable of heating up to 900 m2, and when connected in a cascade, the capabilities of the units increase accordingly.

Boiler fuel

Any solid fossil resources and waste can be used as fuel. A Danko wood-burning boiler is environmentally friendly and allows you to heat a room without harming the environment. The heat transfer of firewood is significantly less than that of thermal coal, so in the most severe cold it will be very difficult to heat with wood. For such situations, you will need more serious fuel.

Danko also work on briquettes, pellets, granules and other waste from the woodworking industry. Heating with recycled products is very profitable from an economic point of view. They have a minimum cost, so the purchase price will be low. Energy savings can bring up to several tens of thousands of rubles a year, which is not such a small amount. And waste-free production also has a positive effect on the environmental situation in the country.

Technical characteristics

Let's look at the parameters of Danko floor-standing gas boilers:

| Parameter | Meaning |

| Boiler type | Gas heating |

| Installation method | Floor |

| Fuel type | Natural gas, conversion to liquefied gas possible |

| Heat transfer type | Convection |

| Functionality | Heating, hot water preparation |

| Efficiency | 92 % |

| Unit power | 8-48 kW |

| Power supply | Absent, some models are connected to a single-phase network 220 V 50 Hz |

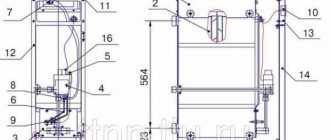

Device

The design and structure of Danko gas boilers are based on the latest developments, to which only minor amendments have been made to eliminate unused or minor functions and components. The main elements are the heat exchanger-gas burner connection .

They work in pairs and prepare coolant for the home heating system. Hot water is heated in a secondary heat exchanger due to partial extraction of coolant energy.

The final preparation of the liquid occurs in a three-way valve, which mixes the cooled return flow with the hot coolant in a given proportion, after which the heating agent enters the heating circuit.

Smoke removal occurs naturally using draft in the chimney, and circulation is provided either by an external pump or it occurs naturally.

What problems happen?

The simplicity of Danko's design allows its owners to carry out minor repair work on their own. One of the most common problems is the burner blowing out. This is especially common in strong winds. Usually no fault is found, the wind is the culprit of the problem, but it is better to check the following points:

- Is there a check valve installed in the chimney? If not, then there will be no reverse thrust, which is why attenuation occurs.

- If the chimney is installed incorrectly, it becomes clogged with soot and other combustion products - it needs to be cleaned.

It happens that before the attenuation, extraneous noise is heard or increased fuel consumption is observed - this may indicate a failure of the controller. The task is to repair or replace a spare part.

Another common problem is the pilot light going out. It goes out due to the activation of the thermostat, which shuts off the gas supply if the burner does not heat up to the desired temperature.

User manual

The boiler operates automatically. The user is only required to maintain the cleanliness of the body, fill and drain water from the system and start the boiler when necessary.

Temperature adjustment is carried out in operating mode, according to the user’s own feelings. The boiler is started either using a piezo ignition system or manually using the principle of a gas stove. To turn on the boiler using piezo ignition, you need to turn the knob to the ignition position.

The thermostat knob must be turned until it aligns with the “asterisk” icon and at the same time pressed in all the way.

Press the piezo ignition button several times to light the burner, but hold the thermostat knob for another 10-15 seconds . If the attempt is unsuccessful, repeat the procedure.

To service and repair the boiler, you should call a technician from the service center. Independent tampering with the structure will automatically void the warranty agreement.

Download instructions Download instructions

for Danko floor-standing gas boiler

.

Installation

The thermal power of the unit must be selected according to the design for heating the house in order to ensure a sanitary thermal regime in the premises.

The lowest ambient temperature during operation is not lower than 5 C. When installing the boiler, the circulation speed of the centrifugal pump and the total volume of coolant in the network must be taken into account.

Basic provisions when installing a Danko boiler:

- Before installing the unit, a heat-resistant horizontal foundation is made. The walls are shielded with heat-resistant materials, the gap between the wall and the boiler is left at least 250 mm. The insulating layer should extend beyond the dimensions of the housing by 150 mm.

- In front of the front working wall of the device, free passage is at least 100 cm.

- It is forbidden to wall up the base of the unit into the floor, since the process of air intake into the combustion chamber will be disrupted.

- The boiler unit is placed below the level of the batteries for efficient coolant circulation within the heating circuit.

- The expansion tank is installed at the highest point of the heating network, mainly in a heated place.

- The unit is installed with a chimney more than 5 m from the level of the chimney, which is located in the boiler.

- The height of the pipe above the roof is set above the level of wind pressure, and not less than 50 cm above the roof ridge.

- The main smoke exhaust duct must be located vertically, have smooth internal surfaces, without turns or kinks.

- The design of the chimney must ensure that the temperature of the flue gases at the outlet of the boiler unit is greater than the dew point temperature.

- The connection between the gas pipe of the unit and the chimney is made with a zinc or non-corrosive pipe.

- The unit must be installed and maintained exclusively in rooms with stable supply and exhaust ventilation

- The boiler is connected to the system using easily removable connections: couplings, union nuts or flanges and cannot be accompanied by high pipe tension.

- Sections of heating pipes operating with natural circulation are made with a slope of 10 mm per 1 m in the direction of the battery to collect air and remove it when the system is filled with water.

- The connection of gas appliances to the boiler is carried out by representatives of Gorgaz.

Basic malfunctions, why does the boiler go out?

The main malfunction of the Danko floor-standing gas boiler is spontaneous extinguishing of the burner.

It can be caused by various reasons:

- Stopping the gas supply (in the main line, or simply forgot to open the gas tap on the boiler itself).

- There were problems with gas equipment - breakdown of automation, failure of the gas valve, other problems.

- Reverse draft in the chimney, strong wind or drafts inside the room.

If the gas supply is interrupted, you should contact the gas service and obtain the necessary information. If problems arise with gas equipment, you must call a technician from a service center who is authorized to perform such work.

Dealing with drafts or backdrafts is more difficult, since they are often caused by external reasons that cannot be influenced. In any case, it is necessary to ensure high-quality and stable air exchange in the room, to eliminate drafts and sudden changes in the direction of air flows.

It is also necessary to monitor the condition of the chimney and promptly clean it from soot and soot.

Features of operation and setup

The requirements are set out in the user manual, which should be carefully studied before starting to work with the unit. During the operation of boilers, the following unforeseen situations are possible:

- The product does not turn on.

- The boiler starts to turn off randomly.

- In strong drafts, the burner may go out.

- The draft is noticeably reduced (for products with natural ventilation).

To eliminate the first two malfunctions, you should invite specialists. During operation, it is important to remember the need to periodically clean the chimney, which over time becomes clogged with combustion waste.

The need to adjust the boiler’s functionality may be required when it is necessary to increase the efficiency and stability of its operation. To do this, you will have to invite a service center specialist or representatives of the warranty workshop. Self-tuning can lead to complete failure of the equipment.

Price range

Danko floor-standing boilers represent a wide group of models, which expands the price range. If you do not take into account powerful samples intended for heating large areas, then the cost of floor-standing boilers is in the range of 20-67 thousand rubles.

The price of a particular model depends on the set of functions and design features.

Before purchasing, you need to decide on the type of chimney, since this is an important factor influencing the choice of a particular model.

NOTE! The chimney is not included in the basic package and must be purchased separately.

Reasons for stopping work

There may be several reasons, let’s consider each one separately:

1. Long boiler downtime.

As a result, the boiler may defrost and become unusable. As a result, there is a sharp attenuation, and the sounds of wind blowing out the flame are heard from the combustion chamber.

Due to these factors, an alarm appears on the dashboard, indicating the need for urgent diagnostics of the device. Modern boilers are a rather complex and fully automated system. Therefore, if one of the sensors signals a problem, the unit stops working.

There is no need to immediately change the boiler or install a new chimney; it is very important to understand the problem and find a way to solve it. 2

Chimney fault

2. Chimney fault.

If there are problems in the form of boiler attenuation, it is also important to check the serviceability and functioning of the chimney. The first reason may be the formation of ice on the walls of the chimney, which occurs through the settling of hot steam followed by the formation of condensation

After a certain period of time, the condensate freezes and becomes a thick layer of ice. After this, the draft decreases and the boiler goes out. The solution to this problem will be to insulate it in order to minimize the freezing of the condensate. 3. Reverse thrust.

Typically, this type of problem occurs during strong gusts of wind.

The wind enters the chimney and accordingly blows out the boiler flame. Backdraft is the most common reason for the boiler to blow out and turn off. Please note:. backdraft is quite dangerous, since some old-type boilers have outdated automation that does not turn off the boiler, and it continues to accumulate combustion products indoors

backdraft is quite dangerous, since some old-type boilers have outdated automation that does not turn off the boiler, and it continues to accumulate combustion products indoors.

4. Insufficient chimney rise.

If the height of the chimney is not enough to prevent air from entering the boiler with subsequent extinguishing, a good solution for quick ignition would be to increase its length, at which the top of the chimney should extend beyond the ridge of the roof by approximately 50-60 cm.

5. Pipe burnout.

Insufficient draft occurs as a result of the presence of a hole in the pipe into which the wind flows, and therefore the chimney begins to function poorly. In this case, a complete replacement of the chimney is required.

6. Voltage surges.

This reason does not depend in any way on external factors and occurs as a result of a drop in voltage level. When the proper voltage level is restored in many boilers, the flame lights up again, and therefore many owners do not even notice this problem.

7. Insufficient gas pressure.

Very often, the problem of a boiler dying out lies in the lack of sufficient gas pressure at the inlet to the boiler, at which point the unit plumps and dies out. The reason may be a malfunction of the network itself or internal reasons, namely:

7.1 Gas meter malfunction.

There are times when the boiler mechanism jams and it blocks the gas supply. To identify the source of the breakdown, it is necessary to check the operation of the counter mechanism, the readings of which must change.

7.2 The sealing of the fastenings is broken.

A gas leak provokes a drop in pressure, at which the system automatically operates and the gas apparatus goes out. This problem can be identified by the presence of a specific odor in the room.

Note:

You can carry out independent diagnostics and identify the problem using a regular sponge with soap suds - bubbles will appear at the leak sites.