Log houses were once quite common, they were built to accommodate people in small towns and villages, they were erected with funds from the local administration in the countryside. Nowadays, municipal housing is not built from timber at all. But there are enough houses like this left, and private construction is now experiencing a boom in this material. Therefore, insulating a house from profiled timber or from ordinary timber is a fairly pressing issue both for the developer of a new home and for the owner of an old one.

The timber used to assemble houses is also used as a supporting structure. Therefore, its insulation will also have a beneficial effect on its durability as the basis of the supporting structure of the entire house, be it a one-story small house, or a municipal three-story apartment building.

How to insulate a house built using profiled timber

Previously (since ancient times), tow was used to insulate gaps between logs. In the last century, insulation of a house made of profiled timber, when this technology began to be used, began to be carried out using jute fiber and flax wool.

Nowadays, various variations of ecowool, mineral wool slabs, fiberglass slabs, expanded polystyrene, and basalt wool are increasingly used for this purpose.

A uniform layer of insulating fiber in the inter-crown space is ensured using tapes of fibrous materials, which are non-woven fabrics attached to the wood using a stapler or glue.

In addition to inter-crown insulation, external installation of insulation is used both in sheets and by the inflatable method. Ecowool, mineral wool, polyurethane foam - everything goes into use.

What is meant by the term “insulation of a house made of laminated veneer lumber”

Insulating a house from laminated veneer lumber can protect the building from drafts or the penetration of cool air. Insulation can also be considered as a set of measures to ensure the preservation of heated air inside the house during winter frosts.

Depending on the specific need, the best insulation for a log house is selected, the specific technology for organizing this part of the construction process, and the varying complexity of the set of measures.

One of the simplest insulation processes is considered to be the process of caulking the roof gaps. Insulation of a house made of profiled timber is organized in this way in several steps:

- At the stage of laying the beams, tow is placed between them.

- After which (when the log house has already been assembled), the remaining gaps are caulked using a special spatula and hammer, jute-flax fiber or the same tow.

The process is not complicated, but it is labor-intensive and time-consuming. In addition, the worker performing this process must be very careful - this work does not like to be rushed.

The technology of creating a thermal insulation cake and the importance of wood processing

The insulation procedure for such buildings can be carried out both from the inside and from the outside. The choice of the location for creating the thermal insulation cake is selected based on the individual preferences of the person and the feasibility of the work. It is impossible to say with 100% accuracy whether insulation needs to be carried out from the outside or from the inside of the building. However, based on the possibility of saving space inside the house, all work is carried out, as a rule, from the outside. In most cases, the main material used to implement such an idea is mineral wool, which guarantees excellent heat retention qualities. Which, together with the qualities of the base material, creates optimal thermal insulation of the object.

The process of creating a thermal insulation cake has its own clear algorithm that must be followed, since the slightest deviation from the insulation scheme can lead to its complete unsuitability.

This is especially true for protecting mineral wool from moisture, which is detrimental to it. In such conditions, laying additional films is an extremely important step to ensure the integrity of the material and maximum thermal insulation qualities of the building. In addition, heat retention is affected by the uniform distribution of insulation and the principles of its installation. They consist in filling all voids and cracks as much as possible, since even the slightest unfilled areas can affect the temperature balance inside the building, in addition to the appearance of drafts and leaks of warm air. Therefore, following a clear procedure for creating a thermal insulation cake, coupled with a responsible approach, can give an optimal result and provide the best heat conservation parameters.

In addition, an important step to guarantee the integrity and safety of the timber itself is its processing. To implement this direction, various antiseptic and insulating agents are used, the action of which is aimed at destroying fungal formations and nests of parasites that can develop in wood, as well as preventing their further spread. In addition, such treatment allows you to identify and close problem areas that may be prerequisites for the penetration of cold air into the house.

The process of insulating walls from the inside

Regardless of what kind of insulation is used for a log house, its initial task is to ensure heat preservation and sound insulation of the interior.

It is worth noting that the insulation must be compact so that there is no significant reduction in the internal space of the insulated premises. Also, the insulation for a log house must be environmentally friendly and resistant to rodent attacks.

After the insulation of a house made of profiled timber from the inside is completed, the structure is closed using plasterboard, wooden/plastic lining or other facing material. For a detailed article about proper insulation of a log house from the inside, see our website in the “Insulation” section.

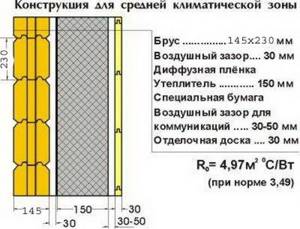

Optimal timber thickness for building a house

An important parameter that affects heat loss through the walls is the thickness of the timber used. Obviously, the thicker the timber, the lower the risk of freezing in winter:

A 100 mm thick beam has a thermal resistance of 0.55 m²×°C/W and is suitable for the construction of outbuildings, since such walls are not able to seriously withstand frost.

Timber with a thickness of 120 mm or more has a thermal conductivity resistance of approximately 0.66 m²×°C/W, so it can be used for the construction of summer houses, bathhouses and other heated structures in which permanent residence is not planned. For a winter house, such walls are very thin, which will negatively affect the indoor microclimate.

A beam with a thickness of 150 mm has a thermal conductivity resistance of 0.83 m²×°C/W, therefore it is already suitable for the construction of permanent residences, but is considered the minimum allowable size. This material is best used in regions with a warm climate, where significant and prolonged frosts do not occur.

A beam with a thickness of 200 mm or more has a thermal resistance of 1.09 m²×°C/W, which is undoubtedly higher than that of a 150 mm beam, but this is still not enough for year-round operation without additional insulation.

It is additionally recommended to insulate winter houses, especially in the northern regions, regardless of the thickness of the timber used in construction. In addition, in order to eliminate drafts between the crowns of the log house, insulation must be laid between the rows of timber and caulking must be done.

Technologies that ensure proper external insulation

Proper insulation of a house made of timber should begin with the need to check the quality of each of the joints, after the beams have dried, select a thermal insulator and calculate the number of layers (the standard thickness of mineral wool is 50 millimeters).

The process of external insulation is carried out in the following ways:

- arrangement of a suspended ventilated facade;

- insulation with external polyurethane coating;

- insulation using foam plastic.

For a detailed article about external insulation of a wooden house, see our website in the “Insulation” section.

Stages of work on arrangement of suspended ventilated facades

Insulation of the façade of a timber house, provided that the timber is dry, can begin upon completion of construction, since there is no need to wait for drying. Work begins with caulking the inter-crown cracks (the process is described above).

Next, insulating a house made of laminated veneer lumber consists of assembling the sheathing (bars with a cross-section of 50x70 mm are used).

The beams are fastened vertically using nails or self-tapping screws. The width between the beams should be slightly narrower than the width of the insulation.

We organize the lathing in two levels to obtain a gap of 30 mm between the surface of the insulation and the finishing coating.

After this, the technology for insulating a house made of timber involves laying insulation boards end-to-end. Following this, the diffuse membrane is stretched and attached to the sheathing using a stapler.

At the finish we install the material chosen for finishing the facade. For more information about the ventilated curtain facade, see the information at the link.

Insulation with polyurethane spraying

Using polyurethane foam, you can create a homogeneous seamless layer, which is primarily required when insulating a house made of timber. Photos of the final layer can be seen here:

One has only to say that the process itself takes place in several stages, and the final layer must be at least 50 millimeters. Next, the insulation layer is covered with finishing materials.

The process of working with insulation materials installed using the inflatable method is well shown in the article “Insulating a timber house from the outside with ecowool.”

The process of insulation with foam boards

Thanks to foam plastic, it is possible to organize both an internal and external insulation layer. Insulating a house made of profiled timber with polystyrene foam is similar to laying mineral wool.

The difference is that when using it, they do not use anchors, but a special adhesive composition, which is applied to prepared, grease-free walls. Just like in previous methods, the insulation of a house made of laminated veneer lumber is completed with the use of finishing materials.

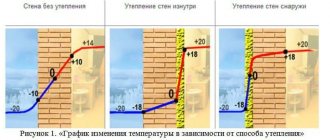

Dew point question

When laying out a pie of boundary walls, construction engineers are often faced with the danger of condensation forming in places where materials with different thermal conductivities come into contact. If the wood and adjacent mineral wool get wet, this will lead to the development of microorganisms and significantly shorten the service life.

When building wooden houses, this phenomenon can rarely be avoided; increased humidity at the border of high and low temperatures almost always remains hidden from the eyes of the developer. Since the formation of condensation cannot be guaranteed to be eliminated, the point of its formation is placed in a layer that is practically insensitive to oversaturation with moisture.

On the outside, the timber wall is covered with polyurethane slabs with a thickness of 25 to 40 mm. During installation, the slabs are temporarily glued with foam, then secured with umbrellas and all joints are thoroughly foamed. On the outside, the polyurethane layer is covered with a vapor barrier membrane with a throughput capacity of no more than 1000 g/m2/day. Next, the first row of sheathing is fastened and the insulation pie is installed.

To prevent moisture from being retained in the main insulation, a ventilation gap of 15–20 mm is left between it and the façade cladding for free air circulation and drying of the mineral wool. The blowing of insulation and the removal of its particles is eliminated by windproof membranes laid between the rows of sheathing or only on the outside of the heat-insulating layer.

Choosing the best insulation

At the moment, two materials should be recognized as the best insulation for a log house:

- Ecowool

- Basalt wool

Both of these materials have all the necessary properties to be considered the best insulation materials:

- They allow water vapor to escape.

- They do not burn and do not support combustion.

- They are the least environmentally dangerous.

- They have excellent, extremely low, thermal conductivity.

The only disadvantage of these two materials is their hydrophilicity; when wet, they lose their heat-insulating properties.

See more on this topic on our website:

- How to insulate and decorate a wooden house from the outside. The construction itself and the thickness of the house walls are to blame for the fact that wooden houses suffer large heat loss. Experience shows that the construction of a timber mansion does not…

- How to insulate external brick walls with polystyrene foam Residents of a brick house, be it a high-rise building or a private house, are always concerned with the question of whether it is worth insulating their house from the outside. This is especially true for those regions where…

- We insulate a log house from the outside with ecowool After a newly built log house has stood for a year and has completely settled, the wood of the walls is often covered with numerous cracks and fissures. I want not only...

- How to properly insulate a facade with foam plastic - let's learn together Insulating facades with foam plastic is one of the best options if you want to save on electricity and gas for heating your home. Polystyrene foam is ideal for insulation,…

- How to insulate a timber house from the outside with polystyrene foam and polystyrene foam After building a house made of timber, many people are faced with the question of how much its walls can save heat, because in our harsh winter conditions this is...

Nuances and recommendations for insulation

Most of the heat loss in any home occurs through windows and doors. Therefore, it is not recommended to save on these elements and install modern entrance doors with thermal breaks and energy-saving double-glazed windows.

A frequently asked question is which is better to install, a stove or a boiler. There is no definite answer here, but a general recommendation can be given. In a small house with 2-3 rooms, you can install a stove; it is quite capable of heating several rooms. In a large, especially two-story house, it is more rational to install a modern boiler, since the stove will not heat many rooms. If desired, you can additionally install a fireplace in the living room or other large room to spend cold evenings near the fire.

Another popular question that consultants of construction companies are asked is whether it is warm in a wooden house in winter, whether it retains heat and how comfortable it is in such housing without insulation. The answer to this question depends on the region of residence and the thickness of the timber used for construction. If the region has a warm climate and a timber with a thickness of at least 200 mm is chosen, it is quite possible to do without additional insulation. If the temperature in the region drops below 10 degrees below zero, you cannot do without insulation.