Boiler room in the garage: is this option possible? This question interests many owners of this utility room. In principle, it can be resolved positively, because modern boilers, if all requirements are met, are considered safe; their installation is allowed even in basements and attics. Another thing is that amateur performance should not be allowed, but standard equipment should be used. Otherwise, such installations can lead to big trouble. In addition, most types of boiler rooms are installed if permitted by the relevant organizations.

Types of boilers

First, it’s worth considering what types of boilers there are.

- Gas boilers - it is advisable to purchase when in the utility room there is a possibility of diverting a pipe from the gas main. This fuel is considered the most budget-friendly. The heat carrier is a liquid that is heated by the boiler. Heating is provided by the convection method using a fan.

- Electric boilers - it is advisable to install them in a room where the coolant is heated by electricity. The operating principle of such a device is that the liquid in the heat exchanger is heated thanks to electric heating elements.

Types of boilers

What heating system should I install in my garage? It should be the owner's choice. It is necessary to choose the most practical and effective option. It is worth considering the following factors:

- ease of installation and maintenance;

- type of fuel used;

- cost of equipment.

When using a garage space only as a workshop and periodically visiting it, it is advisable to install a heat source without a heating system, the main task of which will be to quickly heat the room. In this case, it is advisable to use available inexpensive fuel.

For seasonal heating of premises, the following types of heating are usually used:

- gas;

- electrical;

- solid fuel;

- liquid;

- combined.

These systems can be used to heat a garage, but the cost of operating some heat sources will be excessively high, which means that the feasibility of their use is low.

Choosing the “right” gas boiler

You can purchase a suitable gas boiler yourself. It is worth paying special attention to each component of the equipment. In particular, this applies to the body material itself, the chimney (if there is one), as well as the ignition system. In addition, you need to find out which gas connection option is available.

The most popular devices are boilers made of cast iron and steel. If you choose between the two, preference should be given to the latter, since cast iron is considered a rather heavy metal. A convenient boiler is one that has an electric igniter installed.

Particular attention should be paid to the chimney. Since combustion products are aggressive, this part must be made of durable material. Alloy steel is considered the ideal option. However, there is equipment where there is no chimney as such (the device is equipped with fans).

Gas heating of a garage - nuances of technology and safety

Heating in the garage has long become quite important and, one might say, a pressing issue for a significant number of car owners. Most of us know that starting a car in a frozen garage overnight can require a significant amount of time, effort and nerves. And the solution, it would seem, is quite simple - just make a small heating system in the garage, which will maintain a room temperature of +5-+10° around the clock.

But the question arises - how to do this if, of all the modern “benefits”, only electricity is present in the garage. And even then not always. In fact, there is still a solution - you can heat the garage with gas.

How is this possible?

Heating a garage with gas is very common. And the reason for such popularity lies in the very affordable cost of the fuel itself.

But at the same time, several problems may arise:

- Difficulties with connection - it is not always possible to connect to the gas main, from where fuel will flow into your heating system. You can use gas cylinders, but then the cost of heating will increase significantly.

- Difficulties may arise because the connection of gas equipment must be handled by representatives of a special service. And they won’t connect anything until you fulfill a rather lengthy series of requirements. However, in fairness, it should be noted that all requirements require maximum security – that is, they are completely justified.

- Depending on the heating equipment you choose, you may need an additional room or a large cabinet where it will be installed.

Heating principle

Gas heating of a garage can be implemented in several ways:

- installation of a special gas boiler;

- use of a gas gun;

- using a burner powered by liquefied gas.

Let's consider each of these types in more detail.

Heating using a boiler

Boiler-based heating system

A special gas boiler is installed as a garage heating element if it is possible to supply water.

In fact, you will be able to create a full-fledged heating system with a boiler, pipes and a radiator in a small room. Since the room is quite small, it is possible to create a heating system with natural coolant circulation.

Installing a gas boiler requires:

- Availability of supply and exhaust ventilation.

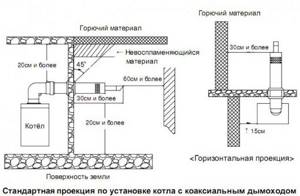

- A separate room with an area of at least 4 square meters, the walls of which are made of non-hot material. The room must have an outward opening door, the width of which is at least 80 cm.

- Special permission from gas service employees.

On the one hand, creating a full-fledged heating system with a gas boiler makes it possible to heat the garage with high quality. But a significant number of requirements and conditions for implementation make such heating not the most profitable.

We use a gas gun

A gas gun from Ballu will serve you for a long time and reliably

Heating a garage with a gas gun is more acceptable and affordable for most motorists.

In fact, such a gun is an analogue of an electric one. But the difference is that the cost of gas used for heating is much lower than the cost of electricity.

The principle of operation of the gun is quite simple. The gas supplied from the cylinder burns in a small burner, while the generated heat, with the help of a small fan, spreads quite quickly throughout the room.

Read about the operating principle of such equipment here: https://kvarremontnik.ru/gazovye-teplovye-pushki-ot-ballona/

The advantage of using a gas gun, in addition to the low price of the fuel used, is that it makes it possible to warm up the room quickly enough. On the other hand, the disadvantage of a gun is that the combustion products released during gas combustion remain in the room. That is, regular ventilation is required.

A gas burner can also become a high-quality and reliable source of hot air for heating a garage.

There are several types of such equipment on the market today:

- Catalytic heaters - gas burns in ceramic honeycombs, and the generated heat spreads throughout the room. The operating principle of this type of heater is very simple, and its advantage is that more than 90% of the waste resulting from gas combustion is neutralized.

- Infrared heaters - they also consist of a burner and a panel with ceramic honeycomb. During the combustion of gas, the honeycombs heat up, gradually releasing heat into the air. The disadvantage of such a heater is the release of combustion products into the room air. That is, again, regular ventilation is required.

You can heat a garage with approximately this type of gun. The video below shows a detailed review of the GAS HEAT 50. Interestingly, the efficiency of this device is almost 100%. Another advantage is that there is no need to make a ventilation system, which we wrote about above, since, unlike liquid fuel guns, this device runs on propane and does not emit odor or smoke. In a word, we recommend watching this review.

Features of gas heating

Gas heating is undoubtedly a very economical way to heat a garage. But the savings are obvious only if a direct connection to the gas main has been made. But heating a garage with gas from cylinders cannot be called economical. But if you decide to use cylinders, then be prepared for the fact that you will have to change them quite regularly.

In some cases, it may take up to 2-3 cylinders per week. This causes a lot of inconvenience, since it requires spending time purchasing cylinders.

In addition, they require special storage conditions in accordance with fire safety rules; the gas cylinder must be located in a locked metal cabinet, which is located far from the heating element. In addition, in winter the closet must be insulated.

Conclusion

Each owner must decide for himself what type of heating to choose for heating the garage. It is important to first understand for yourself all the advantages and disadvantages of suitable methods. Gas equipment, on the one hand, fits perfectly. But one should take into account the fact that the use of gas always involves the possibility of fire.

We hope that the article was useful to you. We will be very grateful if you share it on social networks. The buttons for this are located a little lower. We also invite you to join our VK group.

kvarremontnik.ru

Setting up a boiler room in the garage

Next, we suggest finding out how to organize a boiler room in a garage.

Layout of accommodation

It is better to install a gas boiler in a separate building, the area of which is at least four square meters. There is also a requirement for ceilings - they must be more than two meters. As for the width of the door, its size should be 80 centimeters and above. In addition, the room should be ventilated and have a window that would provide natural light in the room during the day.

It is recommended to build a boiler room at a relative distance from a residential building for several reasons. Firstly, so that the noise from work does not disturb the household. Secondly, the boiler room is a fire hazardous facility .

Preparatory work

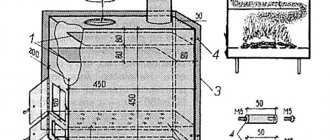

First of all, the walls in the garage need to be finished with heat-resistant material. If it is necessary to install a chimney, the pipe is installed above the level of the garage roof, approximately one meter. In addition, it is worth considering how many bends are present on the pipe. So, the lower this figure, the better, since otherwise the substances that are released during combustion will settle on the sections. As a rule, to equip a chimney, a pipe with a diameter of 130 millimeters is taken.

The area of the roof where the connection to the chimney occurs must be protected with fire-resistant material. Take something like galvanized steel.

Ventilation arrangement

To ensure the safe operation of a boiler room in a garage on your own site, you will need to ensure there is a good ventilation system that can cope with the removal of harmful gases from the room.

For these purposes, the owner must correctly calculate the required fan performance.

Fan power is calculated using the following formula:

- M – fan power;

- S – building area;

- H – building height.

This formula includes the fact that the air in the room is renewed on average in 12 hours, and the minimum power reserve of the equipment is estimated at 30%.

Installation of a heating boiler in a garage

For garages, wall-mounted or floor-mounted boilers are often purchased. The equipment is installed on a brick (concrete) stand.

Do not forget that before installation work the walls are treated with a material that is resistant to fire.

The boiler is fixed horizontally and vertically. Walls and other objects in the room should be 30-50 centimeters away from the device.

Connecting the device to gas and water

After the installation work is completed, the boiler is connected to gas and water supply. Water is supplied to equipment standing on the floor from above or to the side. In the version with a wall-mounted boiler, communications are connected to the transverse side.

Also, the remaining components of the device must be installed. In that situation, if there is no need to purchase an electric pump for the room, the pipes are laid with an inclination of five millimeters (per meter of length). Otherwise, there will be difficulties with circulation in the heating.

System startup and testing

After completing the manipulations to connect the device to the water supply system, the boiler is started in order to check the tightness of the connections. If the test run is successful, the boiler is connected to the gas pipeline.

Gas heating equipment belongs to the category of high-risk devices, therefore its installation is clearly regulated and controlled by relevant standards and authorities. To install a gas boiler in a private house, it is necessary to comply with the requirements for the room, the location of the boiler in it, the requirements for ventilation and the chimney.

The installation of the boiler itself can be carried out independently, however, only the local gas service has the right to carry out acceptance and commissioning (connections to the gas main and commissioning). Before this, it is necessary to obtain permission, draw up a project, and conclude a contract for servicing the boiler unit.

Features of garage gasification

According to SNiP 2.04.08-87 “Gas supply” in clause 6.32, gas equipment can be placed in buildings located separately from residential buildings or adjacent to them. Owners obtain permission from design organizations.

The authorized structure takes into account the availability of a gas line for the implementation of such intentions, and geographical factors of the area. The same criteria apply to rooms in individual buildings as for living rooms. The feasibility of projects and calculations depends on the gas operating specialized company.

In case of problems with conventional gasification, there is an option with an autonomous supply from a gas holder; this is an ideal solution for a garage remote from main pipes

The connecting branch to a non-residential premises or a building under construction is installed according to an individual project based on an agreement between the owner of the property and the gas service. The active process starts after the customer receives technical specifications (TS).

In this sense, the procedure is as follows:

- Submit a request for the preparation of technical specifications.

- Get TU.

- Draw up a written application for the agreement on accession to communications.

- Sign the document to connect.

- Obtain a warrant to put a non-residential building into operation.

- Sign the act of connection to gas communications.

The operational features of garage premises and their compatibility with gas appliances raise the need for regulation and standardization.

Garage owners install gas boilers, stoves, burners, gas heat guns, but this may be hampered by the small size of the buildings, the lack of windows and other rooms besides the main one.

The principle of operation of a gas heat gun is to take in air and warm it up, so that the room will be evenly filled with warm air

You should not strive to gain access to the main pipe in any case, because there are also alternatives with cylinders and tanks for autonomous gasification.

Regulatory documents and supervisory authorities

All rules and requirements for installing a gas boiler in a private house are specified in:

- SNiP 41-01-2003 “Heating, ventilation and air conditioning”;

- MDS 41.2-2000 “Instructions for the placement of thermal units intended for heating and hot water supply of single-family or semi-detached residential buildings”

- SNiP 42-01-2002 “Gas distribution systems”;

- SNiP 21-01-97 “Fire safety of buildings and structures.”

It is not necessary to study the entire list of documents in detail. In this article we will outline all the most necessary requirements for the room, ventilation and chimney. Compliance with the requirements is checked by specialists from the local gas service, usually Gorgaz, less often Oblgaz or Raigaz.

It is at the local gas service that you need to draw up all the necessary documents (more on them later), conclude a contract for servicing the gas boiler, invite their specialists to check for compliance with the requirements, connect the boiler to the gas main, set it up and start it up for the first time.

Please note that the first start-up must also be carried out exclusively by certified gas service specialists, who will put the appropriate stamp in the boiler passport: without it, manufacturers usually refuse warranty obligations.

Organization of the gas system

To properly organize the gas system, gas consumption is calculated. Gas consumption is calculated based on the heated area. The number of cylinders is calculated from the volume of gas consumed. But no more than 6 pieces. in one system. The cylinder system is connected using a ramp, which ensures a safe and stable supply of gas to the gas boiler.

The cylinder system is located in a metal cabinet at a distance of at least 0.5 m from the house. Ventilation holes are drilled at the top and bottom of the cabinet. The cabinet must be freely accessible. It is recommended to place a cabinet with a balloon system on the north side of the house.

Types and characteristics of liquefied gas

Natural gas was used for heating premises; difficulties with its storage prompted the invention of liquefied gas. It is a mixture of propane and butane. Liquefied gas is more convenient to store and transport.

The advantage of liquefied gas

- The production of a gas mixture is not technically complex or costly.

- The gas mixture is environmentally friendly due to low-contamination waste substances.

Disadvantages of propane-butane mixture

- when filling cylinders at gas stations, there is a possibility of filling them with low-quality gas;

- cylinders are changed manually;

- the liquefied gas mixture is explosive, safety precautions must be observed;

- To ensure that the mixture burns completely, the place where the cylinders are stored is ensured with proper ventilation.

Features of choosing a boiler using bottled gas

Houses are heated by three types of gas cylinders:

- Single-circuit boiler.

- Double-circuit boiler.

- Condensing boiler.

A single-circuit boiler is manufactured with a closed combustion chamber. The boiler flame is enriched with oxygen located inside the room. Waste materials exit through the chimney.

A single-circuit boiler is designed for heating a room. Such boilers are installed if the problem with hot water is solved.

Double-circuit boilers are designed for heating and hot water supply at home. The heater operates due to the operation of 2 burners. They are ignited using an igniter with built-in piezoelectric elements. After the pilot light ignites, a temperature sensor is included in the process, which is activated when a certain temperature is reached and closes the combustion chamber. Waste materials exit through a chimney or ventilation. Double-circuit gas boilers running on bottled gas are a convenient option for solving the problem of heating and supplying hot water.

A condensing boiler provides the home with heat and hot water. Cold water entering the heat exchanger is heated by a burner and hot air. After this procedure, part of the water is used for heating the house, the other part of the water is used for household needs. After completing the full cycle, the water from the radiator returns to the heat exchanger.

The bottled gas condensing boiler is available in two types:

- floor-mounted boiler;

- wall-mounted boiler.

Exhaust gas products exit through the chimney to the outside.

Requirements for the premises for installing a gas boiler in a private house

In accordance with the standards SNiP 42-01 and MDS 41.2-2000, the room in which the gas boiler is installed must meet the following minimum parameters:

- room area – more than 4 square meters;

- ceiling height – at least 2.5 m;

- room volume - at least 15 m 3 (when placed in the kitchen there are differences described below);

- the presence of a door with a doorway width of at least 800 mm; according to fire safety, the door must open outward;

- presence of a gap under the door of at least 20 mm;

- the presence of natural light (through a window) at the rate of 0.03 m2 of glazing area for every 1 m3 of room volume (for example, for a room with a volume of 15 m3, the glazing area is 0.03 * 15 = 0.45 m2);

- the presence of ventilation in the boiler room based on - exhaust in the volume of 3 air changes per hour, air flow - exhaust volume + air required for gas combustion (if the boiler has an open combustion chamber. If there is a closed combustion chamber, combustion air is not taken from the room, and through a coaxial chimney);

- walls separating the room from neighboring ones must have a fire resistance limit of at least 0.75 hours (REI 45) or be covered with a structure with the same fire resistance limit, the fire spread limit must be zero (non-combustible materials);

- the floor in the room is horizontally flat, made of non-flammable material.

In addition to the requirements for the room, to install a gas boiler, the location standards (described below) and the chimney parameters must be met at the same time. Volatile wall and floor models must be reliably grounded (point-to-point or connected to the house ground loop).

How to choose a room thermostat and save up to 30% per month on heating

Current standards for installing a boiler in the kitchen

According to MDS 41.2-2000, boilers with a power of up to 60 kW are allowed to be installed in the kitchen. Gas service workers can often refer to other regulations that indicate a maximum permissible power of 35 kW, so before installing a 35-60 kW boiler, consult your local gas service. Only the power of heating equipment is taken into account; other gas appliances are not taken into account. Otherwise, in addition to the above requirements for a separate room, there are some differences when placed in the kitchen:

- the minimum volume of the room is at least 15 m 3 + 0.2 m 3 for every 1 kW of boiler unit power (for example, when installing a 24 kW boiler, the volume of the room is 15 + 0.2 * 24 = 19.8 m 3);

- the window must be openable or equipped with a window;

- the presence of a gap necessary for air flow in the lower part of the door with a cross-section of at least 0.025 m 2 (Section = Width * Height).

Proper organization of an extension for a boiler room

If it is impossible to allocate a separate room for a boiler room, and you do not want to install a boiler in the kitchen, the boiler room is simply attached to the external wall of the house. Extensions are also relevant in wooden houses, when, after providing the walls with a fire-resistant structure, the dimensions of the room will not meet the minimum standards. The same requirements apply to the extension as for standard boiler rooms, but with some additions:

- the extension must be officially registered; without registration, the gas service simply will not allow connection;

- the boiler room is attached to a blank wall, at a distance of at least 1 meter from the nearest windows and doors;

- the walls of the extension should not be connected to the wall of the house;

- the walls of the extension and the wall of the house itself must meet a fire resistance limit of at least 0.75 hours (REI 45).

Types of heating devices

Heating gas is used in the following ways:

- Full heating with boiler. It heats the water circulating through the pipes. Gas service workers themselves must connect the system to the main wire. To do this, you will need to sign the relevant documents and pay the price for the insert.

- Boiler for heating air. Heating in this case is carried out using a heat gun. With this method, the gas burns out in a burner, and heat fills the room through a fan.

Gun for organizing garage heating

- Condensing boiler - economical heating of a garage space. The efficiency is approximately 10% greater compared to conventional gas ones.

The first method is the most difficult, since it takes time to collect, prepare documentation, create a project, and install heating. In addition, you should select, buy, and install a boiler.

For the second method, no special equipment is needed; it is enough to use liquefied gas from a cylinder.

Gas-burner

A burner is an easy way to heat a garage; it is the most affordable method that helps maintain a comfortable temperature in a small room. The burner is easy to operate and meets heating needs even in winter.

There is no need for a chimney under the burner, because during operation it does not release harmful impurities into the space. But a constant supply of fresh air is important.

The burner is an infrared heater, so the heating does not spread in a narrow direction. This is extremely convenient if you need to stay warm and quickly warm up your work area. For uniform heat distribution, you will need to wait about 30 minutes - depending on the power of the device. Fuel consumption (in this situation, gas) is minimal. One cylinder is enough for several days of operation of the device.

Gas-burner

Do not leave the burner on unattended. In other cases, this is a simple, accessible and economical method.

Gas gun

A good heating method is using a gas gun. You just need to choose the right power of the device, this will allow you to maintain highly efficient heating.

The principle of operation of the gun is similar to the operation of a hair dryer. The basis of the device is a fan, the degree of heating is changed by a thermostat located on the body. The fan helps create a directed flow of air passing through the heating element. The heated air flows out, and the gun absorbs a new portion to warm up.

For garages, it is better to purchase a mobile cannon with wheels so that you can always move it to the right place. When using, please note that the device should not be constantly turned on. The garage only warms up to the desired temperature, then the gun is turned off. An important advantage of the device is its efficiency, because only 500 ml of liquefied gas is consumed per hour.

For maximum efficiency of the device, it is important to decide on the choice of a model that is suitable in terms of power. The performance of the device is calculated: 1.4 kW of power for every 10 square meters of room area, if the ceiling height is approximately 2.5 m. Typically, 3 kW of power is enough for a standard garage.

If there are often frosts in your region of residence, you should buy a gun with a capacity of 5 kW. The disadvantage of the device is poor environmental friendliness, because during combustion it releases toxins into the environment.

Gas heater

A heater that runs on bottled or natural gas can be mobile or stationary. Mobile devices are small in size and benefit from their local heating. Stationary devices can operate from the main wire or from a cylinder.

There are no special devices designed only for garages. You should choose taking into account the available assortment. For a garage space, 4 different types of gas heaters are suitable.

Heater

The devices and functions of each are interconnected, because heating in them is carried out according to similar rules:

- first, gas is supplied to the combustion chamber;

- at this stage the gas is ignited using a piezoelectric element;

- fuel combustion products enter the chimney through a special pipe - this is how stationary models are designed;

- heat during combustion affects the heating element, heats it up; the heating element can be ceramic or steel.

Subsequently, the process differs depending on the type of device.

Gas convector

When there is no water in the garage, there is no possibility of connecting to the main line through which gas passes, then the best choice is heating through a convector. For a room of a standard area, just one convector is enough. It economically consumes gas from the cylinder, requiring less costs in contrast to the column or boiler.

During the installation process, you will only need to spend money on a good convector, because radiators and water pipes are not needed. It is better to mount these devices on a vertical wall that is not located adjacent to other buildings.

This placement will help create high-quality heating and safely place the cylinders outside the garage room on the street. The optimal solution is to install the cylinders in a special metal box near the wall, behind which the convector will hang. When all the walls are located adjacent to adjacent buildings, the solution is to place the box with cylinders inside the room, but as far as possible from electrical appliances. There must be holes made in it for ventilation.

A gas boiler

The efficiency of many modern boilers is close to 100%. These are economical devices. For example, a top class boiler is characterized by an efficiency of 94-96%. The efficiency of a middle class boiler is 70-90%. The cost of premium equipment is an order of magnitude higher than average.

Boiler

Professionals advise not to focus on price; you should not purchase the most affordable models, since the difference in price will quickly pay for itself during operation. A cheap boiler will need to be replaced after a couple of years or constantly spend money on repairs and constant maintenance. As a result, the total costs will be much higher in contrast to premium models.

The service life of boilers in the middle price segment is 10-15 years, but more expensive options will last at least twice as long.

The purchased model must be equipped with automatic control. Modern boilers are easy to use, they are completely safe, reliable, and are distinguished by the ability to set a comfortable temperature regime. You can choose even the smallest gas boiler, but it is still very powerful.

Where you can and where you can’t place a gas heating boiler

The most common and suitable accommodation options are a kitchen or a separate room:

- on the first floor;

- on the ground floor;

- in the basement of the house;

- in the attic.

As for the corridor, hallway, veranda and other similar premises: in more than 90% of cases they do not comply with the requirements of SNiP 42-01 and MDS 41.2-2000, as well as the manufacturers’ requirements for the distance from the boiler to the nearest objects specified in the installation instructions allowing for maintenance.

– Is it possible to install a gas boiler in the bathroom?

No, it's not possible. The opinion is becoming increasingly widespread that gas boilers with a closed combustion chamber do not take air from the room, and therefore can also be installed in the bathroom. Firstly, this still does not comply with SNiP standards, so the gas service is almost guaranteed to prohibit this location option. Secondly, even if the combustion chamber is isolated from the room, the high humidity characteristic of the bathroom will greatly reduce the service life of other metal elements of the boiler, especially electronics.

Installation of a gas wall-mounted boiler - kitchen requirements

- Ceiling - 2 meters and above.

- The total volume of the kitchen is more than 7.5 m3, ventilation is equipped, a window is installed and there is a door opening onto the balcony.

- For air exchange, it is necessary to install a grille at the bottom of the wall or door that opens into the next room; the area of the grille is at least 0.02 m2.

If the kitchen in the apartment does not meet the requirements of SNiP, then gas heating equipment can be installed and operated only with the permission of the gas supervision authority.

It is strictly forbidden to install more than 2 heating devices or more than 2 boilers in one room if the volume of the room is less than 7.5 m3

The existing rules for installing a gas boiler in a private house largely repeat the requirements for boilers that operate in apartments in multi-storey buildings. The differences are caused only by the fact that often in a private house a separate room or building is allocated for heating equipment, which is subject to additional requirements listed below.

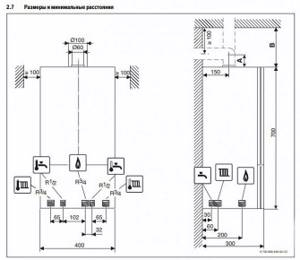

Requirements for the location of the boiler

In the installation instructions, manufacturers usually indicate the minimum required clearances and distances required for normal maintenance or repair of the boiler unit. For example, such requirements are presented in the passport of the famous Buderus Logamax U072-18K (see photo below).

Requirements for distances in the instructions for the gas wall-mounted Buderus Logamax U072-18K.

Minimum distances often differ depending on the model, but on average you need to calculate:

- a gap between the boiler and the wall of 2 cm (usually provided by standard fastening);

- free space of 1 meter in front of the boiler front panel;

- free space of 80-150 cm to the left and right of the boiler;

- a distance of no less than 150 cm to the ceiling;

- the wooden wall must be insulated with non-combustible material or metal sheet with a thickness of at least 3 mm;

- the wall must withstand a load of 35-70 kg (depending on the model), otherwise it must be strengthened.

Both floor-mounted and wall-mounted models are mounted on mounting kits supplied with the boiler from the factory. There are no special requirements for fastening; as a rule, the manufacturer has already calculated the minimum required structure and its strength, so it is enough to use the factory fastening.

DIY garage heating: classic water design

One of the methods of heating a garage structure involves the use of heating devices in which water is the coolant. This method does not require the organization of a separate system. This is an absolute advantage. However, it should be remembered that in this case an additional load is formed that affects the general heating system of the house.

Water heating of a garage requires proper calculation, since adding another branch to the overall structure affects the indicators on which the heating efficiency depends. One of them is the pressure in pipes and heating devices. When choosing radiators for a garage building, it is worth remembering that they must have a certain power reserve.

The addition of an additional branch affects the consumption of fuel, which is used to generate thermal energy. Despite this, this method is more profitable from a financial point of view than many others.

When choosing radiators for a garage building, you need to take into account that they must have a certain power reserve

The easiest way to organize heating of a garage structure is when the building is located in close proximity to a residential building - at a distance of no more than 15-20 m. For water heating in the garage, one radiator is enough. The number of sections is selected depending on the following factors:

- average annual temperature in the region;

- garage dimensions;

- construction material.

As practice shows, to organize normal heating you need a radiator containing from 6 to 20 segments. However, exceptions are possible if the dimensions of the garage are large or the structure has an unusual layout.

Water heating of the garage: installation of a separate boiler

There is a second option for organizing water heating of a garage space. It involves the installation of a separate heating device. This method is recommended by experts when the garage structure is located at a considerable distance from a residential building.

When installing water heating in a garage with your own hands, you should understand the principle of operation of the design

Many experts recommend using antifreeze when installing a separate heating device in the garage. This coolant eliminates the possibility of the system freezing. For regions with cold winters, this option is the most acceptable. If desired, you can choose another coolant. For example, heating in the garage using antifreeze is popular. Making such a system with your own hands is not difficult, you just need to follow the instructions.

When installing water heating in a garage with your own hands, you should understand the operating principle of the structure. Otherwise, self-installation may be difficult. A heating device is necessary to heat up the coolant. After the coolant reaches the desired temperature, it is transported through pipes to the battery. Then it gives off heat to the environment, cools down and returns to the boiler.

To organize normal heating, you need a radiator containing from 6 to 20 segments

Radiators are connected to the boiler according to two schemes. One of them is parallel, and the second is serial. The type of connection depends on the number of pipes coming from the battery. The parallel option ensures uniform heating of each radiator installed inside the garage building. It uses two pipelines. The second option involves installing a single-pipe system, which is more acceptable in such conditions.

Other advantages of the serial connection type include ease of installation and lower financial costs for materials. When organizing heating of a garage with your own hands according to this scheme, it is necessary to take into account that in each subsequent radiator the coolant temperature will be lower than in the previous one.

Many garage owners make their own boilers. This significantly reduces financial costs, but increases the labor intensity of the work. In this case, old radiators and pipes are suitable for the heating system. It is customary to use plastic containers as expansion tanks.

Radiators are connected to the boiler in various ways.

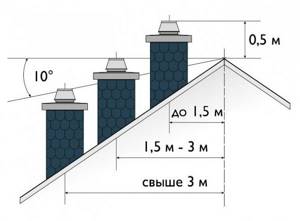

Chimney requirements

The building codes also specify the requirements for the chimney:

- the cross-section of the outlet pipe must correspond to or be larger than the cross-section of the boiler outlet pipe;

- the material of the chimney outlet pipe is stainless or carbon sheet steel, the use of asbestos and other layered materials is possible only at a distance of more than 50 cm from the boiler outlet pipe;

- gas boilers, in which the outlet pipe is located at the top, must be connected by a vertical section at least 25 cm long, only after which bends are possible;

- no more than 3 bends are allowed along the entire length of the chimney;

- there must be at least 20 cm between the chimney outlet through the wall and the ceiling;

- the height of the chimney must ensure the proper force of natural draft (see photo).

The optimal height of the chimney according to SNiP 41-01-2003.

How to choose the right gas wall-mounted single-circuit boiler

How should preparations be made for the first launch?

Before turning on the gas boiler, it is necessary to carry out preparatory work. For this:

- Completely mount the equipment, complete the wiring, and ensure proper installation.

- Do not neglect fire safety rules. Install all fasteners in accordance with them.

- Leave a small space between the boiler and the wall. This distance must be indicated in the instructions. It is not recommended to install the equipment near a window.

- Remove all flammable items away.

- Attach the boiler body evenly, without distortions.

- Connect it to a cold water supply system by removing the plugs on the pipes. At the inlet, mount a filter on which a ball valve is located. This way the system will be protected from contamination, which can lead to breakdowns. A ball valve must be installed on each piping pipe.

- Install gas pipes carefully.

- Make the outlet closer to the heating equipment. Remember that the boiler must operate from a separate power line. In some cases, it is possible to connect the equipment to a gas generator for the purpose of its autonomous operation.

- Connect the chimney pipe and check its draft.

- Fill the boiler with cold water with the power switched off. The initial set will help eliminate the presence of leaks.

- Turn the thermostat to maximum.

The procedure for obtaining permission to install and connect to the gas main

- We go to the local gas distribution organization (Gorgaz, Oblgaz, Rayongaz, etc.), fill out and submit an application for the installation of a gas boiler. As for documents, you must have your passport and any evidence of ownership of the house with you. On average, after a week, technical specifications (TU) - this is permission to install the boiler.

- In the local housing and communal services or fire inspection authorities, we find out the contacts of the organization involved in checking chimneys and ventilation ducts, and invite specialists for inspection. If the chimney meets all the requirements, experts will issue a conclusion on the proper condition of the chimney , otherwise - a list of necessary changes. In practice, this item is not mandatory in all regions and gas workers often accept a boiler without it; details can always be found in the gas service.

- After receiving the specifications, you can order a project from any of the certified bureaus or from the same Gorgaz. In addition to the specifications, the compilation requires accurate data on the models of the gas boiler and meter. It is not necessary to buy them at this stage, but you need to decide on the model for sure, since making changes to an already finished project is impossible.

- With all the documents available at this stage (specifications, design, conclusion on the condition of the chimney), we go to Gorgaz, where we coordinate the project and conclude a contract for servicing the gas boiler unit. Now you can begin installing the boiler yourself or with the help of a gas service.

- After installation is completed, all that remains is to invite the gas service to accept the work performed, connect the boiler to the gas main, and carry out commissioning work.

Registration of a gas boiler is a rather lengthy bureaucratic process, lasting on average 2-3 months. It is recommended to start registration in April-July.

Boiler room in the garage: is this option possible? This question interests many owners of this utility room. In principle, it can be resolved positively, because modern boilers, if all requirements are met, are considered safe; their installation is allowed even in basements and attics. Another thing is that amateur performance should not be allowed, but standard equipment should be used. Otherwise, such installations can lead to big trouble. In addition, most types of boiler rooms are installed if permitted by the relevant organizations.

How to connect a liquefied gas cylinder

Installing a gas boiler designed for autonomous heating with bottled gas is much easier than installing a heating system using mains fuel.

In view of this, independent installation of this unit is not recommended. It is better to invite a responsible specialist. The norms and rules for the correct installation of a cylinder are regulated by a set of fire safety requirements, which states that liquefied gas cylinders should not be located in the same room as the heating device.

Besides:

- Cylinders must be taken into an adjacent room or outside and installed in a special cabinet.

- Empty gas cylinders must be stored outside the building. It is best if you refill the containers immediately.

- If the cylinders that you installed in a cabinet outside freeze, you should insulate the storage using non-combustible thermal insulation.

- Heating containers or the cabinet itself with open fire is strictly prohibited.

- The distance between the gas cylinder and the boiler must be at least 2 m.

- Do not store propane cylinders near the boiler room.

- Storage of containers is permitted only in a specially equipped place located at a distance of no closer than 10 meters. It must have ventilation.

- It is also prohibited to use the basement for this purpose.

During the operation of cylinders, complete depletion of LPG from the container is not allowed. Every 4 years it is necessary to carry out certification of the tightness of containers and the integrity of their body.

The essence of the problem

At its core, any garage is a utility room (usually detached) of a warehouse type, but containing a car and substances belonging to the flammable category. These circumstances give rise to increased requirements for fire safety. Naturally, the question arises: is it even possible to place a boiler room in a garage?

When solving this issue, you should understand what a boiler room is and why it is installed. It is possible to set several tasks. Most often, the concept of a garage boiler room means a boiler for heating only the room itself, but sometimes a boiler room in a garage functions as a source of coolant for heating a private home. If in the first case a small standard boiler of various types is used, then in the second case fairly large areas and special permission are needed.

Gas cylinders in winter

If gas cylinders are located outside the house, then in winter at subzero temperatures the pressure of liquefied gas decreases and the boiler may simply turn off. To prevent this from happening, the cylinders are installed in a special cabinet with good ventilation, insulated with non-flammable materials. Also suitable for this purpose are detached non-residential buildings with minimal heating. When using cylinders, safety precautions should be observed:

Special cabinet for installing cylinders

- It is prohibited to heat containers with gas using open fire;

- There should not be a basement or cellar near the cylinders, since liquefied gas sinks down when leaking, has no odor and can accumulate to an explosive concentration;

- It is advisable to install a gas leak sensor;

- Storage of full containers is allowed at a distance of 10 m from the living space;

- Storing empty cylinders in the house is prohibited;

- Once every 4 years, it is necessary to check the cylinders for integrity and tightness.

How to make everything perfect?

In order for the garage boiler room not to cause criticism from regulatory authorities, the following basic principles must be taken into account during its installation:

- The room must be equipped with effective and reliable forced ventilation. The combustion products must be removed through an air duct, the outlet of which is located on the roof (at a standardized height).

- All fire safety regulations must be strictly followed. In this case, the number of boilers in the room should not exceed 4 units. with a total power of up to 190-210 kW.

- The boiler must be at least 100 cm away from the garage wall.

- The minimum size of a garage in which installation of boilers is allowed is 6.5 sq.m. with a height of at least 2 m.

- A heat-resistant, solid base (foundation) must be built on the floor under the boiler. Combustible materials must not be placed around the boiler.

- Connection of communications must be done professionally, taking into account all standards.

Increased requirements are imposed when using gas. When a gas boiler is installed in a garage, approval is required already at the design stage. Permission to divert the gas main must be obtained and standards for gas consumption must be established. Installation of gas boilers must be carried out in strict accordance with regulatory documents: SNiP 31-02-2001, DBN V.2.5-20-2001, SNiP II-35-76, SNiP 42-01-2002 and SP 41-104-2000.

Rules for installing a floor-standing gas boiler

- In a house under construction, it is necessary to plan a separate room for installing a gas-fired boiler. The room should have a natural flow of air through a grille in the door or through a hole in the wall.

- A separate hole must be made for supply and exhaust ventilation - it must be located under the ceiling.

- A hole in the wall for the chimney pipe, a hole below the chimney for a soot brush (for cleaning the chimney pipe), which is made below the main chimney by 20-30 cm.

- The chimney is made airtight so that smoke and carbon dioxide do not flow back into the room. To ensure tightness, a smaller diameter pipe is installed inside the large chimney pipe, through which gas combustion products are discharged.

- The room intended for installation and operation of a gas boiler must be spacious and provide easy access and operation, maintenance and repair of the boiler. The floor in the furnace room must be made of non-combustible materials - concrete screed, natural stone, paving stones. The furnace room must be connected to the water supply for the operation of the water heating device, and be equipped with a sewerage system.

- The area of the room for the boiler is 4 m2, the height of the ceilings in the room is at least 2.5 m2.

- The outer door must be 80 cm wide.

- The top of the chimney should be higher than the roof. The cross-section of the chimney pipe must be larger than the diameter of the boiler outlet.

- To supply power, the boiler room must be equipped with an electrical panel with grounding.

- The gas line is brought into the room in advance. A separate valve must be installed for each gas appliance.

- The walls of the boiler room are plastered - it is strictly prohibited to decorate the walls with flammable materials (MDF, fiberboard, plastic).

Types of boilers

When organizing garage heating, it is possible to use the following types of heating boilers:

- A gas boiler. If it is possible to divert the pipe from the gas main, installing a boiler running on natural gas solves all problems. Gas as a fuel is considered one of the cheapest. Water heated by a boiler can be used as a coolant. Heating can be provided by convection using fans. When installing for heating gas installations, the following advantages can be highlighted: cheap energy resources, accessibility of highways, autonomous operation, increased energy efficiency, high reliability and durability. Modern gas boilers can operate from a gas central line or from liquefied gas cylinders. The disadvantages include the need for complex coordination and increased requirements for fire safety and the ventilation system.

- Electric boiler. The easiest way is to install a boiler in the garage, in which the coolant is heated by electricity. The operating principle of this equipment is based on heating water into heat exchangers using electric heating elements. Installations of this type are small in size and easy to operate. The main advantages are complete silent operation, automatic adjustment, and the absence of combustion products. The main disadvantage is the significant increase in the cost of electricity compared to natural gas. In addition, the heating system becomes completely dependent on uninterrupted power supply, which causes certain problems, for example, in rural areas.

Requirements for heating with gas from cylinders

As an alternative, you can use bottled gas. Containers should be kept in a closed metal cabinet for storing gas cylinders.

To locate it, you need to choose a place as far as possible from heating devices and flammable appliances.

Gas cylinders in action: a quick and easy option, even taking into account the fact that you have to buy gas cylinder equipment, a reducer and shut-off valves

You cannot install a module with cylinders at floor level, because in this case it will not be possible to notice a gas leak in time and solve the problem.

Fuel boilers

The options discussed above involve connecting the equipment to centralized gas or electrical networks. What to do in the absence of highways and unreliable power supply? A mini-boiler room in a garage can be based on boilers running on liquid or solid fuel, which do not depend on the supply of centralized energy. The following settings are distinguished:

- Solid fuel boilers. A modern boiler of this type can be safely installed even in a room such as a garage. The installations are distinguished by their versatility, i.e. they are able to work on coal, peat, firewood, even construction waste and straw. It is considered optimal to use special combustible briquettes based on compressed coal dust and other components. Fuel consumption occurs in a minimum amount, which is ensured by its complete combustion. The boilers operate on the pyrolysis principle, which gives a fairly high efficiency.

- Liquid fuel boilers. They lay down an important principle of economy. They can be operated on used engine oil. This makes it possible to obtain cheap fuel and at the same time solve the issue of waste disposal.

The main advantage of fuel boilers is the absence of the need to obtain permits and the availability of fuel. An important disadvantage is the presence of a significant amount of combustion products. To remove them, you need a reliable chimney, the pipe of which should go to the roof.

We improve heat transfer

The biggest problem with potbelly stoves: inefficient heat consumption. Most of it literally flies into the chimney with flue gases. This disadvantage is effectively combated in upper combustion furnaces with afterburning of flue gases, such as the Bubafonya furnace (also, by the way, can be made from a gas cylinder) and Slobozhanka.

A variant of a potbelly stove made from propane cylinders with secondary combustion - the efficiency is higher than that of “conventional” models.

Another way to improve heat transfer is to make the chimney longer, thereby increasing the amount of heat that will remain in the room. When designing such a broken chimney, it is better to avoid horizontal sections, and even more so areas with a negative slope.

This gas cylinder stove runs on wood. We increased heat transfer by making a long broken chimney

Another option to use the heat of flue gases is to weld a vertical cylinder-smoke pipe to a horizontally located cylinder-housing. Due to the larger area, heat transfer will be higher. You just need to create good draft so that the smoke does not go into the room.

Such a potbelly stove made from a gas cylinder will warm up the room faster

You can do it the way they do in sauna stoves: put a mesh around a metal pipe and pour stones into it. They will take heat from the pipe and then release it into the room. But. Firstly, until the stones heat up, the air will warm up slowly. Secondly, not all stones are suitable, but only the round ones that are along the rivers. Moreover, they are uniformly colored without inclusions. Others cannot be filled in: they can explode from high temperatures no worse than a fragmentation shell, or emit radon, which is very harmful in significant concentrations.

The solution can be found at sauna stoves: build a grid for stones on the pipe

But this solution also has advantages: firstly, the pipe will not burn. The stones produce even heat. Secondly, after the furnace goes out, they will maintain the temperature in the room.

Often you need to quickly heat a room. To do this, you can use a regular fan that will blow through the body and/or pipe of the furnace. But the same idea can be implemented with a stationary version: weld through pipes into the potbelly stove cylinder in the upper part. On one side, attach a fan to them (heat-resistant, preferably with several speeds, so that you can regulate the temperature).

Pipes are welded into the upper part of the cylinder and pass through. On one side, a fan is attached to them, which drives air through them, quickly warming up the room.

Another option that allows you to achieve active air movement along the walls of the case and not use a fan: make a casing around the case at a distance of 2-3 cm, but not solid, but with holes at the bottom and top. Buleryan stoves or metal sauna stoves work on this principle.

One of the options for such a casing around a horizontally located cylinder is visible in the photo below. Through the gaps at the bottom, cold air located near the floor is sucked in. Passing along the hot body, it heats up and comes out from above.

This is a stove lying on its side: the casing is not solid, there are decent gaps at the bottom and top

The principle is not new, but it is no less effective. Look at the photo below to see what the finished stove looks like with such a casing.

Potbelly stove with improved convection around the body for quick heating of the room

Here is another implemented casing, around a potbelly stove made from a horizontally located cylinder

Note the non-standard door fastening

This shiny sheet improves room heating

A homemade boiler from a gas cylinder for water heating can be made using the same principle: weld a water jacket around the cylinder and connect it to the radiators. Just don’t forget that the system must have an expansion tank with a volume of 10% of the total displacement.

You now know how to make a potbelly stove from a gas cylinder and how to improve it. Watch another video about an interesting option for a combined stove for a summer house or garage made of brick and a gas cylinder.

https://youtube.com/watch?v=SMVD6li2QI4

Installation stages

To ensure safe operation of the boiler room in the garage, it is important to install a high-quality ventilation system that can remove all harmful gases from the room. To do this, you need to correctly assess the required fan performance. Its power can be calculated using the following formula: M = (SxHx12) + 30%, where M is the hood power; S is the area of the room; H is the height of the garage. In this case, the formula takes into account that complete renewal of the air volume must be ensured in 12 hours, and the minimum power reserve of the installation is estimated at 30%.

The design of the heating boiler can be single-circuit or double-circuit. In the first case, the coolant heated in the boiler is intended only for heating the room, and therefore circulates through a closed system with radiators. In the double-circuit version, an additional network is provided for obtaining hot water or removing coolant for heating another room, a house.

If the owner wishes, the boiler room in the garage can easily be installed with his own hands, but using standard equipment. When installing a gas boiler, the project must be agreed upon with the relevant authorities. The arrangement of the system must be carried out taking into account technical and fire safety requirements. After completing all these stages, you can use the installed equipment for many years and enjoy the unconditional comfort that it will give.

Choosing a liquefied gas boiler

An important criterion is power, measured in kW. The heated area is usually 9-10 times larger than this value. That is, by choosing a boiler with a capacity of 11.3 kW, you will heat a room of about 100 m2.

However, it is necessary to make an allowance for the fact that during prolonged and severe frosts, equipment of such power will not be able to maintain the set temperature. Therefore, experts recommend choosing a boiler unit with a reserve.

Other options:

- Boiler type. According to the method of installation, there are wall-mounted and floor-standing models, and according to functionality - single- and double-circuit (heat + hot water), with an open or closed combustion chamber.

- Efficiency The higher the indicator, the more economical and efficient the installation will be. The parameter varies in the range of 90-94%.

- Pressure. A unit operating on liquefied fuel must operate at low pressure (3-5 mbar). A low value will ensure that gas is produced from the cylinders without any residue.

- Gas consumption. The figures indicated by the manufacturer are conditional and depend on the power and efficiency of the unit, the set temperature in the room and outside the window, heat loss of the building and other factors.

When planning to build a house, you also need to pay attention to the design of the heating system. The right solution is to delegate the task to experienced designers who:

The right solution is to delegate the task to experienced designers who

:

- calculate the amount of heat load;

- will develop recommendations regarding the selection of heating equipment and related materials.

Knowing the required parameters of the boiler, all that remains is to choose a device based on appearance and price. Russian boilers are the cheapest. Popular Japanese-made models are twice as expensive. And the “Germans” will cost even more.

LPG boiler

Gas garage heating

Heating a garage with gas from the main pipeline can be considered the most economical in the long term. The fuel burns completely and does not pollute the environment. Unfortunately, this method is not available to all garage owners.

Anyone who has this opportunity and decides to use it must take into account several points:

- The purchase and installation of gas equipment is much more expensive than electric units;

- You cannot assemble and connect gas systems yourself. This can only be done by gas specialists. The risk when handling an explosive substance is great; it threatens not only property, but also life.

This is where gas differs from other fuels like electricity. With it it’s the opposite: the electrical appliances themselves and installation are relatively cheap, but the monthly bills are significant.

When they talk about gas heating in a garage, they primarily mean a gas boiler connected to a water network. But this is not the only way. Yes, and it is mainly used when the box is located near the house and it is possible to extend a line from the home system. Otherwise, costs may become unreasonably high.

The fastest and most efficient heating of a garage is using gas heat generators or convectors. They operate on natural methane or a liquefied propane-butane mixture. This is an analogue of an electric heat gun. The heat generator instantly warms up the air in the room, and thanks to its compact size it can be placed anywhere. True, you also need current to use it. With its help, the fan rotates and the control panel operates.

Liquefied gas cylinders must be stored in a metal cabinet. For stable operation during severe frosts, it is insulated. And get ready for the fact that you will have to change the cylinders every 2-4 days.

Heating a garage with a gas boiler has been used for a long time and is well proven by experience. The system can be installed so that the coolant circulates through the pipes by gravity - this is important for detached buildings. Pump operation leads to additional consumption of electrical energy. The system is a closed circuit consisting of a boiler, connecting pipes and radiators.

Gas boilers for garage heating come in two types: conventional and condenser. The first ones emit the steam generated during combustion out through the chimney. Some of the heat also goes away with it. A condenser apparatus can trap steam and condense it, releasing thermal energy and transferring it to water. It is clear that in this case fuel consumption is reduced.

Metal-plastic pipes are connected to each other with fittings. Do not forget that the diameter of the pipes for gravity circulation must be larger than for forced circulation.

Modern batteries are also quite easy to attach. Dowels are driven into the walls. Radiators are hung on them so that at least 15 cm remains to the floor.

Installation of any gas garage heating system requires permission from the gas service.

The most important thing is to install the boiler. The general conditions are:

- a frost-free building with a ceiling height of at least 2 m and an area of at least 4 m2;

- the room must have supply and exhaust ventilation;

- a 1 m2 window for ventilation and as a light source;

- the walls are made of non-combustible or low-combustible materials;

- a door at least 80 cm wide that opens outwards.

Additional requirements should be checked with your local gas authorities.

But even this list means that it will not be possible to place the boiler in the same box as the car. It is necessary to build a furnace extension.

Steam heating in the garage allows you to quickly and inexpensively warm up rooms of any size. In small buildings, low pressure steam is used, 0.1-0.17 MPa.

The principle of operation is similar to a water system: a boiler-steam generator produces steam, which is supplied to the radiators through a pipe system. The cooled condensate flows (or is pumped by a pump) into the receiver and from there it is again supplied for heating.

A regular hot water boiler can also generate steam if you install a storage tank with a pressure gauge on it. The steam generator can operate not only on gas, but also on other types of fuel.

With steam heating, as opposed to water heating:

- pipes have a smaller diameter;

- battery surfaces are reduced;

- the entire room is heated evenly, without the formation of stagnant zones;

- Radiators heat up much faster.

This method also has its disadvantages:

- it is impossible to control the temperature of the batteries and it can rise to 100 °C and above - this increases the likelihood of fire;

- to prevent overheating, the system must be turned off periodically;

- it is impossible to regulate the heating smoothly;

- The steam installation is noisy during operation.

The pipe layout is selected taking into account your capabilities and boiler power. By design, it can be single-pipe or double-pipe. The latter is more complex and time-consuming, but it allows you to regulate heating and control each radiator separately.

According to the type of installation, a distinction is made between a scheme with upper and lower wiring, with vertical and horizontal placement of pipes.

Which boiler to choose - floor or wall mounted:

svoygarazh.com