458

Any owner of a country house is interested in ensuring that the water supply system installed by him works flawlessly. If there are regular interruptions in the water supply, household appliances will quickly fail.

Any pressure surge in the plumbing system is dangerous for both the water heater and the dishwasher. Connecting a hydraulic accumulator to the water supply system will help prevent a number of potential problems.

How does a hydraulic tank work and why is it needed in a water supply system?

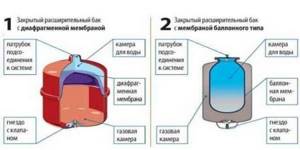

A hydraulic tank, membrane tank or hydraulic accumulator are the names of one device, which is a sealed metal container. Built inside it is a pear-shaped elastic membrane with a small amount of water. The membrane is attached to the hydraulic tank body using a flange with a pipe and divides the tank into two parts. One of the parts is filled with water, the second with air or nitrogen. If you plan to install a hydraulic tank in a domestic water supply system, then purchase devices filled with air. For industrial use, nitrogen is pumped into the accumulator.

As the volume of water in the container increases, the air portion correspondingly decreases, which leads to an increase in pressure in the water supply system. After reaching certain parameters, a specially configured relay sends a command to turn off the pumping equipment.

Metal is used to make the tank, but there is no reason for the formation of corrosion spots. The fact is that the metal is protected from contact with water by a membrane made of high-strength rubber butyl. This material is also highly resistant to microorganisms, which helps maintain water quality in accordance with sanitary and hygienic requirements. It is safe to say that interaction with this type of rubber does not in any way affect the taste properties of water.

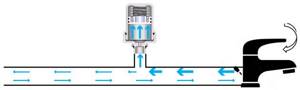

Water enters the membrane compartment through a special pipe, which is equipped with a threaded connection; ideally, the pressure pipe and the connecting outlet of the pipeline have the same diameter. In this case, you don’t have to worry about additional hydraulic losses inside the pipes of the water supply system.

To regulate the pressure inside the hydraulic tank, the air chamber is equipped with a special pneumatic valve. Air is pumped into the intended compartment using a regular car nipple. Also, through this device, excess air mass is released. You can pump air using a compact car or simple bicycle pump.

The design is designed in such a way that the membrane cannot rupture under the pressure of water entering it. The fact is that the compressed air inside the hydraulic tank resists this pressure and prevents its deformation or rupture. It should be noted that compressed air allows you to adjust the pressure before connecting the accumulator. In general, adjusting the hydrophore does not present any difficulties.

Considering the design of a membrane tank, we can distinguish several main components:

- Housing made of metal.

- Membrane made of high-strength rubber.

- Flange equipped with valve.

- Nipple for pumping or bleeding air.

- Legs.

- Platform for installing the pump.

Knowing the design of the equipment, you can independently solve the problem of how to properly connect a hydraulic accumulator for water supply.

Nuances of connecting a hydraulic accumulator

A device with a pear-shaped container assumes that there is water inside it, not air. This feature gives an advantage over the modification with a flat membrane. The reason is that in the latter case the liquid comes into contact with the metal from which the tank body is made. As a result, pockets of corrosion appear. This must be taken into account when choosing a model.

In addition, the bulb is easier to replace if it fails. This usually happens 10-15 years after connecting the circulation pump with a hydraulic accumulator. In addition to the problem of selection, the following aspects must be taken into account during installation:

- The mounting point should be located at the highest possible height. Ideally, this is the attic of the house. This factor allows you to increase the pressure in the pipeline.

- Despite the fact that the flanges are galvanized and the body is painted, the room where the accumulator is installed must be dry. High humidity will lead to condensation, rust and premature equipment failure.

- It is better to connect using flexible stainless steel braided hoses. It should be secured with inch nuts.

- The inlet pipe is where the coarse filter is inserted, which will prevent rust, scale and other suspended solids from entering the container and damaging the membrane.

- A ball valve is mounted at the inlet, with which you can cut off the wiring from the supply line if you need to repair it or service the pump. There will be no water in the house.

Before purchasing, it is necessary to make preliminary calculations. They consist in determining the required operating parameters and characteristics of the hydraulic tank. Be sure to watch this video, where the person tells you how to choose a tank yourself.

The opinion “the larger the capacity, the better” is incorrect. Too much water will cause it to stagnate. As a result, harmful bacteria may multiply, sediment may form, and an unpleasant odor may appear. Such a tank takes up a lot of space and weighs heavily. If the consumption is small and the power is rarely turned off, purchasing such equipment is not practical.

A tank that is too small is ineffective because the pump will turn on frequently, which will adversely affect service life. A special formula is used for calculations. An alternative method for determining the required tank volume is to match the power of the pumping station and the size of the tank. More productivity - larger tank size.

For this purpose, special tables are used. If the conditions are completely cramped, it makes sense to consider purchasing a pump with a soft start, and not spend money on a hydraulic accumulator. But if it is possible to install both elements, the benefits will also include savings. But most importantly, such a system will work for a long time and without interruption.

Operating principle of a hydraulic accumulator

At the first stage, immediately before turning on the accumulator, the air chamber occupies most of the volume of the device. When filled with water, the pear-shaped membrane increases in volume and begins to fill the inside of the hydraulic tank, thereby compressing the air. Filling continues until the pressure reaches a certain limit specified by the relay settings. After this, the relay sends a command to turn off the pump.

When the tap is turned on at the point of water collection, the system depressurizes; compressed air, exerting pressure on the membrane, promotes the release of water from the hydraulic tank. When the pressure in the system drops to the set minimum value, the relay will operate and give a command to turn on the pump. Water will again flow into the storage tank. Therefore, it is important to understand how to properly install a hydraulic accumulator in a water supply system.

The air entering the membrane compartment of the accumulator gradually accumulates, which makes the device less efficient. For this reason, it is periodically necessary to bleed air from the membrane bag. Modern models are equipped with a special valve for bleeding air. If the equipment does not have such a part, then after about 2-3 months it is necessary to carry out preventive measures in relation to the membrane tank.

Correctly solving the problem of how to connect a hydraulic accumulator in the water supply system of a private house will allow you to carry out preventive work without much difficulty, disassemble and reassemble the device if necessary, without completely draining the water from the system.

Accumulator pressure

In the air chamber of the accumulator, the pressure should be 10% lower than the pressure when the pump is turned on.

An accurate indicator of air pressure can only be measured with the tank disconnected from the water supply system and in the absence of water pressure. Air pressure must be constantly monitored and adjusted as necessary, which will increase the life of the membrane. Also, to continue the normal functioning of the membrane, a large pressure drop should not be allowed when the pump is turned on and off. A normal difference is 1.0-1.5 atm. Stronger pressure drops reduce the service life of the membrane, greatly stretching it; moreover, such pressure drops do not allow comfortable use of water.

Hydraulic accumulators can be installed in places with low humidity, not subject to flooding, so that the flange of the device can successfully serve for many years.

When choosing a brand of hydraulic accumulator, you need to pay special attention to the quality of the material from which the membrane is made, check certificates and sanitary and hygienic certificates, making sure that the hydraulic tank is intended for drinking water systems. You also need to make sure that you have spare flanges and membranes, which should be included so that in case of a problem you don’t have to buy a new hydraulic tank

The maximum pressure of the accumulator for which it is designed must be no less than the maximum pressure in the water supply system. Therefore, most devices can withstand a pressure of 10 atm.

The need to install a membrane tank

Without knowing the connection diagram of the deep-well pump to the hydraulic accumulator, we can conclude that the hydraulic tank simply passes the incoming liquid through itself. However, this statement cannot be called absolutely accurate. Such a device functions as a water pressure stabilizer in the water supply system. In addition, the hydraulic tank helps to increase the operating period of the pump and protects the entire system from water hammer. In the event of a voltage drop in the electrical network, the water supply in the storage compartment will allow you to not experience problems with clean water for a certain time.

The advantages of connecting a hydraulic accumulator to a well can be described in more detail as follows:

- Protection of the pump from premature wear. The presence of a certain amount of water in the membrane tank makes it possible to satisfy the needs of residents for some time. The pump turns on only after the membrane tank is empty. Each pump has factory settings, thanks to which the device turns on and off a certain number of times within one hour. If the hydraulic accumulator is set to similar or lower values, then the service life of the pump can be increased provided that the well pump is correctly connected to the hydraulic accumulator.

- Maintaining stable water pressure values. When several taps are turned on simultaneously, a decrease in the pressure and temperature of the water in the system may occur. This situation can cause discomfort to a person who is taking a shower at this time. The presence of a hydraulic tank allows you to maintain stable water pressure values in the water supply system in a private home.

- Water hammer in most cases occurs when the pump is turned on and causes irreparable damage to pipes and other elements of the water supply system. The installed membrane tank reduces the risk of water hammer to a minimum.

- Water supplies. Most country houses have an autonomous water supply system, so water problems can arise for various reasons. For example, power outages significantly reduce the efficiency of the pump, and in some cases the device does not perform its functions at all. This situation forces you to regularly store water in an additional container. When using a scheme for connecting a hydraulic accumulator to a water supply system, this problem does not arise, since there is always a certain amount of water in the device.

Role in the water supply network

It would seem that the device simply passes water through itself. Could you do without it? In fact, it is with the help of a hydraulic tank that stable pressure is maintained in the water supply system. The water pump, if present, does not turn on so often, which allows you to use its operational resource economically. In addition, the water extraction and transportation system is reliably protected from water hammer.

If for any reason the voltage in the electrical network is lost, a small “emergency” supply of water in the tank will help solve priority economic problems. Let us clarify the list of advantages that this fairly simple device provides.

- Premature pump wear. There is a certain supply of water in the membrane tank. It satisfies the primary needs of cottage owners. And only when the supply runs out will the pump turn on. It should be noted that all pumps have a turn-on rate of an hour. If there is a hydraulic accumulator, this figure will not be exceeded, and the unit will last longer.

- Stabilization of pressure in the system. If you turn on two taps at the same time, for example in the bathroom and in the kitchen, pressure changes can affect the water temperature. This is very unpleasant, especially for those household members who are taking a shower at this moment. Thanks to the hydraulic accumulator, such misunderstandings can be avoided.

- Water hammer. These phenomena, which can damage the pipeline, can occur when the pump is turned on. With a hydraulic tank, the risk of water hammer is virtually eliminated.

- Water supply. In a country house, the problem of water supply is especially acute. If there is a sudden power outage and the pump cannot perform its functions, then it is no longer necessary to store a supply of water in a bucket or other container to solve urgent problems. It is available in the hydraulic accumulator tank and is regularly updated.

Obviously, the presence of this device in a water supply system independent of centralized networks is not accidental. It is necessary and useful.

The hydraulic accumulator in the water supply circuit performs a number of significant functions: it protects equipment from water hammer, provides a supply of water, and creates conditions for automating its intake.

Types of membrane tanks

Hydraulic tanks can be installed in water supply systems for various purposes.

In particular, we are talking about the following:

- Meeting the need for hot and cold water.

- Heating systems for a private house.

In the first case, the membrane tank allows you to extend the service life of pumping equipment due to the established on and off mode and protects the system from the destructive effects of water hammer. The second option involves using a hydraulic tank as an expander, which is built into a closed heating system and is its integral part.

According to their configuration, hydraulic tanks are divided into horizontal and vertical models. It is worth noting that the configuration of the tank does not affect the principle of its operation and the connection of the submersible pump to the accumulator.

A distinctive feature of vertical type hydraulic tanks is a special valve through which excess air is released. Moreover, in most cases, models with a volume of more than 50 liters are equipped with a valve. The valve is mounted precisely in the upper part of the container, since the air entering the membrane compartment along with water tends to accumulate at the top of the chamber.

Horizontal tanks also have a device for bleeding air, only in this case the drain device or tap is located behind the accumulator. To remove air from a small container, drain the water completely.

When looking for an answer to the question of where to install a hydraulic accumulator for water supply systems, it is important to understand that horizontal and vertical devices are characterized by the same efficiency and functionality. Therefore, when choosing a device, first of all, the dimensions of the room where the device is planned to be installed are taken into account.

Types of hydraulic tanks

The hydraulic accumulator is a tank made of sheet metal divided into two parts by an elastic membrane. There are two types of membrane - diaphragm and balloon (bulb). The diaphragm is attached across the tank, a pear-shaped cylinder is secured at the inlet around the inlet pipe.

According to their purpose, they are of three types:

- for cold water;

- for hot water;

- for heating systems.

Hydraulic tanks for heating are painted red, tanks for water supply are painted blue. Expansion tanks for heating are usually smaller in size and lower in price. This is due to the membrane material - for water supply it must be neutral, because the water in the pipeline is potable.

Two types of hydraulic accumulators

Depending on the type of arrangement, hydraulic accumulators can be horizontal or vertical. Vertical ones are equipped with legs; some models have plates for hanging on the wall. It is the elongated upward models that are most often used when independently creating water supply systems for a private home - they take up less space. The connection of a hydraulic accumulator of this type is standard - through a 1-inch outlet.

Horizontal models are usually equipped with pumping stations with surface-type pumps. Then the pump is placed on top of the tank. It turns out compact.

Standard device with surface pump

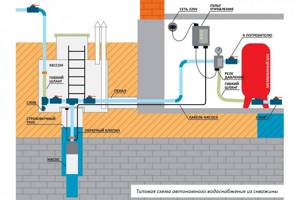

Most often, an autonomous water supply system for a private home requires a hydraulic accumulator and a surface pump. In this case, the manufacturer offers complex factory-assembled pumping equipment, which already includes a hydraulic tank. However, the possibility of placing the membrane tank together with the pump in a caisson or in a heated utility room is not excluded. Therefore, it is important to understand how to connect a deep-well pump to a hydraulic accumulator.

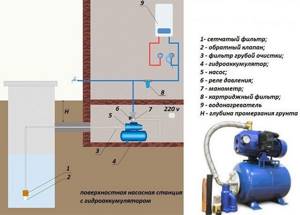

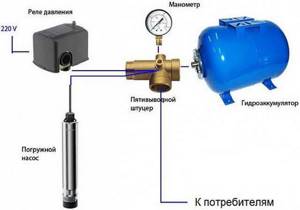

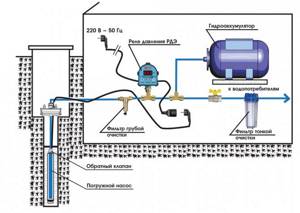

The connection diagram is most often the same. A check valve is installed in front of the hydraulic tank, eliminating the possibility of changing the water flow, followed by a pressure switch that reacts to the slightest changes in water pressure. A mandatory element in such a system is a pressure gauge, with which you can monitor the operating parameters of the entire system.

Before connecting the accumulator to the water supply system, it is necessary to additionally install an angle pipe to connect to the flange.

Connection methods and diagrams

The connection diagram of the well pump to the hydraulic accumulator will depend on the purpose of the equipment itself:

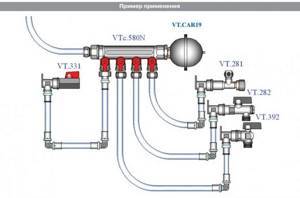

- When installing a cold water supply, a storage tank is installed in a certain place, and pressure sensors are connected using a fitting with 5 inputs. To prevent pump vibrations from affecting the hydraulic accumulator, it is connected with a flexible hose. Such a system will need to be inspected periodically, before draining the water through a tap or a nearby pipe embedded in the main.

- In an apartment building with a centralized water intake, the HA is installed in front of the pump, that is, the container is filled from the central pipe and transported to consumers using the pump. In this case, the HA compensates for the low pressure of the central line.

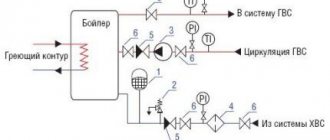

- If the system has a boiler, the accumulator is connected to it.

These are the simplest schemes that allow you to quickly establish a water supply.

Installation of a booster pump

A booster pumping station is installed in places where there is active water consumption. In this case, the device constantly maintains and regulates the water pressure in the pipeline. In most cases, the pumps here operate in constant mode. If there is a need for additional pumping equipment, it is recommended to use a membrane tank that can compensate for differences in water pressure in the system.

A hydraulic accumulator included in a water supply system with a booster pumping station can act as a backup water storage tank. Here you need knowledge of how to connect the expansion tank to the water supply system. In addition, a similar scheme can be used in case of unstable power supply to booster pumps in areas where uninterrupted water supply is required. In this case, the water reserves in the accumulator may well meet the needs during a power outage. In this scheme, the membrane tank plays the role of a backup storage device. It is worth noting that powerful pumping stations require a hydraulic tank of significant volume.

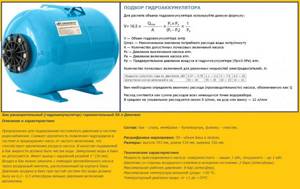

Hydraulic accumulator calculation

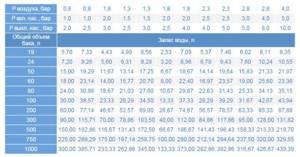

To determine how much water can be used from the accumulator when the power is turned off, when the pump stops pumping water from the water supply system, you can use the membrane tank fillability table. The water supply will depend on the setting of the pressure switch. The higher the pressure difference when turning the pump on and off, the greater the supply of water in the accumulator. But this difference is limited for the reasons stated above. Let's look at the table.

Here we see that in a membrane tank with a volume of 200 liters, with the settings of the pressure switch, when the indicator on the pump is 1.5 bar, the pump off is 3.0 bar, the air pressure is 1.3 bar, the water supply will be only 69 liters, which is equal to approximately a third of the total volume of the tank .

Calculation of the required volume of the hydraulic accumulator

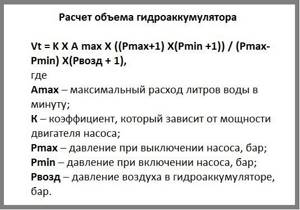

To calculate the accumulator, use the following formula:

Vt = K * A max * ((Pmax+1) * (Pmin +1)) / (Pmax- Pmin) * (Pair + 1),

Where

- Amax – maximum flow rate of liters of water per minute;

- K is a coefficient that depends on the power of the pump motor;

- Pmax – pressure when the pump is turned off, bar;

- Pmin – pressure when the pump is turned on, bar;

- Pair – air pressure in the hydraulic accumulator, bar.

As an example, let’s select the required minimum volume of a hydraulic accumulator for a water supply system, taking, for example, the Aquarius BTsPE 0.5-40 U pump with the following parameters:

| Pmax (bar) | Pmin (bar) | Pair (bar) | A max (cubic m/hour) | K (coefficient) |

| 3.0 | 1.8 | 1.6 | 2.1 | 0.25 |

Using the formula, we calculate the minimum volume of HA, which is 31.41 liters.

Therefore, we choose the next closest GA size, which is 35 liters.

The tank volume in the range of 25-50 liters is ideally consistent with all methods for calculating the volume of hydraulic fluid for household plumbing systems, as well as with the empirical assignments of different manufacturers of pumping equipment.

If there are frequent power outages, it is advisable to choose a tank of a larger volume, but at the same time you should remember that water can only fill the tank by 1/3 of the total volume. The more powerful the pump installed in the system, the larger the volume of the accumulator should be. This sizing will reduce the number of short starts of the pump and extend the life of its electric motor.

If you bought a large-volume hydraulic accumulator, you need to know that if water is not used regularly, it will stagnate in the hydraulic accumulator and its quality will deteriorate. Therefore, when choosing a hydraulic tank in a store, you need to take into account the maximum volume of water used in the home’s water supply system. After all, with a small water consumption, using a tank with a volume of 25-50 liters is much more expedient than 100-200 liters, the water in which will be wasted.

Using a circuit with a submersible pump

To extend the service life of a submersible pump, it is necessary to study the question of how to connect a submersible pump to a hydraulic accumulator and select the correct on and off mode. These parameters must correspond to the technical characteristics of the device, which are specified by the manufacturer in the accompanying documentation. Normal operation of the pump is ensured when turned on 5 to 20 times within one hour.

Very often the pressure in the water supply system is below normal. In such a situation, the relay is triggered and sends a command to turn on the pumping equipment. After reaching the set parameters, the relay turns off the pump and water stops flowing.

It is worth noting another very important point when a small autonomous water supply station is not able to satisfy water needs in full. In this case, the pump will start much more often, which reduces the service life of the equipment.

Using a diagram for connecting water from a well through a hydraulic accumulator in both cases will solve the problem of rapid wear of pumping equipment. In the first option, the membrane tank will maintain pressure and regulate the water pressure in the system. In the second option, the water reserves in the membrane compartment will almost fully satisfy the needs of the residents.

When choosing the volume of a membrane tank, you need to consider the following points:

- Pump power.

- Frequency of device activation.

- Required volume of water per hour.

- The height at which the device is placed.

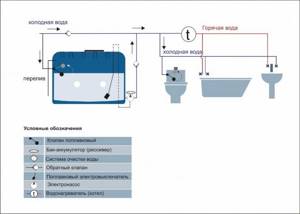

In closed water supply systems with a storage water heater, the hydraulic tank serves as an expander. The fact is that when heated, water tends to increase in volume. The expansion of water in a closed system can have devastating effects. In this case, the hydraulic tank receives excess water, thereby saving the pipeline from ruptures.

When choosing a storage tank for such a system, it is necessary to compare the maximum water heating temperature with the declared characteristics of the installed equipment. In addition, you need to take into account the maximum water pressure values in the water supply system.

Application options

Now let's find out where and how to install a hydraulic accumulator for water supply systems, depending on your goals.

Water reserve

Where to install a hydraulic accumulator for water supply systems, creating a supply of water in case of shutdown?

A capacious membrane tank will provide you with water during the repair of the main water supply

At any point of the cold water distribution system. The water supply accumulator is connected using a rigid connection or a flexible hose.

A couple of subtleties:

- It is not advisable to install a membrane tank in the basement of a private house. In this case, you will lose several meters of water pressure (the loss of pressure will be equal to the vertical distance between the accumulator and the water collection point);

- The installation of a water supply accumulator must be accompanied by the installation of a check valve at the cold water inlet into the house. The valve will prevent water from the tank and internal water supply from flowing into the water supply main when it is discharged.

Expansion tank

Membrane tanks are used as expansion tanks - in water supply systems with capacious boilers (electric or indirect heating).

Membrane tank in the indirect heating boiler piping

Why are they needed there?

You see, when heated, water behaves like all other media - it expands. Meanwhile, there is usually a check valve at the boiler inlet. It prevents heated water from being discharged when the water supply is turned off and at the same time will not allow water expanding when heated to be forced out into the cold water supply system.

The result is obvious - when the boiler heats water, the pressure in it and in the water supply rapidly increases. Connecting a hydraulic accumulator to the water supply system completely solves this problem: with it, the pressure increase slows down many times.

Water hammer protection

As already mentioned, the presence of a membrane tank can protect the water supply circuit from water hammer.

A metal-polymer pipe burst due to water hammer

Here are the typical reasons for its occurrence:

- Excessively rapid filling of the vented circuit with the tap open. A pressure surge occurs at the moment when all the air is forced out of the water supply;

- Instant stop of circulation in the hot water supply system (due to fallen gate valves or a quickly closed ball valve);

- A faucet tap that instantly goes from fully open to fully closed.

Captain Obviousness suggests: in all the described cases, the cause of water hammer is the inertia of the water flow in the pipes.

How to properly install a hydraulic accumulator in a water supply system to protect it from water hammer:

| Image | Description |

| In a water supply system with tee wiring, a small volume tank is mounted between the inlet and the first plumbing fixture. |

| In a water supply system with collector wiring, a membrane tank is placed on the collector and protects the devices connected to it. |

Water supply from a well

Installing a hydraulic accumulator for water supply systems powered from a well or borehole allows you to solve two problems at once:

- Eliminate pressure surges when turning the water supply pump on and off;

- Create a supply of water and thereby make the pump start more rarely (and therefore increase its resource).

Typical connection diagram for a hydraulic accumulator for water supply systems from a well

Such a scheme includes, in addition to the membrane tank, a number of other elements:

| Image | Description |

| A pump responsible for raising water. For a well or well depth of up to 7-8 meters, this can be a surface pumping station; for greater depths, only a submersible pump. |

| Check valve. It is located on the suction pipe of the pumping station or immediately after the submersible pump. The valve keeps pressurized water in the water supply after the pump is turned off. |

| Automatic pump control with pressure sensor. Its task is to turn the power of the device on and off when the pressure in the water supply reaches threshold values. |

Water supply from tank

Often, the source of water in case of long-term outages is not a membrane tank, but a reserve tank without excess pressure. Its advantage is its low cost: a tank with a volume of 1000 liters will cost the buyer 7-9 thousand rubles.

Plastic drinking water tanks

The obvious solution for supplying water from such a container to the water supply is to place it in the attic or under the ceiling of a residential floor.

However, this solution has three serious drawbacks:

- The strength of the floors (primarily wooden) limits the weight and useful volume of the storage tank. A container of 3-4 cubic meters when filled with water has a very real chance of breaking the beams;

The water supply is limited by the strength of the floors

- To operate household appliances, excess pressure is required. Let's give the most illustrative example: a instantaneous water heater simply will not turn on the heating until a pressure sensor in its chamber is set to 0.3 kgf/cm2 (which corresponds to a water column of 3 meters);

In the photo there is a pressure sensor in an instantaneous water heater

- To install the tank in the attic, the latter must be heated. Heating an unused attic means significantly increasing your costs during the cold season.

That is why the correct implementation of such a water supply system looks like this:

- The container is installed in the subfloor, basement or basement;

The storage tank in the photo is located in the boiler room located below ground level

Hint: the ground temperature below the freezing level is stable throughout the year and is always above zero. The water in the tank located in the basement will never freeze and will remain cool in the most intense heat.

- A surface pump with a membrane tank is connected to the tank. A relay with a simple float level sensor is responsible for turning it on and off;

Float water level sensor

- The installation diagram of a water supply accumulator is completely identical to the diagram used for water supply from a well.

Pump and hydraulic accumulators for water supply: diagram of connecting the water supply to the storage tank

Rules for choosing a hydraulic tank

The main element of the accumulator is the membrane. Its quality characteristics determine how long the entire device will last and when the first repair will be required. The best quality is the membrane made from isobutated rubber.

As for the material for making the hydraulic tank housing, this factor in most cases is not particularly important. The only exception is expansion tanks. The fact is that water enters only into the pear-shaped membrane; contact with the metal parts of the device is completely excluded.

When choosing a membrane tank, special attention should be paid to the thickness of the flange, which is most often made of galvanized steel. If the metal is of insignificant thickness, then very soon the entire device may fail. Most often, with a metal thickness of 1 mm, the service life of the flange does not exceed one and a half years. Although at normal values the hydraulic tank can be used flawlessly for up to 15 years.

How to choose the right hydraulic accumulator

Selection of storage equipment is a very responsible process. One of the main criteria to consider is the volume of the membrane tank. If it is insufficient, this will lead to very frequent activation of the pump and its rapid failure. In addition, small containers are unlikely to be effective in combating the negative effects of water hammer.

Installing a device that is too massive for water supply systems will result in water stagnation. This, in turn, will significantly worsen its organoleptic characteristics - smell, color and taste. That is why, in the process of choosing a hydraulic accumulator for installation with your own hands, you should focus on the factors listed below:

- the power of the pumping station of autonomous water supply systems - the higher it is, the larger the volume of the membrane tank should be;

- number of water consumers - plumbing equipment and household appliances;

- Peak water demands for specific systems.

If the volume of the membrane tank you have already installed yourself is not enough, do not despair - at any time you can purchase an additional storage device and connect it to the water supply system

Features of connecting the hydraulic tank to the water supply system

A hydraulic accumulator is not just a container filled with water. This is a special-purpose device that performs a special function in the water supply system. For this reason, installing the equipment may seem quite complicated.

When solving the problem of how to connect a hydraulic accumulator to a well, it is very important to take into account vibration and noise factors. Therefore, special rubber gaskets are used for fixation on the floor, and rubber adapters are used for fastening to the pipeline. In addition, it is important to understand that the outlet diameter of the liner can be much smaller.

Fill the new tank with the utmost care, being careful not to supply water under strong pressure. If the tank is not used for a long time after manufacturing, the membrane may cake. Strong pressure or sudden supply of water can cause damage to the membrane or its complete failure. Experts recommend bleeding all the air out of the bulb before filling, which will help avoid troubles when pumping water into the accumulator.

When choosing where to install the accumulator in the water supply system, it is necessary to ensure free access to any part.

The connection of the hydraulic accumulator to the water supply system is carried out according to a certain scheme:

- A water pipe is led into the house through the foundation or basement.

- A power cable is inserted to connect pumping equipment.

- Collect individual elements into one line.

- Adjust the hydraulic tank.

- Connect the device to the general water supply system.

- If it is necessary to use two hydraulic accumulators in the water supply system, an additional device is installed in the caisson.

- Connect the pressure gauge to the second device.

- If you intend to use a water supply branch for watering plantings, then install a check valve and a drain valve.

Hydraulic accumulator care

To extend the life of the HA, the following rules must be followed:

- monitor for leaks - they can occur due to poor sealing or vibrations transmitted from the pump;

- check the air pressure inside - its drop can cause rubber rupture and fluid leakage from the air valve;

- immediately respond to problems in the operation of the system, since the problem may lie not only in the pump or HA.

To detect the problem in time, experts recommend checking parts for wear every six months. To do this, disconnect the hydraulic tank from the system, drain the liquid and remove the ring holding the membrane - this is where rubber tears most often occur, after which air begins to flow into it. Replacing a pear is not difficult; it is important that it be selected similarly to the first one and meet the technical characteristics.

Rules for setting up a new membrane tank

The first step in tuning is to check the internal pressure level. This value should be 1.5 atmospheres. However, it should be taken into account that leakage is possible during transportation of the device and during storage. Therefore, at the time of sale, the parameters may differ from the values specified by the manufacturer.

To record the readings, you need to remove the cap on the spool. The following types of pressure gauges are used to measure pressure:

- Electronic devices are considered the most expensive products and are quite sensitive to temperature and battery charge. This can significantly affect the accuracy of measurements.

- Mechanical or automotive pressure gauges. In most cases they have a metal body. The measuring scale may have a different number of divisions; to obtain more accurate results, it is recommended to use devices with a large number of divisions.

It is worth noting that inexpensive pumping equipment can be equipped with a pressure gauge in a plastic case; the measurement error in this case is quite large.

When deciding how to connect a hydraulic accumulator to a deep-well pump, setting the parameters of the membrane tank is of great importance for several reasons. For example, if there is insufficient pressure, water takes up most of the volume in the hydraulic tank, and as a result, the water pressure in the system decreases. High pressure provides good water pressure. However, at higher pressure values, there is less water in the hydraulic tank, which leads to frequent activation of the pump and problems with water.

When making adjustments, please note that the pressure parameters should not be less or more than the recommended values. At low pressure, the membrane may come into contact with the walls of the metal housing, which should not be allowed.

Connection to a deep well pump

The technical characteristics of a well do not always allow the installation of a powerful submersible pump into it. For example, if the casing is too narrow and the well is deep. In such a situation, it is necessary to select a deep unit, the power of which is sufficient to lift liquid from the depth to the storage tank. It can be located in a caisson or on the surface of the earth near the well.

Next, another pump is mounted near the hydraulic accumulator - a self-priming one, which will transport water to the house. Another hydraulic accumulator is installed in the room, regulating the pressure in the system and controlling the operation of the second pump.

The second container should be a membrane or balloon. To prevent the liquid from stagnating in the first container, its volume should not be very large. It is possible to connect a hydraulic accumulator directly to a submersible pump only if the parameters of the well and the power of the electrical equipment are fully consistent.

Accumulator volume

Do not buy a hydraulic accumulator based on what your friends or neighbors in the country have installed. Perhaps this model will not be effective for you. The volume of the hydraulic accumulator (like all other equipment!) should be selected only on the basis of the results of hydraulic calculations. The number of models on the market is quite large.

Is there an optimal hydraulic tank volume? As we have already said, only a hydraulic calculation can accurately indicate a specific model of hydraulic equipment that is optimally suited to your conditions. But the number of typical volumes for various models of hydraulic tanks is not so large. That is, if, according to the calculation results, you need a tank with a volume of 51.5 liters, then you will not be able to find such a tank on sale. You will be advised to purchase a 60 liter hydraulic tank. Extra liters of volume will not harm, and will even slightly increase the water supply and reduce the number of pump starts.

The experience of engineers selecting and installing water-lifting equipment tells us the following:

- A hydraulic accumulator with a volume of 25 liters can be installed in a water supply system for three consumers with a borehole pump productivity of 2 m3/h.

- in a system with a number of consumers of 4-8 and a pump capacity of 3.0-3.5 m3/h, a hydraulic tank with a volume of 60 liters is optimal.

- if the number of consumers is more than 10 and the pump capacity is 5 m3/h, then the optimal tank volume will be 100 liters.

How does a hydraulic accumulator work?

Before connecting the accumulator to the water supply, you need to understand the principle of its operation. The principle of operation is to perform the following tasks:

- Through the water supply, the receiver is filled with water, or rather, a rubber membrane. Water supply can be carried out not only from the water supply, but also from a well or well.

- The control relay, which is responsible for the lower and upper pressure thresholds, turns off the power supply to the electric motor with the pump as soon as the set parameter reaches a certain value. The pressure in the receiver can be set independently, but it is undesirable for this parameter to exceed 6 atmospheres.

- As soon as the rubber reservoir is filled to a certain pressure, the pump turns off. When you open a tap in the house, water flows out of the receiver. The more water capacity is consumed, the faster the pressure will drop to the lower limit.

- As soon as the pressure in the tank drops to a lower value, the relay will operate, which will signal the electric motor to turn on the pump. Water is pumped to the upper pressure threshold, after which the engine is turned off again.

If there is a need to use a large volume of water, for example, if a person is filling a bath or taking a shower, then the pump will run continuously until the tap is closed. The smaller the tank, the more often the electric motor will operate to fill the receiver. When choosing a receiver, it is worth considering that each part has its own resources. The larger the receiver volume, the less wear on the pump, flange with valve and electric motor. If the volume of the receiver is small, and water has to be used very often, then the service life of the working elements will depend directly on how often the need for water arises.

Installation with surface pump

In essence, the connection diagram does not change, but there are some nuances that are important to know. Before connecting, it is necessary to calculate the operating and minimum pressure. Different systems may require different water pressure, but the standard for small water supply systems with a small number of water intake points is 1.5 atm.

Different systems may require different water pressure, but the standard for small water supply systems with a small number of water intake points is 1.5 atm.

Before connecting, it is necessary to calculate the operating and minimum pressure. Different systems may require different water pressure, but the standard for small water supply systems with a small number of water intake points is 1.5 atm.

If the system has equipment that requires high pressure, this figure can be increased to 6 atm, but not more, since higher pressure will be dangerous for pipes and their connecting elements.

Determination of critical pressure

This value is set using a relay, after which the pressure in the empty accumulator must be measured.

The result should be 0.5 - 1 atm below the critical value. After this, the system is assembled.

Its center, as in the previous case, will be a five-connector fitting, to which the following are connected one after another:

- the accumulator itself;

- a pipe from a pump connected to a water source;

- domestic plumbing;

- relay;

- pressure gauge

Choice

The question often arises of how to choose a hydraulic accumulator, taking into account its location. Vertical specimens with a volume of 50 liters or more have a special valve for bleeding. In them, air collects at the top, so it is more convenient and efficient to do this. For this purpose, horizontal ones are equipped with an additional pipeline with a nipple, drain, and ball valve. The procedure is less effective and a little more complicated.

If the equipment has a small capacity, then it does not matter which accumulator to choose - both types have a separate pipeline, and in order to get rid of air they need to be completely emptied

Experts recommend options with horizontal installation for systems with external pumps. Vertical mechanisms are better suited in combination with wells with submersible devices for private homes. A small room is allocated for them (basement, basement) or everything is installed together with the pumping station in a pit near the house

The attached instructions contain tables with data that will inform you how to choose a hydraulic accumulator with the required technical capabilities for the amount of water used and the height of the pipes.

Determining the required volume

Switching frequency, supercharger power, hourly resource consumption, installation height are factors that are important for choosing a gas generator with the required amount of space inside. The rule applies: it is better to take more than less, because the less often the pump turns on, the better. The main thing is to meet the minimum requirements of the pipeline. The hydraulic accumulator is adjusted taking into account that its useful capacity is from 30 to 50% of the internal space.

The calculation of the accumulator volume takes into account the following examples:

- to unload the submersible pump, reduce the frequency of its switching on (recommended amount is about 30 per hour) and for the required productivity of 40 l/min. recommended hydraulic accumulator volume – 70 – 80 l or more

- just to maintain pressure and compensate for peak loads, the smallest sizes of 25 - 40 liters will be sufficient

- with 25 - 40 liters, a scheme with 4 units (washbasin, bath, shower, water heater) and the needs of 2 people will work normally. Another example: for two toilets, a sink, a shower, a washbasin with a total consumption of 20 l/min, 50 - 80 l will be enough, which should satisfy 3 - 4 people.

- to form a reserve to ensure the source operates when the power is turned off, 80–100 liters or more will be required

Experts recommend adding 10 - 15 liters to the result obtained in the calculation. If the already installed volume is not enough, then you can mount another device

Pressure

A unit with the required indicator is selected taking into account the hydrostatic pressure determined by the height to which water is supplied. For a house with a pipe height of 10 m, a unit with a capacity of 1.5 - 2 bar will be sufficient. If it is installed on the ground floor, in the basement or basement, then add another 1 bar required for pumping to this level.

Recommendations on how to choose a hydraulic accumulator and how adjustments should be made:

- the operating indicator should not be lower than that of the pump at start. In this case, the minimum difference should be from 0.5, and the maximum should be on average 2 bars

- with low pressure, the water will not reach the top floor. If the norm is significantly exceeded, the tank will be constantly empty

- for a standard two-story house, a container with a minimum power of 1.5 and a maximum of up to 4.5 bar is suitable

- the calculation of the hydraulic accumulator must take into account that if the equipment is used with a submersible pump, then the indicator must be 10% less than the lower pressure limit in it

- for ordinary household appliances, 1.5 - 2.8 atm is required. The buoyancy force should be slightly less than in the system (0.1 - 0.2 atm) - this way the internal membrane will not tear

Manufacturers standardly set 1.5 bar, but the value may be different, so checking with a pressure gauge before connecting is mandatory. It is connected to the nipple of the device. If a different indicator is required, then do it with a regular bicycle pump, the principle is this: air is pumped out - the buoyancy force decreases, air is pumped in - it increases.

The upper pressure level that the membrane tank can withstand must exceed that of the network to which it is connected

The choice of hydraulic accumulator will be successful if you follow the following rules:

- the more often the pump turns on, the larger the capacity is recommended - for an average family of 3 - 4 people, 50 - 80 l is suitable

- the more the better, but keep in mind that unused water stagnates

- the more capacious the device, the lower the frequency at which the pump is turned on, which will increase its service life. This also applies to the pear, since it will shrink less often

- the metal of the flange for connection should be made of galvanized steel thicker than 1 mm or stainless steel, so the part will last longer

Preparing for work

How does a water supply accumulator work? It is charged by a pump to a certain pressure and then supplies the consumer system with water until the pressure drops to the lower limit.

Then the pump turns on again. For everything to work correctly, you need to make settings and check that the tank is filled with air.

Pressure setting

Russian manufacturers, as a rule, set the pump start pressure at 1.5 atm, and its shutdown pressure at 2.5 atm.

Foreign relays are set to 1.4–2.8 atm. There are parameters that are unusual for a private home: 5–7 atm. In this case, make sure that the relay can be adjusted in the desired range: 1–3 atm. Information about this is in the product passport. After purchase, set to 1.5–2.5 atm.

You can set the regulator to other numbers, but there is no point in this. After all, the main household consumers are designed for 2 atm: shower, washbasin, washing machine. Only some, such as a jacuzzi, require 4 atm. At 6 atm and above, seals in the system and consumers fail.

The difference between the pump on and off pressure should be no more than 1.5 atm. A large difference leads to strong stretching of the membrane (balloon) and a shortening of its service life.

If the pressure is indicated in bars, nothing changes in the settings, because 1 atm = 1.01 bar.

Pumping air into the hydraulic accumulator

You can measure the air pressure in the accumulator tank for water supply with a tire pressure gauge, and pump it up with a car pump.

How much you need to pump is indicated in the passport and on the accumulator body. But it is better to use other numbers so that the device works correctly. The air chamber should contain 0.2–0.3 atm less than the pressure at which the pump turns on.

For example, if the relay is set to 1.5–2.5 atm, then the air chamber is inflated to 1.2–1.3 atm. This is done when the water pressure in the system is released.

What pressure should it be

So, it is important to decide what pressure should be in the accumulator. If household appliances are used in a private house, then the pressure range should be in the region from 1.4 to 2.8 atmospheres. To eliminate the possibility of a membrane breakthrough, the pressure in the system should be slightly higher than in the tank itself, at least 0.1 atmospheres. That is, if the accumulator for the water supply system is set to 1.8 atmospheres, then the system should have about 1.9 atmospheres. To set this, a special device known as a pressure switch is used.

When determining the pressure level, it is important to take into account the number of floors of the building. If you have a one-story house, the pressure will be lower than if you had to raise the water to the second floor. Also taken into account is the number of water intake points in the house, how many people live and what is the likelihood that several taps will open at the same time.

If all these nuances are not taken into account, then the following picture may occur. You take a shower while someone else is washing dishes or using the water for other purposes. As a result, the level of pressure and water pressure in the tap will drop sharply. Agree, this is not a very pleasant situation. To prevent this from happening, it is important to correctly set the pressure on the hydraulic accumulator and other equipment. And this will be possible if we take into account all the listed details and more.

How to determine damage to the accumulator

As in a water supply system, a hydraulic accumulator has its own service life. So, for built-in tanks it is determined by the service life of the heating boiler, and a free-standing tank made of ferrous metal usually withstands a 5-6 year period of operation. When filling the system volume with antifreeze, you must carefully study the manufacturer's recommendations to make sure that the material will not react with the antifreeze chemical.

The first sign that the accumulator has failed is a sharp drop in pressure in the system. The fact is that the bottleneck of the accumulator is the membrane. Despite its elasticity and strength, during operation, particles of debris from the internal volume of batteries, pipes, shut-off valves enter its cavity, and insoluble sediments from the water itself often accumulate here. And then, during operation of the membrane, these particles play the role of an abrasive, gradually rubbing the rubber. When the membrane walls break, air from the air chamber penetrates into the heating system and is removed through the air vent, and the freed volume is filled with coolant. In this case, no visible coolant leaks are detected in the room.

If you do not pay attention to the sharp decrease in pressure in the system and simply restore the required fluid pressure, then despite the breakdown of the hydraulic accumulator, the system will continue to operate. But at the first emergency situation, the scale of the accident will be much larger

To systematically monitor the condition of the membrane, it is recommended to periodically check the pressure in the accumulator using a conventional pressure gauge from a road car kit.

To be sure that the equipment is working properly, it is recommended to press the nipple and release a little air 1-2 times every 6 months. A rapid whistling stream of air will indicate that the tank is leaking. But if you hear a faint hissing sound or water drips out instead of air, then you need to sound the alarm - the membrane will most likely be damaged and the device will need to be repaired.

The second common problem when operating hydraulic accumulators is the loss of housing tightness. Unlike water supply system receivers, this problem is relatively rare, but it cannot be discounted. Such damage occurs as a result of improper installation or as a result of improper repair of the device. The tank body is usually made of steel or iron sheet by stamping. The outer part of the tank is painted to protect it from corrosion, but the inside is usually left without an additional protective layer. During operation, pockets of corrosion form on the inner wall of the air compartment, which causes a hole to form over time, and the air simply escapes. It is easy to determine such a malfunction - you need to start deflating the air with a few presses; if you cannot hear a characteristic whistle when pressing, then you need to look for damage to the housing.

Another common type of failure is a spool valve malfunction. This usually happens when setting up the device, when there is a need to constantly pump it up with a pump and check the pressure with a pressure gauge. If the spool is damaged, the pressure usually drops gradually, and on the boiler pressure gauge you can notice that the pressure does not decrease immediately, but over time, in small portions. It should be noted that it decreases, and does not jump in a certain amplitude. Directly on the tank, you can check whether the valve is working or not by applying a small amount of soap solution to it. If the solution does not change its state, then the problem is not with the valve. And if the escaping air blows up soap bubbles, even small ones, then the valve core needs to be replaced. The easiest way to buy it is at an auto store or sporting goods store; the core in the valve is identical to that used in car and bicycle tires.

Kinds

We have already talked about the fact that hydraulic accumulators can be balloon and membrane. In addition, they can be subdivided:

- According to the type of execution - vertical and horizontal: both options differ only in configuration, their operating principle is the same. The choice of design depends on the parameters of the room, the location of the hydraulic accumulator and its piping.

- By purpose - for heating and water supply: in most cases, hydraulic accumulators intended for connection to heating systems have a red body, and their water supply “colleagues” have a blue body. They work according to the same scheme, but water accumulators use food-grade rubber, and heating accumulators use technical rubber. The latter is more durable. Another difference is that the “blue” ones are designed for higher pressure than the “red” ones.

- By volume: various models of hydraulic accumulators can have a volume from 25 liters to 500 and even 1000 liters. Devices with a small capacity are attached to the wall, while larger ones have a floor-mounted design. Hydraulic accumulators with a volume of over 100 liters are equipped with a valve for releasing air, which is gradually released from the water during operation. An automatic air vent can be screwed to the pipe of this valve. Models with a volume of up to 100 liters are not equipped with such a valve, so to remove accumulated air, the water from them must be completely drained periodically.

In private homes it is rare to find a central water supply, so wells and boreholes are the main sources of water. Water supply diagram for a private house connected to a central main line or when connected to an autonomous source - typical water supply diagram, external and internal pipe routing, installation tips.

Why you need a blind area around a private building and how to make it, read here.

In order to avoid contamination of water supply sources, special sanitary standards and requirements for the water supply protection zone have been introduced. Here https://aquacomm.ru/vodosnabzenie/zagorodnyie-doma-v/avtonomnoe-vodosnabzhenie/istochniki/ohrannaya-zona-vodoprovoda.html you will learn what a security zone is and what the consequences of non-compliance with the rules are.

Is it easy to install a hydraulic accumulator?

Summer residents immediately panic when they hear that the hydraulic accumulator must be connected to the water supply system.

They think that the pipes may suddenly burst and then the entire dacha plot along with the house will be filled with water. This is wrong. The hydraulic accumulator is installed according to a standard and proven scheme. Many summer residents have integrated their tanks using it. And they coped with the task perfectly. To do this, they purchased all the necessary components in the form of nipples, pumps and fittings.

To place it in the right place, you need to determine the water flow rate for the entire house. Determine the pump power and the volume of the accumulator. It is also worth knowing the location of the main water supply nodes.

Next, you should write a list of what you need to buy to install the tank:

- Hoses;

- Pipes;

- Fitting;

- Nipples;

- Cranes and so on.

Then look at the installation diagram and just do everything as indicated there.

At first glance, it seems that installing a tank is a difficult task. This is wrong. Decide on a location, look at the diagrams that the water supply system has. Buy the components for the connection and simply connect the tank to the general water supply system.