Despite the traditional popularity of gas and electric boilers, induction heating still occupies a significant market share and poses strong competition.

Induction equipment is positioned as an effective and economical home heating option. Previously, the installations were actively used in industry, but today they are also used for domestic purposes.

Below we will consider the principles of operation of induction heating, as well as popular myths.

Operating principles of induction heating

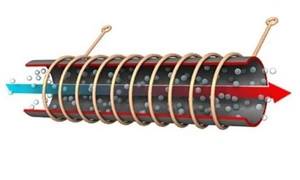

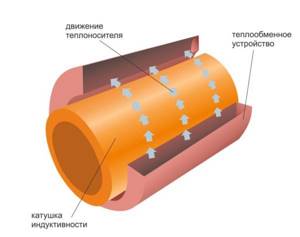

The operation of induction heating is based on the use of electromagnetic induction. Understanding the operation of the system as a whole is quite simple. To do this, pass an electric current through a coil of thick wire. As a result, an electromagnetic field begins to form around the coil.

When a ferromagnet is placed near this field, which acts as an attracting material, it will heat up very soon. Therefore, the most basic example of induction heating is a coil that acts as a heat source. The coil itself is wound on a dielectric pipe.

A steel core must be placed inside this device. When the coil is connected to an electrical source, the metal rod will heat up. After connecting the structure to the mains with circulating coolant, you will get an excellent heating method. Despite the primitiveness of this example, even homemade induction heating will function.

Working principle of induction heating

To briefly describe the principle of operation, it will require only a few judgments. Electrical energy creates an electromagnetic field. The metal core is heated by electromagnetic waves. Excess heat from the rod goes to the coolant, heating it.

The coolant in such systems can be not only ordinary water, but also ethylene glycol and oil. Due to the fact that the liquid is heated intensely, convection currents are obtained. The hot coolant rises, and its power is already enough for a small circuit to work. If the line is long, then it is necessary to install a circulation pump.

Types of induction cookers

Thanks to an induction hob, which is a type of electric kitchen appliance, metal cookware heats up quickly and safely.

Externally, it is a traditional glass-ceramic surface, but inside there are induction coils. The winding on them is made of copper wire, which conducts high-frequency current. There are no heating elements, but the device is equipped with an inverter and a fan.

There are stationary (built-in) stoves that can be combined with an oven, have more than two burners, some of them operate on the induction principle, some on electric.

The built-in panel can be separate, it can be easily installed on the countertop, and an oven can be placed under it, if necessary.

Small portable panels with one burner also work on this principle. This is a convenient option for travel.

Popular myths about induction heating

Sometimes in stores selling equipment for induction heating at home, you can hear simply unrealistic characteristics assigned to it.

DIY induction heating

And, unfortunately, such properties are not always true. There are several main points that you should know the truth about:

- Induction heating is a new high technology (there is an opinion that the principle of induction is an innovative invention based on physical laws. In truth, this phenomenon is already about 200 years old and it was discovered by Michael Faraday. This principle of electromagnetic induction was taken as the basis for heating industry and is actively used in it, but it cannot be called innovative technologies).

- The profitability of induction heating (there is an opinion that the energy consumption of an induction heater is approximately 25% less than that of other electrical installations. In reality, everything is like this: any heating device converts 100% of the energy it uses into heat - of course, if it does not mechanical work. The efficiency may be lower. It all depends on how the heat is dissipated around the heating device. The time it takes for the coolant to heat up to the desired temperature directly depends on how efficient the heating element is. Therefore, there is high talk about revolutionary efficiency is just a gimmick).

- Durability of operation of the equipment (many argue that an induction cooker can last about 25 years, which means it is the most durable method of electric heating. Despite the fact that the coil itself has a large power reserve, the core will still collapse over time. In addition, the shelf life installation will be determined by the service life of the transistors, which on average can last 10 years.The only truthful conclusion that can be drawn from this is that induction heaters work longer than their heating element counterparts).

- Silent operation of the device (of course, most electrical appliances do not make noise during operation, but excess noise can still arise due to the operation of the pumps).

- Compact dimensions (many people believe that an induction device can be placed in any room and this is a true statement, because it is presented in the form of a small piece of pipe).

- Heating water for heating using the induction method is absolutely safe (if a coolant leak occurs, the electromagnetic field will not disappear automatically. The core will continue to heat up, if the power supply is not stopped, the body and mount will melt in a matter of seconds. That is why, during installation, automatic shutdown of the induction boiler should be provided in such situations).

Operating principle

The operation of induction boilers and other heating devices of this type is based on the ability of conductive materials to heat up under the influence of eddy currents created as a result of electromagnetic induction.

The source of induction is a high-frequency alternating current passing through the primary winding of the heating device, made in the form of a coil. The heating element placed inside the coil plays the role of a secondary short-circuited winding. It converts electromagnetic energy into thermal energy.

Eddy currents also occur at an industrial frequency of 50 Hz, but the efficiency of the heater will be low, and the operation of the device will be accompanied by strong hum and vibration. When the frequency increases to 10 kHz and above, the noise disappears, the vibration becomes imperceptible, and the heating increases.

This article talks about how to build stoves for a wood-burning cottage with your own hands. You can learn about the features of operating a wood-burning boiler with a water circuit here. You can see the features and advantages of the design of a brick stove with a water circuit: https://gidpopechkam.ru/pechki/kirpichnaya-vodyanym-konturom.html

What is

Induction vortex heaters are suitable for heating a house, garage, apartment, bathhouse, in general, any square meters where there is insufficient heat or no heat at all. Induction heaters operate using eddy currents (Foucault currents) created by a magnetic field. They heat the surrounding area. To generate such a field, an inductor is required, which is a multi-turn coil in the form of a cylinder. An alternating electric current passing through this very coil creates a magnetic field. Next, the eddy currents are converted into thermal energy.

Heating to high temperatures (70 degrees) using such a device occurs quite quickly, in about 5 minutes.

Standard water heating circuit

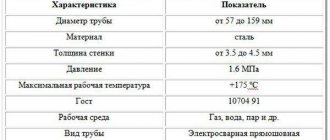

The types of heating pipes are also different. Each of these types has its own characteristics.

Connection diagrams:

- Single-pipe - in this case there is one battery pipe that connects all elements of the system along the water circulation path. In this case, the liquid sequentially passes through each heating device and leaves from the latter to the boiler. Installing such a system is quite simple due to the small number of elements.

- Two-pipe - already has two pipes installed parallel to the movement of the liquid. With this heating method, heat loss is significantly less than with a single-pipe scheme, and the heat is evenly distributed throughout the room.

- Collector - characterized by the presence of supply and return pipelines connected to each other by distribution manifolds. Allows you to clearly control every element of the system.

Of course, each such scheme has its own nuances and features, so you need to choose the one that is more acceptable.

Advantages and disadvantages

Analyzing the work process of the heater and the costs associated with it, I would like to note the undoubted advantages that the owner of such a device receives:

- Efficiency 99%, virtually no heat loss.

- During operation of the system, scale does not form, unlike heaters with heating elements.

- Environmentally friendly room heating.

- When heating, you can use both water (most often) and antifreeze or oil.

- There is no need for frequent preventive maintenance.

- The installation process does not require special skills, unpretentious operation.

- High fire and electrical safety.

- Possibility of combination with other heating systems.

- Works on both AC and DC mains.

- Service life over 20 years.

Despite all the advantages that the device has, one cannot fail to note the significant disadvantages:

- high cost of equipment in stores;

- expensive heating;

- requires a stable power supply;

- heavy weight of the device;

- Possibility of installation only in a closed heating system.

Smart heating system strategy

There is no need to talk once again about how controversial the issue of heating residential premises is. It is directly related to the costs of energy consumption and these costs significantly burden the family budget.

Therefore, the smart heating strategy is a really important and worthwhile topic to not only consider, but also try to implement.

It is enough to set the temperature parameter on a separate thermostat and the “smart” heating will do all the necessary work to provide the owner of the apartment (private house) with comfortable conditions

If you apply the smart home strategy to the heating system in its entirety, there is every chance of significantly reducing costs. Precise control of consumption and rational distribution of heat resources will contribute to savings.

The smart home strategy in relation to the heating system has been calculated and tested in practice. The result promises widespread adoption of this approach.

Application

Heating based on eddy currents created by electromagnetic fields can find its application in:

- heating a residential property, house, bathhouse, garage, industrial or administrative building;

- in the hot water supply system;

- heating of buildings and structures that have certain requirements for heat sources (for safety).

TEST No. 5: gentle heating - everything will be in chocolate

We want to make sure that maintaining the temperature actually makes cooking easier. The most common problem: the chocolate pieces in the center have not yet melted, but around the edges they are already starting to burn. Usually you need to do this in a water bath. Let's check the induction!

Place a few pieces of dark chocolate in a saucepan. Preheat at a minimum temperature of 60°C.

Indeed, very delicate heating. After a minute or two, the chocolate pieces just became soft. (The photo shows the beginning of mixing, and it is clear that the mass has already become very plastic). Used chocolate to decorate ice cream.

DIY induction heater

Due to the high cost of the device, many people decide to make such a heater themselves. On the Internet you can find many articles that describe how to make an induction boiler - heater with your own hands. We will describe the principle of manufacturing the simplest type of device so that any owner can cope with such a task.

Before you start work, prepare the following tools: wire cutters, soldering iron (if you plan to make a core from a metal pipe), screwdrivers.

- Cut 7mm diameter stainless steel wire into approximately 5mm pieces.

- Prepare a plastic or metal pipe (core), the walls of which must be at least 3-5 mm thick so that it can withstand high temperatures.

- Fill the pipe to the top with wire scraps.

- Cover the ends of the pipe with a mesh to eliminate the possibility of scraps falling out of it during operation of the device.

- Next, wind the copper wire in a spiral along the entire length of the pipe, making about 90 turns.

- Make a boiler by cutting out a rectangular section of pipe.

- Insert the manufactured device into the boiler hole.

- Connect the ends of the copper wire to a high-frequency inverter. You can buy it in almost all stores specializing in construction.

Before assembling the equipment, evaluate your strengths and capabilities. Do not start making a heating device if you do not understand anything about electricity.

Conclusions and recommendations

We deliberately presented options for induction water heaters of simple design, so that anyone could make such a unit on their own. But the question remains whether it is necessary to engage in this matter and waste your own time. There are a number of objective considerations in this regard:

Of course, you can do without expensive purchases, thoroughly understand the design and make an induction heater from scratch. But you won’t be able to do everything for free, because you will need to purchase components for the circuit. Please note that the bonuses from such a heating unit are small, so it is not advisable to seriously undertake its manufacture for the purpose of heating a private home.

Read with this

- DIY induction heaters: step-by-step instructions

- Proper maintenance of buderus gas boilers: how to set up and adjust, how to turn on the device and correct errors that occur

- What is a boiler

- Do-it-yourself heat accumulator: making a heat accumulator for heating step by step

- AGV 120 technical specifications

- Efficient boiler for water heated floors

- Baxi gas boiler

- Safe heat: schemes and principles of gas heating in a private house

- Pressure drop in heating when using double-circuit boilers

- Korean gas boilers

Safe use

Please note that an induction heater is an electrical device of increased danger. Rules that should be taken into account when manufacturing such equipment:

- Equip your device with a temperature sensor. If the equipment overheats, the system must have the ability to automatically shut down.

- For homemade equipment, organize a separate electrical wiring line with a larger wire cross-section.

- Do not neglect the insulation of exposed areas, protect your loved ones from electric shock.

- Before turning on the inductor, make sure that the pipe is filled with water. In its absence, the device may burn out and the pipe may melt.

- Do not place the equipment in a residential area. Electromagnetic waves have a negative impact on the health of people and animals.

- The device should be installed at a height of more than 80 cm from the floor, and the distance from the device to the ceiling should be at least 30 cm.

- Ground the equipment.

- The device should be installed via an automatic device, so that in the event of an accident, the device will be disconnected from the power supply.

- To reduce the pressure in the system, it is a good idea to install a safety valve in the pipeline system.

If we summarize the information, we can conclude:

- The induction heater has a high efficiency, for some models it reaches 99%.

- The device can be used both as a water heater and as a boiler in a heating system.

- The design of the heater is quite simple, so its assembly and installation is possible on your own.

- The use of an induction water heater in the Russian Federation is not regulated.

Despite all the advantages, the decision to install such equipment should be made carefully:

- Firstly, it consumes a fairly large amount of electricity.

- Secondly, the device, especially one assembled independently, cannot be called completely safe.

- Thirdly, it has a negative impact on the health of people and animals. Therefore, it should still be installed at dachas or in your own homes.

From this article you will learn how to assemble an induction boiler with your own hands. We will tell you about the operating principle of this device and give possible options for saving on heating. You will also find videos with detailed instructions on how to create an autonomous heating system for an apartment or house.

What a vortex induction water heater is has been known for a long time. RMNT.RU has already provided comprehensive information on induction boilers.

Factory-made products always attract buyers with their neat appearance and ease of execution. However, these benefits have to be paid generously out of your own pocket. Home craftsmen react instantly, copying store-bought products in garages and at home. As a result, they achieve the same performance indicators, but are several times cheaper.

Another option

To make it you will need a plastic pipe with a diameter of 63 mm and a length of 50 cm, steel wire with a diameter of 3 mm, a copper conductor with a cross section of 2.5 mm2 and a length of 11 meters.

- The steel wire is cut into 7 cm pieces. It is placed in a piece of plastic pipe.

- Two adapters for a 1″ threaded connection are soldered into the pipe. Coarse filters are screwed on both sides through 1″ nipples.

- Parallel strips of PCB are glued to the surface of the tube.

- Turns of copper conductor are laid on them. The distance between them should be the same. After this, they are filled with epoxy resin.

- The product is mounted in a heating system pipe and connected to a high-frequency voltage source.

The number of turns, as well as the length of the conductor, will have to be selected experimentally, since the length and capacity of the system is different for everyone. The steel wire, heating up from inductive currents, will give off temperature to the water that will pass through the pipe. This option cannot be used as a stand-alone device, but it will be an excellent addition to the main source, which will allow you to save on coolant consumption.

Advantages and disadvantages of plastic pipe boilers

Advantages of induction boilers:

- The water in the heating system heats up twice as fast and has double heating.

- Inertia is much less than when using gas or other fuel boilers.

- Magnetic induction prevents scale formation.

- Quiet operation.

- There is no need for cleaning and maintenance of the boiler.

Like any phenomenon or design, induction boilers also have their disadvantages:

- Before use, you must make sure that the core is completely filled with water and that the water level should not drop during operation, otherwise the plastic will simply melt.

- The boiler can only be used in a closed forced heating system.

- High cost of industrial designs.

The boiler power must provide the proper level of heating in the room. The most acceptable formula: 1 kW per 10 m 2.

An induction boiler is an excellent alternative to other heating devices. If you have the opportunity to make it at home, the skills to work with tools and assemble equipment, and the ability to install heating equipment, then you can make such a device yourself. If you are not confident in yourself, then it is better to buy a ready-made boiler and invite specialists to install it.

Watch the video that shows how you can make an induction electric boiler yourself:

https://youtube.com/watch?v=F6yIXht5gks

This video shows the process of making a boiler for an induction cooker:

DIY vortex induction heater (VIN)

The main problem with any system with a temperature difference is the heating element or reactor. This is the place where excess energy is generated, which is transmitted directly (as in the case of electric heating elements) or converted (as in the case of VIN).

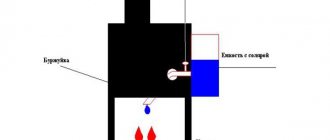

Theoretically, the boiler can be assembled from a large sealed pan, to which two pipes (supply and return), a pump and an expansion tank will be connected. We mentally connect the pipes to a chain of radiators, and place the pan on the gas stove. We fill the system with water (or antifreeze), turn on the pump and ignite the gas - the boiler is ready. Of course, its efficiency will be relatively low, so it’s worth thinking about a cheaper source of energy, since the system itself is quite functional.

For this purpose, we will need the microwave effect, on which the action of an induction cooker is based. It is good because it heats the agent very quickly, harmlessly and safely. Now, if you install not a hypothetical, but a real cast-iron or steel container on such a stove, and include it in the heating circuit, you can heat a three-room apartment, consuming 1.8–2.5 kW/hour (slab power). For comparison, the initial power of an electric boiler with heating elements is 6 kW.

Average cost of induction electric stoves

| Name | Manufacturer | Number of burners | Power, W | price, rub. |

| Kitfort Kt-101 | China/Russia | 1 | 2000 | 3000 |

| Philips HD4959/40 | Netherlands | 1 | 2200 | 6000 |

| Haus Muller 453 | China/Sweden | 1 | 2000 | 6200 |

| Hendi (239780) KITCHEN LINE 3500 (professional) | Netherlands | 1 | 3500 | 12000 |

| INDOKOR IN3500 | South Korea | 1 | 3500 | 12600 |

| ENERGY EN-914 | China/China | 1 | 1100 | 1800 |

| Oursson IP2310T/BL | China | 2 | 2400/1800 | 8000 |

| KROMAX Endever | Sweden | 2 | 2200/1750 | 8000 |

How to choose the right electric boiler

The first thing you need to do when choosing an electric boiler is to decide on its type, taking into account their positive and negative sides. If you are interested in a cheaper option that can operate on both water and non-freezing liquid, then you can choose a heating element electric boiler. But it should be taken into account that the water used as a coolant must in this case be as “soft” as possible in order to prevent or reduce the possibility of scale formation on tubular heating elements. In addition, you must realize that you need a certain place to place it and sooner or later you will have to change heating elements, which rarely have a long service life.

If you want to save space and at the same time get an economical option, you can opt for an electrode boiler. They can be installed directly on the heating system pipes. Such low-power electric boilers are sometimes even difficult to notice among the heating pipes. But at the same time, you need to understand that you will have to constantly monitor the composition of the coolant, which is not entirely convenient, or use expensive special liquids.

The choice of power of an electric boiler of any type depends on whether it will be used for main heating or as a backup or additional heating, as well as on the area of the room or house that will have to be heated. If it is to be used as the main source of heat, then its power should be such that for every 10 m2 of heated area (with a ceiling height of 2.5-2.7 m and good thermal insulation of external structures) there is 1-1.2 kW. If it is used as additional heating, for example: to maintain the temperature in the system during breaks between the operation of another heating device, then perhaps a power of 1-3 kW will be sufficient.

In addition, when choosing an electric boiler, it is important to pay attention to the reliability of the manufacturer. Although such products from reliable manufacturers are more expensive, their future operation may be cheaper if you take into account the costs of repair or replacement of cheaper, but not reliable samples. So, in any case, the choice is yours

So, in any case, the choice is yours

So, in any case, the choice is yours.

Improving the heat exchanger

Of course, a theoretical saucepan is only an intermediate version of a heat exchanger. In practice, it must be reliable, cheap and compact, because we are talking about heating an apartment (small area - up to 50 sq. m). The amount of agent should not exceed 40 liters. A flat metal tank with dimensions of approximately 500x600x50 mm is most suitable for all of the above requirements. Such a container can be welded from a 50x50 profile pipe.

- Cut the pipe 50x50 to 600 mm - only 9-10 pieces.

- Weld the sections together wall to wall to form a row of tubes.

- Cut a length of transverse length lengthwise and remove one wall from the pipe.

- Install and weld the transverse section in the manner of a comb manifold.

- Install the opposite wall in the same way.

- Weld 1-1.5 inches of fittings into diagonally opposite planes.

- Carefully scald the structure - it must be airtight and all chambers must communicate freely.

Can a stove heat a room?

Of course, you can place a pan of water on the surface. During the boiling process, it will heat the air in the room. However, this method is not rational due to the boiling of the liquid. Make your own heater using an induction cooker. To do this, it is enough to have the skills to work with a welding machine and an angle grinder. Let's look at the manufacturing process of this design step by step:

- First, we need to make a square pipe measuring 50*50 cm. You will need about 6 such products. This depends on the dimensions of the induction cooker.

- It is also necessary to prepare two parts 25 and 30 cm in length.

- Elements of 50 cm are connected to each other vertically. All joints must be thoroughly welded.

- For the other two blanks, it is necessary to remove one of the sides to obtain a U-shaped profile.

- Two sections with the wall removed are welded to the resulting part on the upper and lower sides in order to combine all sections into a common contour.

- Then we weld the holes on the sides.

- The outlet and inlet pipes should be located diagonally, one at the top and the other at the bottom.

- All seams must be thoroughly cleaned with a grinder. The resulting product is degreased before painting.

- Next, the installation process begins. The return flow of the coolant is supplied from below, and the outgoing pipe is supplied from above.

- An expansion tank must be added to this system, as well as a pump for forced circulation.

Entering the resulting product, the water warms up. Exactly the same design can be made horizontally and made more complex.

IMPORTANT! An induction cooker must have a current and temperature control system.

Saving on electricity consumption

Consumption of 2.5 kW instead of 4–5 is an excellent result. But it turned out to be not enough for ambitious and thrifty home craftsmen. But where can I get cheap electricity for the stove? It turns out that the answer has been known for a long time. This device is called an inverter, and it converts direct current into alternating current. With its help, you can reduce current consumption for heating to almost zero.

To reduce energy consumption we need the following:

- Two batteries of at least 190 Ah (preferably 250 Ah).

- 4 kW inverter.

- Battery charger (24 V).

- The main pipes must be made of non-magnetic material (plastic, aluminum, copper).

We connect the batteries in parallel and put them on constant “charging”. The process that occurs in an electrical circuit:

- The batteries generate direct current, which is supplied to the inverter.

- The inverter converts direct current into alternating current 220 V.

- Current from the inverter is supplied to the induction furnace, which operates in normal mode (flow).

- The charger continuously recharges the batteries.

Thus, heating the apartment costs the consumption of a 24-volt charger, not counting the cost of operating the circulation pump, which will be used in any option.

Care - with a regular towel

During the test, I probably put the stove in order a hundred times, brushing crumbs off its surface, collecting drops of water and oil, and directly in the cooking process itself. Since this cleaning was quick, I used an ordinary kitchen towel, and after hard work the stove looked like new.

The induction cooker KITFORT KT-102 allows you to control energy consumption - press the sensor. button and kilowatts flowed to the meter before our eyes...

And the induction cooker KITFORT KT-102 shows the true voltage in your electrical network - you never know - the voltage will start to jump...

Safety precautions when installing an induction boiler and an energy-saving circuit

There are no safe reactors, energy carriers, or energy generators. The gas is explosive, electricity can injure a person or cause a fire (short circuit). Microwaves have a minimal impact on human health: they activate molecules of liquid substances, disrupting natural processes in the body. A few simple rules will help you avoid even minimal discomfort when using a homemade induction boiler:

- Microwave pulses can be harmful to humans if they remain within 50 cm of an operating device for an extended period of time. If the heat exchanger is installed in the bathroom, turn off the stove during water procedures.

- A mesh (cellular) screen made of magnetic material will help isolate up to 70% of microwave radiation.

- Batteries should not be kept in residential areas or generally inside the apartment. Set up a place on the balcony for this purpose.

Average cost of parts for an energy-saving unit

| Name | Manufacturer | Index | price, rub. |

| Charger 24 V | |||

| NEVATRONIC 24 | Telvin, Italy | 15 A | 5700 |

| ZU1-24-8(5) | SibContact, Russia | 15-18 A | 6300 |

| Fubag SMART 130/24 027985 | Fubag, Germany | 12-25 A | 4800 |

| "SunEnergy" | "SunEnergy", Russia | 12-15 A | 12000 |

| Battery | |||

| Batbear 6ST-190 LA | Alcor, Russia | 190 Ah | 10000 |

| Titan Standard 6ST-190 | Titan, China | 190 Ah | 11000 |

| MUTLU Mega Calcium | MUTLU, Türkiye | 190 Ah | 13900 |

| Mutlu Blue Silver 6CT-190 euro | MUTLU, Türkiye | 250 Ah | 14000 |

| Inverter | |||

| AcmePower AP-DS2000/24 | WMT Limited, China | 2000 W | 13000 |

| AcmePower AP-DS4000/12DC12V/AC | WMT Limited, China | 4000 W | 27500 |

| IS1-24-4000 DC-AC | SibContact, Russia | 4000 W | 48900 |

The heat carrier (agent) “doesn’t care” what it is heated with, but for the owner of the house it is of great importance, and the choice is always made in favor of saving current costs. In the case of induction devices, heating occurs when magnetic waves oscillate. In this case, heat is not transferred from a more heated surface to a less heated one (as in heating elements), but is formed directly in the agent - the liquid. This provides enormous savings on heating.