Heating is an indispensable attribute of almost all country houses and cottages. After all, the warmth and coziness of home comfort largely depends on how the heating system functions. In the modern heating equipment market, boilers of various modifications occupy a very wide niche. Everyone can choose an individual boiler unit depending on capabilities and technical needs.

However, it is worth noting that the constant growth of different types of fuel leads to the fact that many homeowners are beginning to think about what kind of heating to install so that it effectively heats the room, and at the same time there is a clear saving of money spent on heating the home.

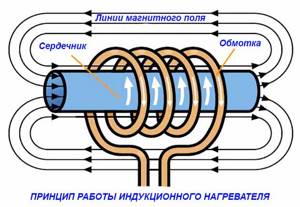

An alternative in this situation can be induction heating, which can rightfully be considered a novelty in technological thought. In order to understand what we are talking about, in this article we will reveal in detail all the important aspects of this type of heating equipment, and also talk about the operating principle of this heating.

The best electric built-in hobs in the premium segment

Premium solutions look great and are easy to use. But similar units are offered for sale at a more affordable price. So why should you choose premium models? Of course, because of their reliability. The final category of our rating includes devices only from German manufacturers. Design, functionality, assembly - everything is top notch here. However, for these advantages the consumer will need to pay an appropriate amount.

Kuppersberg FA6IF01

We decided to start with the most affordable glass-ceramic hob in the premium segment. Model FA6IF01 will cost you about 30 thousand rubles. For this amount you will receive two large and the same number of small heating zones, a burner timer, convenient touch-type controls, a residual heat indicator and a safety shutdown. Also, the device from Kuppersberg provides the possibility of parental control, and the presence and diameter of dishes on the surface of the FA6IF01 can be automatically recognized.

Advantages:

- high heating speed;

- protective functions;

- original design;

- quality of assembly and parts;

- determining the diameter of the dishes;

- boiling function;

- reasonable cost.

Flaws:

square burners.

Siemens EH651FFB1E

If you are looking for a reliable 4-burner cooktop with an oval heating zone and a reasonable price, then we recommend taking a closer look at the EH651FFB1E. It is made of glass ceramics, has a rated power of 7.4 kW, and also has touch slider switches that allow you to conveniently adjust the heating of the burners.

After switching off, the heating zones cool down quickly enough, and the panel itself is able to display the residual heat of each of them. If there are small children in the house, then for their safety the device has a control lock button. The device is also protected from failures, automatically turning off when operating in abnormal mode.

Advantages:

- excellent power;

- the ability to pause a specific burner;

- ease of care;

- low noise level;

- smooth adjustment;

- durable surface;

- beautiful appearance.

Flaws:

demanding on dishes.

Bosch PIF679FB1E

If you dream of a bright kitchen, then black appliances can disrupt the integrity of your chosen interior. In this case, the ideal option for purchase would be a good electric hob PIF679FB1E, manufactured by Bosch. This unit has 4 burners and a convenient control panel. The latter allows you to select one of 9 heating modes for each zone, lock the buttons and set an automatic shutdown timer. If necessary, the user can use a short pause, as well as the oval burner in the upper left corner.

Advantages:

- silver color;

- oval heating zone;

- convenient control;

- tableware recognition;

- chic appearance;

- high-quality glass-ceramic surface;

- There is a pause function.

Bosch PXV851FC1E

The premium model from Bosch leads the list of the best electric hobs. The PXV851FC1E's design and functionality are truly impressive. However, the recommended price tag for this unit is no less impressive - 88,000 rubles. To embed the device, you need a rectangular slot in the tabletop with a width of 75 and a depth of 49 centimeters.

Among the useful functions of the device are protective shutdown and detection of the presence of dishes on the surface. The latter is made of durable glass ceramics, which heats up quickly after the stove is turned on. The device can turn off not only manually, but also automatically. For this purpose, there is a sound timer.

Advantages:

- flawless assembly;

- stylish appearance;

- large heating zone;

- presence of a metal frame;

- precise touch control;

- high power;

- sleep timer.

Flaws:

high price.

Device with nichrome spiral

Device with nichrome spiral

So, to smelt large volumes of metal you will need a furnace with nichrome wire. The operating principle of the design is quite simple: electric current is supplied to a nichrome spiral, which heats up and melts the metal. There are a lot of different formulas on the Internet for calculating the length of a wire, but they are all, in principle, the same.

Step 1. For the spiral, nichrome ø0.3 mm with a length of about 11 m is used.

Step 2. The wire must be wound. To do this, you will need a straight copper tube ø5 mm - the spiral is wound on it.

Frame

Step 3. A small ceramic pipe ø1.6 cm and 15 cm long is used as a crucible. One end of the pipe is plugged with asbestos thread - this way the molten metal will not flow out.

Pipe

Step 4. After checking the functionality, the spiral is laid around the pipe. In this case, the same asbestos thread is placed between the turns - it will prevent short circuits and limit the access of oxygen.

Step 5. The finished coil is placed in a high power lamp socket. Such cartridges are usually ceramic and have the required size.

Finished design

Advantages of this design:

- high productivity (up to 30 g per pass);

- fast heating (about five minutes) and long cooling;

- ease of use - it is convenient to pour metal into molds;

- prompt replacement of the spiral in case of burnout.

But there are, of course, disadvantages:

- nichrome burns out, especially if the spiral is poorly insulated;

- insecurity - the device is connected to a 220 V power supply.

Manufacturers of inverter convectors

The world's first electric convectors with digital INVERTER technology were shown by Ballu, which specializes in the development and production of various climate equipment. Its inverter convectors are capable of achieving energy savings of up to 70% compared to conventional convectors with a mechanical thermostat.

In addition to better energy efficiency, Ballu convectors boast an increased service life (twice) and stability of temperature maintained with maximum accuracy. And this while reducing the load on the power grid.

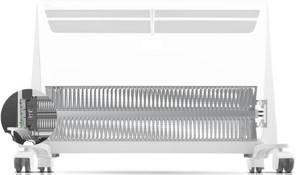

Ballu convectors differ in power and heating area

These heating modules are combined into the EVOLUTION TRANSFORMER SYSTEM group - they are distinguished by a monolithic heating element HEDGEHOG, which has a service life of 25 years. Its surface is ribbed, due to which the metal heat transfer area is increased by 20%, which gives higher performance and faster heating.

This is what the heating element looks like

And the special trapezoidal shape of the body helps the air to be evenly distributed inside the convection chamber, warming up the room faster.

Advantages

- High-speed heating or melting of any electrically conductive material.

- Heating is possible in a protective gas atmosphere, in an oxidizing (or reducing) environment, in a liquid, or in a vacuum.

- Heating through the walls of a protective chamber made of glass, cement, plastics, wood - these materials absorb electromagnetic radiation very weakly and remain cold during operation of the installation. Only electrically conductive material is heated - metal (including molten), carbon, conductive ceramics, liquid metals, etc. For example, the insides of a radio tube can be heated for degassing directly through a glass flask. Electrolytes (salt solutions) cannot be heated by induction heating, since ions, unlike electrons, have a large mass and low mobility.

- Due to the resulting MHD forces, intensive mixing of the liquid metal occurs, up to keeping it suspended in air or a protective gas - this is how ultra-pure alloys are obtained in small quantities (levitation melting, melting in an electromagnetic crucible).

- Since heating is carried out through electromagnetic radiation, there is no contamination of the workpiece with torch combustion products in the case of gas-flame heating or with the electrode material in the case of arc heating. Placing samples in an inert gas atmosphere and high heating rates will eliminate scaling.

- There is no air pollution since there are no combustion products. Small induction heating installations can be operated in a closed and poorly ventilated room that is not equipped with special ventilation equipment and hoods (garages, small home workshops, basements).

- Ease of use due to the small size of the inductor.

- The inductor can be made of a special shape - this will allow it to be evenly heated over the entire surface of parts of a complex configuration, without leading to their warping or local non-heating.

- It is easy to carry out local and selective heating.

- Since the most intense heating occurs in the thin upper layers of the workpiece, and the underlying layers are heated more slowly due to thermal conductivity, the method is ideal for surface hardening of parts (the core of the part remains viscous).

- Easy automation of equipment and conveyor production lines. Easy to control heating and cooling cycles. Easy to adjust and maintain temperature, stabilize power, feed and remove workpieces.

Selecting an induction hob

In order to choose the right panel, you need to take into account personal preferences.

The first step is to deal with the burners, or rather, their number. If you do not plan to cook meals for several people every day, then a miniature version with two burners will suffice. What's the point of paying money for an extra part of the hob? If a family consists of more than three people, then the purchase of a full-fledged appliance with four burners is already required. Purchasing a solid panel without burners is advisable as a replacement for the first option, because such surfaces are of medium size.

Medium size induction

The shape and appearance of the structure play an important role in the case of interior design in the same style. In addition, it is necessary to measure in advance the place for installing the metal-ceramic structure. If there is no suitable place, then it is better to take a closer look at portable models.

You should pay attention to the energy efficiency of the device, which should be at least class “A”. Otherwise, the device will consume more electricity

The cost of equipment also differs from the number of temperature modes, so if you do not plan to prepare culinary delights, then purchase a panel with a minimum set of modes. In other cases, it is better not to skimp and purchase an expensive stove that offers more than 15 modes.

Induction cooker “for a bachelor”

Prices for kitchen induction cookers

Kitchen Portable Induction Cooker

Decide whether you need the booster function. It is not available on all models of appliances and is responsible for quickly heating the dishes. For example, this allows you to bring water to a boil in a matter of minutes.

It is worth considering whether the tile support capabilities will be required. Modern appliances are equipped with a large number of additional functions, including automatic shutdown (when boiling), timer, defrosting food, and storing programs. You should choose a panel with such advantages only when you really intend to use them, otherwise it is just a waste of money.

Manufacturing instructions

Blueprints

Figure 1. Electrical circuit of an induction heater

Figure 2. Device.

Figure 3. Schematic of a simple induction heater

To make a stove you will need the following materials and tools:

- soldering iron;

- solder;

- textolite board.

- mini drill.

- radioelements.

- thermal paste.

- chemical reagents for etching the board.

Additional materials and their features:

- To make a coil that will emit the alternating magnetic field necessary for heating, it is necessary to prepare a piece of copper tube with a diameter of 8 mm and a length of 800 mm.

- Powerful power transistors are the most expensive part of a homemade induction installation. To install the frequency generator circuit, you need to prepare 2 such elements. Transistors of the following brands are suitable for these purposes: IRFP-150; IRFP-260; IRFP-460. When manufacturing the circuit, 2 identical of the listed field-effect transistors are used.

- To manufacture an oscillating circuit, you will need ceramic capacitors with a capacity of 0.1 mF and an operating voltage of 1600 V. In order for high-power alternating current to form in the coil, 7 such capacitors will be required.

- When operating such an induction device, field-effect transistors will become very hot and if aluminum alloy radiators are not attached to them, then after just a few seconds of operation at maximum power, these elements will fail. Transistors should be placed on heat sinks through a thin layer of thermal paste, otherwise the effectiveness of such cooling will be minimal.

- Diodes used in an induction heater must be ultra-fast. The most suitable diodes for this circuit are: MUR-460; UF-4007; HER – 307.

- Resistors used in circuit 3: 10 kOhm with a power of 0.25 W - 2 pcs. and 440 Ohm power - 2 W. Zener diodes: 2 pcs. with an operating voltage of 15 V. The power of the zener diodes must be at least 2 W. A choke for connecting to the power terminals of the coil is used with induction.

- To power the entire device you will need a power supply with a power of up to 500 W. and voltage 12 - 40 V. This device can be powered from a car battery, but it will not be possible to obtain the highest power readings at this voltage.

The manufacturing process of the electronic generator and coil itself takes a little time and is carried out in the following sequence:

- A spiral with a diameter of 4 cm is made from a copper pipe. To make a spiral, the copper tube should be screwed onto a rod with a flat surface with a diameter of 4 cm. The spiral should have 7 turns, which should not touch. Fastening rings are soldered to the 2 ends of the tube for connection to the transistor radiators.

- The printed circuit board is made according to the diagram. If it is possible to install polypropylene capacitors, then due to the fact that such elements have minimal losses and stable operation at large amplitudes of voltage fluctuations, the device will operate much more stable. The capacitors in the circuit are installed in parallel to form an oscillating circuit with a copper coil.

- Heating of the metal occurs inside the coil after the circuit is connected to the power supply or battery. When heating the metal, it is necessary to ensure that there is no short circuit in the spring windings. If you touch 2 turns of the coil at the same time with heated metal, the transistors will fail instantly.

Equipment advantages

An induction-type room heating device has its advantages:

- requires minimal investment;

- has a high efficiency;

- you can assemble such equipment yourself, at home;

- the efficiency factor is almost one hundred percent. The device loses almost no heat during heating;

- usually when heating heating elements or boilers form scale in the system. In this type of heater, there is no such problem;

- when heated, it does not emit any harmful substances, which means it has an environmentally friendly operating process;

- You can pour not only water into the system, but also antifreeze and oil;

Induction heater: operating principle

- does not require constant equipment maintenance;

- Even a non-professional can handle the installation and operation does not require special knowledge;

- The boiler is very well protected from a fire safety point of view. The electrical component is quite reliable and does not fail;

- this type of heater can be used in conjunction with others;

- can operate on both direct and alternating current;

- operation is possible for twenty years;

- The device is very well suited for cottages or private buildings.

But even with so many advantages, the boiler has disadvantages:

- the price of such a device is quite high. And it is unlikely to pay off within 1 – 2 heating seasons;

- there is a need for a constant electrical power supply;

- the device is heavy;

- Installed only with a closed heating system.

But if you decide to replace your wood stove or boiler with a heater of this type, you can immediately get rid of several problems:

- there will no longer be a burning smell in the home;

- there is no soot when lighting the boiler;

- there will be no need to remove soot and ash;

- There will be no need to purchase firewood or coal.

In addition, there is no need to take up space or a special room for storing solid fuel.

https://youtube.com/watch?v=k6fXWhDlyXc

What types of slabs are there?

There is a wide range of kitchen appliances on sale, including induction surfaces.

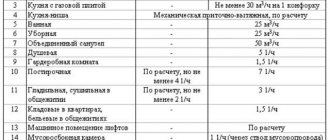

Table 1. Types of induction panels.

| View, illustration | Description |

| Built-in | These are the most popular panels and have a high price. Purchasing a stove and oven of this type will be more expensive than a separate device. But the device will not spoil the appearance of the kitchen and can be combined with various design solutions. |

| Portable | Such slabs have a lower cost compared to the previous type. Basically, there are no more than two burners on the panel. The device is connected to various sockets and placed on a smooth surface. The main advantage of the stove is the ability to move it to any place. The cost of this device starts from 4,500 rubles. This is an excellent option when arranging a budget kitchen. In addition, it is suitable for residents of communal apartments and dormitories. |

| Combined | On sale you can find universal hobs that require two gas burners and two induction. Such devices are suitable for those who do not want to replace all the cookware in order to buy an induction cooker. Only this option costs more than a standard induction cooker. |

| Without burners | Some models of induction hobs do not require burners at all. So, the user can place dishes in any part - the device recognizes the position of the dishes and carries out heating. Despite the fact that up to three or four pans can be placed on such a stove at the same time, you can set the temperature for each of them. In addition to the fact that such a stove looks modern, it will be more convenient to use. |

Selecting the number and type of burners

To choose the right induction hob, you need to consider the number and type of heating zones. On the modern market there are models with from 2 to 6 burners. You can choose built-in domino system appliances or compact portable stoves.

The number of burners depends on the size of the kitchen and the number of people in the family. It is optimal to choose panels with 3-4 heating zones. You can cook the first and second courses on them at the same time. For larger families, 6-burner hobs are available. But you need to keep in mind that such models take up a lot of space, so they are suitable for spacious kitchens.

The diameter of the cookware that will be used for cooking depends on the size of the burners. Panels with a heating zone from 14 to 26 cm are considered standard. Many housewives choose equipment with different burner sizes, which allows them to simultaneously cook dishes in different containers.

Is induction heating economical?

Remember that the induction system is an electric type of heating, so it is very difficult to call it cheap. Absolutely any fuel options can compete with such a system in cost.

In order to make this a more economical form of home heating, the best option is to install a heat accumulator. This will help to run electric heating only at night, and during the daytime the already accumulated heat will work.

At night, there is generally a reduced electricity tariff.

Online and in any store they will tell you that the beneficial effect of an induction heating boiler is 100%.

Of course, this is true, because any electric boiler converts electrical energy into heat. However, few people take into account the fact that part of the heating remains in the room where the boiler is installed.

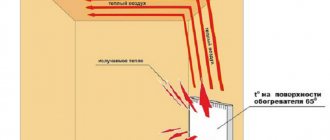

Regarding heat distribution, this heating option is also considered not the most economical and correct. Radiators are installed from the induction boiler, which create heat only for the air that is in the upper part of the room, leaving your feet cold.

The most preferable from this side is a warm floor, in which the cold air remains at the top. In order to accurately select the right option, you need to familiarize yourself with the diagrams and calculations of induction heating.

Types and characteristics of various induction furnaces

There are several types of induction furnaces, the operating principles of which have certain differences. Some are intended only for industrial work, while others can be used at home, so they are often intended for the kitchen, where they provide high-quality heating. Most often, the latest options are formed from a welding inverter and have a simple design, making their maintenance and repair simple work.

The main types of induction furnaces include:

- Vacuum induction furnace. In it, melting is carried out in a vacuum, which makes it possible to remove harmful and dangerous impurities from various mixtures. The result is products that are completely safe for use and of high quality. It should be noted that their repair is considered a complex job, and the creation process itself usually cannot be carried out on its own without specialized equipment and unusual conditions.

- Channel design. It is manufactured using a conventional welding transformer, which operates at a frequency of 50 Hz. Here the secondary winding of this device is replaced by a ring-shaped crucible. A video of the creation of such a furnace can be found on the Internet, and its diagram is not considered complicated. Well-designed equipment can be used to melt a large number of non-ferrous metals, and energy consumption is considered low. Repairs are considered specific and complex.

- Crucible furnace. The scheme of this design involves the installation of an inductor and a generator, which are the most basic parts of the equipment. A standard copper tube can be used to form the inductor. However, the required number of turns must be observed, which should not be more than 8, but also less than 10. The circuit of the inductor itself may be different; it may have the shape of a figure eight or another configuration. It should be noted that repairing this equipment is considered a fairly simple job.

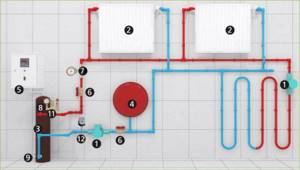

- Induction furnace for heating the room. As a rule, it is intended for the kitchen and is created on the basis of a welding inverter. Typically, this installation is used in combination with a hot water boiler, which allows heating of each room in the building; in addition, it will be possible to supply hot water to the structure. The principle of operation is that the inductor receives power from a welding inverter. It is believed that the efficiency of this equipment is low, but often it is the only one possible for creating heating in the house.

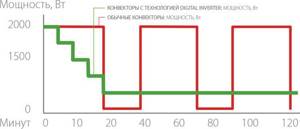

Differences between a conventional electric convector and an inverter

Everyone has probably used an ordinary electric convector (popularly called simply “heaters”) at least once. The principle of its operation is this: when the set air temperature is reached, the thermostat turns off the heating element, and when it gets colder, it turns it on again. And it doesn’t matter whether the control is mechanical or electronic, just in the first case you will have an old-school “twist”, and in the second - a beautiful display indicating the temperature and buttons. But this mode of operation cannot be called energy efficient: in fact, a conventional convector operates on the on/off principle.

Inverter convectors work differently. As soon as the device heats the room to the set temperature, its “brains” give the command to reduce the heating power. The convector does not turn off the heating; instead, it begins to reduce the intensity of the heating element. The latter continues to work only to maintain the desired temperature, so the inverter convector consumes less energy.

Difference between electric and inventory convector

The effect is enhanced by the high sensitivity of the thermostat, which allows you to stably maintain the set temperature with an accuracy of 0.1 degrees Celsius.

DIY induction heater

To buy this device, you will need a significant amount of money, and in a garage it can be assembled from scrap materials. You will need a thick-walled tube with a small steel rod inside. Using conductors on all sides, cover the pipe.

At the next stage, we entangle the central part of the structure with about a hundred turns of copper wire. In this way an inductor is formed. Next, we connect it to the output of the inverter. An integral addition is a thermostat that helps control the heating process.

For assembly you will need the following kit:

- stainless steel rod with a diameter of 7 mm;

- welding inverter;

- fine mesh metal mesh;

- thick-walled plastic tube 500 mm in diameter;

- several meters of enameled copper wire;

- adapter.

Step-by-step algorithm

The assembly consists of the following operations:

- cut the wire into 5 cm pieces;

- We cover the pipe along the edges with a mesh;

- We wind 90 turns of copper wire on top of the coil;

- We remove part of the pipeline and install the boiler;

- connect the coil and the inverter;

- pour water into the boiler;

- We provide system grounding;

- testing performance.

You cannot run such a homemade household induction heater without water, as there is a risk of melting the container. Welding is done in a similar way, in which the heater is a tube inside with wire.

Video - DIY induction heater.

Budget option from inverter welding

A simple and no less effective option for assembling a heater at home - using inverter-type welding:

- take a polymer pipe with thick walls;

- 2 valves and wiring are mounted at the end of the pipe;

- pieces of steel wire 5 mm in diameter are poured inside the pipe;

- the top valve is mounted;

- as in the previous version, all that remains is to make 90 turns of copper wire and the inductor is ready.

The generator is welding, and the heater is a tube with wire. Please note! The appliance should be set to high frequency AC mode. For the whole structure to work, all that remains is to connect the copper wire to the welding pluses and check the structure in action. The heating process involves emitting a magnetic field and heating the wire with vortex currents, causing the water to boil. https://www.youtube.com/embed/XHdl7d7fU8w

Advice from the experts

Experienced electricians recommend following a few tips:

- the induction heater can be used in closed heating systems with a built-in pump;

- For safety reasons, the device should be placed no closer than 80 cm from the ceiling and 30 cm from walls and furniture;

- for safety, it is better to connect a pressure gauge to the device;

- for ease of control, you should connect an automatic toggle switch;

- The heater should be connected to the electrical network using special adapters rather than just anything.

Getting Started

Considering that the induction boiler used for heating does not contain complex elements, any person who has at least once had to work with wire cutters and a welding inverter can make it with their own hands.

- First you should prepare a welding inverter with the ability to change the current.

- You will also need pieces of wire rod or stainless wire, which should have suitable dimensions - 7 mm in diameter and about 5 cm in length.

- To make the heater body, you must get a plastic pipe with a diameter of about 5 cm.

- When creating an induction boiler with your own hands, you will have to connect the device to the heating network. This cannot be done without the appropriate adapters. Such elements will allow the coolant to enter the boiler cooled, from which it will leave already heated.

- Place steel mesh with small cells at the bottom of the plastic tube. This solution will help prevent small pieces of wire from falling out.

- Next, you need to insert pieces of wire into the pipe, and then attach an additional metal mesh to the upper hole of the pipe.

- To create an induction coil with your own hands, you need to take a pipe and wrap it with copper or enameled wire. This must be done so that the cable is positioned very tightly and neatly, and the number of turns should be about 90.

Summary of the work completed:

Having completed all of the above operations, we will have a device that only needs to be connected to the heating system. To do the installation yourself, you will need to cut out a piece of pipe and then insert an induction boiler there. After this, the coil is connected to the inverter, and finally water is released into the system. Please note that the system must contain coolant for the device to operate.

If the boiler starts working in the absence of water or other coolant, this can end extremely disastrously. Due to lack of cooling, the plastic pipe will melt, causing you to have to redo everything

In addition, you need to pay attention to grounding the heating device that you made yourself

How to make

First option.

The features of this scheme are the following important points:

- This design is essentially a multivibrator, which is organized using high-power transistors.

- An important element of the circuit is resistance, which will prevent the transistors from overheating, which will generally affect the efficient functioning of the entire inductor.

- The inductor itself should look like a kind of spiral, and consist of 6–8 turns of copper wire

- In order not to think too much about the design of the voltage regulator, you can take it ready-made from a computer power supply.

Expert advice: since the inductor will generate strong heat, in order to avoid breakdowns, it is recommended to install the transistors on special radiators.

Second option.

Its essence is as follows:

- two pipes are connected to each other by welding in such a way that in cross-section they resemble the shape of a donut (this configuration will simultaneously serve as a conductor and a heating element);

- the copper wire is wound directly onto the body;

- For high-quality movement of the coolant, two pipes are welded into the body, through one of which water will enter the heater, and through the other it will be supplied to the heating system.

You may also be interested in an article on how to make an induction heater from a welding inverter.

Read the article about making your own induction water heater here.

After reading this article, you will be able to make an induction heating boiler with your own hands.

Thus, we have indicated all possible ways to assemble an induction heater using electronic parts. We hope that our tips and recommendations will be very informative for you.

Watch the video in which an experienced user explains one of the options for making an induction heater with your own hands:

Related Posts

- Bathroom ceiling made of plastic panels: installation of frame, panels and lamps

- Decorative 3D panels for walls in the interior of the house

- Connecting the plug to the hob

- Adhesive for plastic: review of waterproof and heat-resistant products

- Interesting ideas for decorating a toilet with plastic panels

- Facade cladding panels

- A supply of hot water that is always at hand: how does an electric water heater for heating work?

- Dimensions and cost of PVC plastic ceiling panels

- What is a boiler for heating water: types, applications and some nuances of operation

- Are MDF panels suitable for ceilings?

- How to glue fiberglass correctly?

- Construction and application of sandwich panels

- How to update old tiles in the bathroom

- Benefits of using a duct extension for radiators

- Connecting the hob to the electrical network: diagrams, selection of cables, sockets, machines

- When health is in your hands: a bathhouse that will be the envy of your neighbors

- Manufacturing and connecting a sauna stove with a water heat exchanger

- How to close the pipes in the toilet

- Do-it-yourself insulation of walls with polystyrene foam - detailed instructions

- How to check grounding

- How to cut metal using a grinder

- Disadvantages of polypropylene pipes in home heating

- Options for making shelves for the garage with your own hands

- Caring for matte and glossy stretch ceilings

- How long should a floor screed dry?

Read with this

- Bathroom ceiling made of plastic panels: installation of frame, panels and lamps

- Decorative 3D panels for walls in the interior of the house

- Connecting the plug to the hob

- Adhesive for plastic: review of waterproof and heat-resistant products

- Interesting ideas for decorating a toilet with plastic panels

- Facade cladding panels

- A supply of hot water that is always at hand: how does an electric water heater for heating work?

- Dimensions and cost of PVC plastic ceiling panels

- What is a boiler for heating water: types, applications and some nuances of operation

- Are MDF panels suitable for ceilings?

Why is an inverter convector more expensive than a regular one?

The answer lies in the design of such a convector. In addition to the heating module, it contains an inverter control unit. However, during the heating season the difference in price can be made up due to lower electricity consumption. For example, installing such a convector will be very profitable in a country house where gas heating is not possible.

How to choose the power of the convector

It is also cheaper than heating using an electric boiler, which requires installing a boiler room, installing pipes around the house and installing radiators; The inverter convector only requires a regular socket to operate.

You can mount the convector on the wall - it looks stylish in any interior