Over the weekend I redid the heating and moved the expansion tank into the attic. The old one was made from a plastic canister into which a special brass adapter was screwed so that a pipe could be connected, I don’t know what it’s called correctly, in order to screw the brass adapter into the canister I had to cut a hole like this (see photo below), at first the heating was imperfect and somewhat since my system boiled, so the canister from under the primer began to leak a little, this is clearly noticeable, but nevertheless, for two winters the canister faithfully served as an expansion tank.

This canister was hanging in an unfinished room and confused me, I had long wanted to take it out into the attic, and suddenly I came up with a way to make a hole in the canister and attach a brass fitting without cutting a huge hole for a hand to insert it from the inside. We take a canister from under the primer, I took 10 liters, this is enough for my heating with a reserve:

We make a hole in the right place, I made it just above the bottom, so that if suddenly some debris gets in, it won’t get into the heating system and will simply settle to the bottom. The hole is easily made using a utility knife; I periodically check whether the fitting fits in and cut off the excess.

Now there are two holes in the canister, one standard and the second made by me, we insert a piece of wire into both, and the fitting slides along it directly to the hole made

I push the fitting into the hole, put on the rubber gasket

I put on the nut and tighten it, the expansion tank is ready

My heating tank is connected by a piece of rubber hose with clamps, but you can solder an American pipe to a plastic pipe and connect it more thoroughly, but as my two years of experience have shown, it’s quite reliable.

After moving the tank into the attic it looked like this:

Heating equipment

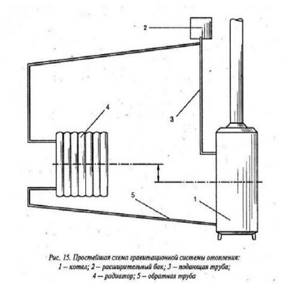

The expansion tank compensates for the increase in the volume of heated coolant, reducing the pressure in the wiring. Therefore, such a unit must be present in both open and closed heating systems. Moreover, you can even make a tank for a closed system with your own hands, using homemade or ready-made containers.

Purpose of the expansion tank for the heating system

The coolant (this is water) circulates throughout the system continuously and this movement occurs because there is pressure inside. It is created under gravity or forcibly if an electric pump is connected. In any case, the heating system cannot be considered complete if there is no expansion tank.

It can be of 2 types:

- Open.

- Closed or sealed.

An expansion tank is simply necessary in a water heating system, because when heated, the liquid tends to increase in volume. There is more water and the pressure in the system increases. Sometimes the pressure can be so strong that the system cannot withstand the load. But nothing can be done with water, because it cannot be compressed. If you install a heating system without an expansion tank, the water can rupture the pipes. To prevent this from happening and to ensure that the pressure in the system remains stable, it is necessary to install a container so that this reservoir compensates for pressure drops when heating the water. This is the expansion tank. It turns out that without this reservoir the heating system cannot operate fully.

An expansion tank can be purchased at a specialized store or made independently.

Main functions of the expansion tank

The first and main thing that the expansion tank must cope with is:

- Stabilize instrument readings (pressure gauge) by compensating for the expansion of liquid in the system.

- Remove air from the system.

- Accumulate hot liquid.

Before you start making an expansion tank, you need to find out how it copes with increased loads. When the liquid in the system heats up, it increases more than we would like. The excess of this liquid must flow into a separate tank, then the operation of the heating system will be stable. It is into this reservoir that the excess heated liquid enters. When the water cools down, it flows back into the heating system. If the tank is sealed, then the membrane handles this part of the work, and in an open system, by gravity the water cools and returns back to the circuit.

Thanks to the expansion tank, the water in the system always remains in the same amount, as well as the pressure. This is the main task that the expansion tank copes with. There are also auxiliary functions that this tank can also handle - removing air pockets. Therefore, it is best to install the tanks at a high point in the system with a slight slope so that the water helps push the air upward.

Where is the expansion tank installed for heating?

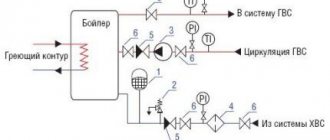

So, the installation of the tank depends on the type of heating system and the purpose of the tank itself. The question is not why an expansion tank is needed, but where it should compensate for the expansion of water. That is, in the heating network of a private house there may be not one such vessel, but several. Here is a list of functions assigned to various expansion tanks:

- compensation of thermal expansion of water in closed heating systems;

- in open networks, the reservoir performs 2 functions - it absorbs excess coolant volume and removes air from the system into the atmosphere;

- under certain conditions, the membrane tank serves as an addition to the standard expansion tank of the gas boiler;

- absorb excess heated water in the hot water supply network.

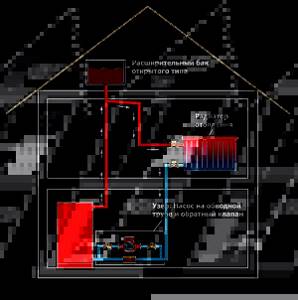

In open heating networks, the water in the tank comes into contact with atmospheric air. Therefore, the installation of the expansion tank is provided at the highest point - on the riser coming from the boiler. Often these systems are made gravity, with increased diameters of pipelines and a large amount of coolant. The capacity of the tank should be appropriate and be about 10% of the total volume of water. Where else if not in the attic to put such a large tank?

Reference. In one-story houses of old construction, there are small expansion tanks for an open heating system, installed in the kitchen next to the floor-standing gas boiler. This is also correct; a container located under the ceiling is easier to control. True, it doesn't look too good in the interior. To put it mildly.

Closed-type heating systems are distinguished by the fact that the membrane expansion tank for water is completely sealed. The optimal installation option is in the boiler room, next to other equipment. Another place where it is sometimes necessary to install a closed expansion tank for heating is the kitchen in a small house, since the boiler is located there.

In closed systems operating on non-freezing coolant, the volume of the tank should be increased to 15% of the total amount of liquid. The reason is the increased coefficient of thermal expansion of glycol antifreeze.

How to make an expansion tank for heating with your own hands

It is very difficult to make a sealed tank at home. As experts say, it is better to pay and buy a quality item than to make it yourself.

But if you have a great desire, then you can make an expansion tank for the heating system with your own hands:

- First you need to make a body or frame. It must be made of 2 metal parts;

- a flange must be attached to each part to screw the membranes and connect both halves;

- there will be 2 chambers inside - air will enter into one, liquid will accumulate in the other. Both halves should not be interconnected, otherwise nothing will work;

- you need to insert a pipe into one of the parts to allow excess liquid to flow in, and insert a nipple into the second part to regulate the amount of free air in the system (to bleed air);

- the body should be metal, but the membrane should be rubber. It must be installed between the two halves of the chamber, and the flange must be bolted together. We remind you once again that absolute tightness must be observed;

- All that remains is to install the tank in place, turn it on to the heating system and check the operation;

- and another very important thing is that the pressure in the tank must be adjusted individually, according to the parameters of the boiler.

How to install the tank correctly

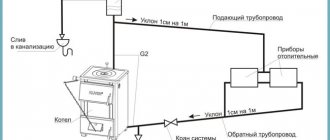

When installing an open tank in the attic, a number of rules must be followed:

- The container should stand directly above the boiler and be connected to it by a vertical riser of the supply line.

- The body of the vessel must be carefully insulated so as not to waste heat heating a cold attic.

- It is imperative to organize an emergency overflow so that in an emergency situation hot water does not flood the ceiling.

- To simplify level control and make-up, it is recommended to install 2 additional pipelines into the boiler room, as shown in the tank connection diagram:

Note. It is customary to direct the emergency overflow pipe to the sewer network. But some homeowners, in order to simplify the task, take it under the roof straight to the street.

Installation of a membrane-type expansion tank is carried out vertically or horizontally in any position. Small containers are usually attached to the wall with a clamp or suspended from a special bracket, large containers are simply placed on the floor. There is one point here: the performance of a membrane tank does not depend on its orientation in space, which cannot be said about its service life.

A closed-type vessel will last longer if it is mounted vertically with the air chamber upward. Sooner or later, the membrane will exhaust its resource and cracks will appear. When the tank is positioned horizontally, air from the chamber will quickly penetrate into the coolant, which will take its place. Installing a new expansion tank for heating will have to be done urgently. If the container hangs upside down on the bracket, the effect will appear faster.

In a normal vertical position, air from the upper chamber will slowly penetrate through the cracks into the lower one, just as the coolant will reluctantly go up. As long as the size and number of cracks do not increase to a critical level, the heating will work properly. The process takes a long time, and you will not notice the problem right away.

A sure sign of critical wear and cracking of the membrane in a closed expansion tank is a drop in pressure in the home heating network. Periodically monitor the pressure gauge readings on the safety group.

But no matter how you place the vessel, you should adhere to the following recommendations:

- The product must be located in the boiler room in such a way that it is convenient to service. Do not install floor-standing units close to a wall.

- When wall-mounting the expansion tank of the heating system, do not place it too high so that during maintenance you do not have to reach the shut-off valve or air valve.

- The load from the supply pipelines and shut-off valves should not fall on the tank pipe. Attach the pipes and taps separately, this will make it easier to replace the tank in the event of a breakdown.

- It is not allowed to lay the supply pipe along the floor through a passage or hang it at head height.

Making an open expansion tank for heating with your own hands

You can make an open type expansion tank with your own hands. Not so long ago, when not many people knew about installing individual heating, there was no talk about an expansion tank - it was attached at the last moment from what came to hand. A large diameter flower pot or any suitable container was used as a tank. Today, an expansion tank can be purchased in a store or you can make an open-type expansion tank with your own hands. This is much easier than making a closed tank.

- marker;

- ruler;

- Metal sheet;

- Bulgarian;

- basalt wool;

- welding machine;

- gloves and other protective equipment.

How to make a tank:

It is better to make the tank from stainless steel, then the tank will last for many years. If there is no such material, then use any metal.

- We make the markings: the dimensions of the tank depend on the length of the heating system circuit. If this is a standard, then you need to cut 5 squares measuring 30 by 30 or 30 by 40 cm. These are the walls for the tank and the bottom.

- The workpieces must be assembled, placed at right angles and welded with a welding machine.

- The design is ready, you need to drill a hole in the bottom of the tank to insert the pipe. Through it, water from the system should flow into the tank. The pipe must be connected to the heating system (looped).

- It is advisable to insulate the expansion tank, because often the highest point of the circuit is in an unheated room in the house (the attic). Therefore, it is necessary that the expansion tank be insulated so that the water in it does not freeze. You can use any insulation, for example, basalt wool. It is resistant even to the highest temperatures.

- You need to be prepared for the fact that in an open tank (open circuit) the water reaches the boiling stage. Therefore, when choosing insulation, take these nuances into account.

DIY expansion tank for heating. Photo

DIY expansion tank from a canister

Metal makes a reliable and durable structure, but not everyone knows how to work with this material, so we suggest you read the step-by-step instructions and learn how to make a tank from a canister:

- We immediately draw the reader’s attention to the fact that a plastic canister will not last long, a maximum of 2 winters. Therefore, although this option is fast, it is not durable. In any case, the time will come when you have to replace the old tank with a new one.

- You will need a canister with a volume of 10 liters; there is no need to cut a huge hole, but in the lower part, closer to the bottom to the right, we cut out a neat hole. This can be done easily with an ordinary construction knife. Check whether the fitting fits well into the finished hole; if not, then you need to cut off a little more excess plastic.

- The canister has 2 holes - the first is factory-made, the second we made at the bottom. You need to insert a wire and a fitting into both holes so that it slides along the wire directly into the lower hole.

- You need to insert the fitting and install the rubberized gasket, then the nut and tighten the thread thoroughly.

- You can connect such an expansion tank to the heating system using a piece of rubber hose (install clamps) or take a piece of plastic pipe and make the structure solid.

DIY expansion tank. Photo:

Expansion tank for heating from a plastic canister

Over the weekend I redid the heating and moved the expansion tank into the attic. The old one was made from a plastic canister into which a special brass adapter was screwed so that a pipe could be connected, I don’t know what it’s called correctly, in order to screw the brass adapter into the canister I had to cut a hole like this (see photo below), at first the heating was imperfect and somewhat since my system boiled, so the canister from under the primer began to leak a little, this is clearly noticeable, but nevertheless, for two winters the canister faithfully served as an expansion tank.

This canister was hanging in an unfinished room and confused me, I had long wanted to take it out into the attic, and suddenly I came up with a way to make a hole in the canister and attach a brass fitting without cutting a huge hole for a hand to insert it from the inside. We take a canister from under the primer, I took 10 liters, this is enough for my heating with a reserve:

We make a hole in the right place, I made it just above the bottom, so that if suddenly some debris gets in, it won’t get into the heating system and will simply settle to the bottom. The hole is easily made using a utility knife; I periodically check whether the fitting fits in and cut off the excess.

Now there are two holes in the canister, one standard and the second made by me, we insert a piece of wire into both, and the fitting slides along it directly to the hole made

I push the fitting into the hole, put on the rubber gasket

I put on the nut and tighten it, the expansion tank is ready

My heating tank is connected by a piece of rubber hose with clamps, but you can solder an American pipe to a plastic pipe and connect it more thoroughly, but as my two years of experience have shown, it’s quite reliable.

It was like this:

After moving the tank into the attic it looked like this:

dom.dn.ua

Purpose and types

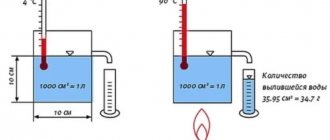

In a heating system, the temperature of the coolant constantly changes, which leads to changes in its volume. It is known that liquids expand when heated and contract when cooled. The expansion tank for heating is precisely designed to absorb excess liquid during heating (expansion) and return it to the system when cooling. Thus, it maintains stable pressure in the heating system.

Heating expansion tank painted red

Open type

There are two types of expansion tanks: open and closed. Open type containers are usually used in gravity systems (with natural circulation). It is called this because it is a non-sealed container. This could be a barrel, a pan, or a specially welded tank. In order for the coolant to evaporate less, a lid is installed, but the container itself is not airtight. The principle of operation of an open expansion tank is simple: it is a container into which excess coolant is forced out when the temperature rises and is supplied back when it cools.

Open type expansion tank - any container, for example, a plastic canister

When calculating open-type tanks, take a significant reserve in volume: you can add coolant and not check its level for some time. The container is not airtight, so there is constant evaporation of liquid and a supply will not hurt. If there is a lack of coolant, air will enter the system, which can stop it. The consequences can be sad - if the boiler’s automatic system works (if it has one), there is a possibility of defrosting. If there is no automation, the boiler may rupture due to overheating. In general, this is the case when the stock is really justified.

If the heating system is filled with water, you can make an automatic replenishment based on a float from the toilet cistern. The principle of operation is exactly the same: when the level drops below a certain point, the water supply opens. When the required level is reached, the supply is shut off.

Expansion tank for open type heating with float

The advantage of this solution is that there is no need to control the amount of coolant, the possibility of airing is minimal. The downside is that you have to pull the water pipe. Since open systems usually operate on natural circulation, the expansion tank for heating is placed at the highest point of the system. Very often this is an attic, so the route turns out to be long.

And these are not all possible emergency situations. Floats sometimes do not shut off the water supply. If this happens to the toilet, the water simply runs into the drain. In the case of heating, water will flow into the attic, flooding the house... To avoid such a situation, it is necessary to control the overflow. In the simplest case, it is a pipe welded/attached at the required level with a hose connected to it. The hose can be led into the sewer, but then you also need to come up with an overflow alarm (at the same time, the level will drop below critical). You can simply lead the hose a meter away from the house or run it into the drainage system. In this case, “traces” of overflow will be visible and it will be possible to respond in a timely manner without an alarm. So an open expansion tank for heating requires some retrofitting.

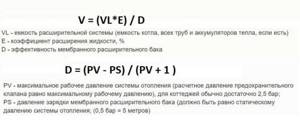

Determining the volume of the expansion tank and its selection

For normal heating operation, the expansion tank must have sufficient volume. There are two ways to determine it: you can calculate it using a formula, or you can use empirical data.

The volume of the expansion tank for heating is selected for each system

Empirical path

Let's start with the empirical method. Based on operating experience, it was concluded that if the volume of the expansion tank for heating is about 10% of the total volume of the heating system, this is sufficient. The question is how to determine the volume of the system. There are at least two ways:

- Count when filling (if it is filled with water and there is a meter, or when filling with coolant from canisters, you will know exactly how much liquid was pumped in).

- Calculate by volume of system elements. You will need to find information about how many liters fit in one meter of pipe, in one section of the radiator. With this data you can already find out the volume of the heating system.

Coolant volume in pipes of different diameters

Knowing how many liters of coolant are in your heating, it is easy to calculate the required volume of the membrane tank - it should be at least 10% of this figure. In the case of an open type tank, the actual volume can be at least doubled - there is less chance that the tank will be empty. At a minimum, you should add half - you will still underfill it by at least 1/3.

A membrane expansion tank for heating is usually taken without overestimating the calculated figure. The fact is that the larger the capacity, the more expensive the expander costs. And the price increase is significant. However, you should not take a smaller one - the pressure will “jump”, which will lead to early wear of components or even shutdown of the system. It is most likely that the heating will fail in cold weather, because in cold weather the coolant is hotter, which means its volume is larger. And it is at these moments that the volume of the expansion tank may not be enough. If you notice such symptoms and the calculation confirms that your membrane tank is of insufficient size, it is not necessary to change it to a larger one. You can put a second one. It is important that their total capacity is not less than the calculated value.

If there is antifreeze in the system

Heating antifreeze has greater thermal expansion than water. Moreover, different brands have different characteristics. Therefore, for this type of coolant, it is advisable to pre-calculate the volume of the expansion tank.

There are two ways: determine how for water, make an adjustment for greater thermal expansion. It depends on the percentage of ethylene glycol (antifreeze). For every 10% glycol, add 10% volume. That is:

- 10% ethylene glycol - must add 10% of the found volume of the water tank;

- 20% ethylene glycol - add 20%, etc.

This calculation is usually justified, but more accurate figures can be found using the formula (shown in the figure).

Formula for calculating the volume of an expansion tank for a heating system

Once you have decided on the volume, it's time to buy an expansion tank. But in the store they are in different colors. At a minimum, there are blue (cyan) and red. So, the membrane expansion tank for heating is always red . Blue ones are for plumbing, and for cold water. They are much cheaper, but the membrane there is made of rubber not suitable for high temperatures. So it will not last long in the heating system.

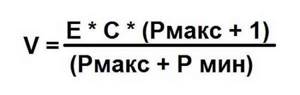

Volume calculation

There is a very simple method for determining the volume of an expansion tank for heating: 10% of the volume of coolant in the system is calculated. You should have calculated it when developing the project. If this data is not available, you can determine the volume experimentally - drain the coolant, and then fill in a new one, measuring it at the same time (put it through a meter). The second way is to calculate. Determine the volume of pipes in the system, add the volume of radiators. This will be the volume of the heating system. From this figure we find 10%.

Shape may vary

The second way to determine the volume of an expansion tank for heating is to calculate it using the formula. Here you will also need the system volume (indicated by the letter C), but other data will also be needed:

- the maximum pressure Pmax at which the system can operate (usually the maximum boiler pressure is taken);

- initial pressure Pmin - from which the system begins operation (this is the pressure in the expansion tank, indicated in the passport);

- coolant expansion coefficient E (for water 0.04 or 0.05, for antifreeze it is indicated on the label, but usually in the range of 0.1-0.13);

Having all these values, we calculate the exact volume of the expansion tank for the heating system using the formula:

Formula for calculating the volume of an expansion tank for heating

The calculations are not very complicated, but is it worth bothering with them? If the system is open, the answer is clear - no. The cost of the container does not depend very much on the volume, plus you can make it yourself.

Expansion tanks for closed type heating are worth counting. Their price depends greatly on volume. But, in this case, it is better to take it with a reserve, since insufficient volume leads to rapid wear of the system or even its failure.

If the boiler has an expansion tank, but its capacity is not enough for your system, install a second one. In total, they should give the required volume (the installation is no different).

What will result from insufficient expansion tank volume?

When heated, the coolant expands, its excess ends up in the expansion tank for heating. If all the excess does not fit, it is released through the emergency pressure relief valve. That is, the coolant goes into the sewer.

Working principle in graphical representation

Then, when the temperature drops, the volume of coolant decreases. But since there is already less of it in the system than there was, the pressure in the system drops. If the lack of volume is insignificant, such a decrease may not be critical, but if it is too small, the boiler may not work. This equipment has a lower pressure limit at which it is operational. When the lower limit is reached, the equipment is locked. If you are at home at this time, you can correct the situation by adding coolant. If you are not there, the system may unfreeze. By the way, working at the limit also does not lead to anything good - the equipment quickly breaks down. Therefore, it is better to play it safe and take a slightly larger volume.

Pressure in the membrane tank and checking it

For a closed heating system to work properly, the pressure in the expansion tank must be 0.2-0.5 Bar lower than in the system. The larger the system, the greater the pressure difference. But, as already said, at the factory they are pumped up to 1.5 Bar, so before installing the expander, it is better to check it and adjust it to your heating system.

The spool is often hidden under a plastic cover

We check the pressure with a pressure gauge by connecting it to the outlet with the spool. If the pressure is higher than you need, bleed off a little. This is not difficult to do - press the petal in the nipple with something thin. You will hear the hiss of escaping air. When the pressure reaches the desired level, release the petal.

If the membrane tank is inflated too weakly (this also happens), it can be inflated with a conventional pump. But it’s more convenient to use a car one, with a pressure gauge - you can immediately control the pressure. After verification, you can install it on the system.