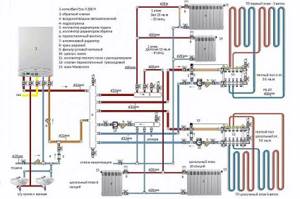

Making water heating for a private house with your own hands is not an easy task, since diagrams of possible designs often do not coincide with reality.

The main task is to accurately select the pipe layout plan. But there are certain assembly nuances, failure to comply with which will lead to heating failure.

Pros and cons of water heating

Any heating device has advantages and some disadvantages that you need to be familiar with so that problems do not arise in the future.

The advantages of such heating:

- Water is considered an ideal heat carrier. It is available and inexpensive. It has high heat capacity and thermal conductivity. Absorbs and transfers more heat than air.

- The design looks like a closed circuit; the volume of water before and after startup is almost the same. You can completely clean the liquid from chemical elements that cause metal corrosion.

- You can use any boilers: electric, gas and solid fuel.

- Heating makes it possible to regulate the temperature zone by zone. To do this, you do not need to regularly turn on the ventilation or ventilate the room.

- Water heating operates almost silently.

In addition to many advantages, there are also disadvantages:

- Tap water contains salts and alkalis that have an aggressive effect on metal pipes and radiators. Over time, scale settles on their walls and a layer of solid sediment appears. As a result, the water flow slows down and heat transfer deteriorates.

- When water freezes, it can expand and cause a circuit break. To prevent this, it is necessary to add salt solutions to the water or drain the liquid before leaving for a long period of time.

- Heating installation is quite complicated, financially expensive and requires special skills.

What does it consist of?

Typically it includes a heat source, piping structure, radiators, circulation pump, temperature sensors, thermostats and controllers.

Boiler

All heating boilers are characterized by a number of qualities that you need to know, and one of them is the type of fuel that is necessary for the operation of the unit.

Gas boilers

Buying a gas boiler is the most important purchase when installing heating, since network gasification is present in almost all remote areas of the country.

If there is a gas main near your home, you need to pay attention to this type of equipment, and then select a device with the required parameters. There are many models of gas heating boilers. In order not to make a mistake in choosing a device, you initially need to decide for what purpose the equipment is installed: heating only or, in addition, supplying hot water. In the first case, a single-circuit device is sufficient: it has a low price and low fuel consumption. A boiler with two circuits is suitable for solving two issues at once. Such equipment heats water using a flow method and has a boiler from 150 to 180 liters. To take a shower or wash dishes, running heat is enough.

When choosing a dual-circuit device, you need to decide on the number of heat exchangers. In equipment with a single heat exchanger, water for water supply and heating is heated together. The advantage of such boilers is their low price, low weight and dimensions. But due to the complex design, if the coolant leaks, the unit is practically beyond repair.

A boiler with two heat exchangers has:

- primary - intended for heating;

- secondary - for heating liquids not intended for consumption.

If the secondary heat exchanger is deformed, it will still continue to operate.

Now you need to choose a material - cast iron or steel. A heat exchanger made of cast iron is not as susceptible to corrosive wear and retains heat longer. However, heavy weight, fragility, as well as susceptibility to temperature changes or overheating are the disadvantages of this material. Steel equipment is less demanding in operation and installation. If used correctly, a cast iron device will last 30-45 years, and a boiler with a steel heat exchanger will last 15-25 years.

The main characteristic of a gas boiler is the presence of an open or closed combustion chamber. The first type with natural traction is considered a classic. It takes air from the room in which it is installed. To remove carbon monoxide, for safety reasons, the boiler must have a vertical chimney. Before purchasing, you should prepare a room with good ventilation. Closed-type equipment is much more expensive, but does not require a boiler room and can be installed in any part of the building. When using this technique, a vertical chimney is not necessary at all, since smoke is removed through a horizontal coaxial pipe.

If there is a sudden loss of power supply, the best solution would be open-type equipment, because only a cooler powered by electricity is able to supply oxygen and remove combustion products.

At first glance, the type of ignition seems to be an insignificant factor, but it is worth paying attention to it. Electric ignition is economically beneficial, since the wick burns changeably, but the boiler will still need electricity. Having purchased equipment with piezo ignition, you will have to start it yourself.

Condensing gas boilers are becoming increasingly popular.

A water economizer, which allows increasing work and reducing fuel consumption, distinguishes convection-type boilers from traditional ones, but it costs much more.

Electric boilers

If it is not possible to install a gas one, then an electric one can easily replace it. It has a number of undeniable advantages: inexpensive, small in size, does not create noise, unpretentious, safe to use and environmentally friendly.

There are three types of electric boilers:

- On heating elements (tubular electric heaters). All elements and instruments are collected in its single body, which is covered with a casing. You can install them on the wall without spoiling the interior of the room. It’s very easy to choose a model according to your taste, the required power and automation. A large selection of coolant types circulating through the unit will be an undeniable advantage for owners of such an electric boiler. Inertia of heating and scale formed on heating elements are disadvantages of this equipment. But an absolute plus is that the heater is very easy to change if it becomes deformed.

- Electrode. If you plan to turn on a couple of radiators, then you can take a “baby” that fits in your hand. There are powerful installations for heating a large house. High performance, quick heating of the liquid and high-quality temperature setting are the advantages of this unit. However, this equipment is too demanding on the composition of the coolant.

- Induction. They are considered the most expensive electronic boilers. They are independent of scale, have an effective overheating protection design, and there are no restrictions in the choice of coolant. Also among the undeniable advantages: high heating speed and good efficiency.

Prices for electric boilers

electric boiler

Diesel boilers

Diesel boilers are quite capable of replacing electric ones. However, for this you will need to install a boiler room with an exhaust hood, as well as equip a room for storing fuel in containers, which will meet all standards. The liquid fuel device is very easy to use and has a good level of automation and performance.

Solid fuel boilers

Solid fuel devices operate on wood, sawdust, briquettes, coal and coal coke.

Three main advantages of this equipment:

- environmental friendliness;

- safety;

- availability of fuel.

There are several types of boilers: classic (they operate exclusively by burning fuel) and pyrolysis (at high temperatures, the fuel releases flammable gas, which is burned in the combustion chamber).

Any heating boiler requires a chimney with excellent draft, as well as cleaning the combustion chamber from ash and tar.

The disadvantage of classic equipment is that fuel will have to be loaded into the device every five hours. Gas-generating boilers require fuel loading every 12 hours. However, their performance often depends on electricity.

Prices for solid fuel boilers

solid fuel boiler

Pellet boilers

Pellet boilers require granulated biofuel from wood waste to operate. They can function autonomously because they have a built-in automatic fuel supply system and temperature adjustment. Fuel is loaded into the chamber once every few days, and ash needs to be cleaned once every thirty days. More respectable models have remote control.

This equipment is characterized by a fairly sealed housing and a service life of more than 20 years. However, pellet ones have their own disadvantages in operation: they are overpriced, pellets must be stored in a very dry room, the fan only operates from electrical power.

Combination boilers

Such models involve the use of several types of fuel at once, so you can easily choose the material that is most accessible. In this regard, you don’t have to worry about the batteries being cold if the gas or electricity is turned off.

Combination boilers work as follows:

- solid fuel/gas;

- solid fuel/electricity;

- gas/electricity;

- gas/diesel fuel.

It must be taken into account that when loading fuel, one type will be the main one, and the second will only be additional, which will maintain the temperature in the home.

In addition, combination boilers are produced in large sizes and with low efficiency.

Prices for combination boilers

combi boiler

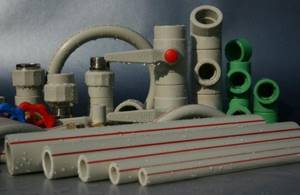

Pipes and fittings

It is recommended to use metal, copper, plastic or metal-plastic pipes for the system.

What are the features of each material:

- The service life of metal products is not long. Corrosion may develop. Mounting is carried out on threaded connections.

- Polymer pipes are more reliable. Service life: up to 50 years.

- Metal-plastic pipes include aluminum and plastic. Collection occurs using press or threaded connections. When temperature changes occur, they may crack.

- Copper piping is considered expensive. Characterized by high reliability and durability. The connection is made by soldering.

According to the technology, pipes with fittings should be characterized by the following qualities:

- strength;

- ease;

- suitability for repair;

- tightness;

- low noise level.

Low price is considered the main component when choosing, since heating equipment requires a large number of products for various purposes.

Steel, copper and galvanized ones are inferior to inexpensive analogues.

The best alternative are polymer products, which are divided into:

- Polypropylene - inexpensive, easy to weld and long service life. The downside is poor elasticity.

- Metal-plastic - sufficiently durable and resistant to temperature changes. Service life: up to 30 years. The weak point is the connecting elements-fittings with a narrow cross-section.

When choosing pipes, you need to focus on important technical indicators and the type of coolant.

Heating radiators (batteries)

There are several types of radiators made of different materials. Each model has certain advantages and disadvantages.

Manufacturers today offer four types of batteries:

- cast iron;

- steel (tubular or panel);

- aluminum;

- bimetallic (steel pipes inside, aluminum on top).

Each type has its own positive and negative sides. For example, cast iron radiators heat up very slowly, but retain heat for a long time. Made of aluminum - they heat up quickly and transfer heat better, but are also susceptible to corrosion. The best option is bimetallic or steel.

It is important to calculate the required number of battery sections, because this will determine how much heat will be supplied to the house.

Table of positive and negative indicators of radiators:

| Cast iron | Steel | ||

| pros | Minuses | pros | Minuses |

| High heat capacity | High specific gravity | High strength | They are afraid of water hammer |

| Long service life | Exclusive models are very expensive | High heat dissipation | Corrosion occurs in the absence of water |

| Withstands pressure up to 22 bar | Unpresentable appearance of accordions | Available in tubular and panel | |

| Low price | Low impact strength | Low price | |

| Requires a small volume of coolant | |||

| Aluminum | Bimetallic | ||

| pros | Minuses | pros | Minuses |

| Highest heat output | They are afraid of water hammer | Withstand high pressure | Low heat transfer compared to other models |

| Low specific gravity | Subject to corrosion | Easily cope with water hammer | Not the lowest price |

| Short service life | Very easy installation | ||

| High resistance to corrosion processes | |||

Shut-off and control valves

The normal functioning of any installation is impossible without shut-off and control valves, which are available in all sections of the circuit, starting from the piping and ending with the last battery.

Shut-off valves

A ball valve can serve as the simplest example as a shut-off device with two operating positions: “open” or “closed”. The body is made of brass with a built-in ball hole.

The steel ball is sealed with polymer material and can be rotated 90 degrees. The tap allows you to not completely shut off the flow, but frequent use of this mode will soon damage this shut-off valve.

Areas of the system where the ball valve is used:

- in areas where radiators are cut off;

- in places where branches and risers are disconnected;

- in the area of water shutoff in order to repair a pump or heating device;

- for emptying and refilling the circuit.

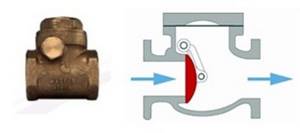

The devices include check valves and shut-off valves with electric drive. In projects of houses and apartments, it is quite rare to install control valves with an electric drive.

The check valve allows the coolant to flow only in one direction and blocks it in the other.

Shut-off and control elements of systems

Shut-off and control valves regulate the operation of the heating system, where the coolant is water. This equipment can turn off an entire section of the heating network if the need arises.

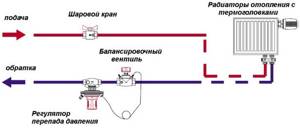

These include:

- balancing valves;

- automatic differential pressure regulators;

- thermostatic radiator valves.

These types of fittings regulate the coolant, partially reducing the cross-section of the pipeline. The balance valve provides the required water flow to the circuit, and the regulator coordinates it with the operation of the radiator thermostats.

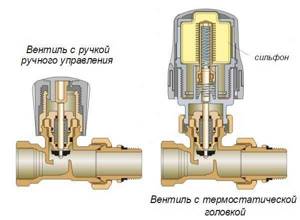

Automatic thermostatic valves are shut-off valves that reduce or increase the flow of coolant to the battery depending on the room temperature.

It is additionally equipped with a thermal head and a remote thermostat, which is considered an indispensable element of the system.

Mixing and control valves

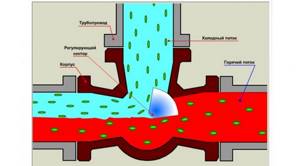

This fitting includes a three-way thermostatic valve, which is responsible for high-quality regulation of the coolant. This element produces coolant at a certain temperature, mixing two streams in the required volumes.

The device is made of brass with three pipes, which contains a rod (regulates the flow of water in the required volume), which is controlled by a thermostatic drive.

Each heating circuit requires fittings that will maintain the temperature in underfloor heating circuits, radiators, and also in small solid fuel boilers.

Filters

In any heating system, dirt gradually appears in the form of rust and salt deposits, which will be enough to damage the pump or heating boiler.

Modern devices contain electronics, the worst enemy of which is dust and dirt, which can lead to malfunction of the equipment.

To prevent damage, it is necessary to install a water filter, which will extend the life of the system. It doesn’t matter what kind of boiler is installed, be it gas or electric, a filter is always needed. Especially in a system where a pump is running.

By taking care in advance, you can forget about repairing expensive equipment that will fail without proper cleaning of the circulating coolant.

Pressure (circulation) pump

For efficient heating, it is recommended to install pumping equipment, with the help of which water will flow through the pipes at a certain speed.

The choice of device is made based on the performance characteristics and power of the system. The pump with great force will increase the circulation of water, which will not have time to heat up. Low power, on the contrary, will not be able to heat the liquid properly and the room will be cold. This will cause the equipment to overheat.

Measuring instruments

A heating pressure gauge determines what pressure is in the pipes, providing prompt information about the state of the system so that adjustments can be made to the operation.

Coolant pressure is one of the main indicators that is taken into account when planning and installing the module. When all indicators are normal, then the equipment is working properly.

If the norm is exceeded, the likelihood of rupture increases. The pressure begins to decrease, and gas bubbles appear in the carrier. As a result, the metal oxidizes and rust appears. The use of pressure gauges in heating helps to effectively combat the listed problems. To ensure that the pressure does not drop, it must be constantly monitored using a measuring device.

The boiler thermometer is characterized by a simple and reliable design. If, when purchasing modern equipment, a thermometer is already included in the kit, then for older devices it must be purchased separately.

The temperature sensor performs two important functions:

- Shows the temperature of the water inside the boiler or system. If necessary, the operating mode can be changed.

- Thanks to the interaction of automation and instruments, there is no need to regularly approach the boiler and adjust it to ensure normal temperature.

Thermometers come in two types:

- submersible;

- remote.

Immersion thermometer

Shows water temperature. It is mounted on system segments or on boilers.

A bimetallic thermometer contains a metal plate and an indicator needle with a scale. The principle of operation is based on the fact that when heat is supplied, one of the metals changes shape and presses on the indicator needle, which displays the temperature value on the scale.

However, if the water temperature changes, this will become clear only after some time.

Remote

They are located outside the system boundaries. However, they are connected either to the boiler or to a special programmer responsible for adjusting the operating parameters of the system.

In simple plans, temperature sensors are installed that transmit a signal through electrical wires to the control unit.

Automation

When installing heating, it is imperative to use automation. It is better to ensure comfortable conditions in your home by setting the desired temperature. This task is handled by the system's automation.

What needs to be automated:

- operation of heating equipment;

- providing comfortable conditions;

- economical fuel consumption.

When choosing a boiler, you must immediately decide what kind of automation will be. Manufacturers have added a control unit to the design, which ensures safe operation of the boiler. Sensors are used for this.

Typically, such a controller provides:

- protection against water overheating, as well as high or low pressure in the system;

- monitoring the filling of equipment with liquid and gas pressure in the pipeline.

What is noteworthy is that some of these functions can be installed at the customer’s request, but the automatic control of the boiler will be complete.

Heating can be controlled by temperature:

- coolant;

- air in the house;

- outside air (weather dependent).

Weather-sensitive control is considered effective because it quickly responds to changing environmental conditions.

Automation is designed using various devices that operate both autonomously and under the guidance of a centralized system.

Control using a heating boiler

Control comes down to setting the water temperature on the boiler. The automation built into it works here. For heating, control on the boiler will be quite sufficient. It will regulate the coolant temperature regardless of its value in the rooms.

Thermostatic valve

It is installed on each radiator and the required temperature value is set on its head. If the room is very hot, the regulator is activated, cutting off the flow of water into the battery. When the temperature is low, the valve opens and water flows into the radiator, heating the room.

Room temperature controller

The heating controller changes the heating of the coolant, creating the desired mode.

The control is completely electronic, triggered by commands from a special center. If you equip such a structure with units with remote communication, a GSM module, then an automatic control unit with remote access will appear.

Combined control option

The overall operation of the regulator and thermostatic valve creates optimal conditions for the operation of the system. The regulator ensures economical fuel consumption and controls the air temperature, and the valve allows you to maintain the desired mode in each room.

Filling a closed heating system

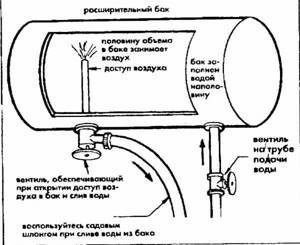

A closed heating system is most often used. Its difference from an open one lies in the structure of the expansion tank. In a closed heating complex, the expander is sealed, and the system is filled in a different way.

To begin, prepare all the necessary materials and tools. Including: a volumetric tank, hoses for pumping water from the tank into the system, clamps for firmly fixing the hoses, pliers for installing clamps, a vibrating household pump to forcefully fill the system with water.

Scheme of removing air from the heating system.

Before pumping, you need to hermetically seal the pump with the prepared hoses using clamps. Fill the prepared tank with water and place it near the system filling tap. The pump should also be located nearby. The hose that takes in water should be lowered into the tank, and the hose that supplies the pumped water should be secured with a clamp to the filling valve. Taps and dampers for venting the heating complex must be open. Turn on the pump and start pumping water into the pipes. The pressure on the pressure gauge should gradually increase. When the entire circuit is filled, the pressure gauge readings should reach two atmospheres. Afterwards the pump should be turned off. Disconnect the hoses and turn off the fill valve.

If it is not possible to use a pump to fill the heating complex, then you can use a water supply. The scheme is quite similar to the one described above. It is enough to attach one end of the water intake hose to the water tap, and the other end to the filler in the system and gradually open first the filler and then the water supply. In this case, the pressure will have to be monitored additionally using a separate pressure gauge.

The final operation of filling the system with water will be to remove excess air from its circuit. Modern installations provide special devices for this purpose. You can ventilate the system using this device on the bypass.

Filling the heating system will be most convenient when two people work, since throughout the entire filling process it is necessary to simultaneously monitor the pressure level in the system and the operation of the pump, being near the injection valve, and monitor the tightness and the process of de-aeration of the heating radiators.

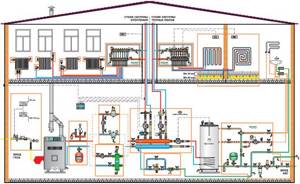

Types of systems

The heating system maintains comfortable conditions in the house during the cold period, but you should know what types of systems there are in modern times.

Gas

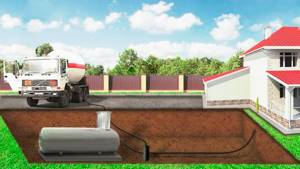

If there is no gas line nearby, then a system with liquefied gas heating is assembled. To do this, a gas holder is installed - a sealed container, which is periodically filled with propane-butane.

Pros:

- environmentally friendly source of heat;

- increasing the service life of equipment;

- complete autonomy.

Minuses:

- complexity of installation;

- inconvenience of refueling;

- difficulties with permits;

- high cost of installation;

- constant monitoring by service departments;

- if there is no access to the gas main, then special installations for storing fuel are required.

Solid fuel

If the gas passes too far from the home, and electricity is expensive, then you can use a solid fuel boiler. The determining factor in the functioning of such heating is the fuel that will heat the building. This includes fossils (coal, peat, oil shale) and renewables (firewood).

When choosing fuel, it is better to give preference to hydrocarbons that have good heat transfer. In addition, in this case, a large fuel storage bunker will not be required, and the chimney will not need to be cleaned too often.

Electric

Electric fireplaces, convectors, infrared heaters, and heated floors serve as coolants.

Pros:

- low cost of installation equipment;

- it is possible to use electric boilers to obtain hot water supply;

- environmental friendliness;

- access to automation to maintain optimal temperature conditions in the building;

- does not require expensive maintenance;

- You can move the device from one room to another.

Minuses:

- high power (up to 24 kW/h) and considerable cost of electrical media;

- installation of multiphase distributors is required;

- In the event of possible power outages, the entire circuit fails.

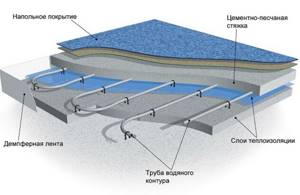

Warm floors - an alternative to radiator heating

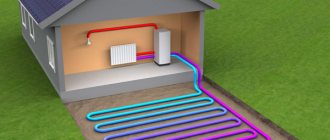

Any of the described circuit units can be connected to a water floor. It is easy to install to the heating system, and the benefits from it are relatively greater than from clear and bulky radiators. Let us consider in detail the advantages of this type of heating:

- Undoubted fuel savings for heating the entire volume of the room. You can spend energy only on heating water, which will do everything else - from the floors, according to the principle of convection, heat will go up, thereby creating an overall pleasant atmosphere.

- Increased usable space due to the absence of heating radiators. The entire structure is hidden under the floor covering and does not reveal itself in any way.

- If desired, installation can be done independently, which allows you to save on contacting professionals.

The private water floor heating system has already earned universal approval from users, as it lives up to all the qualities declared by the manufacturer.

Types of pipe layouts

There are many schemes for laying pipes across households. The most popular are combined ones, which increase the productivity of the system and allow you to heat the house evenly.

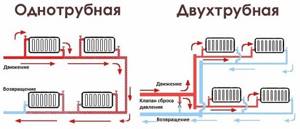

Single-pipe

The single-pipe scheme provides for the systematic flow of water into each radiator. That is, the liquid leaves the boiler, penetrates one battery, then another, and then a third, and so on.

Having reached the end of the system, the coolant turns around and is sent back through a single pipe.

Advantages of the scheme:

- Easy to install - you just need to pass the liquid through the radiators in order and return it back.

- Minimum consumption of materials.

- Low pipe arrangement - installed either at floor level or under the floors.

Disadvantages of the scheme:

- The limited length of the horizontal section is about 30 meters.

- The farther from the boiler, the colder the radiators.

Two-pipe

The two-pipe circuit consists of two pipes - supply and return. Batteries are mounted between them - the input is connected to the supply pipe, and the output is connected to the return pipe.

What does it give:

- Uniform heat distribution throughout the rooms.

- Possibility of adjusting the temperature in the rooms by blocking some radiators.

- Possibility of heating multi-storey private houses.

There are two main types of such a system - with bottom and top wiring.

Bottom wiring is used in many homes, as it makes it possible to install heating unnoticed. The supply and return pipes are joined together under the radiators or in the floors. The air passes through Mayevsky's taps.

Characteristics of a two-pipe system with bottom wiring:

- possibility of masking pipes;

- the ability to use batteries with bottom mounting - this simplifies installation somewhat;

- heat losses are minimized.

Beam with collector

This scheme lays an individual line to all heating devices. The system contains supply and return manifolds, from which straight pipes are supplied to the radiators. This project provides flexible adjustment of system parameters and allows you to connect heated floors.

The radial wiring diagram is used in many modern homes. Pipes can be laid anywhere (mainly in floors). To regulate the temperature and turn devices on/off, small cabinets are installed in the home.

There are many positive qualities:

- The ability to completely hide all pipes in the walls and floors.

- Convenient system setup.

- Possibility of creating remote separate adjustment.

- Minimum number of connections: they are located in distribution cabinets.

- It is convenient to repair individual parts without stopping the system.

- Almost perfect heat distribution.

There are also a couple of disadvantages:

- High price - this includes the costs of equipment and installation work.

- The difficulty in implementing a plan in an already constructed building is that the scheme must be laid out at the design stage of the building.

Collector heating circuit for a one-story house with forced circulation

Another type of wiring is collector wiring. This is the most complex system, involving the use of a large number of different pipes and special distribution devices called manifolds. The principle of operation of a system with a collector heating circuit for a one-story house with forced circulation is that boiling water from the boiler goes into special collectors, which serve as distributors between various radiators. Each battery is connected to it by two pipes. Such a system, while effective, cannot boast of being cheap. It can regulate the temperature not only on each circuit, but also on each battery, which allows you to create your own temperature regime in any room.

It is better to invite specialists to develop and install a collector heating system.

They make such a heating scheme for a one-story house with forced circulation, since water naturally cannot circulate effectively through numerous pipes and collectors. The essence of this scheme is that directly next to the boiler, a centrifugal circulation pump crashes into the return pipe, which continuously pumps water using an impeller. Thanks to this, the pressure necessary to completely pump the entire line appears in the system, heating all the batteries evenly. If you purchased an expensive wall-mounted automatic boiler, then it most likely already has a circulation pump installed, which is set to the optimal pressure for this boiler. If your boiler is simple, then when purchasing a centrifugal pump, you need to consult about its compatibility in terms of the pressure created with this boiler in order to avoid an emergency.

Manifold heating system designed by a specialist.

The collector circuit is rarely used in two-story houses, since, although it is effective, it is very cumbersome. The wiring for two floors will be too complicated. That is why it is in demand only in a heating scheme for a one-story house with forced circulation.

On a note! To install a manifold water heating system in your country private home, you need to take care of purchasing the required number of thermostats and shut-off valves. This will allow you to regulate the climate in the house in a semi-automatic mode.

Circulation pump for forced recirculation of water in the heating system.

Summarizing the above, it can be noted that the choice of the three existing types of water heating wiring should be made carefully. In a small one-story house, only one pipe can be laid. This scheme is also called “Leningradka”. If the area of the house is large or it is two-story, then it is better to make a two-pipe heating system with a return pipe. To create a modern and efficient heating system in your home, you can install it using a collector circuit. It will cost more, but its effectiveness will be much higher. The main thing is that any created system always works well and reliably in any, even difficult, conditions. To do this, it must be built according to all the rules and recommendations.

Criteria for choosing a system and pipe layout

It is not at all difficult to independently choose a system that will meet all the requirements for quality and reliability; the main thing is to take into account several important points.

The following requirements apply to modern systems:

- The presence of high efficiency, since the system needs to provide housing with the required amount of heat.

- Maximum automation available. Modern heating should require minimal intervention when used. A large number of homeowners want to adjust the system only once and never touch it again.

- Reliability. The circuit must be reliable so that parts do not need to be updated regularly.

- Easy to install. Installation must be simple and not costly.

It is also very important to correctly route the pipeline. The coolant is water, which means the lines must be resistant to high temperature conditions.

When choosing a material, you need to pay attention to the markings and the manufacturer.

Polypropylene pipes reinforced with aluminum provide free access of oxygen to the system. A layer of foil metal prevents the formation of corrosion on the heat exchanger.

Requirements for the operation of the heating system

With all the variety of water heating systems, there are a number of general requirements for their operation.

They have to:

- uniformly warm up all the air in the rooms;

- be repairable;

- do not create difficulties during operation;

- be linked to ventilation systems;

- be regulated.

The operating principle of the heating system itself is also common: water is heated, after which it circulates through the pipeline and releases the resulting heat, warming the rooms.

The coolant in winter can be a non-freezing liquid - antifreeze. So that the ethylene glycol contained in its composition does not cause corrosion of pipelines

DIY installation

To install water heating, you will need to purchase all the wiring, boiler and its installation. Below is a description of how to do water heating of a private house with your own hands, and diagrams.

Design

The first thing done when designing systems is calculating heat loss. It helps to estimate how much thermal energy a house or apartment can lose if the required thermal conditions are observed in them. This takes into account the worst case, when the temperature “overboard” reaches its minimum for a specific climate zone. That is, heat loss is calculated to the maximum: how much a building or room can theoretically lose when it is in the worst weather conditions.

From the point of view of the everyday approach, good heating is when during severe frosts the house is warm and the radiators are hot. The system must also compensate for the maximum possible heat loss.

The initial data for the calculation is a fairly impressive amount of information. In any system project, this calculation takes at least half of the labor expended. And this is really difficult even for a specialist. There are methods that allow you to do this in a simplified manner, but, nevertheless, the final result is very close to what would be obtained from an engineering calculation according to all the rules. Considering that when choosing heating equipment they always make a power reserve, you can completely use an approximate calculation.

Installation

Initially, the installation of a heating boiler follows, which is placed on a stand made of cement-sand mortar. Then the exhaust gas exhaust pipe is connected to the chimney. The joining area is sealed with heat-resistant mastic, which does not crack under the influence of high temperature.

The next step is to install the batteries. They should be located under window sills to provide a thermal barrier that will block cold air from entering through cracks in the windows. Installing the radiator is quite simple. The battery should be hung on brackets and secured to the wall using dowels.

Despite this, there are nuances that should be taken into account:

- Before installing radiators, you need to mark the walls. The batteries must be placed at the same level and horizontally so that water circulates unhindered.

- Do not unpack the battery during installation so as not to deform it during installation.

- The radiator should be at a distance of 20 mm from the wall.

After completing the installation of the batteries, it is necessary to begin laying out pipes and installing related components:

- The drain pipe must be installed at the lowest point of the system.

- The expansion tank is installed at the top point at a height of 3 m from the boiler.

- Using taps, it is necessary to separate each element of the system. This will allow the unit to be repaired without completely draining the water.

If the diagram specifies the installation of several risers, then you need to install a balancing valve.

In addition to the boiler, pipes and batteries, when installing heating, you need to prepare related consumables: mounting brackets, adapters and rubber gaskets.

Launch

When all installation work is completed, the heating circuit is filled with water and a preliminary start is performed. As soon as the batteries heat up and maximum pressure appears, you need to check the connections of the pipes with radiators and other heating elements for leaks. If any defect is detected, the water must be drained to eliminate the damage.

Features of a single-pipe heating system

The easiest way to connect radiator batteries to boiler equipment is to install a single-pipe OS. The system design provides for the presence of a single pipe that runs along the perimeter of the housing. It departs from the supply pipe of the boiler unit and enters the inlet. There are bends from the pipeline near each inlet to the battery. Cranes must be installed here.

The principle of OS for one pipe is simple. In addition, such a system is the most affordable - both in terms of components and installation. The use of a single-pipe variation eliminates the need to create a large number of pipe branches, and significantly less various small items are consumed. Many people are aware that the price of reinforcement elements makes up an impressive part of the cost of the OS of the entire building.

It is rational to use such an OS, the scheme of which is simple, in small houses with a simple room layout. Its peculiarity is that the water cools quickly. Therefore, the last batteries on the path of the coolant heat up less than the first ones. This means that if the house is huge, then by the end of the journey the heat carrier will practically not be able to warm anything. This is especially true for the pumpless type of coolant circulation.

For your information!

When a single-pipe OS is carried out, a slight slope is provided - approximately 3–5 ° according to GOST.

It is also recommended that all radiators be equipped with taps necessary to maintain stable pressure in the circuit through timely bleeding of air. Such taps have small holes pressed by a non-sinking ball, and open when the latter enters the air.

Operation and Maintenance

Every summer, city heating networks carry out a set of measures to inspect and repair main networks. Autonomous systems require even more attention.

In order for the heating system to function fully, it is necessary to carry out a set of measures.

Every year:

- Alarm test.

- Heating pipeline inspection.

- Checking the functionality of the automation.

- Chimney inspection/cleaning.

- Inspection of gas boilers.

Once every 3-5 years:

- Replacing the coolant.

- High pressure system testing.

- Calibration of automation devices.

- Chemical flushing of the system.

To avoid corrosion of steel pipelines, they are kept constantly filled with water. For systems with plastic pipes, if there is a black iron heat exchanger, the liquid is drained with the valves on the pipes closed.

Water is drained to replace or flush the system, as well as to repair pipelines and connections.

Water replacement is performed at the beginning of each new heating season thirty days before its start. The liquid is drained, and accumulated deposits are washed out of the pipes. The flushing water must be drained until it clears, then the system is filled with liquid through the lower supply pipe under low pressure.

Inspection of heating elements, revision of starting equipment and re-tightening of electrical connections are related to the maintenance of electric boilers. The elements responsible for heating are removed from the flask, scale deposits are cleaned off and deposits are removed with a cleaning agent. The silver-plated contacts of the starters must be disassembled and cleaned until shiny with sandpaper. Cables and wires must be loosened and tightened again.

Comprehensive boiler maintenance must be carried out by a specialized organization.

First of all, you must do:

- visual assessment of the burner condition;

- inspection without casing;

- inspection of gas pipeline joints using a soap solution;

- checking the serviceability of the piezo ignition;

- inspection of draft and air supply.

In boilers that have passed the warranty, you can clean the flame sensors, air sensors and chimney ducts yourself. It is forbidden to touch the gas pipes and burner.

Cleaning is carried out with a metal brush, removing carbon deposits and scale from the surfaces, without cleaning the surface to a shine. The surface of the heat exchangers should be much cleaner.

The frequency of chemical washing depends on the quality of the water used. Some people never flush the system. If a special coolant is used, this is normal. But if water is used, this is associated with the appearance of scale and other deposits, which increase fuel consumption, reduce the efficiency of heat transfer and damage the unit as a whole.

A special pumping unit is used to flush the system, which can be rented for a while. The system is washed with a special chemical solution, which should be selected according to the type of batteries and the material of the heat exchanger in the boiler. In some cases, the boiler is washed separately.

During flushing, close the taps of the following auxiliary equipment: bleed valves, expansion tank, pumps, etc. In one place, the pipeline ring must be closed, and on both sides of the valve, pipes for connecting hoses for flushing must be placed.

This procedure is carried out in two stages: first, the circuit is pumped with a chemical solution for about 40-60 minutes, after which the chemical is washed several times with clean water. Find out how to make a brick fireplace stove using the link.

Water system "Warm floor"

“Warm floor” can either successfully complement radiator water heating or become the only source of heating for rooms if we are talking about a low-rise building. A huge advantage of the “Warm House” is that this system provides conditions that fully meet the sanitary and hygienic standards of the premises.

The air is heated unevenly along the height of the room: in the upper part of the rooms it is colder, and in the lower part it is warmer.

Warm floors are a wonderful invention that allows you to warm up a room in height in full compliance with the sanitary and hygienic standards required for it (+)

The system temperature is only 55°C, which meets design standards. The installation of heated floors is carried out over the entire area of each room. This is quite a complex job that can only be done efficiently at the stage of building a house. Operating the system also poses a number of difficulties.

Conclusions and useful video on the topic

Comparison of two-pipe and one-pipe heating systems:

The house you plan to live in all year round needs heating during the cold season. To make your living conditions comfortable, you need to choose a water heating system that is most suitable for your individual conditions.

We hope that the information contained in this article will help you make the right choice. After all, high-quality heating is not only comfort and coziness. This is also a prerequisite for maintaining your health.

Do you have anything to add or have questions about water heating systems? You can leave comments on the publication and participate in discussions. The contact form is located in the lower block.