Many residents of the country have noticed that installing gas heating is quite an expensive pleasure. Since gas is too expensive, its use is not always justified. Therefore, firewood is an excellent alternative for heating a country house or country cottage. “Student” stoves, made in various versions, are the most practical option for heating a house or garage. The most significant aspects include maintaining a balance between price, functionality and efficiency of models.

Design and principle of operation

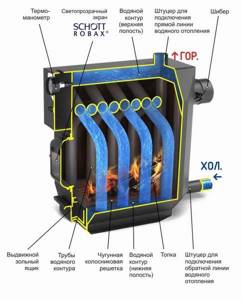

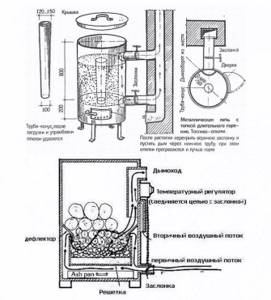

Professor Butakov’s “Student” stove has a fairly simple design, it contains:

- two-chamber ash pan,

- firebox,

- air outlet pipes,

- grate bars,

- chimney,

- cast iron door with glass.

The principle of operation of the furnace used by the professor was known long before his development. Due to the low oxygen content in the fireboxes, the fuel does not burn, but smolderes slowly, releasing a sufficient amount of heat. This is what increases efficiency, eliminating additional bookmarks.

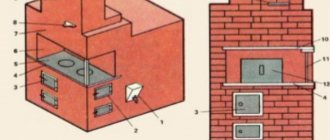

Furnace structure Student

Furnace models

- "Gymnasium student." Power 7 kW for rooms up to 100 sq. m. Combustion products are discharged to a height of 5 meters.

- "Student". Power 9 kW, fuel loading up to 20 kg. It is used to provide heat to rooms with an area of 150 square meters. m. Removes gaseous combustion products to a height of 5 meters.

- "Engineer". Power 15 kW. It is used for heating rooms with an area of 250 square meters. m. Fuel loading up to 40 kg. Removal of combustion products - to a height of 5 meters.

Furnace "Engineer"

- "Assistant professor". Power 25 kW, fuel loading up to 100 kg. It is used for heating rooms with an area of 500 sq. m. Removal of combustion products - to a height of 6 m.

- "Professor" with a power of 40 kW. It is used for heating rooms with an area of 1000 square meters. m. You can load up to 200 kg of fuel. Removal of gaseous combustion products to a height of 8 meters.

- "Academician". Power 55 kW, fuel load - up to 240 l. It is used for heating rooms with an area of 1200 square meters. m.

Characteristics

Considering that the Butakov “Student” furnace has various modifications, their sizes and technical characteristics differ significantly. What these devices have in common is the presence of built-in convective channels used to increase heat transfer. Depending on the type, stoves can work both to heat air and provide water heating.

In this mini-review we will look at stoves from the Termofor company.

Wood burning stove

This device is characterized by maximum thermal efficiency and high efficiency, in comparison with coal analogues. It has the following features:

- Tightness of the combustion chamber - the door closes securely, eliminating the formation of cracks.

- Improved control of air supply - the unique design of the gate valve allows you to set gas generation or simply combustion modes.

- High-quality materials - thick-walled structural steel and cast iron for grates and doors were used to make the body.

In addition, the device is characterized by relatively small dimensions, which are:

- 530*780*370 mm,

- chimney pipe diameter 120 mm,

- weight of the entire oven is 77 kg,

- firebox volume 74 l,

- power reaches 9 kW,

- Efficiency is 85%.

The Student stove has an amazing ability to prevent soot from contaminating work surfaces. Even long-term use will not affect the cleanliness of the glass. The burning duration allows you to make bookmarks no more than once every 6-7 hours. The device is equipped with a replaceable grate, which allows air flows to be evenly distributed in the fuel chamber. This eliminates the formation of soot. The design of the ash box allows it to be cleaned without interrupting the combustion process.

Coal furnace

When designing these heating furnaces, the intensity of the thermal load was taken into account. The device has the following characteristics:

- weight – 77 kg,

- firebox volume – 70 l,

- dimensions – 530*370*780 mm,

- Efficiency – 85%,

- Power – 9 kW.

Burning coal requires more oxygen than wood, but produces significantly more heat. Thanks to the 5 mm wall thickness, metal deformation, which can cause rapid breakdown of the furnace, is eliminated. The tightness and thoughtfulness of the design can significantly reduce coal consumption. A similar stove by Professor Butakov “Student”, operating on coal, is an ideal option for systematic heating.

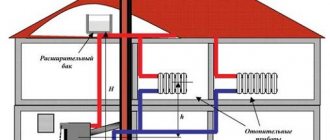

Hydraulic

Thanks to the unique design of the heat exchanger, the long-burning Student water-heating stove has a fairly high heat output. The usual coils in it were replaced with convective channels, partially recessed into the firebox. Thanks to these features, the liquid is intensely heated and enters the heating system. This large-sized device has the following characteristics:

- weight 90 kg,

- power 16 kW,

- firebox – 70 l,

- dimensions – 720*370*770 mm,

- Efficiency – 85%.

In addition, the design provides for the installation of heating elements, which allows you to maintain the temperature of the coolant for a long time.

Features of the furnace design Student Hydraulic

Attention! Electric heaters can be installed independently or purchased together with the boiler.

History of creation

The first example of such a stove was made in 2002 in the north of the country, in the Novosibirsk region. Just two months after this, the necessary certificates were received, and by 2004 a patent for the invention was issued. Its developer is a specialist in the field of heating engineering E. Yu. Zubkevich, who named the stove in honor of his relative Professor S.E. Butakova.

A year later, the inventor entered into an agreement with the Termofor company, which mastered the production and production of products. For a number of reasons, cooperation with her was suspended in 2008 and the patent owner remained out of business. To date, the production of these furnaces has been established on an industrial scale.

Advantages and disadvantages

The devices have a whole list of advantages that are very valuable for products of this kind. Among them it is worth highlighting the main aspects:

- quite convenient installation that does not require specific skills and the construction of additional foundations,

- rapid removal of ash, which can be carried out even during combustion,

- The design of the heating stove by Professor Butakov “Student” provides for an organic combination with any interior.

- large heating area,

- presence of air cooling,

- sufficient dimensions of the heating surface,

- functional firebox, equipped with control of air supply, as well as combustion intensity,

- replaceable grates.

However, despite such a number of positive qualities, there are also some disadvantages. These include:

- strong heating of the surface,

- the need to wet the ash before removing it from the firebox,

- requires the use of enhanced thermal insulation for chimneys.

Nevertheless, the Student heating stove has many more advantages than disadvantages that do not affect the functionality of the device.

Features of installation and assembly

Considering that the surface of the device gets very hot, the installation provides enhanced thermal protection for floors and walls. This can be done in the following sequence:

- A basalt slab is laid on a wooden or other combustible floor, the surface of which should be sheathed with metal.

- Walls located close to the device are protected with basalt insulation. This will reduce the distance between the wall and the stove to 50 cm.

- The presence of supply and exhaust ventilation, both forced and natural, is unacceptable when installing a stove.

- When laying a chimney, you will need to protect the walls from heat. To do this, install a special fireproof cutting and spark arrester.

If you plan to heat adjacent rooms with heated air, you will need to connect thermal extractors and additional air ducts. The oven is installed in such a way as to facilitate the installation of the corrugated pipe.

Installation example

Another installation option (in the corner)

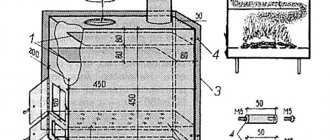

How to make it yourself

To complete the task you will need drawings and diagrams. Their presence will greatly facilitate the assembly process.

To manufacture the mechanism yourself, you must follow the following algorithm:

- Make the base cylindrical. You can use a barrel with a thickness of 10 mm.

- You will need to cut a circle from a metal sheet so that its diameter is 2 cm smaller than that of the main cylinder. A hole with a diameter of 5 cm is cut in the center of the product.

- At the top of the cylinder you need to place a metal lid, having previously cut a hole in it for the pipe.

- Weld the pipe. It must be equipped with a damper designed to trap smoke.

- A hole is made in the cylinder for the future chimney. Its diameter should not exceed 20 cm. Through it, the stove can be cleaned of ash. A door equipped with a handle is installed on the hole.

- Seal the hole with sealant and install the resulting device on a solid and level base.

Important! After installing the stove on the walls, it is necessary to install reflectors that will protect the room from fire.

User manual

It is worth considering that the “Student” dacha stove is a gas-generating equipment that imposes special requirements on the quality of the fuel used.

- It is recommended to use firewood whose humidity does not exceed 25%, since rawer fuel will not allow the unit to switch to gas generation mode. This can provoke a decrease in efficiency with increased fuel consumption.

- For coal modifications, firewood is used as needed. To do this, you will need to completely pull out the grates. When using wood or peat briquettes, the gap between fillings increases significantly. It also generates 28% more heat than wood.

Attention! It should be taken into account that the design of wood-burning modifications does not include the use of coal.

Buying tips

In order for an ignorant user not to make a mistake when buying a stove, it is necessary to know how the original Novosibirsk Termofor product differs from a fake. Considering that the product is designed for long-term combustion, high-quality material is used for its manufacture: thick steel for the body and durable cast iron for the grates and doors. It is the design of the firebox door that is the main difference between the original and the fake.

Depending on the modification, the cost of the structure starts from 15,000 depending on the model. Considering the high functionality and efficiency of the devices, the price of Professor Butakov’s “Student” stove is quite adequate, which allows everyone to economically heat their country houses.