An autonomous water supply system, which independently supplies water to distribution points as in a city apartment, has long ceased to be a curiosity. This is the norm of country life, which just needs to be properly designed, assembled and equipped with equipment capable of starting and stopping the system as the taps are used.

Stable operation of an independent network will be ensured by an expansion tank for water supply. It will protect against water hammer, significantly extend the service life of pumping equipment, guarantee regular filling of the system with water, and eliminate the need to carry it in buckets.

We are pleased to introduce you to the features of the device and the operating principle of the hydraulic accumulator. We carefully describe the rules for choosing a membrane tank, the specifics of installation and connection. We have supplemented the information offered for consideration with useful illustrations, diagrams and video tutorials.

Expansion tank for water supply: selection, design, installation and connection

An autonomous water supply system, which independently supplies water to distribution points as in a city apartment, has long ceased to be a curiosity.

This is the norm of country life, which just needs to be properly designed, assembled and equipped with equipment capable of starting and stopping the system as the taps are used. Stable operation of an independent network will be ensured by an expansion tank for water supply. It will protect against water hammer, significantly extend the service life of pumping equipment, guarantee regular filling of the system with water, and eliminate the need to carry it in buckets.

We are pleased to introduce you to the features of the device and the operating principle of the hydraulic accumulator. We carefully describe the rules for choosing a membrane tank, the specifics of installation and connection. We have supplemented the information offered for consideration with useful illustrations, diagrams and video tutorials.

Where to put the tank

Let's start with the fact that only closed heating systems are installed in private houses. The water flow circuit itself may have open spaces, or rather, one thing is the expansion tank, which can be open or closed, but besides this, the heating system is usually aimed only at heating the house.

In rare situations, a boiler is connected to it, but that's a completely different story.

Traditionally, the connection diagram for an expansion tank is closed or open near the heating boiler.

If we talk about a private house, then this should happen in the boiler room, and in the case of an apartment, heating boilers are usually located in the kitchen, and therefore the expansion tank should be installed there.

In addition, you need to immediately think about the fact that access to this tank was free and convenient for its use or maintenance - there is no need to put it in strange places or behind cabinets.

But we are not finished with the fastening yet. At the same time, we must have a valve to connect the expansion tank.

Although, to be more precise, this valve will control the access of liquid from the system to the expansion tank.

So, this valve is usually not very light, but it should not have a physical impact on the expansion tank - it should have its own supports or fastenings so that these two parts are independent.

Characteristics of closed expansion tanks

A hydraulic tank (or hydraulic accumulator, expansion tank) is a metal sealed container that serves to maintain stable pressure in the water supply and create water reserves of varying volumes.

At first glance, choosing and installing this device should not cause difficulties - in any online store you can see many models that only differ slightly in shape and volume, but do not differ significantly in their functionality.

It's not like that at all. There are many nuances in the design of the expansion tank and the principle of its operation.

Features of the device and design

Different models of expansion tanks may have restrictions on the method of use - some are designed only for working with process water, others can be used for drinking water.

By design, hydraulic accumulators are divided into:

- tanks with replaceable bulb;

- containers with a fixed membrane;

- hydraulic tanks without membrane.

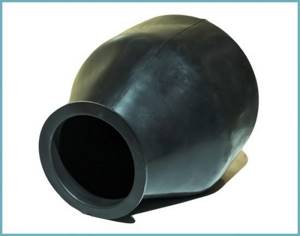

On one side of the tank with a removable membrane (for a tank with a bottom connection - at the bottom) there is a special threaded flange to which the bulb is attached. On the reverse side there is a nipple for pumping or bleeding air or gas. It is designed to be connected to a regular car pump.

In a tank with a replaceable bulb, water is pumped into the membrane without coming into contact with the metal surface. The membrane is replaced by unscrewing the flange held in place by the bolts. In large containers, to stabilize the filling, the rear wall of the membrane is additionally attached to the nipple.

The internal space of the tank with a fixed membrane is divided into two compartments. One contains gas (air), the other contains water. The inner surface of such a tank is covered with moisture-resistant paint.

There are also hydraulic tanks without a membrane. The compartments for water and air are not separated in any way. The principle of their operation is also based on the mutual pressure of water and air, but with such open interaction, mixing of the two substances occurs.

The advantage of such devices is the absence of a membrane or bulb, which is the weak link in conventional hydraulic accumulators.

The diffusion of water and air makes it necessary to service the tanks quite often. About once a season you have to pump in air, which gradually mixes with water. A significant decrease in air volume, even at normal pressure in the tank, causes the pump to turn on frequently.

Operating principle of a hydraulic accumulator

Closed hydraulic tanks for water supply work according to the following scheme: the pump supplies water to the bulb, gradually filling it, the membrane increases and the air that is located between the bulb and the metal body is compressed.

The more water enters the pear, the more it puts pressure on the air, which, in turn, tends to push it out of the container. As a result, the pressure in the tank increases, which causes the pump to turn off.

For some time, when water flows through the system, compressed air maintains the pressure. It pushes water into the water supply. When its amount in the membrane decreases so much that the pressure drops to the lower limit, the relay is activated, turning the pump on again.

Classification by area of application

Tanks for water supply and for the heating system should not be confused, so when choosing, you need to find out their purpose. For clear identification, manufacturers paint hydraulic accumulators for heating red and for water supply blue.

However, some do not adhere to such markings, so the following data can serve as a distinctive feature of devices:

- for water supply, the maximum temperature of use of the hydraulic accumulator will be up to 70 °C, the permissible pressure can reach 10 bar;

- devices intended for heating systems can withstand temperatures up to +120 °C; the operating pressure of the expansion tank is often no higher than 1.5 bar.

All the most important parameters are indicated on the decorative cap (nameplate) that covers the nipple.

The list of functions that a hydraulic tank performs in a cold water supply system is much broader:

- Maintaining an even and constant pressure in the water supply. Thanks to the air pressure, the pressure is maintained for some time even when the pump is turned off, until it drops to the set minimum and the pump starts working again. Thus, the pressure in the system is maintained even when several plumbing fixtures are used simultaneously.

- Protection against wear of pumping equipment. The water reserves contained in the tank allow you to use the water supply for some time without turning on the pump. This reduces the number of pump operations per unit of time and prolongs its operation.

- Protection against water hammer. A sharp jump in pressure in the water supply when the pump is turned on can reach 10 atmospheres or more, which negatively affects all elements of the system. The membrane tank takes the shock, equalizing the pressure.

- Creation of water reserves. When there is a power outage, the water supply system will continue to supply water for some time, even if only for a short time.

For piping the water heater, expansion tanks are used that can withstand high temperatures.

Materials for hydropneumatic equipment

The expansion tank membrane is made of different materials that can withstand different temperature ranges during operation.

The following are used in hydraulic accumulators:

- Natural rubber - NATURAL. The material can come into contact with drinking water and is used to accumulate cold water. Over time, it may begin to leak water. Withstands temperatures from -10 to 50 °C above zero.

- Synthetic butyl rubber - BUTYL. The most universal, waterproof, used for water supply stations, suitable for drinking water. Operating temperature can range from -10 to 100 °C.

- Synthetic rubber made from ethylene propylene - EPDM. More permeable than the previous one, it can come into contact with drinking water. The permissible temperature range is from -10 to 100 °C.

- SBR rubber is used only for process water. The operating temperature is the same as previous brands.

Optimal air pressure

For household appliances to work normally, the pressure in the hydraulic tank must be in the range of 1.4-2.8 atm. For better preservation of the membrane, it is necessary that the pressure in the water supply system be 0.1-0.2 atm. exceeded the pressure in the tank. For example, if the pressure inside the membrane tank is 1.5 atm, then in the system it should be 1.6 atm.

It is this value that should be set on the water pressure switch, which works in conjunction with the hydraulic accumulator. For a one-story country house, this setting is considered optimal. If we are talking about a two-story cottage, the pressure will have to be increased. To calculate its optimal value, use the following formula:

Vatm.=(Hmax+6)/10

In this formula V atm. is the optimal pressure, and Hmax is the height of the highest water intake point. As a rule, we are talking about the soul. To get the required value, you should calculate the height of the shower head relative to the accumulator. The obtained data is entered into the formula. As a result of the calculation, the optimal pressure value that should be in the tank will be obtained.

Please note that the obtained value should not exceed the maximum permissible characteristics for other household and plumbing appliances, otherwise they will simply fail.

If we talk about an independent water supply system at home in a simplified way, then its components are:

- pump,

- hydraulic accumulator,

- pressure switch,

- check valve,

- pressure gauge

The last element is used to quickly control the pressure. Its constant presence in the water supply system is not necessary. It can only be connected at the moment when test measurements are being made.

As you can see, the pressure gauge is not shown in this diagram, but this does not mean that it is not needed at all. It will simply be turned on at the time of control measurements.

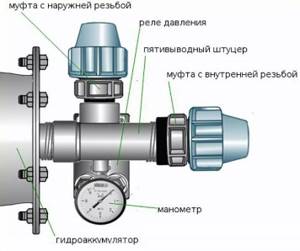

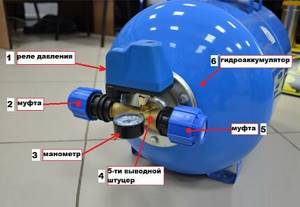

When a surface pump is involved in the circuit, the hydraulic tank is mounted next to it. The check valve is installed on the suction pipeline, and the remaining elements form a single bundle, connecting to each other using a five-pin fitting.

The five-pin device is ideal for this purpose, since it has leads of different diameters. The incoming and outgoing pipelines and some other elements of the connection can be connected to the fitting using American connectors to facilitate preventive and repair work on individual sections of the water supply system.

However, this fitting can be replaced with a bunch of connecting elements. But why?

In this diagram, the connection order is clearly visible. When connecting the fitting to the hydraulic accumulator, it is necessary to make sure that the connection is tight.

So, the accumulator is connected to the pump as follows:

- one inch lead connects the fitting itself to the hydraulic tank pipe;

- a pressure gauge and pressure switch are connected to the quarter-inch terminals;

- There are two free inch terminals left, to which the pipe from the pump is mounted, as well as the wiring going to the water consumers.

If a surface pump operates in the circuit, then it is better to connect the hydraulic accumulator to it using a flexible hose with a metal winding.

The parts that end with couplings will be joined by a pipe from the pump and a water supply system that will go to water consumers.

The hydraulic accumulator is connected to the submersible pump in exactly the same way. A feature of this circuit is the location of the check valve, which has nothing to do with the issues we are considering today.

Characteristics of closed expansion tanks

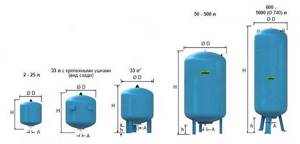

Expansion tanks are cylindrical or spherical tanks with a horizontal or vertical arrangement of the working chamber. Can be floor-mounted or suspended.

The equipment is designed to ensure uninterrupted operation of residential water supply systems connected to the central network. Hydraulic accumulators are designed to work in the structure of a water supply system that supplies resources from underground sources (boreholes, wells). They are supplied as a set of pumping stations; they have the same purpose, but different requirements and operating conditions.

Features of the device and design

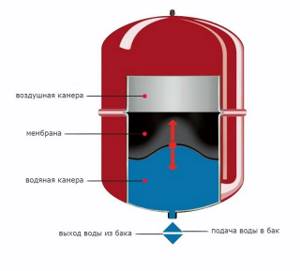

The expansion tank is an impenetrable container made of high-alloy steel. The space of the working chamber of the device is divided into two parts by a rubber membrane, which can be of two types in its shape and method of fastening.

In the first option, it is a vertically installed valve, with air on one side and water on the other. The second modification of the device is made in the form of a solid pear-shaped container made of rubber, which at the bottom, through the outlet valve, is fixed to the body of the device. There is liquid inside the membrane and air outside.

Tanks for domestic use are supplied to retailers in sizes ranging from 8 to 150 liters. Models from 50 l are equipped with support stands, a fitting for connecting additional devices and a pressure gauge for measuring pressure.

Operating principle of a hydraulic accumulator

Operating principle of a hydraulic accumulator.

The hydraulic accumulator is a steel container with metal supports. Inside the housing there are two chambers - air and hydraulic. The top of the air chamber is equipped with a nipple through which air can be released or inflated. The bottom of the container ends with a special fitting for connecting to the water supply.

The principle of operation of the membrane mechanism is as follows: after starting the pumping station, water is supplied to the device tank until the density in the system exceeds the maximum permissible level, after which the relay turns off the accumulator. When the taps are opened, the volume of water in the chamber decreases, the pressure drops, the machine connects the pump, and the pressure stabilizes.

Classification by area of application

Expansion tanks, based on their appearance and manufacturing method, are divided into open and closed structures. Open type equipment is a storage tank that is used in country houses with limited water supply. The size and material of the tank are selected taking into account the required volume of water per day. Cameras of this type are used as additional equipment for heating residential buildings.

Closed-type devices are used to compensate for temperature expansions and stabilize pressure in the following systems:

- cold water supply;

- hot water supply;

- heating;

- water treatment

Materials for hydropneumatic equipment

The trouble-free operation of any hydropneumatic unit depends on the correct choice of membrane. Depending on the application and operating conditions, the part can be made from the following materials:

- Natural rubber – intended for devices with an operating temperature range of -5...+50°C.

- Butyl rubber diaphragm – operates within 0…+120°C.

- EPDM is a synthetic elastomer, operated in the mode +1...+110°C, operating fluid pressure – up to 12 bar.

- SBR diffuser made of styrene-butadiene rubber for hot and cold water supply - up to 15 bar, +1...+100°C.

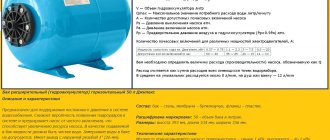

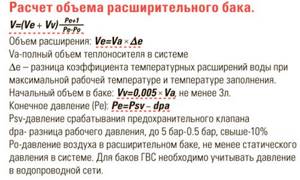

Calculation of tank volume before choosing

In order to correctly set up the apartment’s water supply system, you need to make sure you don’t make a mistake in choosing the volume of the expansion tank. The method for calculating the size of the container is based on collecting information about household appliances located in the apartment.

Calculate tank volume before choosing.

We compile a list of connection points indicating the number of each type of equipment, the frequency of switching on per day and determine the total water consumption coefficient (Cy). For example, there are two washbasins, the total frequency of use is 6 times/day: 2x6 = 12. Such calculations must be made for each item. Then add up all the values. The resulting amount will be an indicator of resource consumption in the apartment.

After this, you need to use the table from the international calculation method UNI 9182, substitute the total coefficient and select the tank of the desired size.

Based on the experience of using the calculation system, the volume of tank for an apartment is equal to:

- up to 3 consumers – expansion tank up to 24 l;

- up to 8 points – 50 l;

- over 10 devices – 100 l.

Down with confusion

In plumbing stores you can find two types of these devices, differing in color:

| Image | Description |

| 1. Expansion tanks installed for heating - water supply are usually red and, in full accordance with the name, are designed to compensate for the thermal expansion of water or coolant liquid when heated. Liquids practically do not compress, and when they expand, the pressure in a closed circuit begins to increase at a catastrophic rate; the air cushion inhibits its growth. |

| 2. Hydraulic accumulators - blue (see Hydraulic accumulators for water supply). They allow you to create an autonomous supply of cold water and act as a damper. That is, they dampen pressure surges when opening/closing shut-off valves and turning on/off the water supply pump. |

The video in this article will help you learn more about membrane tanks.

Device

How are expansion tanks for water supply arranged?

A membrane tank is a steel container with a pipe for connecting to a water supply or heating system and a spool for pumping. It is divided by an elastic membrane into two compartments - air and water. The air compartment is often filled with nitrogen instead of air, which prevents corrosion from damaging the tank walls.

Construction of a water supply expansion tank: a steel container is divided into two compartments by an elastic membrane

Curious: the expansion tank of a hot water supply or heating system is usually equipped with a membrane with increased heat resistance. There are no other design differences between it and the hydraulic accumulator, so the expansion tank can be safely used as a hydraulic accumulator.

Scheme

Now let's take a closer look at why an expansion tank is needed in a water supply system, using specific diagrams as an example.

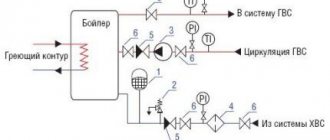

Boiler piping

The boiler piping usually includes two fittings installed on its inlet pipe:

| Image | Description |

| Check valve. It passes cold water from the water supply into the storage water heater, but does not allow it to flow back when the hot water supply is turned off. |

| Safety valve. Since the check valve turns the water supply and the boiler into a closed circuit, when the water is heated, the pressure in it begins to quickly increase. When it reaches dangerous levels, the safety valve releases excess water through the drain tube. |

Helpful: Combined check and safety valves in one housing are often sold under the name “boiler safety group.”

Boiler valve

While the volume of the boiler is small, losses of heated water are insignificant or absent (thermal expansion is compensated by the elasticity of the walls of the water supply system). But with its significant volume, hot water is discharged into the drainage in liters and tens of liters, which significantly affects the costs of hot water supply.

Connecting the expansion tank to the water supply system completely eliminates the loss of heated water. Its excess is contained in a membrane tank, which is accompanied by a slight increase in pressure in the circuit.

Diaphragm tank in the boiler trim

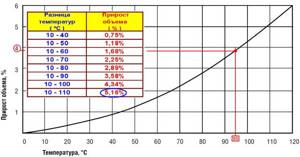

How large should the expansion tank be for a water supply system with a boiler of known volume?

Usually it is taken equal to 10% of the boiler volume. Yes, the thermal expansion of water within reasonable temperature limits is less than 10%; however, do not forget that the capacity of the water compartment is not equal to the full volume of the membrane tank: part of this volume is occupied by air.

Therefore, in practice, rounding up is used: an expansion tank for water supply of 50 liters is capable of ensuring the safe operation of a 500-liter boiler.

Expansion of water when heated

Water supply

How to use a hydraulic accumulator or expansion tank for cold water supply, providing yourself with water during periodic outages?

The instructions for installing the device yourself are extremely simple and consist of only two points:

- Connect the tank pipe to any part of the water supply using a flexible or rigid connection;

The hydraulic accumulator will provide you with water during short-term outages

- Install a check valve at the cold water inlet. It will not allow water to drain from the tank into the disconnected and discharged main water supply.

Please note: the useful capacity of the membrane tank differs markedly from its total volume. For example, an expansion tank of a water supply system of 500 liters is capable of storing no more than 250 liters of water in case of a power outage.

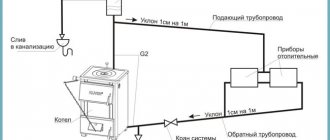

Well water

How to install an expansion tank in a water supply system with water supplied from a well or well? It is again mounted at any point in the water supply system.

Membrane tank in an autonomous water supply system

In addition to the membrane tank, such a system includes:

| Image | Description |

| Gilex line of submersible pumps | Submersible or surface pump. It raises water and creates excess pressure, which ensures the operation of plumbing fixtures. |

| The check valve is located on the outlet pipe of the submersible pump | Check valve. It is placed after a submersible pump or on the suction pipe of a surface pumping station. |

| Automatic relay for pump control with pressure sensor | An automatic relay that controls the operation of the pump (that is, it turns it on when the pressure in the circuit drops and turns it off when the pressure reaches the upper critical value. |

Water supply diagram from a well

What pressure should be maintained in the expansion tank of the water supply system?

The answer cannot be given without knowing the settings of the automatic pump control. The pressure in the water supply expansion tank should be slightly lower (by about 0.2 atmospheres) than the pressure when pumping water from the well. In this case, the pump will start before the remaining water from the membrane tank flows out through the open tap.

How to pump up an expansion tank in a water supply system if the pressure in it has dropped below the required level? This can be done with any air pump - bicycle, car, etc. The pump hose is connected to the spool on the diaphragm reservoir.

Inflating a membrane tank with a car compressor

Water from container

Water supply from a storage tank is practiced in gardening communities with water supply on a schedule, as well as where worn-out water supply lines are often turned off for repairs. The easiest way to supply water to the water supply is by gravity, from a tank installed in the attic.

Gravity water supply with water supplied from a container installed in the attic

However, this scheme has three serious drawbacks:

- The water supply is limited by the strength of the ceiling;

- The attic must be insulated and heated, otherwise the water will freeze in the first frost;

- The pressure in a gravity water supply is limited by the vertical distance between the tank and the tap. Meanwhile, for normal operation of household appliances (instantaneous water heaters, washing machines and dishwashers) a pressure of at least 3 meters (0.3 kgf/cm2) is needed.

Supplying water from a container installed in the basement, underground or ground floor using a pumping station is free of all these disadvantages: the weight of the tank standing on the surface of the soil or screed is not limited in any way, the pressure is created by the pump, and the temperature of the soil below the freezing level is above zero all year round.

A tank with a supply of water is installed in the basement

Connection diagrams for hydraulic tanks

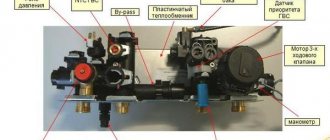

In order to connect hydropneumatic tanks to cold or hot water supply, they must be equipped with:

Hydraulic tank connection diagram.

- supply, drain and outlet pipes;

- pressure gauge;

- safety valve;

- level sensor;

- nipple - a device for regulating and replenishing air.

Expansion tanks for cold water are installed at the lowest point of the distribution system. Tanks for hot water supply are mounted on the pipeline route from the liquid supply side to the heating equipment (heat exchanger, boiler, etc.).

Installing an expansion tank

The unit is installed in a room with a temperature not lower than 0°C. The minimum distance from walls and floor slabs is no more than 60 cm. A passage must be provided around the installed equipment for access to the air valve, drain valve, and shut-off valves. Do not allow the weight of connected equipment and pipelines to impact the device body.

Before installing the hydraulic tank in the chamber, it is necessary to measure the air density with a pressure gauge; it must correspond to the technical characteristics of the mechanism. Fine adjustment can be made through the nipple on the top of the tank. Installation of the device (vertically or horizontally) depends on the volume of the tank and is indicated in the manufacturer’s recommendations when purchasing the equipment.

Features of adjusting the hydraulic accumulator

The operating characteristics of the hydraulic accumulator are configured as follows:

- Check the pressure in the air chamber. To do this, connect the pressure gauge to the rubber valve located in the upper part of the container.

- If the obtained values do not correspond to the recommended ones, then by pressing the nipple we release the air and reduce the pressure or pump in gas to increase the pressure force.

- Then we open the protective casing of the relay and, using a large nut, adjust the upper response level, which is responsible for stopping the pump at maximum pressure.

- The lower limit of equipment launch is adjusted by a small mount.

- We close the relay housing and check the results.

Setting the tank pressure in the water supply system

The hydraulic accumulator is supplied to the retail chain with the basic settings of the equipment manufacturer. Sometimes such parameters do not correspond to operating conditions.

Setting the tank pressure in the water supply system.

Adjusting the operation of the expansion tank is indicated in the following situations:

- After installing the unit. Adjustment of values according to technical standards of the region.

- Weak pressure in the system.

- The tank is not filling.

- Replacing the membrane with a new one.

- Highway repair.

- The air chamber has exceeded the recommended values, the grounds are the pressure gauge readings.

- The temperature regime of the hot water supply is disrupted.

When adjusting the pressure in the gas compartment of the device, it should be taken into account that to protect the container from corrosion, the air chamber is filled with dried nitrogen at the factory. Therefore, when adjusting the air density in the gas cavity or filling the tank after changing the membrane, it is recommended to use technical nitrogen.

The safety valves of the device must be adjusted so that the operating pressure in the protected segment does not exceed the standard value by more than 10%, and with a set value of up to 0.5 MPa ≤ 0.05 MPa.

Adjusting the hydraulic tank in the water heater trim

Expansion tanks for hot water supply systems compensate for changes in liquid volume within the permissible minimum and maximum temperatures, and also maintain pressure in the design range.

The membrane tank for domestic hot water is installed directly at the point of cold water supply to the system. It is considered optimal to install the reservoir after the pressure reducer. The air concentration in the accumulator chamber should be 0.25 bar higher than the operating pressure in the line, or 0.2 bar higher than the set pressure at the outlet of the gearbox.

With this setting, excess water that periodically appears in the system due to rising temperatures will be gradually discharged back into the pipeline during the cooling process.

Accumulator pressure

In the air chamber of the accumulator, the pressure should be 10% lower than the pressure when the pump is turned on.

An accurate indicator of air pressure can only be measured with the tank disconnected from the water supply system and in the absence of water pressure. Air pressure must be constantly monitored and adjusted as necessary, which will increase the life of the membrane. Also, to continue the normal functioning of the membrane, a large pressure drop should not be allowed when the pump is turned on and off. A normal difference is 1.0-1.5 atm. Stronger pressure drops reduce the service life of the membrane, greatly stretching it; moreover, such pressure drops do not allow comfortable use of water.

Hydraulic accumulators can be installed in places with low humidity, not subject to flooding, so that the flange of the device can successfully serve for many years.

When choosing a brand of hydraulic accumulator, you need to pay special attention to the quality of the material from which the membrane is made, check certificates and sanitary and hygienic certificates, making sure that the hydraulic tank is intended for drinking water systems. You also need to make sure that there are spare flanges and membranes, which should be included in the kit, so that in case of a problem you do not have to buy a new hydraulic tank.

The maximum pressure of the accumulator for which it is designed must be no less than the maximum pressure in the water supply system. Therefore, most devices can withstand a pressure of 10 atm.

Hydraulic tank maintenance rules

Hydraulic tank maintenance rules.

Installation, testing and repair of equipment must be carried out in accordance with the manufacturer's recommendations by specialists who have undergone special training.

Any changes to the design of the expansion chamber using welding or mechanical influence are prohibited.

Once a year it is necessary to perform a preventive inspection of the hydraulic tank:

- Check the pressure in the air chamber.

- Carry out an external inspection of the installation body.

- Inspect control and measuring equipment (pressure gauge, valves, relays, etc.).

- Inspect the tightness of pipelines and the operation of shut-off valves.

Installation of an open type hydraulic tank

Open type expansion tanks are attachments that are mounted at the highest point of the pipeline. The installation location must have good ventilation to prevent condensation from forming on the surface of the device. The height of the container must allow free access to the inside of the tank for technical inspection or repair of the working chamber.

The tank is equipped with a float valve, which is installed on the inlet line. It is designed to maintain a liquid level in the storage chamber, which prevents water from overflowing over the edge of the tank.

Design

The expansion tank ensures reliable, long-term operation of the water supply system. There is a large selection of devices. To understand what you need, you should at least have some idea of how the tank works. The purpose of the expansion tank is to maintain operating pressure. They use a tank with a pear-shaped membrane (diaphragm) made of rubber. It divides the capacity into parts: air-water. The water chamber is filled with liquid under the action of an electric pump after the system starts operating, and the heated water pushes through the membrane. As a result, the air part is reduced - the pressure is adjusted. More pressure in the pipeline means more water in the tank. When cooling—the volume of liquid decreases—the membrane, under gas or air pressure, expels water from the tank. The pressure level is usually monitored by a pressure gauge. This helps to control and regulate the operation of the system by setting the necessary pressure limits.

What types of expansion tanks are there?

Depending on the membrane, expansion tanks are divided into types. In the first, the membrane is replaceable - if necessary, this most vulnerable part can be removed to be replaced with a new one. This type of tank is also different in that the water is inside the membrane, that is, it does not come into contact with the inner walls. The solution protects the metal from destruction, and water from accidental contamination, spoilage, and odor, which has a positive effect on its hygienic qualities and extends the service life of the unit.

In tanks of the second type, the membrane is fixed strictly in one place and cannot be removed. This membrane cannot be replaced. Damage to it will entail the need to replace the tank, which will require additional costs, often unforeseen. Another disadvantage of such tanks is the direct contact of water with the walls of the container, which affects the condition of the metal and corrodes it. To avoid this, the inside of the tank walls are coated with a special compound, although such protection does not ensure exceptional durability of the device.

Tanks are available in horizontal or vertical layout - the choice is determined by the chosen installation location.

Types of membrane tanks

There are two types of expansion membrane tanks:

- With a replaceable membrane - models that imply the ability to change the rubber membrane. At the first need, it can be removed through the flange by unscrewing its bolts. In large tanks, the membrane is additionally fixed to the nipple, which allows you to stabilize the device, but even in this case it can be easily removed from the mounts on the back.

Membrane for hydraulic accumulator

- With a stationary membrane - tanks in which the separation membrane is fixed as rigidly as possible and cannot be replaced. If it fails, the entire device will have to be replaced. The price of such expansion tanks is lower than the cost of models of the previous type, but there is no need to talk about complete ease of use.

Advice. When choosing between a replaceable and stationary membrane, consider one important factor: in the first case, the water is completely contained in the membrane and does not come into contact with the inner surface of the tank, which eliminates corrosion processes, and in the second case, the contact is maintained, so it is impossible to achieve maximum protection against corrosion.

What to look for when choosing?

Experts advise installing an expansion tank with a volume of 10% of the volume of the hot water boiler: a 100-liter boiler requires a 10-liter tank, a 200-liter boiler requires a 20-liter tank.

It is important to consider that a smaller capacity means the possibility of more frequent pressure surges. Do not forget that water is stored in the tank. This reserve may come in handy under certain circumstances.

You need to select a special hot water supply tank, for which such a possibility is provided structurally, indicated in the instructions. For example, heating system tanks require higher operating temperatures, but lower pressures. They provide the transfer of coolant at a “hotter” temperature, but the pressure there is relatively low. In such containers, little attention is paid to the hygienic characteristics of the materials. To help the consumer, tanks are made in different colors: blue, blue, white for water supply, red for heating. But it’s better to carefully read the product data sheet to avoid mistakes, since you can’t always trust the labeling.

The safety of using an expansion tank for water is determined by the material of the membrane and tank:

- rubber of natural origin - harmless in cold water, but you should not heat it above 50 degrees - negative reactions are possible;

- artificial rubber is suitable for water of various temperatures - up to boiling - without any consequences;

- rubber (ethylene-propylene) is similar in properties to artificial rubber - it has high performance properties;

- The tanks themselves are most often made of steel.

Another factor in choosing a tank is the manufacturer. A low price can often mean low quality of the product and, as a result, subsequent expensive repairs. A manufacturer with a name and reputation is not ready to sacrifice them, chasing fleeting benefits. They offer tanks and good quality components at reasonable prices. First of all, pay attention to the membrane material (see above), since the service life of the tank, the quality and safety of the water depend on this. The price of the membrane is not an empty question if we are talking about a tank with a replaceable rubber band.

How to install?

When installing an expansion tank for water supply, it is important to know:

- the tank is mounted in such a way that it is easy to maintain and pipes are easy to change;

- the diameter of the pipes connected to the tank is selected not less than the diameter of the tank pipes;

- the equipment must be grounded;

- There must be no obstacles or elements that interfere with the standard pressure between the pump and the connection point.

The liquid flows to the boiler through a valve, which prevents the release of hot water into the cold water supply system. The tank is installed between the boiler and the valve. This way, hot water will come straight from the tap. Sometimes the tank is mounted after the boiler, but then cold liquid from the tank will first flow into the hot water supply.

How to choose tank volume

You can choose the tank volume arbitrarily. There are no requirements or restrictions. The larger the volume of the tank, the greater the supply of water you will have in case of a shutdown and the less often the pump will turn on.

When choosing a volume, it is worth remembering that the volume that appears in the passport is the size of the entire container. There will be almost half as much water in it. The second thing to keep in mind is the overall dimensions of the container. A 100 liter tank is a decent-sized barrel - about 850 mm high and 450 mm in diameter. You will need to find a place somewhere for it and the harness. Somewhere - this is in the room where the pipe from the pump comes. This is where all the equipment is usually installed.

The volume is selected based on the average flow rate

If you need at least some guidelines to select the volume of a hydraulic accumulator, calculate the average flow rate from each water intake point (there are special tables or you can look at the data sheet for household appliances). Sum up all this data. Get the possible consumption if all consumers work simultaneously. Then figure out how many and which devices can work at the same time, calculate how much water will be consumed in a minute in this case. Most likely by this time you will have already come to some decision.

To make it a little easier, let’s say that the hydraulic tank volume of 25 liters is enough to meet the needs of two people. It will ensure the normal functioning of a very small system: faucet, toilet, sink and small water heater. If you have other household appliances, the capacity must be increased. The good news is that if you decide that the current tank is not enough for you, you can always install an additional one.