Checking the operation of the chimney

The chimney works correctly if the gases are removed from the room to the street.

Backdraft, when smoke enters the room from the chimney and stove, is an extremely undesirable phenomenon. Signs of poor traction are easy to spot:

- when the stove operates, smoke enters the room;

- gusts of wind outside affect the movement of gases in the pipe, creating a reverse direction. Popping noises are heard in the stove and ash pan;

- fuel is difficult to ignite;

- even dry firewood burns slowly;

- opening the window or doors sharply reduces traction.

It is more difficult to find out about a bad hood of a water heater or gas boiler. Carbon monoxide can enter a room, but it is difficult to smell or see.

Breathing such gas is deadly.

To accurately determine the operating characteristics of the chimney, you can use an anemometer. It is used to measure the speed of movement of furnace gases

It is a common belief that the quality of a hood’s operation can be determined by the burning of a match or piece of paper. This method leads to an error and cannot be used. When burning, a match emits hundreds of times less smoke than wood in a fireplace, for example. The smoke from the match will go away, but this does not mean that the gases from the operating devices will be completely removed.

The exact parameters of the chimney are determined using special equipment. If you do not take into account the roughness and length of the walls, the speed of gas movement depends on the geometry of the channel and the pressure difference in the room and in the upper part of the pipe.

The gas flow must correspond to the power of the furnace equipment, gas water heater and other devices. Most often, the device readings range from 12 to 20 Pa.

Experts can determine smoke removal parameters using an anemometer. The device is compact and easy to use. They measure the speed of gas movement. But you need to know the geometry of the passages and the cross-sectional area of the pipe.

Before measurements, you need to warm up the chimney and stove. In winter, it is enough to heat a fireplace or use a gas water heater for an hour

The data obtained is checked against the requirements recorded in the passport of the gas or stove equipment. If the volume of gas removal in one hour is insufficient, operation of the equipment is prohibited.

Inlet valve for increased draft

Without air entering the room or directly into the stove, the chimney will not work. Vents or cracks in old windows are not the best method for air flow.

The disadvantages are obvious:

- Cold air enters the room through the cracks even when the stove or fireplace is not working.

- In winter, air from the street constantly changes the indoor environment. At the same time, the relative humidity of the air drops sharply, which has a harmful effect on health. A person's mucous membranes dry out, creating conditions for colds.

- The window must be opened and closed manually.

It is much more effective to provide air flow using a valve. It closes automatically when furnace equipment or gas heaters are not operating.

This is what a wall supply valve looks like, which is installed in rooms with stove heating or gas equipment to improve air flow

Heaters require a boiler room valve to operate. The device has different characteristics than similar operating principles for room ventilation.

The supply valve is placed diagonally or above the heated surface so that the cold air rises to the ceiling. But it is best if oxygen is supplied directly to the firebox. At the same time, the humidity and temperature conditions in the room are not disturbed.

Purpose of a boiler fan

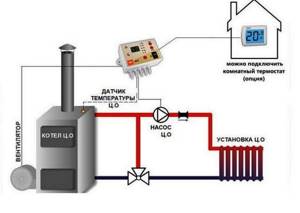

A modern heat supply system involves the installation of an automation unit to regulate the thermal processes of the boiler. It is based on changing the supply of air, which is supplied to the combustion zone by a blower fan and is considered more progressive compared to gravity systems.

The completeness of fuel combustion and the operational productivity of a solid fuel unit largely depend on the volume of supplied air and the size of the draft in the combustion chamber.

The automation unit is equipped with a controller that, according to an established algorithm, regulates the operation of the blower, supplying different volumes of air, thereby supporting the combustion process and, accordingly, the production of a certain amount of thermal energy.

The use of a fan in the boiler control system allows:

- maintain the required temperature of the heating fluid in the heating system;

- increases the time the unit reaches operating mode;

- optimizes solid fuel combustion processes;

- increases the efficiency of a solid fuel installation;

- facilitates the process of servicing the heat supply system;

- reduces specific fuel consumption for the production of 1 Gcal of thermal energy.

Fan for solid fuel boiler

According to parameters and functional characteristics, fans for solid fuel boilers are divided into the following types:

- devices with electrically commutated motors (EC);

- fans equipped with synchronous motors;

- blowers with asynchronous motor.

Each type has its own advantages and disadvantages:

- Electrically commutated motor. This device is capable of independently changing the speed, having previously received the corresponding signal from the control unit, and also has a wide range of adjustment of the fan operation. However, the device also has a number of disadvantages - it is not compatible with most temperature controllers produced by domestic manufacturers, and besides, this equipment has a high price.

- Fan with synchronous motor. The device is easy to manufacture and has a low price. But this type of fan also has a number of disadvantages. For example, a small adjustment range and minimal torque during start-up.

- An asynchronous electric motor has many advantages. First of all, it is simple and easy to use. Secondly, it has a reliable design. However, there is also a drawback - high inrush currents.

Device

Any blower fan, regardless of what country it is manufactured in, consists of a metal casing, and inside it there is an electric motor

Another important part of the blower fan are the blades, which are protected by a safety grille. The structure of the device is not complicated, but at the same time reliable

This is ensured by its robust housing, high operating temperature and reliable electric motor manufacturer. Vulnerable elements and parts are protected by a grille. The blower fan is lightweight, so installation problems do not arise.

Fan for solid fuel boiler

On the Russian market you can find fans for solid fuel boilers from the following manufacturers:

- Injection centrifugal fan (turbine) WPA of various modifications. Manufacturer: Polish company MplusM. This company specializes in the production of turbines for solid fuel boilers. The model is in stable demand on the Russian market, as it is characterized by high quality and good reliability.

- NWS fan of various modifications. Manufactured by Nowosolar (Poland). Its purpose is to pump air into the combustion chamber. This increases the efficiency of fuel combustion in the combustion chamber.

How to choose the right one

The performance of a solid fuel boiler is largely determined by a properly selected fan. What does this mean?

Let's consider several situations:

- If a fan is installed that supplies less of the required air, the fuel will not burn completely. As a result, the boiler power decreases and the rated temperature is not reached.

- If a fan is installed that supplies a larger volume of the required air, then the solid fuel boiler will quickly gain temperature, and the fan will constantly turn on and off. As a result, fan failure is inevitable, the chimney will be constantly hot, and heat will escape through it.

There is only one way out - choose the right blower fan.

The table shows options for installed fans on solid fuel boilers of various capacities.

| Fan model | Volume of supplied air, m³ | Dry wood boiler power, kW | Boiler power Anthracite coal, kW |

| WPA X2 | 285 | 62 | 32 |

| WPA 07 | 160 | 35 | 18 |

| WPA 06 | 255 | 55 | 28 |

| WPA 117 | 180 | 39 | 20 |

| WPA 120 | 285 | 62 | 32 |

| WPA 140 | 395 | 86 | 44 |

| WPA 145 | 505 | 110 | 56 |

| WPA 160 | 600 | 130 | 67 |

| NWS 75 | 205 | 45 | 23 |

| NWS 79 | 205 | 45 | 23 |

| NWS 100 | 240 | 52 | 27 |

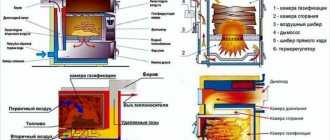

Design and principle of operation

Regardless of the manufacturer, the fan consists of an aluminum or galvanized housing, inside of which there is an electric motor, guide blades and protection in the form of a lattice fence.

This design, despite its simplicity and small dimensions, is reliable. A damper is installed on the supercharger, which is designed to limit the penetration of flue gases into the combustion room in the event of reverse draft.

Also, the damper reduces natural draft when there is no air supply.

The connecting pipes can be located in the upper part of the housing or on the front part of the blowing unit and have various forms of connectors for connection to the boiler. Algorithm for the functioning of the boiler control system using blown air:

- the heating device is filled with solid fuel and ignited;

- the blower is turned on and the air flow is regulated;

- when air is supplied to the combustion zone, intense combustion of the fuel begins, and therefore the temperature of the coolant begins to rise;

- when the temperature reaches the set value, the control unit controller gives a signal to turn off the supercharger;

- air deficiency will lead to a decrease in the intensity of fuel combustion and a decrease in coolant temperature.

Features of choice

The performance of a boiler unit operating on solid fuel is largely determined by a professionally selected supercharger.

In order to choose the right fan, you need to pay attention to the following parameters:

If the equipment is chosen incorrectly, when the fan for a solid fuel boiler is unable to supply the required volume of air to the furnace, the process of incomplete combustion of the fuel will begin, the efficiency of the boiler will drop, and the temperature regime will not be achieved.

If the blower is installed with high power, it will release a large amount of air into the firebox. The combustion process will be intense, the boiler will quickly reach the required temperature and the control unit controller will give a signal to turn off the fan, thus the blowing device will enter the clocking process, when it will often turn on and off, which will lead to premature wear of the equipment and its failure.

Recommended installation options for WPA fans for ZOT or Carbon boilers, for heating units operating on anthracite:

Types of traction fans

Several types of smoke exhausters are sold for solid fuel boilers and wood-burning fireplaces:

- boiler (the design is discussed above);

- centrifugal channel;

- overhead;

- fireplace/stove (aka roof).

Various attachments that improve natural draft, such as deflectors, round rotating elements and rotating weather vanes, should not be classified as smoke exhausters. The effectiveness of these hoods depends on the wind speed, which changes with the weather.

The duct fan is distinguished by its own housing with two connecting flanges or pipes. The unit is installed vertically or horizontally into the gap in the chimney duct. The device and principle of operation are similar to the operation of a boiler smoke exhauster.

The overhead smoke exhauster for a domestic boiler is equipped with a semicircular platform and clamps-ties. Installation is carried out on a vertical section of the chimney (uninsulated):

- An opening is cut out in the pipe using a paper template.

- The impeller of the traction machine is inserted into the hole, and the platform with the electric motor is pressed to the surface with clamps.

- The connection is sealed with an asbestos cord glued to the inside of the installation site of the smoke exhauster.

Note. The overhead element is selected according to the diameter of the flue pipe. The installation process is demonstrated in the video.

Electric fireplace hoods are mounted on the head of a brick chimney and secured with spacer bolts. The power cable is laid through a pipe and introduced into the room next to the home stove.

To choose a traction machine, you need to focus on 3 criteria:

- heat generator power, smoke exhauster models are designed for boiler performance up to 20, 30, 50 and 100 kW;

- installation point - on the boiler itself, pipe or head;

- for overhead models – the diameter of the uninsulated flue.

Overhead (left) and roof-mounted smoke exhauster (right)

Varieties

Today, in the retail chain, it is possible to purchase various models of blower fans for solid fuel heating units, both domestic and European assembled.

The most popular options for the location of blowing units are:

- The invoice is installed on a vertical section of an uninsulated smoke ventilation duct.

- Centrifugal duct, have two mounting pipes installed in the chimney gap.

- Boiler installed directly on the heating device.

The following classification of blowing units is made according to the type of electric motors: asynchronous, electrically commutated EC and synchronous.

Electrically commutated motor

The Electronically Commutated Motor (EC) allows very precise performance adjustments using a pulse width modulation signal.

Electrically commutated drive

In the case when they are installed on blowing devices, it becomes possible, by changing the speed of rotation of the impeller - impeller, to change the volume of air supplied to the furnace, thereby reducing energy consumption from 50 to 80%.

Despite the high cost of such blowing devices, they are preferable in the installations of modern boiler units, since they are energy-efficient devices, and their use reduces emissions into the environment by reducing thermal energy losses due to underburning of fuel.

EC motors operate in a quiet range and have an extended service life.

Synchronous motor

The blower fan for a boiler with a synchronous motor is characterized by a simple design and a low price. The disadvantages of this model include a limited adjustment range and low torque when starting the engine. As a rule, such blowing devices are installed to supply a constant volume of air into the combustion chamber.

Boilers with fairly large dimensions are equipped with such engines. Basically, such engines are mounted in a separate block.

When operating synchronous motors at low speeds, winding overheating often occurs. In an exhaust type boiler, fans are installed on the chimney; they are also called smoke exhausters.

Blowers with asynchronous motor

Such electric motors have many advantages. They are convenient and easy to maintain and are durable in design. A disadvantage of this type of electric drive is high starting currents.

Therefore, it will be necessary to properly arrange the power part in order to put into operation such a device that is sensitive to current parameters.

The asynchronous electric motor makes it possible to easily adjust the speed. Certain modifications also have a reverse mode. The main positive qualities of fans with an asynchronous electric motor:

- simple and easy to use;

- have a durable design;

- traditional control scheme;

- used by a variety of control systems paired with a thermostat, for example, like the budget fan DP-02 from a Polish manufacturer.

Reasons for installing a supercharger and cost

The use of a fan, which pumps oxygen into the firebox and removes heat from combustion products, can significantly increase the efficiency of the boiler installation. Top modifications of gas and solid fuel boilers are initially equipped with smoke exhausters, the operation of which is fully coordinated with the heating installation. But most factory models of heaters and home-made installations do not have fans, which somewhat reduces the efficiency of the equipment.

Don't miss: Chicken coop for the winter: how to insulate it yourself from the inside and outside, budget insulation materials

Installing a fan on a gas and solid fuel boiler will be necessary in the following cases:

- In case of problems with draft, including due to traffic jams in the flue and numerous turns of the chimney, wind aeration, narrowing of the pipe diameter.

- When there are cracks in a brick chimney, which leads to fumes leaking into the room.

- Due to an incorrectly calculated chimney height, draft problems arise when the pipe cut falls into the wind support zone.

- When, due to the design features of the heater, the boiler smokes into the room when the door is opened.

It is not recommended to install a fan on a boiler without coordinating the operation of the heater and blower. In the latter case, there may be a significant deterioration in the efficiency of the boiler, problems with kindling firewood may appear, and after complete combustion of the fuel, carbon monoxide may enter the room from the firebox.

You should not consider boiler fans as the only solution to draft problems. In case of such malfunctions, the chimney should be repaired, the boiler should be serviced and the height of the pipe above the roof should be adjusted. Only such an integrated approach will increase the efficiency of the boiler and make its operation completely safe.

The cost of boiler fans can vary significantly. Depending on the specific model and its type, the smoke exhauster will cost the buyer 3-6 thousand rubles. Automation, taking into account its capabilities and functionality, will cost 3-5 thousand rubles. It is not worth saving on a fan and control unit, since low-quality equipment will not be able to provide the necessary efficiency of the heater, and the blowers will not be the most reliable.

Why do you need a fan? Its main functions

A solid fuel boiler in the usual sense is a heating device, where the main work is carried out by burning fuel. In the presence of draft and natural air flow, the combustion intensity is weak, and heat transfer is correspondingly low. An example is a fireplace. The natural flow of air does not allow the flame to flare up strongly in the firebox, so this heating device has limited technological capabilities.

It's a completely different matter when the supercharger comes into play. An additional volume of air is pumped into the furnace of the heating device. The combustion becomes intense, the fuel burns out completely, releasing the maximum amount of kilocalories.

Therefore, for modern models of solid fuel boilers, of almost all types and types, the fan is one of the most important elements of the control system. Typically, the automation kit for heating devices today includes a blower, a smoke exhauster and a control unit. Competent and correct installation of such devices and devices on boiler equipment will ensure reliable and balanced operation of your unit.

Note: the combustion process is 90% dependent on the operation of the supercharger. Thanks to the action of this device, air is pumped into the combustion chamber, the combustion intensity increases, and the efficiency of the heating equipment increases accordingly.

Today, domestic and foreign industry produces a huge number of household fans (coolers), specially designed for installation on heating devices. When choosing a supercharger for your unit, you need to focus on the power of the boiler and your own household needs. A solid fuel unit with a fan is a high-tech and efficient heating machine. All processes, from flue gas extraction to better combustion chamber performance, depend on the operation of fans.

* In other words: there are exhaust fans installed in the chimney and blowing devices specifically designed to pump air into the firebox of the heating device. Typically, an air blower is used when working with fuel that is difficult to ignite. Coke, coal or wet wood do not burn well at first. Therefore, for better combustion in this situation, a pressurization device is used. Other types of fuel, such as pellets, briquettes and dry firewood, require constant air supply. By installing fans on the boiler, you will be able to achieve economical fuel consumption for a solid fuel boiler, and the safety of boiler equipment will significantly increase. There is no more reason to worry about the quality of combustion in the firebox or worry about the operation of the hood.

When do you need a smoke exhauster?

Manufacturers of heating equipment equip their products with traction fans due to the increased resistance of the heat exchanger, where gases change direction of movement several times through the flame tubes. The goal is to remove maximum heat from combustion products and increase the efficiency of the boiler installation.

A nuance: the operation of the smoke exhauster in a factory-installed boiler is coordinated with the combustion process and is controlled by an electronic unit. When installing a fan unit on a “brainless” heater, such consistency is excluded; you need to buy an automation unit or adjust the speed manually.

Organize fresh ventilation in the boiler room, and only then think about installing a smoke exhauster

We list the situations when a smoke exhauster will help improve the operation and maintenance of a solid fuel heat generator:

- problems with draft - blowing by the wind, air pockets in the gas duct, many turns, narrowing of the diameter;

- due to the design features, the boiler smokes into the room when the door is opened;

- the height of the chimney is insufficient or the cut of the pipe fell into the wind support zone behind the ridge of the roof or another building;

- Cracks have appeared in the brick pipe, from which smoke is leaking.

Important point. No fan will save the situation if there is no influx from the street in the boiler room. At first, the working impeller will create a slight vacuum, but then the blades will begin to mix the air in place. Supply ventilation is a prerequisite for the normal operation of any heater.

It is better to operate the V. G. Kholmov mine heat generator with a traction fan

Some wood boiler designs (for example, shaft type) tend to emit smoke through an open loading hatch. A similar picture is observed in heat generators with a three-pass fire-tube heat exchanger of high resistance. The solution to the problem is to install a traction or blowing machine controlled by a controller.

Strengthening natural draft with the help of a smoke exhauster also has a downside. If, after warming up the pipe, natural exhaust has not been restored, the unit cannot be turned off - you may get burned. Now imagine that in the middle of the night the power supply goes out and the fan stops. While the chain thermostat closes the damper, smoke will fill the boiler room.

Recommendation. The smoke exhauster should not become a panacea. Be sure to take measures to restore draft - repair or alter the flue in accordance with the requirements specified in the boiler instructions.

How to choose and install a smoke exhauster for a solid fuel boiler or fireplace

Previously, draft and blower fans were used only in industrial boiler installations. The first ones are placed inside the chimney channel and create a vacuum, the second ones pump air into the firebox. Gradually, the units migrated to the domestic sphere - manufacturers began to equip heaters with a closed combustion chamber with turbines. The idea was picked up by home craftsmen, because a smoke exhauster for a boiler helps solve the problem of poor draft in the chimney pipe. Let's figure out whether forced exhaust of combustion products is always necessary.

Why install a smoke exhauster

The correct and durable service of the heating device, its efficiency and the normal microclimate in the room depend on a high-quality chimney and good draft. Complete exhaust gas removal, that is, an effective smoke removal system, ensures complete combustion of fuel and maximum efficiency. All technical nuances of the design and construction of chimneys are aimed at obtaining excellent draft. It must be sustainable and sufficient.

And traction occurs when there is a temperature difference. According to the laws of physics, the hot air from the firebox rushes upward, taking with it the smoke and soot that are formed during combustion. In modern wood-burning boilers, the mode can vary from sub-zero temperatures to plus 350 degrees. And at the same time there should always be excellent air movement in them. Natural traction in such conditions may not be enough. This is how separate draft amplifiers, or smoke exhausters, were invented. They acquired particular importance with the advent of modern high-efficiency boilers, which are more capricious and demanding.

The main reason for installing a smoke exhauster is that the horizontal section of the transition from the boiler to the chimney is too long. Most often this happens due to thick walls. One and a half meters of horizontal section is bad for any boiler or stove. Smoke does not like to travel through horizontal channels, and in the case of high-efficiency boilers (such as pyrolysis boilers, for example), this situation can lead to an almost complete absence of draft.

Types of smoke exhausters

If a chimney shaft has been built in your house, the draft of which is not enough for the operation of a new heating unit, then a simple smoke exhauster for the boiler will help solve this problem. It is not at all necessary to immediately purchase electromechanical devices; sometimes it is enough to install a special deflector at the end of the pipe, which creates additional natural traction. But when all such options have been tried, you can purchase and install one of the proposed devices:

- fan – natural draft amplifier;

- flow exhauster;

- centrifugal traction machine.

A draft amplifier is a device equipped with an axial fan; it is placed at the end of an exhaust shaft or pipe. The performance of the device can be adjusted manually using a thyristor control unit.

Flow-through smoke exhausters for boilers are installed immediately at the outlet pipe of the unit and also serve to increase the draft force. The design of the apparatus is such that inside the smoke channel there is only an impeller that does not block its cross section. The electric motor and other elements are located outside, which allows the device to be turned on when necessary, and the rest of the time the shaft can successfully remove smoke using natural draft. You can control the switching on and performance of the device either manually or automatically by connecting it to the automation of the boiler installation.

In reality, this type of smoke exhauster cannot always serve as a full-fledged traction unit, but only as an exhaust amplifier. The reason is the insufficiently high pressure developed by the impeller of the device due to its design. To get a good result, it is better to install a centrifugal type smoke exhauster on a solid fuel boiler. In this case, the control of all functions of the device should be linked to the electronic unit of the heat generator, then the operation of all elements of the system will be consistent. In addition, centrifugal fans are capable of not only creating a vacuum in the combustion chamber, but also developing high pressure, which will force any chimney to operate.

High-power heating units use a forced draft circuit with two fans; this is an ideal option. But the implementation of such a scheme is associated with certain difficulties, since for balanced operation of the system it is necessary to calculate the smoke exhauster and blower, the amount of air for combustion and the resistance of the entire gas-air path, including the exhaust duct.

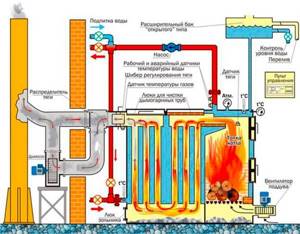

Fan for gas boiler

Gas boilers with a closed combustion chamber are equipped with a coaxial ventilation duct. Combustion products are removed through it and air is supplied from the street at the same time.

They use a forced draft fan. It is responsible for air intake and combustion products removal.

The power of the turbo boiler fan depends on the power of the gas boiler.

The fan is located above the combustion chamber: in the upper part of the boiler. It creates a vacuum, as a result of which air is sucked into the combustion chamber.

Two tubes are mounted to the fan body: a venturi tube and a pitot tube. Using these devices, you can measure dynamic and static pressure.

Hoses run from the venturi tube and are connected to the pressure switch.

Designed to regulate the smoke removal process and control the functionality of the fan. Pressostat (air pressure switch)

The functioning of turbocharged boilers is as follows:

- Boilers with a closed combustion chamber are connected to a double-walled chimney, which is designed according to the principle: a pipe in a pipe, or to a two-pipe system - where one channel exhausts smoke, the other takes air from the street.

- Combustion products are discharged through an internal pipe.

- The external cavity in the separate chimney of a turbocharged gas boiler is connected to an air duct, which supplies the combustion chamber with oxygen.

Thus, the boiler fan is designed to ensure uninterrupted operation of the heating system in the house.

It is difficult to imagine modern heating technology without various mechanisms and devices. Thanks to technological progress, it was possible to equip the solid fuel boilers familiar to us all with additional electromechanical devices. It has become possible to automatically regulate the intensity of combustion and improve the technological capabilities of ventilation. A special place in the automation of basic processes is occupied by the fan used to operate a solid fuel boiler. These devices are associated with perhaps the most important stages of the functioning of the entire heating system.

Principle of operation

Pellets can be supplied to the firebox using a bulk system, which is installed on non-volatile equipment. This design is typical for household boilers with minimal power that supply pellets automatically.

Don't miss: How to make a heated floor in a bathhouse: detailed instructions with installation diagrams

Regardless of the type of unit, it has two key subsystems:

- providing the burner with solid fuel,

- maintaining a given combustion mode.

A standard household boiler with automatic supply of pellets operates according to the scheme of double combustion of fuel and gas inside the firebox. Briefly, the operating principle is as follows:

- Pellets are fed into the primary heating chamber.

- The fuel ignites.

- The temperature of the heating element increases, as a result of which the granules emit flammable gas.

- The flue gas enters the afterburning chamber (secondary ignition), where a flare, fireplace or volumetric pellet burner is located.

- Pellets enter the same secondary combustion chamber.

Here, solid fuel is exposed to direct fire, resulting in complete combustion.

Construction of a solid fuel boiler

Firebox

This is the main element of any component equipment, performing a dual function: a heat exchanger and a combustion chamber.

Detailing its design, it should be noted that the product has:

- a smoke exhaust hole that provides air access to the combustion site;

- ash pan;

- grate;

- dome upper part of the smoke exhauster (for collecting and subsequent removal of gases and combustion products that are in the volatile stage);

- portal through which fuel is supplied.

Burning in the furnace, solid fuel heats the walls of the equipment with a fan and heats the water, which is located in the water jacket of the boiler with a buffer tank, to a high temperature. For better performance, it is often equipped with a smoke exhauster.

Water jacket

In almost all models of solid fuel equipment with a fan, the jacket is located between the double walls of the firebox. Acting as a coolant, water (in the vast majority of cases), passing through the jacket, takes heat from the firebox, thereby protecting it from overheating, and carries it into the heating system. Hot water leaves the jacket through the pipes in its upper part, and the cooled water in the system enters the jacket through the lower pipes.

Solid fuel equipment with a fan is capable of operating when the coolant moves through the heating system lines by gravity (so-called open systems). Although it is technically possible to equip boilers with circulation units and pumps of varying power and performance (in this case, you always need to have the necessary components for them). The presence of system blocks significantly increases the heat transfer of the unit.

Despite this, open systems with a fan are in high demand, as they are independent of external power sources, economical and very reliable. Equipment with a buffer tank equipped with a fan, used not only for heating the room, but also for providing consumers with hot water, have boilers connected to them and are necessarily equipped with a control unit.

Gas removal system

Inside a boiler with a fan, a lot of smoke is generated during the combustion process. Therefore, if you do not provide it with a properly working smoke exhauster, all this will end up inside the room. As a rule, the role of a chimney is performed by thermally insulated pipes that remove combustion products outside the building. Smoke exhausters and/or a fan for a solid fuel boiler are often installed here.

Temperature regulation and control unit system

A constant supply of fresh air to the combustion site by a smoke exhauster is a necessary condition for any combustion process. The greater the air flow, the more intense combustion can be achieved.

That is why the design of any solid fuel equipment must have mechanical dampers and dampers used to regulate the air supply (and components for their prompt repair and replacement). Smoke exhausters are often installed.

Rice. 6 UPS for solid fuel boiler

Control unit systems based on the use of such control methods are simple and very reliable. The smoke exhaust damper is specially fixed to the regulator. When the set temperature is significantly exceeded, the walls of the regulator expand, which leads to the lowering of the damper (the flow area of the supply air duct decreases), which helps cool the firebox and protects it from overheating.

Some tips

To make or buy a smoke exhauster correctly, you need to follow some recommendations. For example, if the house has a special technical room for a boiler room, then the hood is installed in it, since in this case it will be more convenient to service it.

If you need to install a powerful smoke exhauster for a large ventilation system, then it is better to install it outside. The fact is that such devices are very noisy, and this noise will not be heard from outside.

The electric motor is usually equipped with a separate circuit breaker. It will be convenient when the control of the smoke exhauster is transferred to the general control panel of the heating system.

If the smoke exhauster is mounted not near the boiler, but outside or in any other place, then it is necessary to provide free access for cleaning it.

Thus, protection from rain and snow must be installed at the end of the chimney pipe. The fan and all moving parts must be lubricated regularly, and the hopper must be cleared of accumulated particles.

Weather factors should also be taken into account. Excessive humidity and temperature changes lead to severe corrosion of some elements of the smoke exhauster.

Exhaust fans for the boiler: which ones can be purchased on the market

Today there is a wide selection of household exhaust systems. Smoke exhausters for gas boilers can be purchased for a small apartment or country house. They are distinguished by their simplest design and mediocre power, but they cope with the task quite well.

In the case of solid fuel boilers, everything is a little more complicated. To buy the most efficient and reliable exhaust equipment, you should make accurate calculations. Especially when a boost fan is installed in the system. The values are the diameter, the smoke exhaust engine, the design of the product and a number of other parameters. In particularly difficult cases, installing such a device can be expensive.

Features of using smoke exhausters

Smoke exhausters, unlike air blowers, have higher performance. They allow you to add firewood during work without negative consequences in the form of smoke in the room, since they manage to draw out all the smoke. When installing them, it is necessary to correctly match the power and cross-section of the ventilation pipe so that the structure works efficiently.

A high draft hood will protect residents from carbon monoxide poisoning. This is only possible when installing smoke exhausters. With natural cravings, such indicators cannot be achieved.

Pellet burners or boilers running on sawdust or peat do not burn well without well-organized draft. Only with the additional installation of a smoke exhauster can truly effective operation of such units be achieved.

production of a smoke exhauster

The use of smoke exhausters in solid fuel boilers has a number of significant advantages :

- there are no unpleasant odors in the room, since smoke does not enter it and does not accumulate;

- deposits on the walls of the chimney are reduced to a minimum, since there is a filtration system;

- even if the firebox door is open, gases will not enter the room;

- the efficiency of the heating device increases, since the wood burns almost to the ground.

There are practically no downsides to such devices. Unless it needs regular maintenance. At the same time, the service life of the smoke exhaust unit is comparable to the operation of the boiler itself.

Device structure and types of fans

According to their functional characteristics and parameters, fans are divided into three types, each of which is determined by the design of the engine. The electric motors used for these purposes can operate on both alternating and direct current. The advent of electronic equipment created the prerequisites for the active use of AC motors. Unlike DC motors, AC electric motors have virtually no disadvantages. The simple and unpretentious design of electric motors has made it possible to establish mass production of a wide variety of electromechanical devices. Most fans are equipped with just such electric motors.

Today on the market you can find the following types of fans:

- devices in electrically commutated motors (EC);

- products equipped with synchronous motors;

- blowers with asynchronous motor.

All products have their obvious advantages and disadvantages. In the case of an electrically commutated motor, we can talk about one quality. The device itself is capable of changing the speed, receiving the corresponding signal from the control unit. Here we can talk about a wide range of fan operation adjustments. However, the device has a significant drawback - the device is not compatible with most domestic temperature controllers. In addition, this equipment is expensive.

Speaking about fans with synchronous electric motors, we can focus on the following: the devices are quite cheap and easy to manufacture. However, this type of equipment has certain disadvantages. Such devices have minimal torque during start-up and a small range of speed adjustment.

For reference: usually fans with synchronous motors are installed to constantly pump air mass into the combustion chamber. The synchronous motors with which the devices are equipped have fairly large dimensions. Typically the supercharger motor is located in a separate unit. When operating at low speeds for synchronous motors, winding overheating is common.

* As for the rotation speed range, the values here are not large. On some models the range is adjustable from 30-70%, and from 90 to 100%. This feature is characteristic of a synchronous motor. According to experts, it is not recommended to equip household solid fuel boilers with fans with synchronous electric motors. Microprocessor temperature controllers are poorly compatible with a device in which the number of revolutions is limited and the power is within strict limits.

The last, third type of fans used in modern heating systems has a number of advantages. The asynchronous electric motor allows you to easily regulate the number of revolutions. On some models there is even a reverse. The main advantages of such a device are as follows:

- Such fans are simple and easy to use;

- They have a reliable design;

- Conventional control scheme;

- Supported by all currently available MRI scanners.

The only drawback that is typical of asynchronous motors is high starting currents.

Making a smoke exhauster with your own hands

If you wish, you can assemble such a device yourself from scrap materials. We only need an electric motor. Everything else can be made independently, although it is better to purchase a factory-made impeller, even if it is used.

Tool you may need:

- Bulgarian;

- Welding machine or inverter;

- Drill, plumbing tool, hammer;

- Ruler, caliper.

The easiest way to manufacture is an exhaust fan, which will be installed inside the pipe. To do this, you will need a small electric motor with a power of up to 1 kW and a suitable impeller with blades. It is mounted on the motor shaft, and its housing is equipped with fasteners for placement in the pipe. When connecting the wiring and starting up for the first time, pay attention to where the air flow will go.

A self-made smoke exhauster for a solid fuel boiler can be seen in the following video.

A design with a volute and a centrifugal fan will be more complicated. The procedure for its manufacture is as follows:

- For a ready-made turbine, we select a piece of pipe with a diameter 2-3 centimeters larger. Cut it to the size of the fan plus 3-5 mm;

- We cut a hole on the side for the outlet pipe, and weld a lid to one of the ends with a hole in the center for the chimney from the boiler. The incoming flow will be perpendicular to the outgoing one; with this scheme, the electric motor is located horizontally;

- The most critical stage is installing the shaft and fan . For accuracy, you can use bushings for centering and pressing the bearing. When the engine is turned on, beating and vibration are unacceptable.

- We weld or screw the back cover and install the engine on the stand. We connect air ducts and electrical wiring.

How to make a long-burning solid fuel boiler with your own hands: instructions, drawing, diagram.

We install a sandwich chimney with our own hands: assembly rules, installation and operation.

How to properly install a smoke exhauster on a fuel boiler

Here are some tips:

- If there is a separate room for the boiler, then the hood is mounted in it for ease of maintenance;

- It is advisable to place powerful chimneys outside the house due to the loud noise during operation;

- The electric motor is protected by a separate circuit breaker, and its control is conveniently transferred to the general heating system control panel;

- There must be free access to the smoke exhauster for cleaning.

Cost of installation of a smoke exhauster

For homemade products, the price is determined by the cost of the electric motor and impeller. The cost of a three-phase electric motor with a power of 0.18 kW starts from 1950 rubles , the simplest blade impellers - from 350 rubles. Add to this the purchase of wires and small accessories. There will be benefits if you can get a used engine.

A ready-made smoke exhauster costs a little more. So, for a device with a capacity of 2000 m3 per hour you will have to pay from 14,000 rubles for an unknown manufacturer to 23,500 for a smoke exhauster from the company Wirbel . Simple blade units cost inexpensively 6-8 thousand rubles. If the installation of a smoke exhauster on a solid fuel boiler is carried out by a specialist, then for the work and turnkey connection you will have to pay up to the cost of the pump itself, depending on the complexity.

How to make an exhaust unit

The main difficulty in assembling a smoke exhauster with your own hands is making a balanced impeller; the remaining parts are not difficult for a home craftsman who knows how to weld. If the impeller blades vary in weight, normal fan noise will turn into rumble due to vibration.

In addition to the blades, you will need the following elements:

- electric motor with a power of up to 150 W, maximum shaft speed – 1400 rpm;

- snail or homemade box shown in the drawing;

- a shaft with ventilation holes or an additional cooling impeller;

- studs with M8 nuts and other fasteners;

- power cable.

Sources

- https://ProUteplenie.com/otoplenie/dymosos-dlya-kotla-bytovoy-ustanovka-ventilyatora-svoimi-rukami

- https://kotle.ru/tverdotoplivnye/ventilyator-dlya-kotla

- https://otivent.com/dymosos-dlja-tverdotoplivnogo-kotla

- https://oventilyacii.ru/otoplenie/kak-vybrat-ventilyator-dlya-kotla-na-tverdom-toplive.html

- https://www.tproekt.com/kak-soorudit-samodelnyj-dymosos-dla-kotla/

- https://www.teplodar.ru/help/articles/detail/konstruktsiya-i-osobennosti-pelletnogo-kotla-s-avtomaticheskoy-podachey-topliva/

- https://ZnatokTepla.ru/kotly/tverdotoplivnie/vidy-i-funktsii-ventilyatorov-dlya-tverdotoplivnyh-kotlov.html

[collapse]