Here you will learn:

Before you start troubleshooting the Oasis geyser and choosing a way to eliminate them, you must clearly understand what type of device it is, know the device, and the principle of its operation.

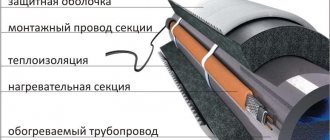

The layout of the Oasis gas water column components is typical for most models of Chinese-made flow columns

The diagram above shows the design of a typical gas water heater, which is also typical for Oasis columns. Let's look further at how the most common type of brand's flow-through chimney model with automatic ignition works.

When the tap is opened, water is supplied through the inlet pipe into the water-gas unit, which turns on the ignition and gas supply. As soon as it ignites, a signal is sent from the flame sensor to the electronic unit to stop sparking.

Next, the water passes through a coil rigidly fixed to a heat exchanger, which is heated by burning gas. The coil transfers heat to the flowing water coming out.

When the tap closes, the water-gas unit turns off the gas supply. The combustion stops and the column goes into standby mode for the water tap to open.

An important condition for the normal and safe operation of the column is the removal of combustion products through the ventilation chimney. If the hood is missing or insufficient, the draft sensor is triggered and the column is turned off.

An overheating sensor is responsible for timely shutdown of the column when the maximum temperature is reached. It is an important element of the column, providing protection against overheating

Maintaining the required temperature regime is an equally important condition for fire safety and long service life of the column. Overheating negatively affects the condition of all elements, primarily the heat exchanger, which leads to their premature failure.

Features of using the device

So, in order for the Oasis geyser, the operating instructions for which are included with the product, to work effectively, you must follow certain rules for using the device:

- Use only the type of gas specified in the technical recommendations;

- It is necessary to monitor the charge of the batteries on which the device operates;

- If you want to turn off the device, you must first turn off the water;

- If you are going to use the equipment for the first time, you need to take into account that there may be air in the gas supply tubes, so the device may not ignite right away;

- Setting the degree of water heating must be done by turning the tap handle or gas regulator on the body of the device;

- If you are going to turn off the device for a long time, you must first turn off the hot water tap and gas shut-off valve.

Now let's look at what you should not do when using equipment such as the Oasis geyser:

- You cannot turn on the device if there is no draft in the chimney.

- Do not leave the device unattended for a long time.

- There is no need to purchase and install damaged or defective models.

- Do not disassemble the device without permission, do not repair it, or touch it during operation.

Ariston boiler cleaning

You can see for yourself that after disassembly, the heating element fell inside the container, which is coated with enamel so that the tank does not rust from the inside. Of course, when metal hits metal, both the heating element and the internal coating of the water heater can be damaged, which cannot be repaired independently.

Based on this, in order to disassemble a storage water heater with an oval flange, everything must be done without removing the boiler. The product is assembled in the reverse order. A fairly popular design, which is found in heaters of the Termex, Ariston, Polaris and Combustion brands, is considered to be fastening the heating element flange with bolts in a circle. These bolts can be 4, 5 or 6, depending on the model.

Error codes for the gas water heater "Oasis"

- Error E1: Ignition faulty. Reasons: lack of gas supply, or gas pressure is too high. The control ignition electrode is faulty.

- Error E2: The air pressure switch does not close. Causes: clogged chimney.

- Error E6: No flame. Causes: Air has accumulated in the system.

- Error E7: Low pressure. Reasons: there is not enough liquid in the hot water supply system.

- Error E9: Indicates that the pump has broken down and the pressure in the system is unacceptably low.

Brief operating instructions

Before connecting the device to the water supply system, you should drain the liquid from the pressure pipeline, which will minimize the risk of contamination entering the equipment during the first start-up.

After connecting the piping system to the unit, the correctness of all connections is checked, as well as their reliability and tightness. For this purpose, a standard water fill is carried out and the shut-off valves for cold water supply are opened in conditions of a closed water supply valve. Leaks at connections detected during test filling are completely eliminated.

The next step is to check the electronic ignition of the burner:

- installing batteries in a special compartment;

- opening the hot water tap;

- monitoring the presence of an electronic continuous discharge occurring in any area from the spark plug elements of the electronic ignition to the sectional part of the burner.

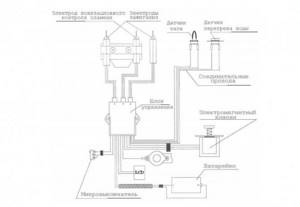

The absence of electronic discharge will require verification of the correct installation of the entire system in accordance with the electrical connection diagram below.

Electronic ignition of the burner is possible if the system is correctly connected according to the diagram

At the final stage of preparation for operation, the tightness of all connections of the gas supply system should be checked when the unit is not operating and the shut-off valves are open. For this purpose, it is recommended to use “soaping” of connections or other safe methods; a bubbling soapy composition indicates a gas leak.

An important condition for the trouble-free operation of the Oasis column is the proper setting of the water temperature, which can easily be done in several basic ways:

- setting the water regulator to the extreme right position when turning the flame knob until a comfortable heating temperature is obtained;

- turning the gas regulator and changing the gas supply to the main burner;

- change in the level of water consumed.

It should be remembered that excessive heating of the water inside the heat exchanger is the main reason for the rapid formation of scale and blockages. This entails failure of the unit.

Equipment maintenance involves:

- cleaning the burner;

- cleaning of all filter systems;

- cleaning the heat exchanger;

- replacement of seals in gas and water supply systems;

- regularly checking the tightness of systems;

- checking the functionality of sensors;

- lubrication of moving elements.

Attention! Any preventive measures are carried out only after the standard disconnection of the water heater from the gas supply system.

Main causes of malfunction and their elimination

The designs of all geysers are similar to each other. Why not summarize all the problems and describe options for solving them? Because each brand has its own weaknesses. This is when malfunctions specific to specific brands appear. We analyzed user reviews to collect reliable information for you.

Factory defects in Oasis water heaters are extremely rare.

The cause of failure can be external and internal factors:

- Incorrect installation and connection.

- Incorrect operation.

- Blockages in the chimney and ventilation.

- Problems with internal components: scale, corrosion.

We have described ways to resolve these problems below.

Column does not light up

There can be many reasons, we will help you figure it out. The main thing is to correctly determine the location of the breakdown.

If the device does not ignite at all, no spark is produced, then:

- The batteries are low. Devices with automatic ignition operate on batteries. To replace, take high-quality elements with a good charge. If you find a leak where they are installed, clean all contacts and install new batteries.

- Problems with traction. For normal operation of the equipment, there must be draft in the chimney. If it is not there, inspect the ventilation hole for blockage. It could be a foreign object, soot or debris from the street. If possible, clean the hole. Make sure that the chimney outlet from the outside is not blocked.

How do you know if you have cravings? Light the match and bring it to the viewing window of the column. The flame deviates - there is draft; it burns evenly - no. You can also lean a sheet of paper against the ventilation. If there is traction, the sheet will press against the output, otherwise it will fall.

- The water pressure regulator is set to the minimum level. A small pressure is created in the system to trigger the membrane and open the gas valve. Set the regulator to the maximum value.

- Low pressure in the line. Does a thin stream flow when you open the tap? Contact the water utility and wait for the supply to be restored. If this happens often, it is recommended to install a circulation pump.

- The strainer is clogged. The part is located at the entrance to the water unit and traps small debris that comes with the water flow. You need to disassemble the unit and rinse the filter under running water.

- The membrane has stretched. The element serves to activate the gas valve. When there is pressure in the line, the membrane stretches, pushes out the rod and opens the valve. Over time it wears out and needs to be replaced. You can read about this here: “Geyser water unit.”

- Microswitch failure. It cannot be repaired, so a replacement is needed.

- Wiring problems. Remove the casing and inspect all wires leading to the control unit. If the insulation is damaged, replace the cable.

- Malfunction of the solenoid valve in the gas unit. It is necessary to inspect, check and install a new part.

Installation and wiring instructions

Before fixing and connecting the column with your own hands, buy 3 ball valves - one gas, 2 water plus connectors with a cap washer - American. The diameter of the fittings is ½” (DN15). Fastening elements are supplied with the water heater.

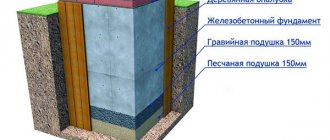

Connecting a water heater to the communications of a private house

Recommendation. If there is no filter at the cold water supply inlet, purchase a mud filter and place it in front of the inlet pipe of the device.

How to install the speaker yourself:

Starting and checking water heating for DHW is done according to the manufacturer’s instructions, but only after the device has been put into operation by a representative of the supplier organization. When it is necessary to replace the device, the procedure begins with dismantling, then work is carried out in a similar order.

Comment. It is allowed to supply water and gas to the device with flexible hoses no longer than 2.5 m. But with this connection scheme, the number of joints increases; it is better to connect the pipes to the heater directly, through taps and American connectors.

Installation of the flueless (turbocharged) version of the dispenser with automatic ignition differs in the way the flue is laid - horizontally through the wall to the outside. A double-walled coaxial pipe is placed with a slight slope towards the street so that the resulting condensate drains. The device must be connected to the mains and grounded - mount a socket nearby, powered through an 8 A circuit breaker, as shown in the diagram.

How to prevent breakdown of the Oasis geyser

In order to prevent a situation where repair of the Oasis geyser is required, it is necessary to properly care for gas equipment and operate it correctly. These are the recommendations that can be read in the instructions for geysers. Here are some operating tips:

- You need to monitor the battery charge.

- When turning off the unit, you must first turn off the water.

- If the unit is turned off for a long time, then it is necessary to shut off the supply of bitter water.

- Periodically clean the column from scale.

- Use only the gas recommended by the manufacturer.

- Do not turn on the column if there is no traction.

- Do not carry out repairs yourself.

Features of using batteries

Of all the parts, batteries require the most frequent replacement. For geysers, you should choose only alkaline batteries made using Alkalin power technology, size “D” and the first letter “L” in the designation is LR20. Their capacity and service life are five times greater than those of salt ones: from 1 to 1.5 years.

It is better not to buy elements that are too cheap, as they may turn out to be fake. It is possible to install NiMH or Li-Ion batteries, but their price with a charger is higher

High-quality batteries cost from $1.2. There is a radical way to reduce the cost of replacing batteries - converting the speaker to power from the mains.

To do this, you can buy a special 3 V power supply, or use a 5 V mobile phone charger with an additional stabilizer. The main requirement is that its power is sufficient for ignition, which occurs at a supply voltage of 3 V and a current of 350 mA.

In case of a power outage, you can always keep batteries in reserve; fortunately, alkaline batteries have a shelf life of 5 years or more.

Column heat exchanger quality

When choosing a column, special attention should be paid to the quality of the heat exchanger. The type of metal and its quality have a great influence on the lifespan of the radiator. They are made of galvanized steel, stainless steel, copper.

The most durable of stainless steel, but inferior in thermal conductivity to copper. Accordingly, they are less economical and have lower efficiency. Copper is the most efficient in heat transfer, but also the most expensive.

When replacing the heat exchanger with a new one, pay attention to the thickness of the metal and the weight of the radiator. Quality should not be too light

The high cost of copper leads to the fact that manufacturers save as much as possible on the thickness of the heat exchanger wall, bringing it down to 0.5 mm, which significantly reduces the service life. For the same reason, other metals are added to copper. The alloy obtained in this way may have unpredictable properties. As a result, such a heat exchanger cannot even be soldered.

System water quality

If the water in the system is subjected to frequent chlorination, this will negatively affect the condition of the copper heat exchanger. In combination with the thinned walls of the pipeline, this can quickly lead to corrosion and the appearance of fistulas.

Increased water hardness in combination with heating causes no less problems. Scale deposits require periodic washing.

You can improve water quality using aquafilters and magnetic softeners.

Overheating of the geyser

The most important factor leading to malfunctions and reduced service life of the column is its overheating. It is important not to raise the temperature to 65 degrees or higher.

To reduce the risk of the water becoming too hot, do not use the faucet to cool the water. Only change the temperature using the flame and water flow control knobs intended for this purpose.

The procedure for disassembling the boiler for cleaning and repair

Drain the water through the check valve. If there is no valve, you will have to unscrew the cold water supply hose. Be sure to disconnect the boiler from the power supply before you start draining.

Next, remove the bottom cover, unscrew the screws, take out the heating element and magnesium anode. If it burns out, change it and clean the heating element from scale. You can boil it in vinegar or citric acid for this purpose.

Clean the inside of the water heater from scale and reassemble it in the reverse order. In short, the order of parsing SGHP 80 ve 1.

The boiler should be cleaned every few years. If you use your water heater intensively and the water quality leaves much to be desired, you need to wash the product more often. Of course, it’s easier to turn to plumbers for help, but if you want to save money, you can do the cleaning yourself.

After cleaning the boiler, the pin broke. Is it possible to change it somehow? Maybe the problem is in the outlet tap on the boiler itself. It may also be that the check valve is not working - it creates the pressure necessary for the hot water to come out.

There are situations when the check valve becomes dirty, it also needs to be cleaned.

Electric water heaters Oasis Oasis are reliable, safe and easy to use. The Russian company Oasis is successfully operating in the market. Oasis electric water heaters have an elegant design and excellent performance characteristics. But even such high-quality units as the Oasis storage water heater sometimes fail.

In general, in my opinion, there are 2 necessary actions - replace the faucet on the water heater with a new one and replace the valve on the return line. Add a comment or review Cancel reply.

Construction and Dacha in clear language

Nowadays, many residents use gas water heaters in their homes, especially residents of private houses who use such gas water heaters very often.

Of course, geysers, like any equipment, have the ability to break down, and one of the most popular such breakdowns is when the geyser does not ignite.

Oasis geysers are very popular - these speakers are quite large and of high quality, but they, like other speakers, tend to break.

Geyser Oasis does not light up

What, in this case, could be the cause of such a malfunction, how to fix this malfunction, is it possible to fix it yourself and, if so, how.

Problem #1 - the flame in the burner does not ignite

If the Oasis gas water heater does not light up, there may be several main reasons. Let's talk about the main ones.

Insufficient power supply to the speaker

Insufficient power supply or no power supply. The most likely and simplest reason for this malfunction lies in dead batteries . If, when you open the tap, you hear a discharge crackling sound, there is a spark, the pressure is normal, but the gas does not ignite, then the reason is most likely in the batteries.

Over time they lose their capacity. Their power drops, they cannot supply the required current to the load. It is only enough to start a high-voltage generator, and there is not enough power to open the solenoid valve.

Deterioration of contacts in the battery compartment due to corrosion and contamination can also cause ignition problems. Corrosion can be caused by leaking batteries or moisture entering the contacts from the outside.

Remedy: replace the batteries with new ones. Alkaline elements should be installed. First you need to check the condition of the contacts. If necessary, wipe them with alcohol, or clean them with sandpaper, a knife or a file. If corrosion damage occurs as a result of moisture ingress, the source should be identified and the leak repaired.

For chimneyless speakers, the lack of ignition may be due to a malfunction of the mains power supply . Only in this case there will be no spark discharge.

Weak pressure at the water heater outlet

Deterioration of water flow through the column is a common occurrence.

If the water pressure in the system is normal, but the outlet of the column is weak, then there may be several options:

- the filter at the inlet of the water block is clogged;

- the throughput of the heat exchanger coil is impaired due to scale;

- the mesh divider (aerator) on the hot water tap is clogged;

- a piece of scale got into the flexible hose supplying hot water to the tap.

Remedy: remove, clean, rinse mesh filters under running water. Replace flexible hose. Clean the heat exchanger.

If there is salt deposits on the filter, it is necessary to boil it in a 10% citric acid solution for 15 minutes

Water unit malfunction

Under the pressure of the incoming water flow, the membrane pushes the rod, which opens the mechanical gas valve and presses the microswitch button that activates the ignition.

This mechanism may fail for the following reasons:

- the membrane is worn out, over time it loses its properties, elasticity, and breaks;

- the rod is stuck.

Remedy: disassemble the water unit. If the threaded connections are stuck, treat them with anti-corrosion agent WD-40 or brake fluid and leave for half an hour. Then replace the membrane, lubricate the rod, spring and seal. It is better to install a new silicone membrane; it will last longer.

Malfunction of microswitch or solenoid valve

You can check the serviceability of the microswitch and solenoid valve with a multimeter. To do this, it must be switched to resistance measurement mode with a minimum limit. Connect the probes to the microswitch terminals and alternately press and release the button.

If the readings of the device vary from one ohm to infinity, then the switch is most likely working. If the readings do not change, the microswitch is faulty.

To check the solenoid valve, you need to measure the resistance of the solenoid windings at the connector terminals. It should be about 400 ohms between the black and yellow wires, and the yellow and red. Between the red and black wires - about 7 ohms. If the measurement results are significantly different, the solenoid valve is faulty.

Sometimes traces of corrosion and moisture are found on the microswitch, in which case it needs to be replaced after eliminating the leak and its consequences

Remedy: these elements cannot be repaired and must be replaced.