Smoked products are distinguished by a bright and rich aroma, pronounced taste and a fairly long shelf life, especially when it comes to cold smoky processing.

For lovers of smoked delicacies, it is expensive to regularly buy them in stores. Plus, the quality does not always meet expectations and cost. Therefore, in many respects the most correct decision is made. You are building your own smokehouse, and it is not necessary to build huge brick structures. If somewhere in the country or in a country house there is an old gas stove, it can be turned into a full-fledged smokehouse.

Features and specifics

The attractiveness of such a device is that you can make a smokehouse from an ordinary gas stove with or without a water seal. Another feature is that the slab needs to be redone at minimal cost.

A homemade smokehouse works on the principle of other similar devices. A grille is installed inside the device. Products are laid out on it. You can place hooks and hang workpieces on them. In this form, smoke will emit from the smoldering wood chips, with which the raw material is impregnated.

On such a smokehouse it is proposed to use cold and hot methods. This will allow you to smoke fish, poultry, pork ham, bacon, and different types of meat.

What is special about a home smokehouse on a stove? One of the advantages is the absence of a negative impact on the atmosphere, for which you need to install a water seal or smoke exhaust on a homemade device, which will prevent smoke from spreading over the entire area. Therefore, such a smokehouse can be located in an apartment or at home.

Firewood and wood chips: how to choose the right one

The key to the taste of smoked meats is properly selected firewood . It is known that smoke from different types of wood has completely different flavors. The easiest way is to use purchased wood chips in this case, choosing the one suitable for each type of product:

- alder - universal, suitable for meat, lard, fish and vegetables;

- oak - mainly for smoking game and red meat;

- willow, birch - game with a specific taste, for example, elk or bear, as well as swamp fish;

- cherry, apple tree - cheeses, vegetables, nuts and berries.

The humidity of firewood and wood chips should be within 15%, otherwise too much steam will be generated and the smoked meats will become soggy, after which they will not be stored well.

The costs of making a smokehouse are insignificant; you can use scrap materials and leftovers. A self-made smokehouse and a properly selected smoking mode will allow you to prepare delicacies that are unique in taste and will surprise your family and guests.

Selecting a base

What model is needed to get a functional home smokehouse for preparing different dishes? The main requirement is the integrity of the oven. The cooking surface is not of fundamental importance.

On a note! But for hot smoking from such a device, you also need a top, since a bucket or smokehouse made from old utensils of a different type is placed on it.

The oven is equipped with everything you need for work:

- a door that closes hermetically;

- the presence of a chamber measuring about 50 l;

- tray for draining juices and fats;

- guides for fixing gratings;

- regulator that adjusts the heating of wood chips, fire, temperature conditions.

There is also a gas burner, which is installed at the required distance from the bottom.

Smokehouse with fuel poured into the chamber

There are two fundamentally different designs, differing in the principle of laying wood chips or another source of smoke. The simplest is considered to be a smokehouse with filling at the bottom of the cabinet, since it requires performing a minimum number of operations with your own hands.

Work order:

- Remove the drying cabinet door and its back wall;

- Remove the gas burner from the oven;

- Install an electric stove (1.5-2 kW) or build a fire pit under the bottom of the oven or inside the drying chamber;

- Drill two to four holes with a diameter of 10-20 mm in the lower part of the side walls for air flow and one to two in the upper part to remove exhaust smoke. To do this, you will have to use a drill with a regular cylindrical or step metal drill.

This camera has a number of significant disadvantages that limit its use:

- Impossibility of cold smoking;

- Difficulty in adjusting smoke distribution: the number and diameter of holes will have to be selected by trial and error;

- High heating inertia (impossibility of quickly reducing temperature) can cause too intense smoldering of wood chips or ignition of fat, which will lead to food spoilage;

The process of assembling a unit from a gas stove

Usually a smokehouse is made from a gas stove, since this is the most common solution. But hot smoking can only be achieved from the oven. To do this, you need to assemble grids from other similar devices. Re-equipment does not cause problems. Drawings and diagrams are not needed to obtain a convenient unit from an old stove.

To smoke in such a unit, you first need to scatter wood chips and sawdust on the bottom. Secure the grille to the bottom row using fasteners. Place a tray on it, because when we smoke, we need a container in which the fat will accumulate.

Other gratings are placed at higher levels. Prepared products are laid out on them.

The fire is lit, and as soon as smoke begins to emit, the heat in the home smokehouse should be reduced by a few degrees.

Note! If there is no special tray, a homemade hot smoker can be equipped with an old baking sheet. If you need a larger and more spacious smokehouse, it is proposed to install the tray at the very bottom. But you will need to place a stand.

It is important to understand that a do-it-yourself home smokehouse for a gas stove is not connected to the gas supply system. For the device to work, a fire must be lit under its bottom. Therefore, smoke comes out during operation. For this reason, it is recommended to install a gas stove smoker outdoors and smoke outside.

This option is often made for smoking fish or lard. The device allows you to smoke pork ham or neck, beef, cheese, chicken, etc.

Types and conditions of smoking

You can smoke completely different products: the usual fish, meat and lard, as well as nuts, cheeses, vegetables and even fruits and berries. Of course, they require different modes: smoke temperature and smoking duration, as well as the wood chips used for this.

- cold, with slightly warm smoke 30-50ºС;

- hot, with a smoke temperature of 70-120ºС;

- semi-hot, at 60-70ºС.

- First of all, the firebox is located directly below the smoking chamber . It is not necessary to make a firebox with wood; you can make it yourself from a gas burner or electric stove. The main thing is to heat the bottom of the smokehouse to a temperature at which the wood chips will begin to smolder.

- The smoking chamber in hot smoked smokehouses is sealed . This ensures more uniform heating of all levels of the product - there can be several of them in the smokehouse, and also allows you to use the smoke completely, without allowing it to leak.

- Some smokehouse models have a lid with a water seal . This water seal is a U-shaped depression around the perimeter of the chamber into which water is poured. The edges of the lid fit into this recess, resulting in a barrier for air from the outside and smoke from the inside. The water seal not only allows you to isolate the chamber, but also reduces the amount of carcinogens in the smoke.

- At one or several levels there are removable gratings or rods for hanging hooks. Products are placed on them during smoking. You can use barbecue grills of a suitable size if you make supports for them from a corner with your own hands and cut off the handles with a grinder.

- Another prerequisite is a tray for collecting juice and fat . If they drip directly to the bottom of the smoker, the fat will begin to burn and the food will acquire a bitter, unpleasant taste. For fish, due to the low combustion temperature of its fats, it is better to do it with an outflow from the chamber. The tray must also be removable and must be regularly cleaned of residual grease.

The higher the temperature, the faster the meat and fish cook. Giving the smoke the desired temperature is a problem solved by the correct design of the smokehouse.

Cold smoked

Its main difference is the long chimney , in which the flue gases have time to completely burn out, harmful carcinogens from them are deposited on the walls of the chimney, and the products being smoked are enveloped in a light aromatic smoke. Meat after this treatment can be stored for several months, fish - from three to 12 weeks.

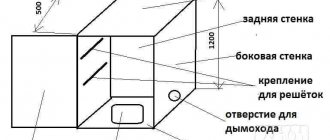

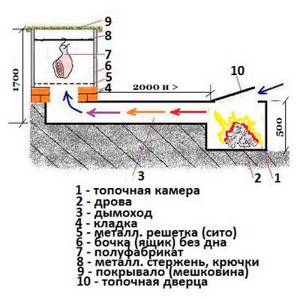

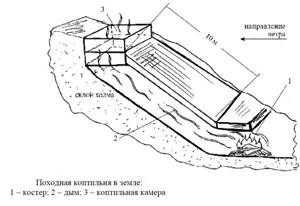

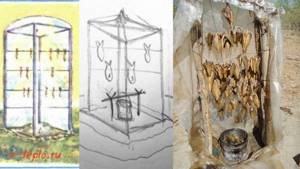

The picture shows a traditional cold smoked smokehouse; it can be installed on a site in a country house. The dimensions are arbitrary, so only the main structural elements are indicated in the drawing.

A cold smoked smokehouse consists of three main blocks: a firebox, a smoking chamber and a chimney connecting them. The firebox can be made of blocks, bricks or welded from metal. It must be equipped with an easily cleanable ash pan - the smoking time of some products is several days, and the ash must be removed during the combustion process.

Read also: Solid fuel boiler with a buffer tank diagram

The smoke output is adjustable; when igniting and at the beginning of the fire, the wood emits dark acrid smoke, which can spoil the taste of smoked meats. Therefore, the firebox is equipped with a smoke damper, directing its flow either into the chimney or out. Most often it is made in the form of a combustion chamber lid.

For smoking, you cannot use resinous ones - spruce, pine, or those that emit tar - maple, birch, firewood. The best wood is cherry, alder, oak and apple.

The photo shows a cold smoked smokehouse made from a wooden barrel, equipped with removable rods.

Due to the low temperature, the smoking chamber can be made from anything, for example, metal or wood. The use of porous materials, such as bricks, is not recommended - they absorb smoke, and after smoking, moisture, they form a sediment, which over time acquires an unpleasant rotten odor.

The simplest option is a metal or wooden barrel with a hole in the bottom into which smoke will flow. It is equipped with hooks or grates for placing products. The role of the lid is usually played by damp burlap - it traps smoke inside the chamber while absorbing excess moisture. The photo shows an example of a willow smoking chamber covered with burlap on top.

Making such a smokehouse with your own hands is quite simple. To do this, you need to choose an area with a slight slope that provides natural smoke draft. A firebox is placed at the bottom of the slope. A groove is being dug on the slope, which will serve as a chimney. It is covered with iron sheets on top, and a layer of soil is poured on them for better thermal insulation. The chimney leads into a smoking chamber; it can be made in different ways.

Hot smoked

Hot smoking is a fairly quick process, from 15 minutes to several hours, depending on the size of individual pieces of meat or fish. The smoke is hotter, about 100ºС, and it is obtained not from firewood, but from special wood chips, so the design of a hot smoked smokehouse has its own characteristics.

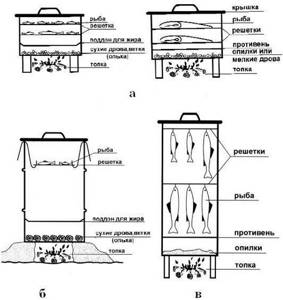

A drawing with options for making a smokehouse for hot smoking is shown below.

The best material for such a smokehouse is stainless steel, but they are often made from scrap materials, for example, from a metal barrel, as shown in the video.

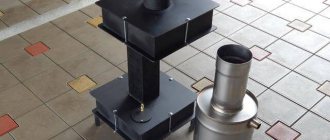

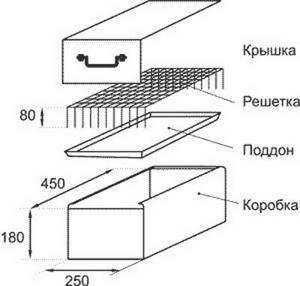

Portable mini-smokehouses for semi-hot smoking

The temperature in such a smokehouse is optimally maintained at 60-70ºС, which corresponds to the semi-hot smoking mode. The preparation of products for such smoking is short, and their shelf life is about three days.

Material for manufacturing: sheet steel, preferably stainless steel . The thickness should be such that when heated, the walls of the smokehouse do not move away, otherwise, due to uneven heating, it will become deformed. Typically, black steel 2-3 mm thick is used, stainless steel - from 1.5 mm. In any case, the gratings must have a stainless steel coating.

Video: how to make a mini smokehouse with your own hands.

Electric stove option

People are often interested in how to make a smokehouse using an electric oven. The peculiarity lies in the unique design of the device. After all, electric stoves differ from solid fuel and gas models.

Heating can be provided by a disk or flat electric heater. Then sawdust is poured directly onto it. If you are creating a smokehouse for an electric stove that runs on heating elements, you will need to use additional capacity. Sawdust is loaded into it.

When creating a smoking apparatus from an old electric gas stove, it is important to provide a built-in fan. This element will speed up the processing of products.

To convert a unit for hot smoking from an electric stove, you need to install an individual chimney or smoke generator. To begin with, the body will need to be raised. It should be located above the smoke generator.

Then on the electric stove on the outer and inner side walls, retreating to a height of 3 cm, holes are cut for the chimney.

All that remains is to connect the smoking chamber and the smoke generator with a chimney.

How to smoke food on such a device? Just like a smokehouse on a gas stove implies.

What does a kitchen smokehouse consist of?

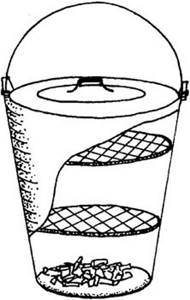

The mentioned bucket, boiler or other container must be modified with your own hands for a smokehouse as follows:

- Small holes are drilled in the bottom in a sufficiently large number, through which smoke from below from the smoldering material passes to form smoke.

- You can make a stand for a grease catcher using wire yourself. The stand should provide a gap of 3-5 centimeters between the bottom and the grease trap, which is necessary for good smoke flow into the container. If you look for something suitable in a store or market, most likely your search will be successful and you will be able to buy a ready-made stand for a hot kettle or frying pan.

- A grease catcher is a bowl or plate that catches the grease that drips from the product during smoking. The ideal grease catcher is a cupcake rosette with a wavy edge, stamped from thick foil and available in a wide range. Therefore, it is better to buy a socket of a suitable diameter, since its wavy edge will best allow smoke to pass through and be combined with other elements of the smokehouse.

- The surface of the first tier for placing the processed product. Such a surface can be made with your own hands from wire in the form of a stand on three legs. This stand is placed inside the container and rests its legs on its bottom, so you need to drill holes in the bottom, stepping back from the edge 1-1.5 centimeters, so that later the legs of the stand do not fall into them. The surface of the stand is located slightly above the grease trap.

- It is better to make the surfaces of the second and, if the height of the container allows, the third tier in the form of a flat, removable stainless steel grid. The grid supports will be two parallel rods made of thick welding electrodes. For the rods, corresponding holes are drilled in the walls of the container. In order for the rods to be securely fixed, but at the same time removable, it is necessary to make them so that nuts are screwed onto the ends of the rods protruding from the body.

- To hang the product from the top edge vertically down 1.5-2 centimeters, cuts are made with a grinder , into which either skewers for cooking shish kebab or welding electrodes are placed. The depth of the cut should ensure that the lid fits snugly so that it does not rest on the skewer or electrode. Hooks are hooked onto them, on which the product intended for smoking is suspended.

The electrodes must be free of flux, and the smokehouse accessories that come into contact with the product must be made of stainless steel. That's the whole smokehouse on the kitchen gas stove. All that's left is:

- place the frying pan on the burner;

- put material into the pan to create smoke;

- Place a modified bucket or other container with all the necessary contents in the frying pan and smoke the product for the required time. And don't forget to turn on the hood fan.

Option #1. Cold smoked design

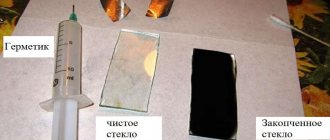

This type of smokehouse is made from a wide variety of materials. Below is a step-by-step guide to creating a simple design using plastic film.

Step one.

First you need to purchase the plastic film itself. Two meters of thick film (the kind used for greenhouses) will be more than enough. From one end, the sleeve of the purchased film is sewn up in such a way that the result is a kind of bag.

Step two.

Next, you need a place where the mini-smokehouse will be located. To do this, you will need a small leveled area of 1 square meter. A two-meter stake should be driven into each corner of this site. At the top, the stakes must be connected to each other using crossbars. It is important that the structure is sufficiently stable.

Step three.

Opposite stakes must be connected using diagonal slats in approximately two to three rows.

Step four.

Fish, already prepared for smoking, should be hung on these slats. It is also important that the bodies of the fish do not touch each other.