In the overwhelming majority of individual houses, owners have to independently solve the problems of choosing the type and installation of an autonomous heating system. Most owners prefer the option with forced circulation of coolant, which uses special expansion tanks for a closed-type heating system.

Before choosing an expansion (storage, membrane) hydraulic tank, it is useful to study its operating principle, rules for selecting volume and settings. It is also important to follow the recommendations of specialists in installing the expansion tank, install it correctly and in the right place in the heating circuit.

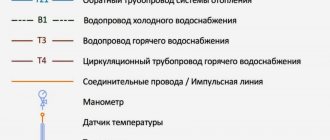

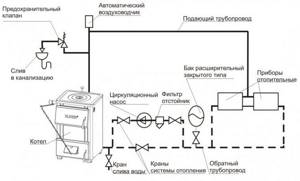

Rice. 1 Examples of the use of expansion tanks

Types of household heating systems with liquid coolant

There are many different heating options for individual homes. The premises can be heated with electric convectors, heat pumps, electric heating cables, stoves, films, and receive thermal energy using solar panels.

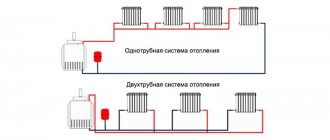

However, in everyday reality, for a number of reasons, most consumers use water heating boilers, the coolant from which is directed to underfloor heating circuits or to radiator heat exchangers. In this case, the following two main types of hydraulic heating systems are distinguished.

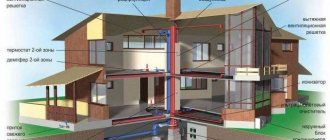

Rice. 2 Scheme of the gravitational system

Gravity

In gravity (gravity) systems, as the name suggests, the circulation of heating fluid along the circuit occurs naturally.

This is due to a simple physical law, according to which heated water has a lower density than cold water. As a result, after heating in the boiler, it is pushed out by cold water masses and rises upward.

The heated coolant fills the expansion tank and spreads down the circuit with the heat exchange radiators. The gravity system has the following features:

- The storage tank to support pressure is made with an open lid. As a result, there is constant evaporation of the liquid and it has to be regularly replenished, which creates significant operational inconveniences.

- In an open heating system, you cannot use the inexpensive toxic antifreeze liquid ethylene glycol. As an anti-freeze agent, you will have to use propylene glycol, which costs twice as much, or make do with ordinary distilled water.

- The working pressure in gravity systems rarely exceeds 1 bar and requires a hydraulic tank raised to a height of 10 m from the boiler to obtain it. This is clearly not enough for long heating circuits with radiator heat exchangers, and especially for underfloor heating. As a result, an additional circulation electric pump is often installed in a gravity heating system.

- The speed of movement of the coolant in gravity circuits is low, therefore, to ensure good heat transfer, the use of large diameter pipelines of 32 or 40 mm is required.

Rice. 3 Gravity tanks

Article on the topic:

Heating in a private house from polypropylene pipes - nuances, calculations. It may be interesting to read in more detail about organizing a heating system made of polypropylene pipes in a private house.

- The pipeline in gravity systems goes to the heat exchange devices from above along the walls, which does not contribute to improving the aesthetic appearance of the premises.

- If the expansion tank in an open-type heating system is located in the attic and it is not heated, it will have to be well insulated to reduce heat losses.

- Also, the process of heating water is accompanied by some noise, which worsens the comfort of living in living rooms.

- Since the coolant comes into contact with air, it is saturated with oxygen. This leads to accelerated corrosion of the metal elements of the boiler and triggers the processes of decomposition of non-freezing liquids.

- A significant advantage of the gravity system can be considered the ability to operate in the absence of electricity, however, this statement is not entirely correct, since most heating boilers cannot function normally in the absence of electricity.

- A more important advantage is the upper location of the expansion tank in an open system. Thanks to this, the problem of air exhaust is effectively solved and you can do without a number of air vents. This allows you to save some money.

Rice. 4 Closed circuit

Closed type

When considering an open heating system, quite a few disadvantages were cited that such a connection scheme has. This led to the widespread use of another scheme with a closed hydraulic tank and forced supply of the working fluid.

Installation of membrane device

A hydraulic accumulator of this type is installed where there is a minimum probability of coolant turbulence, since a pump is used for normal circulation of water flow along the circuit.

Correct container position

When connecting the expansion tank to a closed heating system, be sure to take into account the location of the air chamber of the device.

The rubber membrane periodically stretches and then contracts. Due to this impact, microcracks appear on it over time, which gradually increase. After this, the membrane has to be replaced with a new one.

It is better to install an expansion tank with a membrane so that the air-filled compartment is on top, this will extend the life of the device

If the air chamber of such a tank remains at the bottom during installation, the pressure on the membrane will increase due to gravitational influence. Cracks will appear faster and repairs will be needed sooner.

It makes more sense to install the expansion tank in such a way that the compartment filled with air remains on top. This will extend the life of the device.

Features of choosing an installation location

There are a number of requirements that must be taken into account when installing a membrane expansion tank:

- It cannot be placed close to the wall.

- The device should be freely accessible for regular maintenance and necessary repairs.

- The wall-hung tank should not be positioned too high.

- A shut-off valve should be placed between the tank and the heating pipes, which will allow you to remove the device without completely draining the coolant from the system.

- When installing on a wall, the pipes connected to the expansion tank must also be attached to the wall in order to remove possible additional load from the tank pipe.

For a membrane device, the most suitable connection point is the return section of the line between the circulation pump and the boiler. Theoretically, it is possible to install an expansion tank on the supply pipe, but high water temperatures will negatively affect the integrity of the membrane and its service life.

When installing an expansion tank, it is necessary to provide shut-off valves that will allow you to disconnect the device from the system and drain the water from it

When using solid fuel equipment, such placement is also dangerous because steam can enter the container due to overheating. This will seriously disrupt the operation of the membrane and may even damage it.

In addition to the shut-off valve and the “American” connection, it is recommended to install an additional tee and tap when connecting, which will allow you to empty the expansion tank before disconnecting.

Setting up the device before use

Before installation or immediately after it, it is necessary to correctly configure the expansion tank, otherwise called an expansion tank. This is not difficult to do, but first you need to find out what pressure should be in the heating system. Let's say an acceptable value is 1.5 bar.

Now you need to measure the pressure inside the air part of the membrane tank. It should be less by about 0.2-0.3 bar. Measurements are carried out with a pressure gauge with a suitable gradation through the nipple connection, which is located on the tank body. If necessary, air is pumped into the compartment or excess air is vented.

Before installing the membrane tank in the heating system, check the air pressure in the air compartment and adjust it according to the requirements

The technical documentation usually indicates the operating pressure, which is set by the manufacturer at the factory. But practice shows that this is not always true. During storage and transportation, some air may escape from the compartment. You must take your own measurements.

If the pressure in the tank is not set correctly, this can lead to air leakage through the air removal device. This phenomenon causes a gradual cooling of the coolant in the tank. There is no need to pre-fill the membrane tank with coolant; simply fill the system.

Tank as additional capacity

Modern models of heating boilers are often already equipped with a built-in expansion tank. However, its characteristics do not always correspond to the requirements of a specific heating system. If the built-in tank is too small, you need to install an additional tank.

It will ensure normal coolant pressure in the system. This addition will also be relevant if the heating circuit configuration changes. For example, when a gravity system is converted into a circulation pump and the old pipes are left behind.

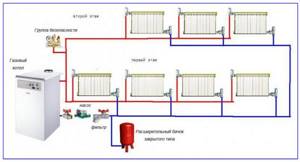

This is true for any systems with a significant volume of coolant, for example, in a two- or three-story cottage or where, in addition to radiators, there is a heated floor. If a boiler with a small built-in membrane tank is used, installing another tank is almost inevitable.

An expansion tank will also be appropriate when using an indirect heating boiler. A relief valve, similar to that installed on electric boilers, will not be effective here; an expansomat is an adequate way out of the situation.

Why do you need an expansion tank?

The tank for the heating system should not be confused with a hydraulic accumulator, which has found application in individual water supply systems, despite the fact that they perform approximately the same functions. The difference between these devices lies in their name: the first type collects the working medium that has expanded in volume, and the second accumulates it (accumulates) in its tank.

The expansion tank for heating systems plays the following role:

- It is well known that when water is heated, it becomes less dense, which, while maintaining the same mass, leads to its increase in volume. If you heat 100 liters of water at a temperature of 20 °C to 90 °C, its volume will increase by 3.5 liters. It is the collection of increased liquid volume that is the main purpose of the expansion tank.

- Like a hydraulic accumulator in a water main, an expansion tank prevents damage to equipment, pipelines, and fittings from water hammer.

- A closed expansion hydraulic tank stabilizes the pressure throughout the entire circuit at different temperature parameters of the working fluid and prevents sudden changes.

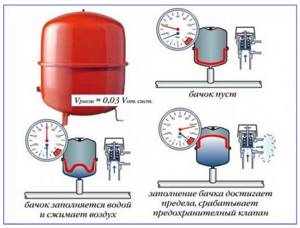

Rice. 6 Design and operation of the membrane tank

Calculation of tank volume

First of all, let’s determine the relationship between the required volume and the parameters that influence it. When making calculations, it must be taken into account that the larger the capacity of the heating system and the higher the maximum temperature of the coolant in it, the larger the tank should be. The higher the permissible pressure in the heating expansion tank, the lower it can be. Of course, the calculation method is quite complex, so it is better to consult a specialist. After all, a mistake in choosing an expansion tank can cause frequent operation of the safety valve or other troubles.

The volume is calculated using a special formula. Here the main quantity is the total volume of coolant that is present in the heating system. This value is calculated taking into account the power of the boiler, the number and types of heating devices. Approximate values: radiator – 10.5 l/kW, floor heating system – 17 l/kW, convector – 7 l/kW.

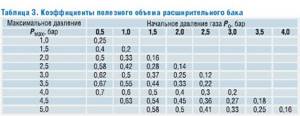

To make a more accurate calculation of a device such as a vacuum expander for heating, the formula is used: Tank volume = (Volume of water in the heating system * Expansion coefficient of the coolant) / Efficiency of the expansion tank. The expansion coefficient for water is 4% when it is heated to 95 degrees. To determine the efficiency of the tank, another formula is used: Tank efficiency = (Highest pressure in the system - Initial pressure in the air chamber) / (Highest pressure in the system + 1).

Expansion tank useful volume coefficients

Thus, the vacuum expansion heating tank is selected taking into account the strength and temperature characteristics, which should not exceed the permissible values at the connection point. The volume of the tank can either be equal to or greater than the result obtained as a result of the calculations.

The structure of the expansion tank and the principle of its operation

In order not to mislead the buyer, expansion tanks are produced in red. Devices from some manufacturers and foreign suppliers sometimes have other colors - white, gray, black.

A typical expansion tank is structurally made in the form of two halves pressed together, the main material of which is carbon steel coated with epoxy polyester or other paints and varnishes.

Between them there is an elastic fabric (membrane) that can withstand temperature loads up to 100 °C. The material used to manufacture most membranes is EPDM (ethylene-propylene-diene thermopolymer rubber).

The design of the tank can be collapsible or not, depending on the manufacturer. Therefore, in non-separable models, if the membrane is damaged, the tank will have to be replaced.

Depending on the capacity, hydraulic tanks are designed for hanging on a wall or installing in a floor position on legs. Their volume can vary quite widely from several units to many hundreds of liters.

In front of a typical tank there is a threaded fitting (usually 3/4 inch in size), through which the expansion tank is connected to the heating system. At the back of the tank there is a nipple from which air is pumped in or released.

Also on the market you can find designs in the form of two flattened halves, their connecting fitting and nipple are placed on the side on one side.

The principle of operation of the expansion tank is quite simple. The liquid, which has increased in volume as a result of heating, flows into the tank and presses on the membrane. It bends inward and thus ensures constant pressure in the system. As it cools, the coolant decreases in volume and is squeezed back into the circuit by the membrane.

Purpose of the equipment

The main purpose of the expansion tank is to level out the expansion of the coolant (water) when the temperature changes, thereby avoiding the occurrence of water hammer, extrusion of gaskets and destruction of pipelines and fittings. The volume of the tank is calculated individually based on the system parameters. The operating principle and design of the models differ for different types of systems.

Expansion tanks for a closed heating system - selection rules

When purchasing a membrane expansion tank, be guided by the following considerations.

The main criterion for its selection is the volume of the tank. Since heated water expands by approximately 3.5%, when filling, the amount of liquid poured into the circuit is measured and from this data the required capacity of the hydraulic tank is found.

It should also be taken into account that the expansion tank should not be filled completely to increase the service life of the membrane. Also, when using anti-freeze, their thermal expansion is slightly higher than that of ordinary distilled water.

Therefore, it is generally accepted to select the volume of the hydraulic tank to be 10% of the amount of coolant.

Do not forget that some boilers are equipped with an internal small expansion tank. In this case, the external membrane tank is chosen with a slightly smaller capacity, taking into account the internal boiler tank.

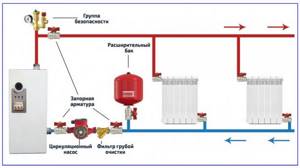

Rice. 8 Diagram of correct installation of a membrane hydraulic tank

Installing the tank yourself

To prevent water hammer inside the heating system, you must adhere to the following rules when installing the expansion tank:

- It is impossible to make a tie-in after installing a circulation pump.

- To be able to regulate pressure, it is necessary to provide access to the shut-off valves.

- There must be no static pressure in the circuit piping.

Expansion tanks on the return line in front of the boiler are considered a profitable option. For floor-mounted installations, special stands are sold, and for wall-mounted installations, brackets should be used. There are brackets that are pre-welded to the body, and there are also separate ones that are included in the kit and need to be assembled yourself.

If you need to replace the membranes, you will need to completely disassemble the entire system. To avoid this, you can screw a ball valve onto the expansion tank pipe. This way you can remove the tank without disassembling it.

The general diagram of the device looks like this:

For a more precise position of the expansion tank, brackets with a safety group are made, which facilitate installation.

For high-quality sealing of threaded connections, it is not recommended to use FUM tape. A better option would be Unipack winding.

The expansion tank is an indispensable part of closed-type heating.