Peculiarities

Infrared heaters have a rather interesting operating principle. They heat not the air itself, but objects located around them due to infrared radiation. As a result, they become warm, releasing part of the thermal energy into the atmosphere - the room becomes warm and comfortable. Let's look at the main features of IR heaters:

The most striking drawback of these heaters is the high electricity consumption, which is typical for any, even the most economical electrical appliance.

- Correct heat distribution. If you install traditional radiators indoors, it will be cool near the floors and hot near the ceilings. In the case of IR heaters, the floors will be warm, since they will be heated by IR radiation;

- When installed correctly, they do not cause harm to human health - if this equipment is installed correctly in its normal place, then it will not have a negative effect on the body (in particular, there will be no headaches);

- Fast heating of rooms - they warm up noticeably faster than traditional radiators;

- Almost complete silence - only gas appliances make noise (and even then they are practically inaudible);

- Can work in rooms with high humidity levels;

- Available for use in outdoor conditions, creating a comfortable environment in open areas;

- No negative impact on the environment.

Installing an IR heater in a living room will create a warm atmosphere in which it is pleasant not only to relax, but also to work.

Types and their characteristics

Note that the principle of use and structure of various thermal regulators can vary significantly. There are two categories of thermostats:

- mechanical.

In the case of mechanics, it is a small plastic box with a switch. Usually it has a round shape, which makes it possible to smoothly change its position. The value of one division may differ - from 1 degree to different values. Also on the box there is usually a power key and a light indicator that indicates the activity of the device at a certain moment. There are also more advanced mechanical solutions equipped with a display. Despite this, they do not display as much information as we would like, and you can control the temperature with just a couple of keys.

Electronic models have more features. Their design and construction are constantly being improved - the most modern ones are already equipped with entire liquid crystal displays. Depending on the specific model, adjustments can be made using either physical keys or a sensor. Sometimes such thermostats are equipped with a hinged lid.

In addition, there are electromechanical devices. These are standard devices that are mounted on the body of the heating device or inside and react to the temperature of the surface of the heater or the liquid in the radiator. They are divided into regulated and unregulated. Adjustable ones control air heating in the room thanks to the device’s on-off cycle, which is carried out after the heater enters operating mode according to a certain process. Typically, the device heats up first, after which the regulator turns off the heating element. Then it cools down and the regulator activates it again. It turns out that the heating of the room can be controlled by pre-selecting a certain degree of heating of the device.

It should be added that the design of controlled devices can be of two types:

- capillary;

- with a bimetallic strip.

In the first case, there is a special relay, similar to a small narrow cylinder, where there is a cylindrical capsule with a liquid that has a high coefficient of thermal expansion. When the temperature changes, the circuit can close and open contacts using a special drive. In the second case, we are talking about an element that is combined from two different metals that have a serious difference in thermal expansion coefficients - when heated, half of the plates elongate so much that they bend in the seat and simply open the electrical circuit, and after cooling they again become the same size and close the contacts.

There are also unregulated electromechanical devices. Their essence is to turn off the heating element when the unit reaches a critical level of 105 degrees.

Varieties

They are divided into two categories - electric and gas appliances. The first ones operate from a household electrical network and are equipped with electric emitters. They are characterized by extreme structural simplicity, which ensures their compactness. However, this comes at the cost of high energy consumption.

Gas IR heaters operate from liquefied gas. Their main advantage is autonomy - they do not require access to the power grid to operate. They are in little demand at home; most often they are used for heating open street areas and industrial buildings. Some models operate using built-in miniature gas cartridges.

Installation of infrared heaters

If you use infrared gas heaters, installing them on the wall is exactly the same as with electric models.

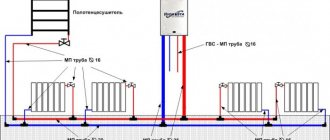

Installation of infrared heaters is carried out in two ways - on walls or on ceilings. Wall placement is optimal, since in this case the IR radiation will heat the rooms as evenly as possible, including reaching the floors. In some cases, when the ceilings are very high and installation is difficult, they resort to wall installation.

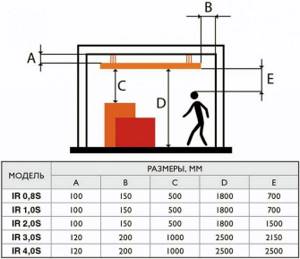

Installing an infrared heater on the ceiling begins with choosing the height of the placement. In the case of living rooms, the optimal height is 2.5-3 meters. Usually this parameter is indicated in the equipment data sheets - the greater the power, the higher the suspension.

Otherwise, your health may deteriorate and headaches may appear.

Connecting an infrared heater via a thermostat

Ceiling models must have a connection via a thermostat. Sometimes it comes included. Several heaters can be connected in parallel to one thermostat if they are installed in the same room. In this case, the total load should not exceed 3 kW.

An important rule: do not place the thermostat close to a heating source or in a draft. Otherwise, it will not work properly

The recommended installation height is 1.5 meters from the floor.

Sooner or later, developers or future homeowners have to face one of the most troubling issues: how to choose the right heating system. There are quite a lot of options for arranging a heating system, but increasingly, owners of new buildings deliberately choose electric infrared heaters and convectors for heating. Unlike bulky water and gas heaters, using electrical appliances is much easier and cheaper. You just need to choose the right layout and install an infrared heater in each room of the house. Nothing complicated at first glance, but there are certain nuances in installation and use.

Installation process

Installation prices from heating equipment specialists are surprising. It’s clear that none of us will agree to work for pennies—we all want to eat. But you need to maintain at least some limits of decency in pricing. Therefore, the easiest way is to carry out the installation yourself - it will not require special knowledge from you and any unnecessary licenses.

Direct installation of hangers on mounting hooks is also possible - this is done in rooms with low ceiling heights.

To install the heaters, you can use the standard brackets included in the kit. With their help, equipment is suspended from ceilings using cables or chains. Therefore, we will need mounting hooks for wood or concrete - the latter are supplied with plastic dowels. Next, we install the fasteners, screw the hooks into the ceilings and adjust the length of the chains or cables to achieve a suitable suspension height.

Thus, there is nothing complicated about installing infrared heaters yourself - everything will take you a couple of hours maximum. The most difficult thing to install such heaters on is concrete ceilings, where you will need a powerful hammer drill to install mounting hooks. For wall installation, the same hooks are used in conjunction with hangers - in this case, the heaters should hang horizontally and look slightly down.

Main process

Hanging the case

First you need to determine the installation location of the infrared heater in the house (or apartment). As we said above, the housing can be placed both on the ceiling and on the walls, depending on the individual preferences of the owners.

The first thing you need to do is mark out the mounting locations yourself. To do this, use a tape measure to measure the same distance from the ceiling to the selected area. It is also recommended to use a building level, with which you can level the brackets in a horizontal plane.

After marking, proceed to drilling. If the ceiling (or wall) is made of wood, drill holes with a drill. If you have to deal with concrete, you cannot do without a hammer drill. You need to drive dowels into the created holes and screw in the brackets, after which you can install the infrared heater in its place.

Please note that the design of the unit varies. Some products have guides that are fixed into brackets

A simpler option is chains attached to the ceiling (special holders attach to them). Also on the market you can see infrared heaters on a leg, which are simply placed on the floor.

Electric installation work

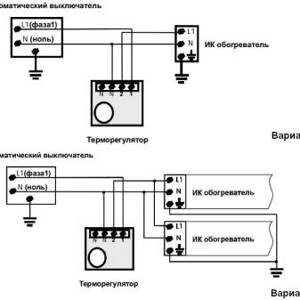

As we said at the beginning, the process of connecting an infrared heater to the network will be carried out using a temperature controller.

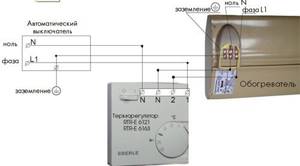

First you need to connect the contacts of the collapsible electrical plug to the thermostat terminal blocks, which are installed in the product body. Each “socket” has its own designation: N – zero, L – phase. It should be noted that there are at least two of both zero and phase terminals (from the network to the regulator and from the regulator to the heater). Everything is quite simple - you strip the wires, insert them into the seats until they click (or tighten the screws). Be sure to follow the color coding of the wires so that the connection is correct.

For your attention here are the correct connection diagrams:

As you can see, connecting an infrared heater through a thermostat is quite simple, the main thing is not to mix up the wires and tightly tighten them in the terminal blocks.

A very important nuance is the correct choice of location of the regulator. You should not install the product next to a heater, because in this case, the incoming warm air will negatively affect the accuracy of the measurements. It is best to place the device in a more distant area, at a height of one and a half meters above the floor.

Also note that you need to install the controller in the coldest room, otherwise the heating problem will not be completely solved. As for the number of infrared devices served by one temperature controller, it all depends on the power of the heaters

Typically, one 3 kW controller is used for several products, with a total power of no more than 2.5 kW (so that there is a reserve of at least 15%).

You can read more about connecting a thermostat to an IR heater in our separate article, which provides several installation diagrams!

So that you can clearly see the entire connection process with your own hands, we provide these lessons for viewing:

Video instructions: connecting an infrared heater with your own hands

How to connect a temperature controller

Connection

All infrared heaters are connected to conventional single-phase networks. The exception is high-power industrial designs that require a power supply of 380 Volts. The connection diagram for an infrared heater is extremely simple - they are mounted and connected to a thermostat.

The thermostat is an important part. It provides support for a given temperature regime, focusing on the temperature of the surrounding space. Control method: mechanical, with dry contacts. As soon as the temperature reaches a preset limit, the thermocouple is activated and disconnects the equipment from the power supply. When the air cools, the contact closes and the supply of electricity is restored.

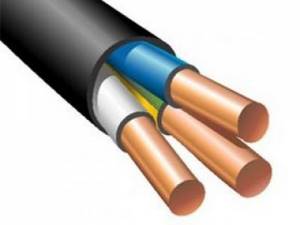

If there is a good grounding circuit and three-wire wiring in the house, use a VVG 3x1.5 or VVG 3x2.25 cable - one grounding conductor here. The optimal height for placing the thermostat is 1.2 m, but in no case close to the heaters.

In order to connect IR heaters after they are installed, we need a good wire that can withstand heavy loads. The best option would be VVG 2x2.5, which should be laid in the walls and ceilings, and then hidden under a layer of plaster. Considering the not very high power of the devices, it would be possible to use a VVG 2x1.5 wire for these purposes, but it is most often used to connect lighting devices - for power loads it is recommended to choose a cable with a large cross-section.

Principle of operation

If we talk about the principle of operation of such a thermostat, it should be noted that this is not an ordinary household appliance, but an entire climate system with an intellectual twist. To better understand the essence of its work, you need to understand that this is not just a thermostat, but also a kind of sensor. After all, it not only measures the temperature, but also activates and turns off heating equipment if the temperature in a closed space reaches certain maximum values. At first glance, it seems that the thermostat for an infrared heater is the same as for others, but it has a difference. Typically, these devices simply measure the temperature at the heating devices, rather than in the room. Then the thermal relay is supplied in its own housing and is fixed at the owner’s request where he wants it. For example, it can be floor- or wall-mounted. In addition, thermostats allow you to:

- program the shutdown of the entire system after several hours of use;

- set an auto-start program at a certain time;

- maintain the selected temperature;

- create cyclic programs for various time periods.

Connection diagram

There are no difficulties in connecting such heaters after their installation - we need to run the cable from one device or group of heaters to the thermostat, and then to the nearest junction box. Our thermostat simply breaks one wire (phase), no additional cables or conductors are needed. If the power of a heater or group of heaters is 3 kW or more, lay a separate solid line to the distribution board and equip it with an RCD.

The most difficult part of installation is laying the wires. To prevent them from being conspicuous, it is advisable to recess them into walls and floors. If this is not possible, install plastic cable channels. In utility rooms, use corrugation. Groups of heaters are connected to each other in plastic junction boxes, trying to avoid twists.

Of the wide variety of additional heating, many prefer IR panels, because they are easy to use and quickly warm up the room. In addition, using the built-in thermostat, you can quickly set the required temperature. You can entrust the installation of infrared heaters to professionals or do it yourself, which will significantly save money.

Correct connection of electrical appliances

Infrared heaters sometimes do not have a ground terminal added. This makes exploitation potentially dangerous. Especially for people who get too close.

Safety when connecting infrared heaters

Let's talk about connecting an infrared heater. The topic of safe handling of electrical appliances has been raised more than once. For example, in the bathroom there should not be appliances powered by 220 V. When installing, you need to take care of safety! For this, differential protection devices are used:

- There is a transformer inside the case, the first winding catches the input current, the second the output.

- At the slightest imbalance, the core moves, opening the power relay. Moreover, the switching of both contacts is controlled.

- A group of fuses is added to the design, further protecting the devices (and differential protector) from overload.

- For the differential protection device to operate correctly, the leakage current must not return. There is a ground connection for this purpose. It does not differ in potential from the neutral wire, but will allow the leakage current to escape, bypassing the protector. In case of danger, at the slightest sign of breakdown, the differential protection device will be switched off. This way, human lives can be saved. In view of this responsibility, increased requirements are placed on the grounding loop: extremely low resistance and sufficient thickness of conductors capable of passing a conceivable, large leakage current.

- Fuses have nothing to do with human safety. If a person is killed, and the current does not exceed the specified one, the specified glands do not care. The task of the device is to monitor the critical value of power (not necessarily breakdown on the housing and leakage), heat up and burn out at the right moment. According to experts, most fuses turn off when it is too late to save. Security cannot be guaranteed.

The information was shared so that people understood that anyone is in danger until the necessary measures are taken. Fuses and access plugs protect the power grid from overloads and equipment from combustion. These elements will in no way ensure the safety of people.

The power of infrared heaters is flexibly distributed over an area and is an economical way to maintain heat. The gas boiler is kept in reserve. Therefore, people set a series of thermostats and go on business, confident that everything will be in order. We recommend choosing not quartz infrared heaters, but those with a metal plate for radiation. Or it is allowed to create combined complexes.

For quartz lamps, the spiral heats up to 500 ºС and higher, creating a potential danger; you should not believe PR managers and assurances that the situation is the opposite. If a working infrared heater is broken and a piece of paper is brought near the hot metal, a fire will occur.

As for infrared heaters with a metal emitter like Peony, the temperature is below 200 ºС. The experiment is easier to carry out. But it's more important to make sure that proper overheating protection is built inside.

Imagine that a hanging lamp has fallen. It works according to the readings of an external thermostat. The palace will light up after some time, and the smoke catcher will not help, because in large areas the volume cannot be filtered through the sensor. In the latter case, the internal thermostat or safety devices will prevent trouble. Worry about the devices in advance; if the matter is serious, ask to open the model and show what and where will prevent your home from burning down in case of danger. This is not the only simple thermal fuse, like in an iron. Control requires temperature measurements at at least three points. Example:

- The heater fell from the ceiling, but did not lose power.

- Approximately the middle of the radiating surface was on a soft chair.

- The fuse located at the edge (or two at the edges) “blowed” the increase in temperature in the center.

- The chair caught fire when the thermostats did not respond.

Application area

Such heating devices are characterized by high efficiency rates, as a result of which they almost instantly warm up the room and slowly cool it. These factors indicate greater efficiency of the devices. Because of this, their use in rooms with high ceilings and large heat losses can be considered justified.

In addition, infrared panels are often used to heat civil and agricultural premises. In particular, these are schools, offices, greenhouses, kindergartens, shops, etc. There are also modifications that are designed to heat open areas.

Before purchasing a specific heating device, you should compare the upcoming operating conditions with the technical characteristics. For each specific object, it is advisable to choose certain products:

- Shortwave devices. They are often used in production. This is due to the aggressiveness of the design in operation due to the instantaneous heating of the object due to the temperature increase to hundreds of degrees.

- Long- and medium-wave instruments. They are in demand in private homes, as well as on civilian sites.

From this video you will learn how to install an infrared heater yourself:

Dependence of temperature and heating power on the connection diagram option

Heater power is a very important parameter that many buyers focus on when purchasing a heating element. In fact, the power of the heating element depends only on the resistance of the heating coil. Of course, if you do not use transformers and the power from a certain network will be constant. This property of dependence can be easily calculated using a simple formula from a school physics course:

Power (P) = Voltage (U) * Current (I)

In this case, we take the potential difference between the terminals of the electric heating element as the voltage value, and the current strength must be measured that will flow through the heating coil.

The current strength can be calculated using the formula I=U/R, where R is the electrical resistance of the heating coil. Now let’s substitute this value into the power formula, and it turns out that the power of the heating element depends only on voltage and resistance.

Thus, we conclude that at a constant power supply voltage, the power of the electric heater will change only when the resistance changes.

The resistance value of the resistive element in the bulk of heaters is directly dependent on the temperature release value. But in heaters with a nichrome or fechral spiral, for example, within a hundred or two degrees the resistance practically does not change.

In the situation with high-temperature heaters made of silicon carbide or molybdenum disilicide, the picture will be completely different. In high-temperature heaters, as the temperature increases, the resistance drops very significantly, ranging from 5 to 0.5 ohms, which makes them very beneficial in terms of electricity consumption in furnaces.

But because of this quality of high-temperature CENs, they cannot be connected directly even to a 220V power supply network, not to mention 380V. Technically, it is possible to connect to 220V CENs if you connect them in series. However, with this method it will be impossible to control the power and temperature output of the heaters in the furnace. To connect high-temperature non-metallic heaters, special adjustable transformers or standard statistical EM devices should be used.

At the Polymernagrev company you can buy electric heaters that are manufactured specifically for connection to a three-phase power supply. These are dry ceramic heating elements, a block of heating elements for water and three-rod heating elements. The type of connection of these heaters depends on the voltage rating in a star or delta circuit.

When connecting electric heating elements in accordance with the TRIANGLE diagram, three heating coils are connected, which have equal resistance values and 380V will be supplied to the power supply. Connecting STAR heating elements implies the presence of a zero terminal, and 220V will be supplied to each heating element. The neutral wire allows you to connect consumers with different resistance values.

If you still have questions about the types of connecting heaters to a three-phase network, you can contact our specialists by phone in Moscow or ask your question in the form below, we will try to answer you in detail as soon as possible.

Source

Principle of operation and varieties

A characteristic feature of such products is the release of heat, which helps to heat various surfaces - walls, floors, ceilings, etc. It should be noted that the air is heated partially, because the main flux of radiation is directed towards objects, which subsequently give off heat from themselves.

Infrared radiation is not afraid of wind, drafts and can warm you up even on a windy day

The device consists of a reflector and an emitter. The latter is responsible for the transmission of radiation during the heating process. The reflective element is a reflector, which is made from heat-resistant materials with high reflectivity. The heating elements can be:

- plates;

- open or closed spirals;

- quartz, infrared or halogen lamps;

- heating elements;

- carbon conductors.

Infrared equipment differs in several ways: purpose, installation method, energy source. According to the last parameter, they are divided into stationary and mobile. Devices can be for domestic and industrial needs.

According to energy sources, all heaters are divided into several types:

- Electrical. The most popular type of devices that are installed in any premises. A mandatory element in the system is a mirror reflector for transmitting radiation in the required direction.

- Gas. Best suited for open areas or industrial buildings. Due to their high power, they are rarely found in residential areas. The fuel is a gas-air mixture.

- Diesel. They are in demand in rooms where wiring is weak. Such devices are often found on the street or in garages. The device does not require chimneys; cleaning is carried out through several filters.

- Film - often used in residential areas.

What to look for when choosing

Halogen heater

New generation devices are constantly appearing, which complicate the choice of heating equipment. When arriving at the store, the first thing they evaluate is what the heater looks like. The case should be both stylish and strong, the cable should be reliable, with a high-quality plug. In Moscow you can often find downright cheap devices. It's better not to choose these. There is a high probability that the components are of low quality, and therefore the heater will not “live” for long.

An important point when choosing is power. It is calculated simply: every 10 m2 requires 1.2 kW of energy.

Carbon Ceiling Infrared Heaters

In the reviews there are different devices, some are placed on the floor, others are attached to the wall or ceiling. After the installation method, the type of heating element is considered an equally important criterion. There are four varieties.

- Halogen. The source of infrared waves is an incandescent filament, which emits visible golden light and waves in small ranges. The latter do not have the best effect on human health. Therefore, such IR heaters are cheaper than others.

- Carbon. The heating element is made in the form of a quartz emitter. It heats up quickly, the efficiency is the highest among this equipment, but it “eats” a lot of electricity. The radiation is safe for human health. However, this heater cannot be used continuously.

- Ceramic. The heating element is protected by a ceramic shell, which “blocks” the radiation spectrum that is unpleasant to the human eye. Advantages: moisture resistance, strength, cost-effectiveness. Ceramic elements take a long time to heat up and take just as long to cool down.

- Tubular. Another name is heating element. One of the popular options, suitable for constant use. The air is not dried out and no radiation is emitted. True, they make a slight crackling noise when turning the heater on and off.

Advantages and disadvantages

Any equipment has both positive and negative sides. The advantages of infrared heaters include:

- Cost-effective (especially when using devices as an additional heat source).

- The device does not burn oxygen.

- No harmful effects on human health (scientists have proven that devices can even have a positive effect on the body).

- When mounted on the ceiling, they take up minimal space in the room.

- Safety for children.

- Quiet operation. In addition, the products can be used as a light source.

- Many models are equipped with a built-in thermostat, with which you can maintain the optimal temperature level.

- The heat remains for a long time, because heated objects release energy into space.

- Infrared systems are resistant to moisture, so they can be installed in gazebos, bathrooms or on terraces.

Connection via a thermostat plugged into an outlet

The main disadvantage of the previous scheme is the lack of automatic adjustment of the heater. This can be solved by using a thermostat.

In this case, the simplest option is to purchase an additional thermostat that plugs into a standard household outlet and connect the heater to it. The same principle is obtained when using a heating device with a built-in regulator, which is connected to a standard outlet in an apartment or house.

Main disadvantages

— binding to the location of sockets

As in the previous option, you remain tied to the existing location of the outlets.

— the need to purchase additional equipment - thermostat for socket

Additional purchase costs will be required, and in addition, such specific equipment is not available for purchase everywhere.

— There is no possibility of connecting several heaters to one independent thermostat

If you plan to use several heaters, for each of them you will have to use its own individual thermostat in the outlet.

— Installation appearance

All conductors remain visible, the socket is occupied.

Advantages:

— Simplicity

Implementation does not require any preparatory work or skills and knowledge.

— Possibility of automatic adjustment and maintenance of the desired temperature

You get a fully automated heating system.

Security measures

Please note that installation of IR panels involves working with electricity. It is very important to exercise extreme caution and follow safety rules:

- It is prohibited to install an infrared heater on the ceiling if fire hazardous objects are located nearby.

- Electrical wiring must be located on a non-combustible base.

- Fasteners must not come into contact with the heating element.

- It is not recommended to install devices with a power of more than 800 W in residential premises.

- The device must not be connected to the network until installation work is completed.

For more efficient operation of the device, it is recommended to place the device near objects that absorb heat well: stone walls, wood, carpets, etc.

Experts do not recommend installing the heater near reflective surfaces, as this reduces the efficiency of the product. The mounting surface must be strong, because some structures weigh about 30 kg, although most of them weigh less.

How to install an infrared heater yourself

Infrared panels are gaining more and more popularity every year. They are easy to use and provide quick heating of the room, and the built-in thermostat allows you to set the desired heating temperature in a few clicks. Moreover, installing infrared heaters yourself is quick and easy if you follow the instructions. Other advantages of this equipment include:

- long service life;

- noiselessness;

- safety;

- spot heating;

- Possibility of use in open space.

It is not surprising that many people are interested in installing infrared heaters themselves. This process does not require special skills and takes from 25 minutes to an hour and a half.

Preparation

Required Tools

In order for the installation of an infrared heater to go as expected, you must have the following tools:

If necessary, more complex equipment can be used. For example, if you are interested in installing several infrared heaters with your own hands, it is best to use a pyrometer for calculations. It will allow you to determine the warmest and coldest places in the room. Based on the information received, you will select the optimal location for each device.

Safety precautions

There is a set of measures that will prevent accidents both during installation and during operation:

- Do not install IR panels near flammable or explosive objects;

Electrical cables must be laid on a non-combustible base;

The fastener should not touch the heating element;

The height at which the panel should hang is 2.5-3.5 meters;

For a house or apartment, devices with a power of no more than 800 watts are purchased.

The device must not be turned on until installation is complete. The device must have an appropriate degree of protection if the panel is installed in a bathhouse or sauna. If all these rules are followed, the installation of an infrared heater will be quick and easy.

Choosing a suitable location

The most important requirement when installing an IR panel is the distance to a person’s head. This is especially true in work areas where people stay in one position for a long time.

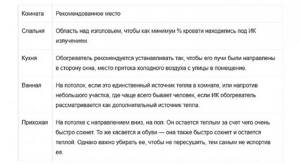

The distance should be at least 1.5-2 m, it all depends on the power of the device. If it is less than 800 W, the device can be placed at a distance of 70 cm. If the indicators are 1-1.5 kW, then the minimum gap is 1 m. The specifics of specific premises determine a number of features of the installation of structures and the optimal layout of their placement. The table clearly shows the recommended location for the device in each specific room

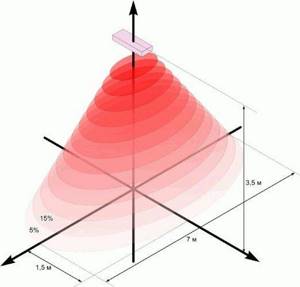

To heat open areas, it is advisable to install several devices so that the radiation covers most of the human body. The units are capable of providing different temperature regimes for individual zones of the facility. To do this, it is enough to place several devices of different power in one room.

Installation

Installation process

To make the installation of an infrared heater as simple as possible, it is better to place the panel with the connector facing the wall. Most models have self-clamping contacts. The delivery package includes elements for attaching the device to the ceiling.

The installation process includes the following steps:

- remove the device from the packaging and place it on any flat surface with the heating plate down;

- mark the installation location and make several holes;

- screw in the screw rings;

- hang the chains, adjusting the height (if necessary).

- Secure the device using mounting hooks or brackets.

As you can see, installing infrared heaters with your own hands is not a particularly difficult process. The panels can also be mounted on the wall, but the heating effect will be significantly less.

Installation of different models of IR heaters:

Network connection

The device is connected to a thermostat, which will maintain the desired temperature. This is done through three terminals: “ground”, “phase” and “zero”. Accordingly, the supply cable must be three-core. As an option, you can use PVA 3x1.5.

The ends of the cable are connected to the terminals. The polarity is indicated on the ends of the wires. After the device is installed and connected, it is advisable to wipe the panel with an alcohol solution before turning it on.

Connecting multiple devices

If you are interested in installing infrared heaters with your own hands in large rooms, then you need to take into account that you will need several devices. To ensure coordinated operation, all panels are connected to one thermostat. This will allow you to effectively regulate the temperature throughout the facility.

Step-by-step instruction

The manufacturer must include step-by-step instructions for installation and operation in the set of heating panels. It is necessary to study it carefully, because all units are different, so recommendations for them may differ.

Heater installation

Mounting the device to the wall is quite simple. To work, you will need a screwdriver, drill and hammer drill, as well as basic knowledge of working with the listed tools.

Designs may vary between devices, so please pay attention to manufacturer's advice.

Step by step process:

- Determine the locations for fastening the product and mark them. It is recommended for these purposes to use a measuring tape to measure the height of the mount from the ceiling. You will also need a building level. You need to make sure that all points are at the same height.

- Drill holes into which to then insert dowels.

- Using the parts included in the kit, secure the structure to the wall.

To properly install an infrared heater, you must strictly follow the recommendations described above.

Electrical connection

Any device is installed with a thermostat, which is needed to maintain a constant temperature. Any network consisting of one phase is suitable for connection. The exception is high-power industrial models. In a home or apartment, you don't need to worry about this.

Using a thermostat, the room temperature is monitored. This is necessary to ensure and maintain specified modes. If the values are higher than the specified level, the device automatically turns off, and the supply of electricity to the unit is resumed after the air has cooled.

Installation requires minimal preliminary preparation, no additional communications required

When installing the unit in several rooms at the same time, one thermostat will not be enough. It is necessary to install a separate one for each room. You don’t have to use them at all, but in this case the panels will consume significantly more electricity. In addition, it will be less comfortable to be in the room.

Step-by-step instructions for connecting the product:

- A high load resistant conductor should be used and installed in the ceiling or walls.

- Cover the cable with a layer of plaster. An alternative option is to use special boxes that can be used to hide electrical wires.

- The heater wiring must be connected in parallel to the main line.

- Then you should install a thermostat in each room at a height of 1.5 m.

Installing an infrared heater is not as difficult as it seems at first glance. Today, these designs are the most economical for heating homes. The devices can be used both as the main and additional heat sources.

Infrared ceiling heaters differ from other types of heating equipment in their operating principle. IR heaters do not heat the air, but the objects and people in the room. Having received heat from a heating device, objects release some of the heat into the air. As a result, the air temperature in a heated room is always 5-7 degrees lower than the temperature of surrounding objects. In this case, there is no overheating of the air, and people receive the necessary warmth.

For heating purposes, IR equipment is used as:

- basic;

- additional;

- for warming up local zones.

Pros and cons of ceiling IR heaters

Infrared heaters are safe to use

Electric infrared heaters with ceiling installation are in demand for apartments, cottages and industrial buildings. This is explained by their positive qualities:

- Efficient heating. Suspended equipment in the form of a heater does not affect the air, but objects and people.

- Efficiency reaching 90%. Compared to traditional appliances, they consume less electricity. Many ceiling infrared heaters are supplied with a thermostat - this is necessary to automatically turn off the heating when the set temperature is reached.

- Safe to use. IR technology does not “dry” the surrounding air. For this reason, it is suitable for installation in children's rooms.

- European standards are responsible for environmental cleanliness. No harmful materials that are hazardous to health are used for production.

- Easy to install. The owner can easily handle the installation; in addition, the fastenings are already included. You can attach the equipment both to the wall and to the ceiling. It is also suitable for plasterboard ceilings, but you will first need to install a support beam that will hold the device. Compact models, several centimeters thick, are increasingly being produced, for example, Ballu BIH AP 08.

There are not many disadvantages, but they should also be taken into account:

- Due to constant heating, painting coatings may deteriorate. If you have a humidifier at home, this problem does not occur.

- If you turn off the device, the room will quickly cool down.

These disadvantages can hardly be called significant. In order not to be afraid of overheating, many users equip their equipment with thermostats.

Classification of IR heaters

Infrared heating equipment differs in several ways: by energy source, purpose and installation method.

According to energy source:

- Electrical is the most common type of device installed in premises of any purpose. An indispensable element of the system is a mirror reflector for supplying radiation in the desired direction.

- Gas - ideal for industrial buildings or open spaces. Due to the excessive power, such equipment is rarely used in residential buildings. The fuel is an air-gas mixture.

- Diesel - usually used in rooms with weak wiring. Diesel IR devices are often used in garages or outdoors. Such devices do not require smoke removal, since cleaning is carried out by three layers of filters.

- Film is the optimal method of heating in residential buildings.

Film infrared heaters are the best option for heating a residential building

By installation method:

- mobile (mobile);

- stationary.

Note! IR heaters are not recommended to be installed directly on the floor.

What is a thermostat

A thermostat or thermostat combines two devices.

The first one measures the indoor temperature at certain intervals and records this data. The second device regulates the operation of the heater.

Internal electronics or mechanisms (depending on the design and features of a particular model) coordinate the operation of the two units. The thermostat takes temperature measurements and if they are higher than the set mode, a signal is sent to the heater to stop working. Next, the temperature is measured in the same mode and as soon as it drops below the desired temperature, the heater turns on again.

Thus, connecting an infrared household heater through a thermostat allows you to constantly maintain the desired temperature in the room.

Types and characteristics of thermostats

Thermostats are presented in a wide range of models; they can have different designs and vary greatly in size. Their main difference is in the principle of operation; they can be electrical or mechanical.

- Mechanical. They have poor functionality and only allow you to set the temperature that should be maintained indoors. The front panel of the thermostat can also have an operation indicator and a power button. This device measures temperature rather approximately, but this is quite enough to create comfort in living spaces.

- Electronic. They are equipped with a display on which you can set fairly accurate temperature readings, set a schedule for changing the temperature at night, and adjust the operation of the heating system for a week or even a month. Some models are controlled remotely, including using mobile phones.

On a note! The main difference between mechanical and electronic thermostats is their cost. The former are much cheaper, although they do their job just as effectively. Moreover, regardless of the chosen model, any thermostat only regulates the switching on and off of heating devices by controlling the temperature inside the room.

Advantages and disadvantages

Ceiling heaters have a number of important advantages, including:

- efficiency;

- increased heat transfer;

- low noise level;

- autonomy;

- there is no problem of oxygen absorption;

- do not emit unpleasant odors;

- small sizes;

- no need for design work;

- it is possible to install it yourself (although the seller will probably impose his own installation);

- Can be installed on suspended ceilings;

- ease of operation.

In addition to the advantages, infrared devices also have disadvantages:

- possibility of overheating during prolonged use;

- considerable cost;

- stationarity of equipment.

Comparison with other types of heating equipment

Competing heating devices (batteries, convectors, heat fans, oil radiators) are aimed primarily at heating the air. Only then does the warm air partially transfer heat to surrounding objects and people.

This method has a number of disadvantages:

- As a result of heating the environment, “air stratification” occurs. In this case, warm air accumulates at the top of the room, and cold air at the bottom. This disadvantage is especially noticeable if tiles are used as flooring.

- Mixing warm and cold air form convection currents, creating drafts in the room.

- Heating of the room is extremely slow.

On all of the above points, infrared heaters beat their competitors.

Installation rules

Many homeowners have found themselves in a situation where batteries interfere with the placement of large household items in a room. Installing an infrared heater on the ceiling will avoid this problem. This device does not attract too much attention, but at the same time allows you to achieve uniform heating of the space in the room.

Installation of heaters is carried out together with laying of thermal insulation and finishing work. As a result, the equipment is virtually invisible.

The installation will be correct only if the following conditions are met:

- a safe distance is maintained from the emitter to interior items, walls, electrical sockets, switches and people;

- During installation, special brackets, hooks and dowels are used;

- Ceiling materials are heat resistant.

Effective mounting is an important requirement for proper installation of infrared equipment. Individual heaters are mounted on suspensions. In this case, the cover is removed from the device, and the suspensions are directed into the grooves. After this, the cover is returned back, and the equipment is put in its place.

To ensure proper installation work, you must connect the grounded electrical cable to the terminal block. Before connecting the equipment, you need to apply alcohol to it, and only after the surface has dried, connect the device to the network. Next, the heater must work non-stop for a couple of hours (to evaporate the lubricant from the manufacturer).

Advice! During the two-hour test period, unpleasant odors may appear. No need to pay attention - this is a temporary phenomenon.

How to install an infrared heater on the ceiling

- Start installing an IR heater on the ceiling by calculating the height of its location. For living rooms, stop at the optimal height for this of 2-3 meters, this parameter is indicated in the passport for this equipment. The more powerful your heater, the higher the suspension should be. Otherwise, your health may worsen and your head will start to hurt.

- When installing an infrared heater yourself, make sure that there are no crowded places near its placement. Since it is a rather intense emitter, which can lead to unpleasant symptoms - itchy skin and headaches.

- The ceiling infrared heater can be installed using the standard brackets that come with it. Use them to suspend equipment from the ceiling with cables or chains.

- Purchase mounting hooks for wood or concrete in advance, complete with plastic dowels. Next comes the installation of fasteners, screwing the hooks into the ceiling and adjusting the length of the cable or chain to adjust the appropriate height of the suspension.

As you can see, self-installation of infrared heaters is an easily accessible process that can take a maximum of 2 hours of your time. The situation is more difficult with installation on a concrete ceiling, where you cannot do without a powerful hammer drill.

If you decide to install the heater on the wall, then use the same hooks with hangers. Heaters should be tilted slightly downward and in a strictly horizontal position.

Instructions for installing an IR heater

Below are instructions for installing a ceiling heater:

- We fix the thermal insulation on the ceiling. We use lavsan-based material. Moreover, the thermal insulation material should cover not only the entire area of the ceiling, but also slightly extend onto the walls. This way you can avoid heat loss in the corners of the room.

- We put thermal film on top of the thermal insulation. To attach the film to the ceiling, we use the places provided for the cuts. This way we will not damage the conductors and heating elements.

- After installing the thermal film, we insulate the contacts on one side, and connect the wiring on the other side. The individual sections are connected in parallel.

- We install a thermostat on one of the walls, which will control the heating system.

- We are conducting a test run. If everything works as it should, you can begin finishing the ceiling surface.

Materials for finishing the ceiling can be: plastic lining, MDF, plasterboard or any other material with low heat-reflecting abilities. A properly installed ceiling infrared heater can become both the main heating device and an excellent addition to the overall heating system of the house.

Installation Tips

An incorrectly chosen location for the thermostat is one of the main reasons why there is no effect from using this device. Having studied the diagram of how to connect the thermostat to the heater, some experts take the advice literally and mount the thermostat on ready-made networks, somewhere in the area between the machine and the heating device.

As a result, the device reads information about the temperature in the corridor or adjacent room and, based on this data, regulates the operation of the infrared heater. To avoid such mistakes and create truly comfortable conditions in the room, you should carefully select the location for installing the thermostat:

- installed in the same room where the heater is located;

- The thermostat should not be located directly under or near heating devices;

- To measure temperature correctly, it is not allowed to cover the device with curtains, paintings, or interior details;

- You should avoid placing in drafts, near ventilation openings;

- placement on cold and damp walls gives a strong distortion of indicators;

- It is not recommended to install it opposite a window, in direct sunlight.

Attention! The optimal height for placing the device is 1.5 meters. This will provide not only the most accurate data, but will also allow you to independently monitor and regulate the operation of the device without unnecessary effort. Given the relatively small height, it is very important to securely fasten the device so that it remains in place if it is accidentally touched.

At the same time, care should be taken to minimize this likelihood - both electrical and mechanical thermostats can be easily damaged, which will lead to incorrect readings on the device itself and to malfunctions of the infrared heater.

Watch a video about installing an infrared heater