Heating equipment in a home is often installed in a room called a boiler room. Since this is technological equipment and unsafe in emergency situations, the room for heating equipment must be installed in accordance with existing standards and rules for its operation. A boiler room is usually equipped if the house is not connected to central heating, but has its own autonomous heating system, so the characteristics of each boiler room will be different, but they must be brought to general requirements, which depend on the type of heating device and its placement in the room. Therefore, before installing heating equipment, its placement is designed.

Boiler room on the house plan General provisions Places where it is recommended to equip a boiler room in a private house: 1. Attic or attic; 2. Separate economic building; 3. Autonomous module – mini-boiler room in a separate container; 4. Room in the house; 5. A room attached to the house. The optimal placement of boiler equipment is an attic or basement, but when installing heating in an old house, it is better to do this in a separate building or an attached room to the house. The arrangement of a boiler room in a private house depends on the type of heating unit - it can be gas, electric or solid fuel, so the choice of building or room largely depends on this. When drawing up an equipment installation project, it must include a diagram of the location of heating equipment and requirements for boiler rooms in a private house.

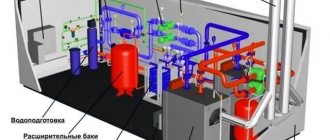

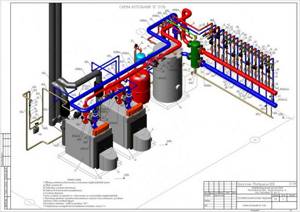

Boiler room and equipment diagram

The project must be coordinated with government organizations, but higher requirements are imposed on gas equipment. Requirements for a boiler room in a private house with any type of boiler: 1. Up to two boilers are allowed to be installed in one room; 2. The walls of the boiler room must be made of non-combustible building materials; 3. The floor in the boiler room must be concrete or have metal sheet protection. Ceramic tile cladding is allowed; 4. You cannot store or use any flammable substances in the boiler room; 5. The door to the boiler room must have fire protection - metal, asbestos or other non-combustible upholstery; 6. All doors in the furnace room must open outward; 7. If the furnace room is located in an extension, then one door should lead into the building, the second - outside; 8. All heating devices and equipment must be accessible for maintenance and control; 9. Artificial ventilation must be three times the capacity relative to the requirements of SNiP; 10. The furnace room must have a window with a window ≥ 50 x 50 cm.

Boiler room project in a private house

Standards and requirements

For each type of boiler, there are additional requirements for placement, operation and safety, described in SNiP 42-01-2002. The basic general requirements for a boiler room in a private house with gas equipment include: permission to install a boiler ≤ 30 kW not in a separate building or room, but in the house. The room must have a ceiling height ≥ 2.5 m, area ≥ 6 m2, volume ≥ 15 m3. Usually, a kitchen is used to install gas boilers, and it is necessary to focus on the power of the boiler - the larger it is, the larger the area and volume the room should have. The minimum window area in the kitchen is 0.5 m2, door width ≥ 0.8 m. In any room with gas equipment for heating the house there must be natural and forced ventilation; to ensure natural ventilation in the kitchen, holes of size ≥ are made at the bottom of any wall or door 30 x 30 cm, forced ventilation is provided by installing a hood. If the boiler has a power ≥ 30 kW, it must be installed in a separate building or room. When installing a boiler in a house, the following conditions are taken into account: 1. A separate door to the street; 2. Artificial and natural lighting; 3. Availability of artificial and natural ventilation and/or exhaust; 4. Fire resistance of walls.

Ventilation diagram

Types of boiler houses

There are many types of modern boiler houses. They differ in the type of fuel, type of energy carrier, location, and level of mechanization.

Taking into account the type of fuel, they are divided into:

- Liquid fuel. They run on oil, fuel oil, petroleum, and diesel fuel. They are put into operation quickly, without permits or restrictions.

- Gas. They are considered the best option, as they are economical and environmentally friendly. The advantages include the absence of equipment with large parameters and possible full automation.

- Solid fuel. The premises are heated using firewood, peat, coal, briquettes and pallets (timber and agricultural waste). A positive aspect is the low cost and availability of fuel, but it requires the installation of additional equipment.

- Electrical. They work from the electrical network. It is expected to be equipped with special equipment, such as circulation pumps, safety valves, automatic air vents, and closed expansion tanks.

Depending on the type of coolant, they are divided into:

- hot water (heat rooms and heat water both in residential buildings and in industrial premises);

- steam (installed mainly at industrial facilities);

- combined type (includes both previous types);

- on diathermic oil (use of organic high-temperature liquids).

There are different types of accommodation, and therefore there are:

- stationary - are permanent structures with foundations, walls, partitions, roof, equipment is installed on site;

- block-modular - quickly installed and put into operation, you can increase power, autonomy, mobility, and high efficiency.

Considering the degree of mechanization, they are divided into:

- mechanized (no need for an operator);

- manual (fuel is supplied manually);

- automated (full automation is assumed, without the participation of the human factor).

Requirements for a room with an electric boiler

An electric boiler and related devices are the safest of all types of heating, so there is no need to allocate a separate building or room for an electric boiler. There is also no need to equip ventilation and exhaust, and the boiler can be installed in any room of the house. The disadvantage of this equipment is volatility and high energy consumption. Requirements for a combustion room with a solid fuel boiler 1. The area of the combustion room is 8 m²; 2. Free access to all equipment; 3. The ventilation duct is calculated based on the proportions of 8 cm²/1 kW of unit power; 4. The boiler is installed on a separate foundation, as well as on a foundation - on a podium made of non-combustible materials up to 10 cm high; 5. Natural and forced ventilation is arranged in the same way as for gas equipment. The same applies to lighting – natural and artificial; 6. Building materials of walls, floors and ceilings must be non-flammable. A steel sheet measuring 500 x 500 mm is laid in front of the firebox; 7. The chimney must have a height of ≤ 5 m, with a number of turns or bends ≤ 3. When installing a gas or solid fuel boiler, it is recommended to carry out parallel installation of automatic protection, fire protection and other safety components and elements: bypasses, shut-off safety valves, temperature sensors, sensors smoke, other protective devices and equipment.

Fire extinguishing means in the boiler room

Method of application, choice of fuel and operating features of a solid fuel boiler

The question of how to properly heat a solid fuel boiler directly depends on its type. All these units operating with solid fuel can be divided into two main groups - boilers with automatic fuel supply and units with physical loading.

The first group includes the so-called pellet heating products. Their design features are more complex, and the work is almost independent; it is necessary to heat such an apparatus, maintaining a fire in it, quite rarely.

The second type of solid fuel boilers is the most common. They come in three types:

- pyrolysis;

- classic;

- long burning.

Classic devices are practically not used today, this is due to the frequent need for their maintenance, as well as the insufficient safety of the unit for consumers. But pyrolysis apparatuses and long-burning boilers are widely used and popular. This popularity is due to their correct construction and fuel efficiency.

Rice. 1 Pyrolysis solid fuel boiler

Requirements for the placement of gas equipment

For a separate room with a gas boiler, the following standards exist: 1. The foundations of the house and boiler room must be separate; 2. A separate foundation is built for a floor-standing gas boiler; 3. Building materials of the roof and walls must be non-flammable; 4. On the foundation, the boiler rises 20 cm on a metal or concrete base; 5. The chimney pipe rests on its foundation. Installation of a gas boiler is permitted in the kitchen (in the toilet and bathroom is prohibited) or in a separate room built from non-combustible materials, which must have a ceiling height of ≥ 2.20 m, room volume ≥ 15 m3 and/or 6 m2. The window in the boiler room must have an area of 0.5 m2, plus equipment for natural and artificial ventilation and/or exhaust. The perimeter of the room can be of any shape, but the width of the doorways must be ≥ 0.8 m, and the passages themselves must be located at a distance of ≥ 1 m from the boiler and to the wall opposite. A gas boiler can be installed on any floor of the house, as well as in the basement and attic.

Boiler room with gas boiler

Dimensions of a boiler room with an oil-fuel boiler

The volume of combustion chambers, regardless of type, is identical. But there are specific requirements that relate to the installation of chimneys and the determination of fuel storage locations. These data are usually indicated by manufacturers in boiler data sheets. But if they are absent, then you should proceed from the following:

- The cross-section of the boiler outlet pipe must be larger than the cross-section of the chimney. Moreover, this ratio must be maintained throughout the entire chimney;

- the chimney must be straight or with a minimum number of bends;

- At the bottom of the wall you need to make a hole for the flow of clean air. Its area must be at least 8 cm² per kilowatt of the boiler;

- the chimney must exit either through the wall or through the roof;

- It is necessary to have a cleaning hole in order to carry out regular inspection and cleaning;

- materials for the chimney and its connecting elements must be made of material that is gas-tight;

- the base for installing the boiler must have fire-retardant properties. If there are wooden floors in the furnace room, you must do the following: lay an asbestos sheet on top, and a metal sheet on top. You can make a brick foundation, which is then plastered or tiled.

Installation of ventilation in the boiler room

Natural ventilation is ventilation using artificial openings in the surfaces of the room, without the use of equipment or forced-exhaust devices. The most effective location of the hole, ventilation pipe or hood is above the boiler. The disadvantage of natural ventilation is the difficulty of ensuring its power, which should be three times the norm per hour. Forced or artificial ventilation is equipped with fans and/or air conditioners with the installation of an exhaust duct. The advantage of such a system is that the power of the air flow can be adjusted. Disadvantage: dependence on energy supply. The hood power can be calculated as follows using a specific example: With a room width and length of 2 m, a ceiling height of 2.5 m, we obtain: 2 m x 2 m x 2.5 m = 10 m³. Based on the requirements of SNiP, the result must be multiplied by 3, that is, the final result will be equal to 30 m³/h. To ensure a power reserve, you need to add 15-20% to the result.

Ventilation equipment of the boiler room To reduce the energy consumption of the entire system, it is recommended to install an automatic control system for ventilation and fuel loading, which will operate when the boiler is turned on, and when the fuel burns out, the fans will stop. The ventilation pipe is ducted outside - if this is a room inside the house, then the pipe can be ducted out the window located next to the fan. The height of the ventilation pipe is 50-100 cm higher than the roof of the house. This height provides the required draft for the removal of exhaust gases accumulating in the boiler room.

Documentation for the project

After preparing a project for a gas boiler house in accordance with all existing standards SNiP 42-01-2002, it must be approved by the relevant authorities and organizations. This is necessary to confirm the safe operation of your boiler room, and also so that in the future you can sign an agreement for connecting gas to the boiler and/or laying an internal gas pipeline to the equipment. Permits must be issued before the installation of a boiler room begins in the following supervised organizations: 1. Fire safety service; 2. Technical supervision of gas equipment; 3. Sanitary and epidemiological inspection; 4. Architectural department of the district or region; 5. Housing and communal services and local gas service.

Requirements for gas boiler houses

If you start building a boiler room without the approval of these services and organizations, you may receive a ban on operating your seemingly safe boiler room. This means that a lot will have to be redone and the documents will still need to be completed. Therefore, the construction and equipment of a boiler room should be started only after receiving all permits. When connecting a house to a central gas pipe, an additional design for connecting the main line to the house with distribution to distribution points is required.

Choosing fuel for a solid fuel boiler

Many users of solid fuel boilers are very careful when choosing fuel. This is not at all surprising, since the quality operation of the unit depends on this product. Moreover, it needs to be purchased in large quantities, not only because of the cold climate, but also because the long-burning device requires refilling with large quantities of raw materials.

The following types of gas stations are considered the most popular today:

- firewood;

- coal;

- pressed briquettes.

Not knowing what is the best way to heat a solid fuel boiler, you should pay attention to briquettes and pellets, which are easy to use and have a long burning time. But when using them, there is also a significant disadvantage - the high price, which is derived from the difficulty of manufacturing these products.

Firewood is no less convenient to use, but in some cases it has high humidity, which is difficult to deal with even for the newest boiler models.

But heating with coal is beneficial from all sides - its combustible effect is quite long, and during combustion it does not emit any harmful substances. The low price of the material is no less pleasing.

Rice. 3 Cleaning a solid fuel boiler

The method of loading firewood as an attachment to this product is extremely popular for the reason that after the firewood is burned, black fuel continues to act for a long time, increasing the time before a new refueling is required. Although none of the heating methods can be called correct, each user chooses the option that suits them.

Safety measures when operating a Solid Fuel Boiler

The boiler must be installed in compliance with the following safety requirements:

- “Rules for the technical operation of thermal installations and networks”

- “Fire safety rules in Ukraine” NAPB A.01.001-2004

- “Rules for the design and safe operation of steam and hot water boilers” DNAOP 0.00-1.08-94

During operation it is PROHIBITED:

- Shutting off the air supply to the room with the boiler running. Due to the lack of air for fuel combustion, tarring and the formation of semi-coke gas are possible.

- Use of fuels not specified in the operating instructions. To avoid poisoning, burning of plastics, materials and liquids that emit toxic gases during combustion is not allowed.

- Use any liquids to ignite and increase the performance of the boiler.

- Operating the boiler with an empty or partially filled heating system;

- Filling a heated boiler with cold coolant;

- Fill the heating system and top it up at a pressure exceeding the operating pressure in the boiler. Excessive pressure can lead to destruction of the boiler heat exchanger;

- Direct selection of hot water from the boiler circuit (heating system) for domestic needs;

- Operating the boiler with a faulty smoke exhaust duct and impaired draft;

- Operating the boiler with the loading and ash doors open or not tightly closed.

- The owner is prohibited from independently repairing the boiler communications and making any changes to its design;

- Installation of shut-off valves on the pipeline that connects the heating system to the expansion tank;

- Installation of shut-off valves and filter in the area between the boiler and the safety valve;

- Reducing the water temperature at the boiler inlet below 45°C;

- Increase in boiler outlet temperature above 90°C;

- Starting the boiler when the water in the heating system freezes;

- Reloading the boiler with fuel if heat extraction is stopped and the heat accumulator is heated.

- Access for children to a room with a working boiler;

- The presence of children in the room in which the boiler is installed at the time of ignition and shutdown of the boiler;

- Leave the boiler running for a long time unattended;

- Carry out any work on a boiler that has not cooled down.

- Store flammable materials or liquids near the boiler.

- Store ash in an open container made of combustible materials.

Adhere to safety measures, since their violation can lead not only to an emergency, but also to harm your health!

ATTENTION! If the boiler stops operating during the heating season and there is a threat of water freezing in the heating system, it is necessary to completely drain the water from the boiler and heating system (at ambient air temperatures below 0°C).