Although household sewer lines made of cast iron pipes became obsolete several decades ago, due to their high service life they are still found in residential communal buildings. Replacing them with popular polymer materials is not always rational from a financial point of view and in terms of labor costs, so many specialists or owners who independently carry out repair work have to solve the problem of how to connect a cast iron pipe with a plastic sewer.

The main problem when connecting pipelines made of different materials is the discrepancy between their dimensional parameters and the different design of the connecting pipes. Therefore, methods for joining cast iron and plastic pipelines are a little more complicated than connecting identical pipes. It is worth noting that the task of connecting cast iron and plastic sewers is greatly facilitated due to the availability on the market of shaped elements and cuffs specially designed for these purposes.

Rice. 1 Indoor sewage system made of old cast iron and polymers

When is such a connection required?

Certain sections of the iron sewer system are removed in a number of cases:

- Leak formation due to prolonged use or rupture of communications due to impact loads.

- Major renovation of the facility. All plumbing fixtures are replaced, but metal structures are left in some areas due to the difficulty of providing access to them or because they are in good condition.

- Organization of an autonomous wastewater disposal system on the site. They install plastic pipes from metal communications inside the house to a septic tank located at some distance.

- Updating the sewerage system. The goals are to facilitate maintenance, increase the rate of outflow of contaminated water, and the need to replace metal elements with rough internal walls with plastic counterparts with a smooth surface.

What are the benefits of plastic sewerage?

Plastic pipes (made of PVC or polypropylene) have several advantages:

- light weight, which makes it easy to work with pipes; installation of plastic sewerage does not require special equipment; ideal smoothness of internal surfaces reduces blockages of the riser; are not afraid of corrosion.

There is one drawback: the sound insulation characteristics of plastic are noticeably lower than those of cast iron.

If you are sure that you can handle sewer replacement, carefully understand the process. There are some subtleties of preparation and the work itself.

You can also hire professionals. Then knowledge about the entire process will be needed just in case

To understand what to look for and how to accept a job

Dimensions of cast iron and plastic pipes

The internal sewerage system of the overwhelming majority of individual houses and communal apartments is installed from two pipe sizes - 110 mm and 50 mm. A riser was installed from a large diameter pipe and a sewer pipeline was installed connecting it to the toilet. A 50 mm pipe is used to lay lines from kitchen sinks, sinks and bathtubs, showers to the central riser.

To understand the best way to connect a cast iron sewer pipe with a plastic one, it is useful to consider their dimensional parameters, the typical values of which are for:

Cast iron. It is worth noting that the dimensions of any metal pipes are specified by the nominal diameter DN, which is approximately equal to the diameter of their internal passage channel.

For pipe cast iron, this is an internal cross-section of 50 and 100 mm. To determine the external dimensions in a circle, the pipe wall thickness S must be added to these digital values. For a 50 mm pipe its standard value is 4 mm, for a 100 mm pipe it is 4.5 mm. As a result of elementary calculations, we obtain the outer diameters of the pipes 58 and 109 mm.

As for the dimensions of their socket outlets, they have a conical shape inside, which is optimally suited for joining by caulking. For a 50 mm pipe, the dimensions of the socket from the inside are 65 - 72 - 76 mm, for a 100 mm pipe - 118 - 123 - 127 mm. It should be noted that when indicating the dimensions of transitional shaped elements, the average values are indicated - 72 and 123 mm.

Plastic. For indoor sewage systems, a plastic pipe made of polyvinyl chloride (PVC) of gray color is widely used. Its dimensional parameters are set by the outer diameter, the typical values of which are 50 and 110 mm. When considering any methods of connecting them, the internal circumferential dimensions and wall thickness (can vary significantly for products with different classes of ring stiffness SN) do not play any role - all PVC connections are made externally to the pipe.

So, the main conclusion that can be drawn from the considered pipe dimensional parameters is that the outer diameters of a 110 mm PVC pipe and a 100 mm cast iron pipe are practically the same, their difference of 1 mm is not significant.

Repair with cement and bandage

To eliminate a clearly visible hole, cement mortar and a bandage are used:

- the damaged part of the sewer system is cleaned with sandpaper and treated with a solvent;

- the bandage is cut into several pieces (each length is 0.4-0.5 m);

- a cement mortar is made, which should have a uniform consistency (you can use liquid glass instead of water);

- the bandage is dipped into the prepared solution;

- after soaking in the mixture, the bandage is wrapped around the damaged section of the pipe;

- a small amount of dry cement is poured on top of it (until a “cocoon” is formed);

- At the site of the crack, a layer of liquid glass is placed on the bandage.

The bandage is wrapped around the pipe 4-5 times. You can use the sewer system after a day, when the cement mixture is completely dry.

Benefits of switching from cast iron to plastic

Polypropylene sanitary products have a number of operational advantages:

- withstand temperature changes;

- resistant to aggressive environments;

- deposits do not accumulate in them and blockages do not form, since the inner surface of the products is smooth;

- are light in weight;

- easy to install;

- affordable.

Fittings have a service life of up to 50 years.

We suggest ordering transitions from cast iron to plastic using the catalogue, contact us by phone. Orders are formed promptly, delivery is made throughout Moscow and Russia on favorable terms. All products are provided with quality certificates. The TERMA-MSK online store accepts retail and wholesale orders, offers convenient payment options and favorable prices for shaped fittings for the installation of internal sewerage.

Methods for connecting cast iron sewers to plastic ones

The method of installing old and new communications is chosen taking into account the condition of cast iron products. Evaluate their appearance. Determine whether there is a bell and how smooth the cut is. The degree of reliability of the end section is established.

Often, during prolonged use or due to exposure to intense loads, cracks appear, which is due to the fragility of the metal. In addition, the method of connecting plastic to cast iron is chosen depending on the availability of the necessary tools at the time of installation.

Connection with rubber gaskets

This joining option is used if the sewerage section is in good condition: there are no cracks, the inner walls are smooth. When defects appear inside the cast iron product, it will not be possible to ensure a tight fit of the rubber element.

Instructions:

The rubber cuff for connecting pipes must be selected according to size.

- Clean the drainage system in the area where the plastic pipe will be connected to the cast iron pipe. Removes layers of plaque and rust.

- The internal surfaces of metal and external walls of polymer pipes are treated with a sealing compound.

- Insert the rubber gasket into the socket of the metal product. On the other hand, a polymer pipe is inserted into it.

- The joints are additionally treated with sealant.

The advantage of this method of connecting the sewerage system is ease of installation. If necessary, the connection is easy to disassemble. After this, the surfaces are cleaned of sealant and reinstalled.

If you are replacing a section of the system without a bell, you should follow other instructions:

- The edges of the metal product are trimmed with a grinder.

- The outer walls of the cast iron pipe and the inner surface of the rubber cuff are treated with sealant. These elements are connected by first installing a seal.

- A plastic adapter is connected to the other side of the cuff.

- All joints are sealed with silicone compound.

- A PVC pipeline is connected to the adapter.

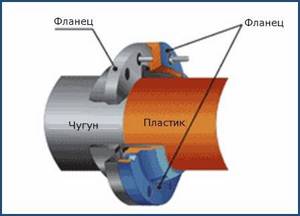

Flange connection

It is more difficult to implement this method on your own, since it requires experience and the availability of special tools and necessary parts. In addition, this option is chosen for large diameter plastic and metal pipes.

The advantages of the flange joining method are strength, high reliability, and the possibility of dismantling.

To work, you will need a mallet (with a rubber nozzle, since cast iron is damaged under the influence of shock loads), a grinder, and a welding machine.

For installation of structures:

- Cut off communications.

- The edge is cleaned of burrs.

- A flange is welded to the prepared metal pipe.

- A crimp sleeve is applied to the PVC pipe. There must be a gasket between the flange connection elements.

- Tighten the crimp coupling and the welded part of the flange using bolts.

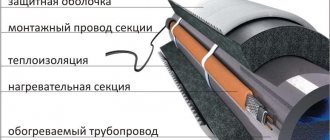

Types of insulating material: self-adhesive tapes and their properties

As for the choice of insulating material, special anti-corrosion tape coatings should be used. They are used to seal joints between pipes, seal coupling units, tie-ins, and bends related to the sewer system.

What is a sealing tape that insulates a sewer pipe? The product is based on a bitumen-rubber mixture and a protective film.

The peculiarity of the material is that it has a high degree of strength, is used to work with various compositions, and does not collapse for a long time.

You can avoid the unpleasant consequences of a leaking sewer riser by sealing the joints with a silicone compound. For work, 2 types of materials are used:

- acid insulation;

- neutral sealant.

Repairing defects using a neutral compound will cost the owner much more than working with acidic insulation. The use of silicone is economically beneficial, since the material has significant adhesion.

As for the use of other sealing compounds, here you can choose the following types:

- bitumen mastic;

- cement mortar;

- asbestos cement composition.

If the bell is damaged

If the bell is damaged, then the methods described above are not suitable. When performing installation, you will need to purchase an additional part - an adapter that allows the transition from a cast iron pipe to a plastic one. The procedure for connecting pipeline elements is as follows:

- the damaged socket is carefully cut off with an angle grinder;

- the edges are processed;

- a rubber sealing ring and a rubber cuff are put on the prepared part of the cast iron pipe;

- the edge of the rubber part is lubricated with sealant, then a plastic adapter is put on;

- lubricate the adapter pipe with sealant and install another rubber O-ring;

- After this, you can insert the plastic part into the adapter.

Basic methods

There are the following methods for connecting cast iron sewer pipes to plastic ones:

- flanged;

- fitting;

- using rubber gaskets;

- pressing tow or sanitary flax.

The main options for connecting a cast iron pipe to a plastic one

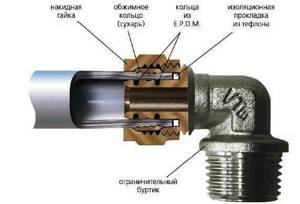

Application of fitting

Cast iron fittings for sewer pipes

From a technical point of view, the optimal solution is to use a fitting, a special adapter made of durable polyvinyl chloride. It has a thread on one end and a socket for inserting a plastic pipe on the other. Fittings are used if the cast iron pipe does not have a socket at the end, or its use is impossible.

You will need a die for cutting external threads, a fitting of a suitable caliber, FUM tape or plumbing flax or tow. It is necessary to cut off the cast iron socket with a metal grinder or a hacksaw. During this, you need to make sure that the cast iron does not crack.

It is necessary to clean the cast iron from dirt and paint and cut a thread of 3-5 cm on it. Re-clean it from dust and metal residues and wind several turns of FUM tape or flax to seal the thread and screw the fitting.

After this, all that remains is to insert the end of the water or sewer pipe into the fitting collar.

If a cast fitting without thread is used, then first an O-ring is placed in the socket, securing it with special glue, and then a narrow fitting pipe is inserted into it.

Press fitting for connecting metal and plastic pipes

Rubber gaskets

It is possible to simplify installation with the help of rubber gaskets, if the cast iron part is well preserved, its edges and inner surface are smooth, not rusted and without chips. As a rule, the sockets of strong and thick sewer pipes remain in this state.

The bell is pre-cleaned from dirt and rust.

A rubber adapter gasket of a suitable caliber must be well coated with silicone sealant. Insert into the connection until it stops, but not less than 3 cm. After this, insert the pipe of the connected water supply into the cuff. The work is finished.

Scheme of connecting pipes using a rubber gasket

Linen winding

Sealing joints of cast iron sewer pipes using linen strands

Press-fitting with linen winding is used if other connection methods are not available, or as a temporary measure. Several layers of plumbing flax or tow are tightly wound onto the plastic pipe at the junction. It is inserted into the sewer connection, the flax is pressed into the gap with a knife or spatula and sealed with silicone sealant or a mixture of cement and PVA glue. All you have to do is wait a day, and you can use the connection.

This connection of sewer pipes can be used for a limited time (up to a year) until it becomes possible to install a more reliable structure.

Connecting sewer pipes with glue

The strength of this joining method is based on the mutual penetration of polymers at the molecular level. First of all, you should purchase a special glue that is used to coat the edges of the pipes. After that:

- the surfaces to be bonded are cleaned of dirt, sanded and degreased;

- the prepared edges are greased with glue;

- the ends of the pipes are placed inside each other;

- In order to ensure tightness, the joint is coated.

It is necessary to start connecting the pipeline elements immediately after applying the adhesive composition, since it quickly loses its properties in air. Bonding must be completed within 90 seconds.

What to consider when choosing a method: which is better?

The choice of technology for connecting pipelines made of different materials directly depends on the integrity and general condition of the cast iron socket.

To insert into a cast iron sewer pipeline and switch from plastic to cast iron or vice versa, several methods can be successfully used, but the use of a fitting in the form of a compensating pipe is considered optimal.

Such a plumbing fixture quite easily compensates for deformation and failure of the sewer network as a result of linear thermal expansion or contraction, and also helps to give the drainage areas the required level of inclination.

It is advisable to use pipes along with corrugated pipes if it is necessary to adjust the height of the cross to create an optimal angle for installing the toilet.

What is the purpose of sealing cast iron pipes?

Often the sewer riser or outlet parts of a cast iron pipe receive serious damage. An inspection shows that a piece of the cemented patch is falling off, and the pipe itself may fail. In this case, the master decides to use sealant for cast iron sewer pipes. During the work, the recommendations specified in SNiPs and technical regulations, pipe wear, hydraulic effects and the possibility of leaks are taken into account.

Sealant for sewer pipes must be selected taking into account the fact that this external sewer has a significant diameter and a large length.

Sealing sewer pipes is necessary to prevent sewage from entering the apartment and eliminating unpleasant odors in residential areas.

Solving the problem of sealing joints must be taken quite seriously.

Having identified the cause of the malfunction that is interfering with the operation of the cast iron pipe, the owner can carry out the entire cycle of necessary work to eliminate it.

The causes of pipe leaks are varied:

- defect in the material used to install the sewer;

- improper laying of cast iron sections;

- the presence of cracks and holes in the riser.

GOSTs and standards

The production and dimensions of cast iron sewer pipes are regulated by GOST 6942-98.

For plastic pipes, there are many GOSTs and SNiPs that regulate their individual characteristics.

Each type of polymer, depending on the scope of application (sewage, heating or water supply), has its own GOST standards.

For example, the characteristics and dimensions of plastic pipe products intended for cold and hot water supply and heating systems in buildings for various purposes are regulated by GOST R 52134-2003.

Purpose of fittings

The role of adapters in the sewerage system cannot be overestimated. Without their help, not a single repair of plumbing pipes or construction of a new line can be completed. Fittings are of particular value in cases where it is necessary to make a transition from pipes of one diameter to pipes of another - larger or smaller. Adapters are indispensable when carrying out repair work indoors, when it is not possible to change the entire sewer system, and only a certain section of it has to be changed.

Very often, the material of pipes in common building networks does not match the material of the pipes installed in the apartment. The most common situation is the following: the common sewer riser is made of cast iron, and the apartment owner plans to install plastic in his bathroom. In such cases, adapters come to the rescue, which are capable of connecting pipelines of different materials into a single network and at the same time ensuring a reliable and tight connection.

Related Posts

- Rules for laying sewer pipes

- Features of using PVC sewer pipes with a diameter of 50 mm

- Instructions for inserting into a sewer pipe with your own hands

- Connection of sewer pipes

- Disadvantages of polypropylene pipes in home heating

- Connecting the toilet to the sewer without corrugation

- Do-it-yourself installation and replacement of sewer pipes in an apartment

- Plastic sewer bends 110, sizes and types

- How to eliminate sewer odor in your home or apartment

- Effective methods of thermal insulation of sewer pipes

- Sewage check valve

- Which pipes for heated floors to choose: characteristics and installation methods

- Sealant for sewerage

- Thin-walled metal pipe for electrical wiring

- Trenchless pipe laying options

- Why cast iron sewer pipes are still popular

- Hydrodynamic sewer cleaning

- What are polyurethane foam pipes and where are they used?

- Drain cleaning tool

- How to choose high-quality pipes for water supply in an apartment

- What sizes of sandwich pipes are best to use for a chimney?

- How to lay sewer pipes in the ground

- Dismantling of heating systems

- What kind of pipes are used for the gas pipeline?

- Which pipes are best to choose for a water well?

Read with this

- Rules for laying sewer pipes

- Features of using PVC sewer pipes with a diameter of 50 mm

- Instructions for inserting into a sewer pipe with your own hands

- Connection of sewer pipes

- Disadvantages of polypropylene pipes in home heating

- Connecting the toilet to the sewer without corrugation

- Do-it-yourself installation and replacement of sewer pipes in an apartment

- Plastic sewer bends 110, sizes and types

- How to eliminate sewer odor in your home or apartment

- Effective methods of thermal insulation of sewer pipes

Diameter standards

For domestic domestic sewerage, cast iron pipes with an internal cross-section of 50 mm (DN) and 100 mm (DN) are used.

The dimensions of external sewerage are determined by SNiP standards. In intra-block networks, a diameter of 150 mm is used, in street networks - 200, 250 mm.

Polypropylene products are produced in accordance with GOST 26996-86. The standard has not established a specific size for the sewer sector. But in practice, the following diameters of sewer plastic pipes have developed: 32, 40, 50 and 110 mm.

For polyethylene pipes, working diameters - 40, 50, 90 and 110 mm - were determined by GOST 22689.2-89.

For PVC products, the cross-section of sewer products is regulated by GOST 51613-2000. Its requirements: PVC pipes must have a Ø from 10 to 315 mm.

In order to make drainage, lay external sewerage, septic tank pipes, you will need products with a cross-section of 110-200 mm.

We combine cast iron and plastic

Joining cast iron and plastic sewers

If you decide to change the sewage system using modern materials, then you may have a question - how to connect a plastic pipe with a cast iron one? Many home craftsmen simply insert one into the other and seal the joint with cement mortar. In this case, the plastic may become deformed and leak.

Repair of sewer riser

The connection between the cast iron pipe and the plastic product must be done very carefully. The fact is that when heated, these materials expand in different ways. As a result, the seal will be broken and leakage becomes inevitable. Mechanical influences (for example, constant vibration or shock) can also affect the appearance of a leak.

Replacing a cast iron elbow with a plastic one

There are two ways to correctly connect pipes made of plastic and cast iron. The choice will depend on the availability of the bell. If there is one, then the first thing you need to do is visit the store. Here you need to purchase a special adapter that will be installed in the socket. It is produced with a standard diameter for sewer pipes (usually 50 and 110 mm), but you can also find a non-standard option (if you need it). Therefore, please check this value before purchasing.

Insertion into a sewer bed

Now you need to clean the socket of the cast iron pipe from rust and dirt. The purchased adapter is inserted into the pipe. It is better to lubricate the socket itself and the plastic element with a sealant (for example, silicone). Make sure it goes in completely. Then a plastic pipe is inserted into the adapter. This completes the connection. This method is fast and simple, and the connection is reliable. In addition, it is easy to dismantle for cleaning. When installing, do not forget about the slope, it should be towards the riser.

If there is no socket on the cast iron pipe, then for the connection you need to use two adapters of the required diameter. First of all, we clean the ends from rust and dirt. Then a rubber adapter is put on the cast iron pipe, and a plastic adapter is put on it. The plastic drain pipe will be inserted into the latter. Seal all connections with silicone (or other suitable) sealant. This will prevent leaks and unpleasant odors. A connection using two adapters, just like the previous one, can be easily disassembled for repairs.

Step-by-step technique for connecting pipes with your own hands

The technology for performing the work includes the following stages:

- Preparatory stage.

- Selection of tools and materials.

- Dismantling part of the old pipeline.

- Preparing two parts of pipes for connection.

- The operation of joining parts.

- Required tools and materials

At the first stage, the location of the connection is determined and the method of its implementation is chosen. Make the necessary measurements and determine the need for materials.

Required tools and materials

Polymer pipes are purchased in the appropriate size. To connect the toilet to the crosspiece, you will need elements with a diameter of 110 mm; for laying pipes to a sink or bathtub, the best option would be plastic with a diameter of 50 mm.

In accordance with the project, the necessary connecting materials are purchased: seal, fitting, sealant, etc.

Select the necessary tool. It may include:

- a set for dismantling the cast iron part - a hacksaw or grinder, a mallet, possibly with a rubber pad;

- screwdriver;

- spanners.

To cut the thread you will need a thread cutter.

For plastic joints you will need either a hand press or a welding machine - an iron.

Required materials for strapping

The materials below will relate to the piping scheme, which is performed in a two-pipe heating system. Both pipes are in a horizontal position and pass under the radiator. They have a diameter of 32 mm. The heating device is connected in a diametric way.

List of materials:

- Tee. Dimensions – 32x20x32 mm. 2 pcs.

- Pipe with a diameter of 20 mm.

- Corner. Dimensions 20 x 1/2 nr. 2 pcs. At one end there is a metal pipe with a thread.

- Adapters that provide a rotation angle of 60°. 3 pcs.

- Linen.

Connecting a toilet to a cast iron pipe

If your toilet's drainage system is made of old cast-iron pipes, then when purchasing a new toilet, find out how to connect it. Here everything will depend on the direction of the toilet outlet (that part of the structure from where wastewater enters the sewerage system).

If your sewer system has not been changed since the day the house was built, then the pipe may stick out from the floor, at a decent distance from the wall (unless it is a common riser going to the upper floors). For this case, you need to buy a toilet with a vertical outlet (at the bottom of the structure). A toilet with a vertical outlet is very easy to connect; just insert it into the pipe socket.

A toilet with a horizontal outlet is also connected. Such designs can often be found on imported products. To connect such a toilet, you need to insert the outlet into the socket. It is better to seal the joint area with sealant or tow. This way, you will prevent leaks and prevent the appearance of an unpleasant odor.

The more common option is with an oblique release. To connect such a toilet to a cast iron pipe, you can use a bend with the desired angle. It is inserted into the pipe, and the toilet outlet is connected to the outlet. It is also advisable to seal the connection point.

But with all these connection options, it is necessary to connect the toilet directly to the pipe. This does not allow you to install the plumbing fixture in a place convenient for you. The installation location will depend on the location of the sewer pipe. That is why a special device, a corrugation, is used to connect the toilet to the sewage system.

Dismantling an old pipe

The cast iron pipeline must be dismantled very carefully to prevent chips or cracks.

We recommend that you familiarize yourself with: Tool for installing cross-linked polyethylene pipes

In the past, joints were often sealed using cement and tow, so it may take a lot of effort to release the joints.

It is necessary to disconnect the pipes by twisting, and in no case by rocking. If you are not sure that the socket of a cast iron pipe can be released without damage, it is better to carefully cut it with a grinder.

It is important! You should not try to break off a cut cast iron pipe. Most likely the break will be uneven and you will have to cut again. It is better to work with the grinder a little longer and cut the cast iron product completely.

Sewage installation rules

When replacing the sewerage system for an apartment, it is important to carry out all work in accordance with the rules, since the quality and durability of the updated system depends on this.

These implementation approaches must meet the following requirements:

- vertical fall - at least 3% (3 cm per 1 meter of length);

- the correct diameter is selected, which is recommended to increase it when there are more than three turns on the route.

- toilets are not connected to the same line with other plumbing fixtures, but are connected directly to the riser;

- brackets for fastening pipes must allow their thermal movements.

Of course, larger diameter pipes provide better drainage and are less likely to clog, but the thicker they are, the more difficult they are to hide. However, it is worth increasing the diameter of the approach to the sink from 40 to 50 mm - this will not interfere with the work and improves the drainage of wastewater. If several appliances are connected to one approach, a larger wastewater flow must be taken into account, however in apartments and houses there is usually no need to use approaches with a diameter of more than 70 mm.

In any case, before starting work, it is necessary to draw up a clear and competent project for the work and invite experienced specialists to implement it. And only in this case you are guaranteed to be able to complete all the work at a high quality level, and you will not have to worry about choosing the correct method for connecting plastic and cast iron pipelines. This means that repairing and replacing the sewer system in the house will ensure durability and long service life.

Smooth pipe connection

Coupling for connection

In addition to cast iron pipes with a socket, smooth structures are also used to create pipeline systems. Various devices are used to connect them. Among them there are couplings, saddles, crosses, elbows, etc. Which one to use will depend on the diameter of the pipe and the type of connection.

The most common fitting is the coupling. It comes in three main types:

- If pipes of the same diameter are connected, then a coupling in the form of a cylinder is used. There is a thread inside this fitting.

- To connect pipes with different diameters, a device in the form of two cylinders is used. This coupling is also equipped with an internal thread.

- The heating system uses a futorka. Such a coupling is the same cylinder, only with threads on both the internal and external surfaces.

The connection process using a coupling is quite simple. First you need to mark them to see how much each pipe should fit into the coupling (you need to calculate so that the ends meet exactly in the middle). Then both pipes are simply inserted into the coupling. For sealing, you can use a special sealant.

But the pipeline may run at an angle or include branches. Other devices are used for this. For example, connecting cast iron sewer pipes at an angle is carried out using bends. They are a piece of pipe bent at a certain angle (10, 15, 30, 60 and 90 degrees).

In addition, there are other devices for connecting pipes. For example:

- Tee. With its help, you can connect three pipes at once into a single system. As a rule, such a connection is necessary in places where the sewerage system branches.

- Cross. A design that helps connect four pipes at once.

- Saddle . This device allows you to connect a smaller diameter pipe to the main line (for example, from a free-standing plumbing fixture).

All these devices may have sockets or straight sections at the ends. To seal the joint, various sealants or tow are used.

Difficulties when connecting pipes made of different materials

The different physical and operational properties of cast iron and plastic cause the main difficulties when connecting two sections of the pipeline.

Cast iron is a fairly brittle metal and requires careful handling during operation. If, when dismantling old sewer pipes, it is permissible to use a hammer, sledgehammer and brute physical force, then when transferring a fragment of a pipeline from cast iron to plastic, you have to carefully cut the pipe with a grinder and clean the chamfer from rust and dirt.

Plastic also imposes certain restrictions on the work of a plumber. It is necessary to take into account the coefficient of thermal expansion of polymer pipes if we are talking about replacement in an area near a kitchen sink or bathtub.

The third point that determines the complexity and responsibility of the task is the difference in the diameters of the connected pipes. It is not always possible to find products that allow you to make a strong connection into a socket by placing a pipe of a smaller cross-section into a larger one. You have to buy additional adapters, expansion joints, fittings, as well as sealants, FUM tape and other materials in order to achieve the necessary sealing of the joint.

Important! These difficulties do not mean that it is impossible to connect a cast iron pipe to a plastic one. You can use different connection methods based on a specific situation, as well as use a combination of materials, and get excellent results at minimal cost.

Additional pipe sealing products

When sewerage equipment becomes unusable, it is repaired using technical sulfur . What is its mechanism of action? The material is pre-melted in an electric furnace at a temperature of 130-135˚C, and then poured into the socket. Unfortunately, the repair may be of poor quality if it was not possible to fill it at once.

Observing special precautions will help you avoid unpleasant consequences when working with sulfur, since the sealant easily spills, and careless handling leads to a chemical burn.

Cast iron pipes are insulated using petroleum bitumen. It is not difficult to seal the riser from the inside and outside, and after the work has been done, the operating life of the equipment is significantly increased and its efficiency increases.

After coating the inner surface of the pipes with petroleum bitumen, the coefficient of friction of the liquid medium decreases and the fluidity of the wastewater enclosed in the sewer pipe increases.

Epoxy resin is the most common material used for joining sewer pipes. The joint is sealed by pouring resin into the gap, and to obtain a lasting result it can be used in hot and cold conditions.

When working with Portland cement, it is necessary to apply the mixture over the joint.

Common mistakes: how to avoid problems

Quite often, rubber seals are inserted into the socket part of the pipe without proper preparation of its internal part, using force.

In this case, a violation of the integrity of the seal may well cause a loss of tightness of the completed connection, which will provoke a leak in the areas where the elements are joined.

Also, the reason for insufficient tightness and frequent emergency situations as a result of stagnation of water or blockage is the failure to maintain a sufficient slope of drainage from plumbing fixtures towards the sewer riser.

Among other things, when performing installation work, it is strongly recommended to use lubricant or insulation when joining, as well as strictly control the tightening force of all threaded connections.

Method three - connection using a fitting

A fitting is a coupling where there is an internal thread on one side and a socket on the other, and most often this method is used when a flat plastic pipe is used. The reliability of the connection here is achieved on both sides, that is, using a rubber seal in the form of a ring on the socket side and sealing the threaded connection.

This type of connection is the most labor-intensive, since it will be necessary to cut threads on a cast iron pipeline. The edge of the pipe is leveled in any way with simultaneous chamfering. After that, the edge must be lubricated with machine lubricant and thread cutting must begin, the depth of which should not exceed 50 mm. Sealing the thread is achieved using tow or fum tape.

After cutting it, you need to install a press fitting with a socket. It is necessary to tighten the fitting by hand, since the use of wrenches can cause the thread to fail and leaks are guaranteed. After installing the fitting, you can install a plastic extension with a sealing collar.