Types of boilers for heating a private house

At the heating system design stage, the homeowner may be faced with a seeming variety of boilers. Selecting the right unit will simplify the availability of energy resources. Manufacturers produce 4 types of heaters: electric, gas, solid and liquid fuel boilers. The latter modification is rarely used due to the high price of fuel (mainly diesel).

The most common boilers are those using natural gas. They operate in manual or automatic mode and do not require constant monitoring. Even budget models are able to independently maintain the temperature at a given level. A significant limitation in using a gas boiler is the availability of fuel. If there is no gas pipeline connected to the house, the owner will have to look for another source of heat.

Electric boilers can become an alternative to gas ones. However, the cost of electricity is higher compared to blue fuel. The heaters also operate automatically, they are silent and take up little space, which eliminates the need for a separate room for installation of equipment. In addition, they do not require the construction of a chimney.

In the absence of access to a gas pipe and unwillingness to pay electricity bills, homeowners install boilers that burn solid fuel. You can burn wood, coal, and pellets in them. However, such heaters require constant supervision: as the fuel burns out, it must be periodically added and the ash must be removed. In addition, solid fuel boilers are installed in a separate room so that soot does not settle in living rooms.

For your information!

Some manufacturers produce automatic solid fuel boilers with ultra-long burning. They independently regulate the temperature of the coolant, and fuel enters them from the bunker, which ensures continuous operation of the unit.

Types of systems

Before you begin installing a heating system in a house, you will need to learn to distinguish between the one-pipe and two-pipe methods of arranging it. In the first case, wiring from one pipe is used, which forms a closed loop with coolant circulating through it. A sequential scheme is implemented, according to which the water medium, passing through the boiler, is heated, after which it gives off heat to the radiators. At the final stage of its movement, it, already cooled, again enters the solid fuel boiler.

The dual-circuit system is more complex, as it consists of two separate branches, each of which performs its own function. The first of them is designed to transfer heat from the boiler to the radiators, and the second is to remove the cooled coolant back to the boiler unit.

The choice of wiring option is determined by the preferences and financial capabilities of the home owner, since installing a 2-pipe system is associated with high costs.

Requirements for boiler installation

The norms and rules that ensure trouble-free operation of boilers vary for each type of heater. The most stringent requirements are imposed on units operating on gaseous fuel. This is associated with the risk of depressurization and subsequent explosion of the gas-air mixture. When installing heating in a private home, the homeowner should be guided by several documents:

- SNiP 41-01-2003 “Heating, ventilation and air conditioning”;

- SNiP 21-01-97 “Fire safety of buildings and structures”;

- SNiP 2.04.01-85 “Internal water supply and sewerage of buildings.”

To approve the project, the homeowner submits an application to the local utility service, which specifies the type of equipment to be installed. After considering the request, the regulatory authority agrees on the technical conditions that must be fully implemented when installing the boiler and heating system. The next stage is drawing up and agreeing on the project. The processing time for the latter depends on the complexity and can range from several weeks to 3 months. If the project has not received approval, then the applicant is given a list of actions that need to be performed to obtain a positive conclusion.

Installation of heating from polypropylene pipes

You can also install heating from polypropylene .

This means that heating installation can be carried out using polypropylene pipes.

The fact is that in most houses that are built on the territory of the Russian Federation, the main problem is that communications cannot last for a long time. They can be used for just a few decades.

Modern industry has given humanity such a wonderful material as polypropylene pipes.

They have a lot of advantages. This is precisely what justifies the installation of polypropylene heating systems in many houses, dachas and country cottages.

- Firstly, unlike steel pipes, they are not subject to corrosion processes.

- Secondly, they are not susceptible to rust.

- Thirdly, polypropylene is a material that will never tear if the temperature changes sharply.

- Fourthly, installation of heating from polypropylene pipes does not present any difficulties. That is why it cannot be called labor-intensive or financially expensive. You can even do it yourself without turning to professionals.

To install the heating system of a private house, you can use special batteries.

Installing heating using batteries will also not be particularly time-consuming and financially expensive. This is one of the most commonly used methods of heating a country house or cottage.

Requirements for a boiler room in a separate building

Boilers and related equipment may be installed in a separate building - a boiler room. The dimensions of the latter, as well as the building materials from which it is made, are regulated by the relevant SNiPs. More stringent requirements are established for a gas boiler room, since during its operation an explosion and fire of the gas-air mixture is possible. Such a project must be approved by the supervisory authorities.

For your information!

The latest change in legislation regulates the installation of a gas alarm, which automatically stops the gas supply to the boiler room when a leak is detected. This standard applies to boiler units with a capacity of more than 60 kW.

For boiler rooms that are designed for equipment running on electricity or solid fuel, less stringent requirements are put forward, since the unit in this case is not classified as explosive. Therefore, design and construction work can be done independently. When constructing a building, non-flammable or low-combustible materials are used to prevent the spread of fire in the event of a fire.

What to do to stay warm when the main power source is turned off

The natural answer is to turn on the heating with another, backup energy source. For example, if the gas is turned off, turn on the electric heater or fireplace. But this is only good for local heating. The system in other, distant places in the house may freeze, pipes will burst, and repair costs will be very high.

There are two options to resolve this issue.

Antifreeze

Pros:

- Antifreeze does not freeze down to -55–65 0C, depending on the manufacturer. It is convenient to use if in winter the house is not heated constantly, but periodically.

- Does not oxidize the metal of the radiator and metal pipes, therefore, does not lead to the formation of rust.

- Does not create scale and does not settle on the internal walls of the heating system.

- Heats up 10% faster than water and cools down 10% longer.

Although antifreeze is more expensive than water, it will help save energy during operation Source sovetystroi.ru

How to install a heating boiler in a private house with your own hands

Most models have built-in circulation pumps and expansion tanks. The simplest and most common piping scheme involves the location of a supercharger with a bypass line and a sump on the return line. An expansion tank is also installed there, which is necessary to compensate for the temperature increase in the volume of the coolant. A pressure gauge is used to monitor pressure, and air is removed from the boiler circuit through an automatic air vent.

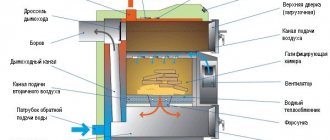

A solid fuel heater must be equipped with an external circulation pump, an expansion tank and a safety group. Additionally, a cooling circuit is installed, designed to lower the temperature of the coolant in case of overheating. To protect the internal surfaces of the boiler from condensation, the system is equipped with a three-way valve that regulates water heating.

Heating of private housing construction can be implemented independently. The owner must carefully comply with the requirements of regulatory documents, follow the recommendations of manufacturers and the advice of specialists. The successful completion of installation is facilitated by watching videos that show the step-by-step execution of the work.

Vodyanoye

Water heating is a closed system through which hot water continuously circulates. The boiler acts as a heating element. Radiators are installed in each room. From the boiler, water circulates through pipes along the circuit and, passing through radiators, gives off heat.

The benefits of a water system depend on the type of fuel used by the boilers. If there is a gas main nearby, then it is wiser to purchase a gas boiler. Gas fuel is considered the most economical. However, such structures require regular maintenance by special services. For non-gasified areas, it is better to purchase solid fuel boilers.

It is not advisable to use liquid fuel for the boiler, since it is expensive and will require the construction of a special tank in the ground to store it.

Fuel consumption

Example No. 1. Calculation of fuel consumption in a water heating system: gas will act as fuel, since it is the most common. For the calculation, you will need the power of the unit and the area of the heated housing. The boiler power for a private building is determined based on the proportion: 1 kW per 10 m². For a room of 100 m² you will need a 10 kW boiler.

To calculate fuel consumption, it is necessary to multiply the boiler power by 24 hours and by 30 days. As a result, we get 7200 kW/hour. Since the unit does not always operate at full capacity, this number must be divided by 2. Monthly fuel consumption is approximately 3600 kW/hour. The heating season lasts approximately 7 months. Fuel consumption during the heating period is 3600*7 = 25200 kW/hour. Considering that 1 m³ of fuel produces 10 kW/hour of energy, we get: 25200/10 = 2520 m³.

Let’s convert the resulting value into a monetary equivalent: the national average cost of gas per 1 m³ is 4.97 rubles. Accordingly, gas heating for the year: 4.97 * 2520 = 12524.40 rubles.

Advantages and disadvantages

The main advantages of a water heating system are:

- prompt heating of even a large room;

- quiet operation;

- ensuring the same temperature in all rooms;

- fuel economy;

- ease of maintenance and repair;

- increase in operational life.

How to include a circulation pump in the circuit

This structural element can be installed directly at the assembly stage of the system or embedded into an existing structure with a natural flow of water. Recently, pumps have appeared on sale that can be installed on both the return and supply pipes. However, they are quite expensive. Therefore, most owners of country houses prefer to purchase less durable old-style models. Since the latter do not tolerate elevated temperatures very well, they are installed strictly on the return pipe on a bypass with three taps. In this case, a coolant purification filter must be installed in front of the pump itself.

Single pipe connection

Installing heating using the single-pipe method is the least expensive, while at the same time, installing it in two pipes will be the most effective, especially if the rooms in the house are large.

The advantages of such a scheme are as follows:

- Easy installation and repair;

- Cost-effective;

- Possibility of laying the main line at floor level;

- Using the system in a one-story and two-story house;

- Possibility of forced or natural circulation.

With a single-pipe system, water moves from one radiator to another through a pipe, and upon reaching the last radiator it cools down greatly. Such a system cannot be adjusted.

Types of radiators

For heating systems of country houses, cast iron, aluminum or bimetallic batteries can be used. The last variety is the most popular. Cast iron radiators are quite reliable and efficient. However, they do not look particularly aesthetically pleasing. In addition, they are too heavy and therefore inconvenient to install. Aluminum batteries look modern and are easy to install.

But they have one very serious drawback. With prolonged contact with air dissolved in the coolant, they begin to corrode, as a result of which they quickly fail. Bimetallic radiators are free from all these disadvantages. Their aluminum body is protected from the inside by steel. And therefore there is no contact with the coolant. Consequently, such radiators can be considered much more reliable than aluminum ones. Bimetallic batteries weigh little, but look very modern and aesthetically pleasing.