Holidays at the dacha are not only a battle for the harvest or barbecue picnics, but also a New Year's round dance around the Christmas tree in the yard and snowball fights. And if in winter you visit your dacha as regularly as in summer, then your house and all its inhabitants need warmth and comfort. Which means it's time to warm up! How to make heating in a dacha is the most common question among lovers of country holidays who prefer warmth and home comfort at any time of the year. Moreover, it is better to start worrying about heating at the level of designing a house.

Water heating has a number of important advantages, such as a simple operating principle (hot water, constantly circulating in the pipes, warms the home) and the absence of the need to stockpile coal and firewood. Water is an excellent heat conductor, cheap and accessible. Pipes for water heating are small in diameter, and therefore such a system can be made even for the smallest country house. The heating operates silently, without disturbing the countryside silence, and the owner has the opportunity to regulate the temperature in the room with his own hands.

The most common heating options in the country

a heating system at the stage of building a house. But installation is also possible in an already built house.

Vodyanoye

Water accumulates and releases heat well . Therefore, a water heating system is one of the most common for summer cottages.

This complex consists of the following parts:

- boiler;

- pipes;

- radiators;

- expansion tank;

- circulation pump (not always present);

- shut-off valves, leakage sensors, etc.

The boiler heats the water , which passes through pipes to the radiators. There it gives off heat, warming the house, and returns back.

Liquid expands when heated. To prevent it from breaking pipes or radiators, an expansion tank .

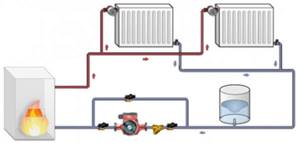

The coolant circulates through one of two possible systems :

- natural;

- or forced.

In the first case , water moves on its own due to expansion. In addition, all elements are positioned to facilitate this movement. The boiler at the dacha is placed as low as possible (preferably in the basement). The batteries are placed at a higher level, so the pipes run at an angle.

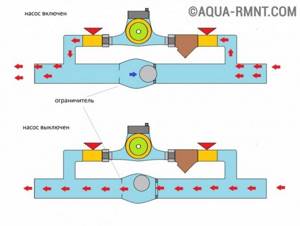

For forced circulation, a pump is included in the circuit, which drives the liquid through the pipes. The boiler can stand at any height relative to the radiators.

Peculiarities. The forced movement pattern is more effective . The cottage warms up much faster. And if two floors , only this is used.

two schemes for connecting heating pipes :

- sequential;

- parallel.

When connected in series, the coolant enters all batteries in turn. Therefore, in the latter it is noticeably colder. This option can only be used in small houses.

Photo 1. Diagrams demonstrating the principles of serial and parallel connection of heating pipes.

If you need to heat a large room or several rooms of the cottage at once, assemble parallel circuit. Two pipes are connected to each battery . Hot water comes up one way, and cooled water returns to the boiler through the other.

Reference. These options are also called one-pipe and two-pipe systems.

Types of boilers

Boilers for heating a house are divided according to the type of fuel used :

- gas;

- electrical;

- solid fuel.

Attention! Often boilers already have a circulation pump . If the pump is purchased separately, it is necessary to select it, taking into account the pressure created by the boiler.

Advantages and disadvantages

Advantages of the water heating method for a summer residence:

- Water is an affordable and high-quality coolant .

- Dust doesn't rise.

- There is no noise during operation or it is insignificant.

- With a two-pipe system, it is possible to regulate the temperature in each room .

Flaws:

- Difficult to install , especially for large houses.

- To prevent pipes from bursting, you have to drain the water or add antifreeze .

- Due to the content of impurities, pipes undergo corrosion , sediment accumulates and over time the operation of the system deteriorates.

- Leaks are possible .

- A cold house heats up relatively slowly .

- Installed only during construction or major renovation of a summer house.

Electrical

In apartment buildings, electricity is used as a supplement to water heating. And at the dacha it can become the main source of heat .

In addition to boilers powered by electricity, there are the following options:

- convectors and radiators;

- infrared heaters;

- warm floor.

Operating principle

In convectors powered by electricity, the heating element heats the air, which exits through openings in the housing and spreads throughout the house, warming it.

Most often, such heating devices have a fan that accelerates air movement.

Such devices work automatically . A certain temperature is set. When the sensors show that the air in the room has warmed up enough, the convector turns off.

By location they are divided into:

- floor;

- wall;

- in-field.

The latter are recommended to be installed under the windows of the house. The rising flow of warm air will prevent the penetration of cold air from the street.

In infrared heaters, electrical energy is also converted into heat, but the peculiarity is that it is not the air that is heated, but the objects at which the device is directed.

in heated floors . As a result, the entire surface heats up.

This type of home heating is comfortable and healthy , as your feet are warm. But it is not enough to completely heat the dacha, especially in winter.

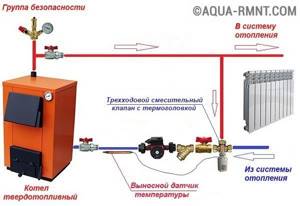

Typical wiring diagrams for solid fuel boilers

The opinion that a solid fuel boiler is an obsolete unit covered with dirt and soot is wrong, isn’t it?

The complexity of controlling the combustion process in solid fuel boilers leads to high inertia of the heating system, which negatively affects the convenience and safety during operation. The situation is further complicated by the fact that the efficiency of units of this type directly depends on the temperature of the coolant. For efficient heating operation, the piping must ensure the temperature of the thermal agent is within 60 - 65 ° C. Of course, if the equipment is not integrated correctly, such heating at above-zero temperatures “overboard” will be very uncomfortable and uneconomical. In addition, the full operation of the heat generator depends on a number of additional factors - the type of heating system, the number of circuits, the presence of additional energy consumers, etc. The wiring diagrams presented below take into account the most common cases. If none of them meets your requirements, then knowledge of the principles and structural features of heating systems will help in developing an individual project.

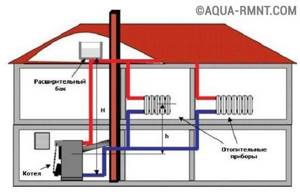

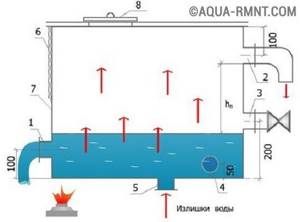

Open type system with natural circulation in a private house

First of all, it should be noted that open gravity-type systems are considered the most suitable for solid fuel boilers. This is due to the fact that even in emergency cases associated with a sharp increase in temperature and pressure, the heating will most likely remain sealed and operational. It is also important that the functionality of the heating equipment does not depend on the availability of power. Considering that wood-burning boilers are installed not in megacities, but in areas remote from the benefits of civilization, this factor will not seem so insignificant to you. Of course, this scheme is not without its drawbacks, the main ones being:

- free access of oxygen to the system, which causes internal corrosion of pipes;

- the need to replenish the coolant level due to its evaporation;

- uneven temperature of the thermal agent at the beginning and end of each circuit.

A layer of any mineral oil 1–2 cm thick, poured into the expansion tank, will prevent oxygen from entering the coolant and reduce the rate of evaporation of the liquid.

Despite its shortcomings, the gravity scheme is very popular due to its simplicity, reliability and low cost.

Installation diagram of a solid fuel unit in an open heating system

When deciding to install using this method, keep in mind that for normal coolant circulation, the boiler inlet must be at least 0.5 m below the heating radiators. The supply and return pipes must have slopes for normal coolant circulation. In addition, it is important to correctly calculate the hydrodynamic resistance of all branches of the system, and during the design process try to reduce the number of shut-off and control valves. The correct operation of the system with natural coolant circulation also depends on the installation location of the expansion tank - it must be connected at the highest point.

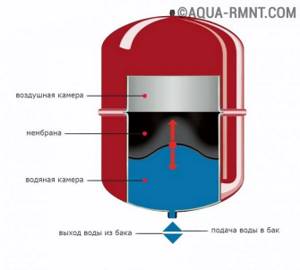

Closed system with natural circulation

Installing a membrane-type expansion tank on the return line will avoid the harmful effects of oxygen and eliminate the need to control the coolant level.

Design of membrane expansion tank

When deciding to equip a gravity system with a sealed expansion tank, consider the following points:

- the capacity of the membrane tank must contain at least 10% of the volume of the entire coolant;

- a safety valve must be installed on the supply pipe;

- the highest point of the system must be equipped with an air vent.

Additional devices that are included in the boiler safety group (safety valve and air vent) will have to be purchased separately - manufacturers very rarely equip units with such devices.

The safety valve allows the coolant to be discharged if the pressure in the system exceeds a critical value. A normal operating indicator is considered to be a pressure of 1.5 to 2 atm. The emergency valve is set to 3 atm.

You will learn more about this system in our next article:.

Features of systems with forced coolant movement

In order to equalize the temperature in all areas, a circulation pump is integrated into the closed heating system. Since this unit can provide forced movement of the coolant, the requirements for the level of installation of the boiler and compliance with slopes become negligible. However, you should not give up the autonomy of natural heating. If a bypass branch, called a bypass, is installed at the boiler outlet, then in the event of a power outage, the circulation of the thermal agent will be ensured by gravitational forces.

The use of a bypass will allow, if necessary, to switch to the natural method of coolant circulation

The electric pump is installed on the return line, between the expansion tank and the inlet fitting. Thanks to the lower coolant temperature, the pump operates in a more gentle mode, which increases its durability.

Installing a circulation unit on the return line is also necessary for safety reasons. When water boils in the boiler, steam may form, the entry of which into the centrifugal pump can completely stop the movement of the liquid, which can lead to an accident. If the device is installed at the inlet of the heat generator, it will be able to circulate the coolant even in the event of emergency situations.

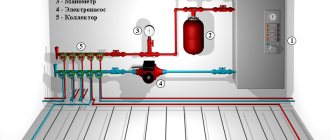

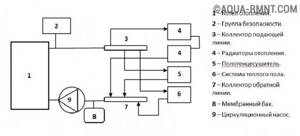

Connection via manifolds

If it is necessary to connect several parallel branches with radiators, a water heated floor, etc. to a solid fuel boiler, then balancing of the circuits is required, otherwise the coolant will follow the path of least resistance, and the remaining parts of the system will remain cold. For this purpose, one or more collectors (combs) are installed at the outlet of the heating unit - distribution devices with one input and several outputs. Installation of combs opens up wide possibilities for connecting several circulation pumps, allows you to supply a thermal agent of the same temperature to consumers and regulate its supply. The only disadvantage of this type of piping can be considered the complication of the design and the increased cost of the heating system.

Manifold piping of a solid fuel boiler

A separate case of manifold piping is a connection with a hydraulic arrow. Its difference from a conventional collector is that this device acts as a kind of intermediary between the heating boiler and consumers. Made in the form of a large-diameter pipe, the hydraulic arrow is installed vertically and connected to the inlet and pressure pipes of the boiler. In this case, consumers are inserted at different heights, which allows you to select the optimal temperature for each circuit.

Installation of emergency and control systems

Emergency and control systems serve several purposes:

- protection of the system from depressurization in the event of an uncontrolled increase in pressure;

- temperature control of individual circuits;

- boiler protection from overheating;

- prevention of condensation processes associated with large differences in supply and return temperatures.

To solve system safety problems, a safety valve, emergency heat exchanger or natural circulation circuit is introduced into the piping circuit. As for the issues of regulating the temperature of the thermal agent, thermostatic and controlled valves are used for these purposes.

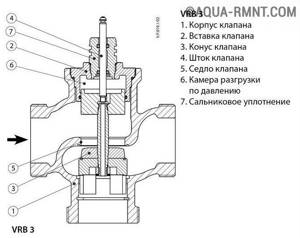

Trim with three-way valve

Three-way mixing valve design

A solid fuel boiler is a periodic heating unit, so it is at risk of corrosion due to condensation that falls on its walls during heating. This is due to the ingress of too cold coolant from the return into the heat exchanger of the heating unit. The danger of this factor can be eliminated using a three-way valve. This device is an adjustable valve with two inputs and one output. Based on a signal from the temperature sensor, the three-way valve opens the hot coolant supply channel to the boiler inlet, preventing the formation of a dew point. As soon as the heating unit enters operating mode, the supply of liquid in a small circle stops.

Trim diagram with three-way valve

A fairly common mistake is to install a centrifugal pump before a three-way valve. Naturally, with the valve closed, there can be no talk of any liquid circulation in the system. It is correct to install the pump after the adjusting device.

A three-way valve can also be used to regulate the temperature of the heating agent supplied to consumers. In this case, the device is set to work in the other direction, mixing cold coolant from the return to the supply.

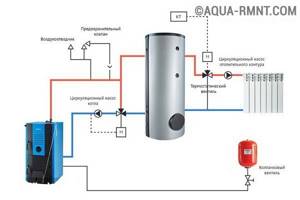

Circuit with buffer capacity

Diagram of a heating system with a buffer tank

The low controllability of solid fuel boilers requires constant monitoring of the amount of firewood and draft, which significantly reduces the convenience of their operation. Installing a buffer tank (heat accumulator) will allow you to load more fuel without worrying about possible boiling of the liquid. This device is a sealed tank that separates the heating unit from consumers. Due to its large volume, the buffer tank can accumulate excess heat and transfer it to radiators as needed. The mixing unit, which uses the same three-way valve, will help regulate the temperature of the liquid coming from the heat accumulator.

Trim elements ensuring the safety of the heating system

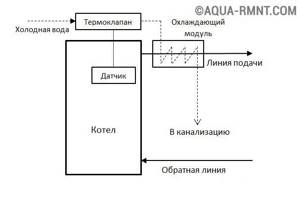

Emergency circuit harness

In addition to the safety valve mentioned above, protecting the heating unit from overheating is achieved using an emergency circuit through which cold water from the water supply is supplied to the heat exchanger. Depending on the design of the boiler, the coolant can be supplied directly to the heat exchanger or to a special coil installed in the working chamber of the unit. By the way, it is the last option that is the only possible one for systems with filled antifreeze. The water supply is carried out using a three-way valve, which is controlled by a sensor installed inside the heat exchanger. The “waste” liquid is discharged through a special pipeline connected to the sewer system.

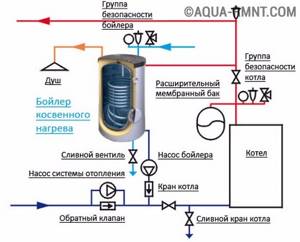

Connection diagram for an indirect heating boiler

Connection diagram for an indirect heating boiler

Piping with connection of a boiler for hot water supply can be used for heating systems of all types. To do this, a special heat-insulated container (boiler) is connected to the water supply and hot water supply system, and a coil is installed inside the water heater, which is cut into the heating agent supply line. Passing through this circuit, the hot coolant transfers heat to the water. Often, an indirect heating boiler is also equipped with heating elements, thanks to which it becomes possible to obtain hot water in the warm season.

A three-way valve can also be used in a piping circuit for an indirect heating boiler. Read more about this in our material:.

Video: Tying a solid fuel boiler

Heaters

Depending on the operating principle and heat source, heaters are divided into oil, infrared, gas, etc.

Oil heater

What is an oil heater? This is the reservoir in which the heating element is located. Oil is also poured in there. Oil was not chosen as a coolant by chance: it takes a long time to heat up, but then, after maximum heating, it is able to maintain a high temperature for a long time.

This device has other advantages:

- relatively low price;

- mobility (unlike a battery, the heater can be moved to any place in the room or country house);

- there are no foreign odors or noise during its operation;

- When heating, it does not dry out the air in the room.

The disadvantages include the following:

- the oil heats up very slowly, so you will have to wait a long time for the air in the room to warm up. Oil heaters equipped with a fan do not have this drawback, although they are more expensive;

- Due to the massive body and the oil poured into the tank, these devices are quite heavy. If you have a two-story cottage, then when moving the device from one floor to another this can turn into a big problem;

- Due to the high heating temperature of the housing, there is a risk of burns. This is especially important in families with children;

- considerable cost of energy consumption during prolonged heating of the heater.

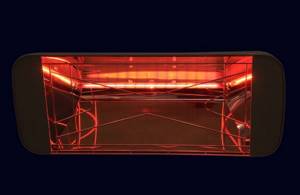

Infrared heater

An infrared heater has a completely different operating principle. The temperature rise there occurs due to the action of infrared rays (hence the name). They act like the sun's rays: they pass freely through the air without heating it. When some “obstacle” (person, animal, furniture, etc.) is encountered along the way, infrared rays are absorbed by it, and at the same time the temperature of this object or living creature rises. Thus, infrared heaters do not warm the air, but us and all objects that are in their zone of action. And now we give this heat to the air, increasing its temperature.

Infrared heaters can be installed on any surface: floor, wall or ceiling. They have tip-over protection, which immediately turns off the device after a fall. They also have other advantages:

- these devices do not waste time on prolonged warming up, like oil devices, but begin to give off heat immediately after switching on;

- they operate silently, do not create odor and do not burn oxygen in the room;

- Many models have sensors that prevent the device from overheating and maintain the temperature at the level desired by the owner.

Infrared heaters are not without their disadvantages:

- quite high price compared to oil heaters;

- limited distance between the device and an object/person, beyond which the effect of the device is no longer felt;

- If you stay in the area of infrared rays for a long time, your health may deteriorate: headache, dry skin and eyes.

Convectors: electric and gas

A slightly different type of heating device, which is often used to heat country houses during the cold season, are convectors. The principle of their operation is based on the property of cold air to sink down, displacing warm air from there. The latter rises up, cools there and falls down again. This is how natural air circulation occurs - convection. She gave the device its name – convector.

An electric convector consists of a housing, in the upper and lower parts of which there are air intake openings. There is a heating element located inside the housing. Cold air enters the housing from below and flows around the heating element. At this time, its temperature rises, and a hot air flow comes out of the case through the upper holes, which immediately rises up to the ceiling. There it gives off its heat to the surrounding space, cools and sinks down again. This heats up the room.

Advantages of convectors:

- warms up the air in the room very quickly;

- unlike heaters, the body of convectors hardly heats up, so it is impossible to get burned on it;

- fairly low noise level;

- The temperature sensor helps control the heat level in the room and turns off the device when the desired temperature is reached. Thanks to this, energy savings occur.

There is nothing ideal in the world, so convectors also have disadvantages:

- while the convector is operating, the humidity level decreases, the air becomes very dry;

- high electricity consumption;

- Without a working convector, the air cools very quickly, so the device must be turned on constantly.

Gas heating

If the cottage is connected to a gas main, you can warm the room using gas. Gas heaters have high heat output and can warm up a house in 15 minutes. Due to high heat transfer, gas equipment can be equipped with batteries that will accumulate excess heat and consume it after the gas installation is turned off.

While stove heating does not require complex installation and maintenance, heating a cottage with gas requires skill.

It is better to think about various arrangement options in advance. Heating equipment will cost more than with a stove. To install gas heating, you will need to draw up a plan and invite specialists to install it. After all, improper operation of gas equipment can cause an explosion.

Heating systems for a country house: varieties

There are several popular and quite affordable ways to heat suburban housing so that in winter, even in severe frost, the owners will be warm. By the way, this kind of work can be done not only with the help of professionals, but also with your own hands. When choosing the heating project that is optimal for you, be sure to consider several important points:

- First, take into account the age of the structure, as well as the materials used to construct it. If the most heat-resistant materials (for example, brick, wood) were used for the construction of a residential country house, it will be easier to retain heat even in the coldest winter.

- Secondly, when thinking about how the heating of your dacha will be organized, take into account another important aspect - the presence of communications in the house. Do you have access to a gas pipeline? In this case, you can purchase a boiler and equip the heating system in this way. If gas has not been supplied to your country house and such work is not planned, or there is no gas supply at all in your country house, the options for organizing heating become significantly fewer.

- The third point that must be taken into account when organizing a heating system is the level of fire safety (that is, how protected your building is from possible fires). If materials with low fire safety were used in construction or finishing work, the issue of organizing heating for a country house must be approached with the utmost care and attention.

Who does the heating installation?

The construction and installation company DESIGN PRESTIGE, known in the most remote corners, has been operating in the Moscow region for more than 20 years The popularity of the company is facilitated by its focus on providing heating services in a complex, which is called “turnkey”.

The company's design and engineering group carries out heating of any degree of complexity, the supply and logistics department supplies equipment and materials according to customer requests at wholesale prices, a team of mechanics performs high-quality heating installations

, adjusters start up and regulate

the heating system .

By performing work using such an algorithm, the company guarantees the reliability and economic efficiency of gas heating. In addition, by concluding an additional contract, the customer is provided with periodic off-season heating maintenance. Heating of private houses in detail by cost

- Heating 100 m² Cost of work 49,500 rub.

- Heating 150 m² Cost of work 52,500 rub.

- Heating 200 m² Cost of work 72,500 rub.

- Heating 250 m² Cost of work 87,500 rub.

Heating 100 m²

Heat loss calculator Calculator

for the number of radiator sections

Heated floor calculator

| Cost of work | from 49,500 rub. |

| Cost of equipment | from 120,000 rub. |

Heating 100 m²

Heating 150 m²

| Cost of work | from 52,500 rub. |

| Cost of equipment | from 200,000 rub. |

Heating 150 m²

Heating 200 m²

| Cost of work | from 72,500 rub. |

| Cost of equipment | from 250,000 rub. |

Heating 200 m²

Heating 250 m²

| Cost of work | from 87,500 rub. |

| Cost of equipment | from 300,000 rub. |

Heating 250 m²

Heating services: Baseboard heating, Water heated floor, Radiator heating, Warm wall

Installation of heating systems for a private house

Heating system requirements

Depending on individual conditions, different requirements may be imposed on the heating of a country house, but there are also general ones that will always be relevant:

- quick heating of rooms;

- the heating system must use available energy carriers, possibly several;

- reasonable cost of equipment and installation work;

- efficiency and economy;

- the ability to function in periodic mode and withstand frost during downtime without consequences.

In order to make it easier for you to choose the optimal method of heating your dacha, we will consider real options for heating with different energy sources and how well they meet the listed requirements. Then you can add your wishes to them and determine which method is better.

Installation

The question of how to install a heating radiator is the most important after abandoning the centralized system or dismantling the old radiator.

- The radiator must be installed on a prepared surface: painted or plastered.

- Use a pencil to mark the mounting level of the new radiator. The following are considered optimal distances: from the window sill - up to 10 cm, from the wall - up to 5 cm, from the floor - up to 12 cm.

- After this, the radiator can be mounted. It must be remembered that during installation the radiator must remain in its original packaging. Cuts are made on the packaging where necessary.

- Couplings are installed at the inlet and outlet; a Mayevsky valve is required for air release. Next, you can install the tap and valve. It would be useful to use a sealant.

- After installing the heating radiator, it is necessary to carry out pressure testing.

Let us remind you that all work on the assembly and installation of radiators must be performed by craftsmen who have professional tools and experience in this field. Only thanks to this, you can avoid the cost of expensive repairs in the future.

Calculation

So, we have made our choice. How to calculate bimetallic heating radiators according to the parameters of your apartment?

With standard (2.5 - 2.7 meters) ceiling heights, you can use the simplest calculation scheme:

- For 1 square meter of room, 100 watts of heat is taken;

- Depending on the climatic zone, a coefficient from 0.7 (Crimea) to 2.0 (Yakutia) is used;

The heat output of the section is estimated on average at 180 watts.

Fastening

How to hang a bimetallic radiator on the wall?

- Standardly, pin brackets are used for fastening, which are screwed into plastic dowels;

- Instead, you can use pieces of smooth steel reinforcement with a diameter of 10-12 mm, driven into pre-drilled holes of a slightly smaller diameter.

Harness

What components for bimetallic radiators will be needed when installing them yourself?

- Set of radiator plugs (4 pieces, external thread DN25). The diameter of the internal thread of the passage plugs is determined by the number of sections of the device: if there are fewer than 10 of them, a liner with a nominal diameter of DN15 is sufficient, if more, it is better to take plugs with an internal thread of DN20;

- Throttle or thermal head and ball valve with American connectors for connecting to plugs. The throttle will allow you to regulate the heat transfer of the device manually, the thermal head – automatically, depending on the air temperature in the room;

- In the apartment at the top of the riser, the radiator will have to be equipped with a Mayevsky valve to bleed air.

Radiator connection kit.

What pipes should I use for connection? Preferably corrugated stainless steel.

We invite you to familiarize yourself with an overview of Purmo heating radiators and their technical characteristics

What is this instruction related to?

They have high tensile strength;

- They bend with a minimum radius and do not require precise sizing;

- They are mounted with compression fittings using a pair of adjustable wrenches.

The radiator in the photo is connected with a corrugated stainless pipe.

Assembly Tips

Radiator plugs are sealed with paronite or silicone gaskets - the same ones that are used to build up a bimetallic radiator with additional sections.

Other connections are wound with Tangit Unilok sealant thread or flax with paint.

A diagonal connection will allow you to heat the maximum number of sections.

Simple heating of a country house: without gas or electricity

Heating a home with electricity is expensive and unreliable . Using gas is cheaper, but it is not always possible . Then you have to look for other options.

There are several modern alternative sources : energy from the sun, underground resources or an ice-free reservoir. But their installation is quite expensive and complicated. a traditional option is often chosen for a dacha .

Pechnoe

It has been known for quite a long time , but remains relevant to this day. There are many variations of stoves. They can heat the entire house or a single room. Sometimes they are connected to a water heating system. Stoves not only heat, but also cook food .

Fuel burns in the combustion chamber. It heats the walls of the stove, which release heat into the house. The following materials are used:

- brick;

- cast iron;

- stainless steel.

The brick takes a long time to heat up, but it also takes longer to release heat. To maintain a comfortable temperature at the dacha, 1-2 heatings per day are required . Steel furnaces heat up quickly and cool down just as quickly. Cast iron ones also heat up quickly, and in terms of heat transfer they occupy an intermediate place between other varieties.

The following is used as fuel:

- firewood;

- coal;

- pallets;

- fuel briquettes.

Advantages and disadvantages

The advantages of heating a dacha with a stove include:

- Autonomy . There is no dependence on gas and electricity.

- Suitable for houses where people do not live permanently.

- You can also cook in the oven .

There are the following disadvantages :

- Requires space to store fuel.

- Brick stoves are quite massive , and it is advisable to lay them together with the house.

- Less heating efficiency.

- If the water circuit is not connected, far from the stove will be cooler.

- It is necessary to make a chimney .

Cottage with two floors

The dacha is located in a gardening cooperative and is a two-story house with an area of up to 150 square meters. At such a dacha, you can live all year round with fairly short breaks. There is no gas in the cooperative.

In such a situation, in order to heat a two-story cottage, you should take into account:

- Stove type heating. You can cook food with this type.

- Water heating when consuming energy in the form of diesel or solid fuel.

Oven with water circuit

If a decision is made about a water type of heating for a two-story dacha, it is necessary to consider the use of antifreeze for the equipment as a heat carrier. In another situation, the homeowner will need to drain the water before leaving and then fill the system again upon returning. You also need to additionally insulate the house to reduce heating costs.

Water heating

A common heating system can be water heating, because in this case water is heated in a stove or boiler. In all country premises, coolant circulates through radiators and pipes.

Boilers are classified into:

- electric boilers;

- operating on liquid fuel;

- gas;

- solid fuel.

Heating is quite effective, but of course it is also expensive. But this also has its advantages; you can come to the dacha around the clock. This version of the heating system is well suited for those who will often come to their dacha in winter, but if not, then you should think carefully about whether it is worth making such efforts and costs for this type of heating.

Options for connecting heating radiators in a private house

We talked about methods of laying pipes throughout the premises and found out that two-pipe systems are most effective, as they provide more uniform heating of the entire building. If the building is small, you can limit yourself to a single-pipe system - it will be cheaper. Now we will talk about how to connect heating radiators in a private house. The following schemes exist:

- Side diagram;

- Bottom diagram;

- Lower for two-pipe systems;

- Diagonal.

Let's look at ways to connect heating radiators in a private house in more detail.

Side diagram

The side connection scheme is often used in apartment buildings, when the coolant descends from top to bottom, passing through radiators in apartments. In order to partially compensate for the cooling of the coolant, a connection is made with a jumper. Radiators are also connected laterally in private houses, using a two-pipe scheme - the coolant is supplied from above, after which it passes through the radiator and goes down into the return pipe.

Sometimes the side scheme is called one-sided - in fact, they are the same scheme. It is recommended for use when installing large radiators for heating large areas.

Bottom diagram

When considering the diagrams for connecting heating batteries in a private house, one cannot fail to mention the lower diagram. In it, the coolant is supplied in the lower part from one side and exits from the other side. The circuit is quite effective, but it is aimed at single-pipe systems with radiators connected in series. In two-pipe systems such a connection is practically not used. This radiator connection scheme is often called a saddle connection.

Lower for two-pipe systems

Some radiators are designed so that their inputs and outputs are located nearby (usually in the lower part). Such batteries are intended for use in two-pipe heating systems. The circuit is not without certain disadvantages associated with uneven heating. That is, the furthest part of the battery will be cooler than the rest of the surface. Therefore, the use of such radiators is not justified.

Diagonal pattern

The diagonal connection diagram is one of the most common. Its main advantage is the uniform distribution of the heated coolant throughout the battery. The coolant itself is supplied from the upper right part and removed through the lower left part (or vice versa). Due to the fact that it flows diagonally (and always from top to bottom), uniform heating of the entire battery is ensured.

This scheme is intended for use in two-pipe systems. In single-pipe systems, the presence of excess bends will cause an increase in hydraulic resistance.

How to choose the right system

To make the right choice, you must consider :

- available fuel ;

- dimensions ;

- the material from which it is constructed;

- how often is it visited?.

For a brick house

Brick walls absorb and then retain heat. a fire occurring is low.

Therefore, it is better to use water or stove heating. The final choice depends on:

- gas supplied to the house ?

- prices for various types of fuel in a given area.

For wooden structure

It is unsafe to light a stove in such a dacha , since wood is a highly flammable material. In this case, it is better to stick to water heating. If the house is small and power , this will do.

Features of choosing pipe material

The choice of material from which the pipes will be made also depends on the preferences of the owner, but more often on his material wealth.

Plastic pipes are cheap and easy to install. They are corrosion-resistant, durable, and do not require complex welding. But a significant drawback for a summer resident is the threat of freezing of the heating system if the boiler is turned off. Then it is necessary to look for an alternative coolant.

Copper and steel

The most reliable for water heating systems are copper pipes, but they are very expensive, few people can afford to invest such funds in a country house. Steel ones are susceptible to corrosion, so galvanized or stainless steel is used. If you do the installation work yourself, this will help to somewhat reduce the overall costs of arranging country heating.

Plastic

Plastic pipes are cheap and easy to install. They are corrosion-resistant, durable, and do not require complex welding. But a significant drawback for a summer resident is the threat of freezing of the heating system if the boiler is turned off. Then it is necessary to look for an alternative coolant.

Coolant

If your winters are severe, and you do not plan to live in your dacha permanently, then it is not economically profitable to constantly heat your house. But then the heating system may freeze; in this case, it is more rational to replace the water in the pipes with antifreeze.

This will protect the system from frost, and when you come to relax in winter, you can quickly warm up your home. The only “but” is that antifreeze heating is incompatible with aluminum radiators; it will be necessary to install steel or bimetallic batteries.

Gas equipment: heaters and convector

In addition to firewood and electricity, there is another source of thermal energy that many summer residents successfully use - gas. If gas is not supplied to your dacha, you can use liquefied gas (it is supplied in cylinders): currently, many heating devices can operate on any of these types of fuel. Equipment that runs on gas in a country house is used:

- infrared gas heater,

- gas convectors,

- catalytic gas heater.

The operating principle of the first two devices is no different from their counterparts powered by electricity. But the action of a catalytic heater is based on the interaction of burning gas with a special catalyst plate. During combustion, the gas, thanks to the catalyst, is oxidized. The oxidation reaction is accompanied by the release of a large amount of heat, which warms the room. Gas consumption is quite small, because the oxidation reaction depends simply on combustion, and not on its power.

Advantages of gas equipment:

- fairly low gas prices;

- ease of installation, mobility;

- rapid heating of the room;

- reliability.

Not without its drawbacks:

- when using gas cylinders there is always a risk of gas leakage;

- at low temperatures there may be a problem with turning on the gas heater;

- infrared gas heaters are quite expensive, and if they break down, repairing them will also cost you a pretty penny;

- When gas is burned in convectors, combustion products are formed, for the removal of which a chimney is required;

- Catalytic heaters have practically no combustion products, but they have another disadvantage - a limited service life. When using low-quality gas, it is greatly reduced.

What are the advantages of a solid fuel boiler?

The main advantages of such equipment are recommended to include the following options:

- - Low cost.

- — Ease of installation.

- — High level of maintainability and energy independence.

- — Safety of use.

- — The presence of the possibility of using various types of solid fuel. Here you can use both coal and sawdust, as well as firewood, as well as other options for plant waste.

Heating a dacha with a solid fuel boiler is characterized by the presence of energy independence, which plays an important role when selecting a boiler. Since in some villages there is no possibility of using electricity for some time, which is far from a rare occurrence.

| Monday | Open 24 hours |

| Tuesday | Open 24 hours |

| Wednesday | Open 24 hours |

| Thursday | Open 24 hours |

| Friday | Open 24 hours |

| Saturday | Open 24 hours Now open |

| Sunday | Open 24 hours |

Heat loss calculator

Calculator for the number of radiator sections

Heated floor calculator

The operation of a solid fuel boiler is considered safer compared to the use of gas equipment. And for those areas where there is a lot of firewood, this type of heating is considered even more profitable. One single loading of a solid fuel boiler is enough to heat the dacha for a week.

Engineering communications service Heating, water supply, drainage, sewerage systems

around the clock tel: 8

INSTALLATION, REPAIR, MAINTENANCE, MODERNIZATION, REPLACEMENT

Seasonal cost comparison

What is cheaper to heat your home? What is more profitable for a summer house or a home? Expenses for the season consist of the following items:

- purchase of energy resources;

- equipment service;

- chimney cleaning.

When making comparisons, it is also necessary to take into account intangible indicators: the level of comfort and the amount of manual labor during daily heating.

Prices for fuel and services vary from region to region. On average, systems are arranged in the following order of increasing costs:

- solid fuel boilers;

- gas boilers;

- liquid fuel boilers;

- electric heating

Which heating is cheaper? As a rule, heating costs are inversely proportional to the amounts invested in installing high-tech systems and insulating the house.

Installation of pipes for a water-type heating system

When figuring out how to equip water heating for a dacha with your own hands, great importance should be given to installing pipes for the system. Thus, the filling diameter must be large, so for a house with a large area, it is best to use larger pipes.

As for batteries, pipes of a smaller diameter can be used for them, since the throughput of one small pipe will be quite sufficient for these purposes.

Speaking about the material, it is impossible not to note some well-established standards that provide for the installation of steel samples. However, this is not at all a prerequisite, since the temperature of the water in the heating system for a dacha will definitely not exceed the boiling point, so pipes made of polypropylene or metal-plastic may well be an alternative.

So what is the best way to heat a dacha in winter?

It is difficult to answer this question unequivocally. Heaters that are powered from the electrical network are the simplest and most convenient, but at the same time the most expensive option. Solid fuel stoves (mostly firewood or other wood-based fuels) are the cheapest, but at the same time the most labor-intensive way to heat a dacha in the cold season. Somewhere in the middle between them there is heating equipment that runs on gas.

According to experienced summer residents, it is best to use a combination of several methods to heat a house. For example, immediately after arrival you need to quickly heat the house. Here a stove will come to the rescue (both a potbelly stove and a Buleryan stove will do). When the stove stops producing heat (for example, at night), heaters come into play. Infrared heaters that have a function of maintaining a constant temperature are best suited for this purpose: the temperature in the room has dropped - the sensor has triggered and turned on the heater.

There are a lot of options for heating a country house in the cold season. How do you heat the room?

Heating methods

For the heating system of a dacha, you can use either a permanent system based on a boiler and radiators, or mobile devices such as IR heaters, fan heaters, oil batteries and others. At the same time, almost all mobile options operate on electricity, and a stationary boiler can be either electric, gas or even solid fuel, although without a brick-lined stove with a good exhaust system, this option is accompanied by a number of difficulties. A country house must not only have efficient heating, but at the same time the version of this device must be economical. For this you can use all kinds of lamps, an electric heater, a heat gun, wood heating or with pellets, learn how to work with propane cylinders or air conditioning.

Electricity

The simplest method of heating a summer house is electricity. Most types of heating equipment powered by electricity do not require any skills or knowledge for installation, except for familiarizing yourself with the methodology and studying the instructions for the device. The most common types are: electric fireplaces, IR emitters, oil batteries and fan heaters. In addition, an electric boiler can be installed for full heating using hot water.

Installation of heated floors

Installation of infrared floor heating does not require any special conditions and can be carried out both in warm and cold seasons. Installation work does not require special skills and is easy and simple. First you need to buy infrared film, hydro- and thermal insulation, a thermostatic block and covering material; the best option is laminate.

The installation proceeds as follows:

- the floor surface is cleaned and leveled;

- the thermostat is installed so that it is convenient to use;

- thermal insulation is laid and secured with mounting tape;

- the strips are laid according to the instructions in the instructions, the surface in the places where the furniture is placed is not lined;

- pieces of film are fastened together, and the cut points are isolated with bitumen tape;

- power supply is connected to the heating elements, and from it to the temperature control unit;

- the system is tested for readiness for operation;

- waterproofing is laid, and a floor covering of your choice is placed on it: laminate, carpet or another option.

Boiler designs

When choosing a heating device, you should primarily consider the type of energy carrier. When considering this issue, you should pay attention to its cost and the possibility of its delivery. The second most important factor influencing the choice of boiler is the power of the equipment. On average, it is considered that for heating 10 sq.m. The room area required is 1 kW.

When designing a country heating system, it is necessary to take into account the installation location of the boiler equipment. It is recommended to take it outside the house and place it in an extension. In any case, the specific installation conditions determine the method of placing the boiler.

Let's consider options for heating equipment for a summer residence.

Liquid fuel boilers

Such units run on diesel fuel or waste oil. The latter option is more preferable, since the cost of fuel is significantly reduced. Liquid fuel equipment is attractive not so much for its efficiency as for the possibility of fully automating its operation. Using diesel fuel does not allow for cost savings. At lower temperatures, fuel becomes more viscous, which prevents a stable combustion process. Such a boiler requires the construction of a separate room, since its operation is accompanied by loud noise.

Liquid fuel boiler

Solid fuel boilers

Despite the fact that it is necessary to constantly replenish firewood, the cost of solid fuel is not comparable with liquid fuel, and even more so with electricity and gas. You can save money by collecting dead wood in the nearest forest belt.

The disadvantage of this type of fuel is that it burns out quickly; one fill is enough to operate the boiler for no more than six hours. Installing pyrolysis boilers increases the operating time of the equipment on one bed, but it is not practical to use them for a small area.

It is impossible to regulate the combustion temperature in solid fuel boilers. There is only one way to influence the combustion process: change the air supply using a damper. In addition, to store fuel reserves, the premises must be organized in a certain way.

Energy consumption of electrical systems

How to save on heating your home with electricity? Economical heating with electric systems is still possible, despite high tariffs. To do this, the following conditions must be met:

- thorough thermal insulation of the building, including walls, floors, roofing;

- installation of modern metal-plastic windows;

- connecting heaters to a computerized control system.

The control system regulates the power of the heaters in each room based on the temperature indoors and outdoors, the dynamics of its changes, the strength and direction of the wind. This avoids overheating and unproductive costs.

Efficient heating will also help ensure system programming. The program will lower the temperature in rooms while residents are away and warm up the building before they return. The smart home system makes it possible to control heating remotely.

Correct installation of a solid fuel boiler in a closed heating system

A huge advantage of solid fuel boilers is that their installation does not require any permits. It is quite possible to carry out the installation yourself, especially since this does not require any special tools or special knowledge. The main thing is to approach the work responsibly and follow the order of all stages.

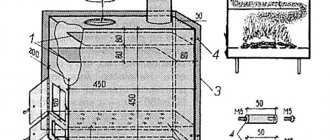

Boiler room arrangement

The disadvantage of heating units used to burn wood and coal is the need for a special, well-ventilated room. Of course, it would be possible to install a boiler in the kitchen or bathroom, however, periodic emissions of smoke and soot, dirt from fuel and combustion products make this idea unsuitable for implementation. In addition, installing burning equipment in living rooms is also unsafe - the release of fumes can lead to tragedy.

A solid fuel boiler is best installed outside residential premises

When installing a heat generator in a boiler room, several rules are followed:

- the distance from the combustion door to the wall must be at least 1 m;

- ventilation ducts must be installed at a distance no higher than 50 cm from the floor and no lower than 40 cm from the ceiling;

- There should be no fuel, lubricants or flammable substances and objects in the room;

- The base area in front of the ash pit is protected with a metal sheet measuring at least 0.5 x 0.7 m.

In addition, at the location where the boiler is installed, an opening is provided for the chimney, which is led outside. Manufacturers indicate the configuration and dimensions of the chimney in the technical data sheet, so there is no need to invent anything. Of course, if the need arises, you can deviate from the documentation requirements, but in any case, the channel for removing combustion products must provide excellent traction in any weather.

How to properly install a chimney

When installing a chimney, all connections and cracks are sealed with sealing materials, and windows are also provided for cleaning the channels from soot and a condensate catcher.

Preparing to install a heating unit

Before installing the boiler, select a piping scheme, calculate the length and diameter of the pipelines, the number of radiators, the type and quantity of additional equipment and shut-off and control valves.

Despite all the variety of design solutions, experts recommend choosing combined heating, which can provide forced and natural circulation of the coolant. Therefore, when making calculations, it is necessary to consider how a parallel section of the supply pipeline (bypass) with a centrifugal pump will be installed and to provide for the slopes necessary for the operation of the gravity system. You shouldn’t give up on buffer capacity either. Of course, its installation will entail additional costs. However, a storage tank of this type will be able to level out the temperature curve, and one load of fuel will last for a longer time.

Connecting the boiler to a heating system with a dual-purpose buffer tank

Particular comfort will be provided by a heat accumulator with an additional circuit, which is used for hot water supply. Considering the fact that due to the installation of a solid fuel unit in a separate room, the length of the hot water circuit increases significantly, an additional circulation pump is installed on it. This will eliminate the need to drain cold water while waiting for hot water to flow.

Before installing the boiler, be sure to provide space for the expansion tank and not forget about devices designed to reduce pressure in the system in critical situations. A simple strapping diagram that can be used as a working design is shown in our drawing. It combines all the equipment discussed above and ensures its correct and trouble-free operation.

You will learn even more information about the arrangement of the boiler room and installation of equipment from our article:.

Installation and connection of a solid fuel heat generator

After carrying out all the necessary calculations and preparing the equipment and materials, installation begins.

- The heating unit is installed in place, leveled and secured, after which the chimney is connected to it.

- Heating radiators are mounted, a heat accumulator and an expansion tank are installed.

- A supply pipeline and a bypass are installed, on which a centrifugal pump is installed. Ball valves are installed in both sections (direct and bypass) so that the coolant can be transported by forced or natural means.

We remind you that the centrifugal pump can only be installed with the correct orientation of the shaft, which must be in a horizontal plane. The manufacturer indicates diagrams of all possible installation options in the product instructions.

- The pressure line is connected to the heat accumulator. It must be said that both the inlet and outlet pipes of the buffer tank must be installed in its upper part. Thanks to this, the amount of warm water in the container will not affect the readiness of the heating circuit. We definitely note the fact that cooling the boiler during the reboot period will reduce the temperature in the system. This is due to the fact that at this time the heat generator will work as an air heat exchanger, transferring heat from the heating system to the chimney. To eliminate this shortcoming, separate circulation pumps are installed in the boiler and heating circuits. By placing a thermocouple in the combustion zone, you can stop the movement of coolant through the boiler circuit when the fire dies out.

Installing separate pumps on the boiler and heat exchange circuits can solve the problem of heat leakage through the boiler when it cools down

- A safety valve and an air vent are installed on the supply line.

- Connect the emergency circuit of the boiler or install shut-off and control valves, which, when the water boils, will open the main line for its discharge into the sewer and the channel for supplying cold liquid from the water supply.

- Install a return pipeline from the heat accumulator to the heating unit. A circulation pump, a three-way valve and a settling filter are installed in front of the boiler inlet pipe.

- An expansion tank is mounted separately on the return pipeline.

Note! Shut-off valves are not installed on pipelines that are connected to protection devices. These areas should have as few connections as possible.

- The upper outlet of the heat storage tank is connected to a three-way valve and the circulation pump of the heating circuit, after which the radiators are connected and the return pipeline is installed.

- After connecting the main circuits, they begin to install a hot water supply system. If the heat exchanger coil is built into a buffer tank, then it will be enough to simply connect the cold water inlet and the outlet to the “hot” line to the corresponding pipes. When installing a separate indirect heating water heater, use a circuit with an additional circulation pump or three-way valve. In both cases, a check valve is installed at the cold water supply inlet. It will block the path for heated liquid into the “cold” water supply.

- Some solid fuel boilers are equipped with a draft regulator, the function of which is to reduce the flow area of the blower. Due to this, the air flow into the combustion zone is reduced and its intensity, and, accordingly, the temperature of the coolant is reduced. If the heating unit has this design, then install and adjust the drive of the air damper mechanism.

Installing an automatic draft regulator will allow you to control the fuel combustion process

The places of all threaded connections must be carefully sealed using plumbing flax and a special non-drying paste.

After installation is completed, coolant is poured into the system, centrifugal pumps are turned on at full power and all connections are carefully inspected for leaks. After making sure that there are no leaks, fire up the boiler and check the operation of all circuits at maximum modes.

Features of integrating a solid fuel unit into an open heating system

The main feature of open heating systems is the contact of the coolant with atmospheric air, which occurs with the participation of an expansion tank. This container is designed to compensate for the thermal expansion of the coolant that occurs when it is heated. The expander is installed at the highest point of the system, and in order to prevent hot liquid from flooding the room when the tank is overfilled, a drain tube is connected to its upper part, the other end of which is discharged into the sewer.

Open type expansion tank design

The large volume of the tank forces it to be installed in the attic, so additional insulation of the expander and the pipes suitable for it will be required, otherwise they may freeze in winter. In addition, you must remember that this element is part of the heating system, so its heat losses will lead to a decrease in the temperature in the radiators.

Since the open system is not sealed, there is no need to install a safety valve or connect emergency circuits. When the coolant boils, the pressure will be released through the expansion tank.

Special attention should be paid to pipelines. Since the water in them will flow by gravity, the circulation will be influenced by the diameter of the pipes and the hydraulic resistance in the system. The last factor depends on turns, narrowings, level changes, etc., so their number should be minimal. In order to initially impart the necessary potential energy to the water flow, a vertical riser is installed at the outlet of the boiler. The higher the water can rise along it, the higher the coolant speed will be and the faster the radiators will warm up. For the same purposes, the return inlet should be located at the lowest point of the heating system.

Finally, I would like to note that in open systems it is preferable to use water rather than antifreeze. This is due to higher viscosity, reduced heat capacity and rapid aging of the substance upon contact with air. As for the water, it is best to soften it and, if possible, never drain it. This will increase the service life of pipelines, radiators, heat generators and other heating equipment several times.

Pay attention to the article on choosing coolants for heating systems:.

Installation features

As we have already said, when connecting electric heating in a wooden house, you must adhere to several important requirements, namely:

- When heated, wood can dry out and crack, so avoid direct contact with the heat flow on the walls and ceiling. It is best to point the devices towards the floor and towards the center of the room.

- If you decide to use radiators, their installation in a wooden house also has its own peculiarities. Over time, wood shrinks. If you do not provide special compensators on the risers in the design of the house, during shrinkage the heating main may be disrupted and fail.

- The power cable from which the electric boiler (or boiler) will be powered must be able to withstand current loads with a reserve. Otherwise, ignition may occur from spontaneous combustion of the electrical wiring. To prevent this from happening, calculate the cable cross-section based on power.

- When using UV intensifiers, place them in such a way as to prevent direct (or very close) contact of the heating element with other objects.

General requirements

To avoid problems with reliability and efficiency, it is recommended to follow some instructions:

- Insulating the risers will maintain the original temperature of the coolant and help reduce fuel costs.

- If the total length of all pipes does not exceed 30 meters, efficient water circulation can be achieved naturally. If the pipes initially have a large diameter and length, additional installation of a circulation pump is strongly recommended, since friction reduces the flow rate.

Useful tips

In addition to the basic rules and regulations, there are small nuances that can, one way or another, deepen knowledge in the issue of arranging heating in a dacha, and as a result improve the final result.

- The heating speed directly depends on the heat retention in the room. Unfortunately, a house is not a thermos and there are weak areas in it that contribute to heat loss. The most vulnerable place is a cold wall, because up to 40% of the heat escapes through it, followed by doors and standard double-glazed windows - up to 20%, and the least vulnerable floor - up to 10%. If you insulate them during the warm period, this will not only affect the heating rate upon arrival at the dacha, but will also save money on fuel and, over time, will fully pay for the insulation.

- The most cost-effective source of heat is gas. If there is a main line, it should be preferred as a fuel for the heating system.

To find out how cheaper it is to heat a country house, see the following video.

Country cottage

The dacha is located in a rural area or cottage settlement. It is an ordinary house with all amenities. It is used as a place where people permanently live if gas is available. In such a situation, the problem of installing country heating can be solved quite simply. A conventional water type of heating for a country house is possible. If desired and possible, heated floors will add convenience.

Heating system with warm floor

One- or two-pipe heating

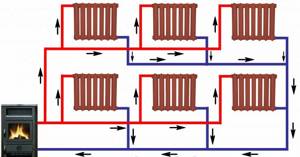

Single pipe system

This design of the heating system is made in the form of a closed ring with heating devices connected in series. As the coolant passes through the radiators, it gives off heat and moves further until it reaches the last of them. After which the liquid is returned to the boiler. This system is used for heating buildings with an area of no more than 100 sq.m.

Single pipe system

The cost of installing a single-pipe heating system is not high and is not complicated. It does not require a large amount of materials to create it.

The serial connection of heating devices leads to the stoppage of the entire system if one of its elements fails. The large length of the pipeline leads to significant heat losses. To regulate the heat transfer of radiators, the purchase and installation of additional thermostats is required.

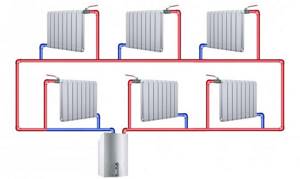

Two-pipe system

This heating scheme can be used to heat houses with different areas and number of floors. It consists of two pipeline lines. One of them serves to supply coolant to heating devices, and the other to drain liquid from them.

Two-pipe system

This design has a number of advantages compared to a single-pipe system. In this case, it is possible to regulate the supply of coolant to each radiator individually, which allows you to create a uniform temperature regime in the rooms. It is also possible to install modern radiators. A breakdown in one section of the structure does not stop the operation of the entire system.

The cost of constructing a two-pipe heating system in a country house increases significantly. This is due to increased labor intensity of installation and a greater need for materials. However, despite the increase in the length of the pipes, this disadvantage is compensated by a decrease in their diameter, which reduces costs.