Advantages

Main advantages of the material:

Versatility. It is used for insulating floors, walls, attic floors, and attics. High thermal properties. Thermal insulation provides the necessary resistance to heat transfer with a minimum thickness. Vapor permeability. Minslab is a breathable material, which prevents moisture condensation. Low moisture absorption. The mineral wool board does not absorb or accumulate water. Used in internal structures, such as Knauf partitions, as sound insulation. Stone wool is non-flammable and can be used in structures with any fire hazard class. Price

It is important that the price of this insulation is lower than that of the same rockwool.

Rocklight vs foam

Since the price of polystyrene foam is significantly lower than the cost of mineral wool from TechnoNIKOL, many often choose a cheaper option for insulation material. Of course, it is more profitable to pay 200-300 rubles per package than 600-800 rubles. But how will foam plastic behave in practice and what can Rocklight provide?

The strengths of polystyrene foam include its lightness, ease of installation and affordable cost.

But Rocklite, as opposed to foam, provides important advantages:

- The material is not subject to combustion. Mineral wool will not spread the resulting fire, but will simply begin to gradually melt. The foam catches fire and burns very actively;

- Duration of service life. Polystyrene foam can effectively serve for 10 years, after which its gradual process of destruction begins. Rocklight mineral wool serves for more than 50 years, maintaining its original technical characteristics;

- Rodents simply adore polystyrene foam. In many houses they chew through the insulation and settle under the ceiling or in the walls. Mineral insulation is not characterized by such features;

- Ensuring wall ventilation. By insulating rooms with mineral wool, they can breathe. If you use polystyrene foam, the room will turn into something like a thermos. Moisture will have to be removed through a specially installed ventilation system. These are unnecessary financial costs and time.

Flaws

It cannot be said that the TechnoNIKOL product is an ideal insulation material, and nothing better exists. This is wrong. Each insulation exhibits its negative qualities to one degree or another. If you use mineral wool correctly and for its intended purpose, you will not know about the shortcomings. But if you violate the recommendations, the disadvantages will definitely come out.

Mineral wool does not absorb moisture, but due to its exposure, the material can still gradually deteriorate. When working with mineral wool, it is imperative to use waterproofing materials. This is additional cost and labor. Is this a disadvantage? For some, yes. I combine thermal insulation from Rocklite mineral wool with waterproofing materials, you need to carefully evaluate the properties of the latter. Some insulators are capable of keeping moisture and air out at the same time

Therefore, an important advantage of mineral wool is lost due to improper insulation design. So, by insulating the floor and ceiling at the same time, it will be just as difficult to breathe inside the room as if you had used polystyrene foam.

Properties of Rocklight products

Rocklight insulation of the TechnoNIKOL brand is made of basalt rock.

Mineral wool from a well-known manufacturer is insulating non-combustible boards characterized by low thermal conductivity. They are made from natural minerals (basalt rocks) and are intended for insulation and sound insulation of objects under construction. The properties that characterize this material include ease of installation and attractive performance parameters.

The qualities of Rocklight mineral wool insulation are appreciated by most specialists and ordinary users. They attract many private developers with their properties. Of particular practical interest for the latter are the technical characteristics of Rocklight insulation.

Scope of application of Rocklight thermal insulation

Rocklight insulating boards are widely used to create a sound-proofing and thermal layer when interior and exterior finishing of a building is carried out. The only condition for normal operation is the absence of external load on the surface of the slabs.

Sheets can be installed in any direction. They will retain heat in a vertical or horizontal position. If necessary, they can be installed at an angle.

https://youtube.com/watch?v=v28_oDcqDyA

The sheets are mainly used for insulation:

- ventilated facades;

- pitched roof;

- siding;

- partitions;

- floors

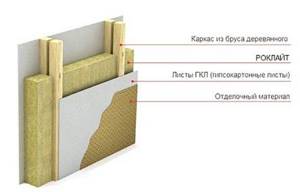

Insulation of a small attic

Rocklite is best suited for this type of work. The stoves do not burn, so the room will always be completely safe. For installation, a special frame is installed. To create higher reliability, the sheets are fixed with additional construction staples or special profiles designed for creating interior decoration.

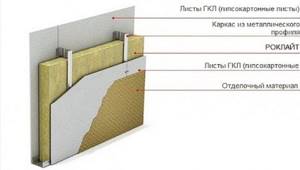

Home partition decoration

The main purpose of partitions is to create sound insulation. It should not allow noise coming from other rooms to pass through. To install heat-insulating boards, first install a vertical frame. One side is pre-sheathed, the inside is filled with mineral wool, then the opposite side of the partition is finished.

https://youtube.com/watch?v=eHT165_JaYA

Scope of product use

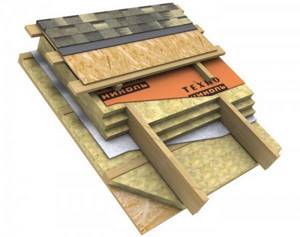

Rocklight thermal insulation boards can be used as a heat and sound insulating layer when finishing structures both inside and outside, but without external load on their surface. They can be placed vertically, horizontally and obliquely. Main areas of application include:

- pitched roofs;

- ventilated facades;

- walls using siding;

- arrangement of partitions;

- insulation of floors.

On the roof or attic

Insulating the attic of a residential building requires due attention, and Rocklight stone wool comes in handy. It is fire resistant and will provide adequate safety to the room over which it will be placed. Installation is carried out in a specially equipped frame, and for greater reliability, additional fastening can be done using a construction stapler or profiles for interior decoration.

Partitions

An important purpose of partitions is to isolate noise from nearby rooms. Before installation, a vertical frame made of wooden blocks or a thin metal profile is installed. After covering one side with finishing material, the interior can be filled with mineral wool, and then the second side of the partition can be finished.

Living in buildings where stone wool is used as insulation on the walls is quite comfortable. When using it, heating costs in winter are significantly reduced, and the house itself is reliably protected from cold winds and severe frosts. For installation it is not necessary to hire specially trained specialists, because this process is quite simple and you can do it yourself.

The use of mineral wool guarantees a long service life and the preservation of all useful characteristics during this time.

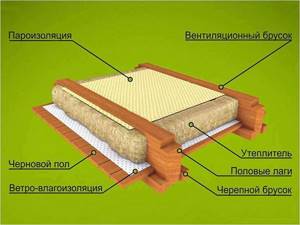

Insulation of floors and ceilings

When installing thermal insulation in the attic, wooden logs are installed with a pitch of 600 mm, with a height no less than the thickness of the insulation. A layer of vapor barrier film is laid over the ceiling.

Next, the space between the joists is filled with mini-slabs; for most regions, it is enough to lay 1200x600x100mm slabs in one layer. Cement particle boards are laid over the joists.

Good to know: when operating such a ceiling, the thermal insulation should not be allowed to get wet.

Thermal insulation of floors is carried out in the same way as flooring; the finished floor covering can be made of boards or prefabricated screed. The use of mini-slabs will ensure the required level of heat absorption by the floor.

Properties and technical specifications

A product of a new generation of mineral wool, lightweight basalt insulation Rocklight, due to its properties and excellent technical characteristics, has become one of the leaders in the list of thermal insulation materials.

- It has a high heat-saving ability; only ecowool can compete with this indicator.

- It is highly resistant to high temperatures and can easily withstand +450°C.

- For decades after insulation work, the shape and volume of mineral wool is preserved.

- Low water absorption is achieved subject to preliminary vapor and waterproofing during installation. This quality is an advantage and the only disadvantage of modern material, so it is impossible to insulate all surfaces in the room so that there is access to oxygen.

- The material has a high degree of sound insulation, this quality is due to its structure.

- In contact with many materials, such as concrete, metal, it remains neutral.

- Not afraid of insects and rodents, various microorganisms.

- The insulation is simple and easy to work with; it can be installed not only by experienced craftsmen, but also by people without experience in thermal insulation installation.

- The service life of Rocklight stone wool is approximately 50-60 years.

- Environmentally friendly material, breathable.

- An acceptable price for most citizens.

Thanks to the special production technology of this material, TechnoNIKOL Rocklight does not melt even at a temperature of +1000°C, and if it heats up, it does not emit harmful substances. According to the flammability class, Rocklight belongs to the NG class. The main technical characteristics of stone wool include the following indicators:

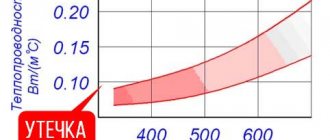

- At 10°C the thermal conductivity will be 0.039 W/(mxC)

- Compressive strength 30 kPa

- Density of TechnoNIKOL mineral wool up to 40 kg/m3

- The vapor permeability indicator is 0.3 mg (mhchPa).

What is the material

General information

Rocklight insulation consists of mineral wool boards from the well-known domestic manufacturer TechnoNIKOL. The basis of these plates are interwoven fibers obtained by melting basalt rocks.

The insulation contains binding components that glue the fibers together, as well as a water-repellent impregnation that increases the moisture resistance of the material.

The high thermal insulation properties of this insulation are due to the fact that 98% of its volume is occupied by air.

Thanks to the hydrophobizing additive, the insulation has moisture-repellent properties.

Basic qualities

Like any other thermal insulation material, Rocklight slabs have both advantages and disadvantages, which we will discuss below.

Pros:

- Low thermal conductivity. As a result, the insulation can be used as a filler in frame walls and other structures;

- Environmentally friendly. The boards contain no toxic materials. In addition, basalt fibers do not cause the same skin irritation and allergies as glass wool.

- Vapor permeability. This property makes it possible to provide a favorable microclimate in housing;

Basalt wool is fire resistant

- Fire safety. Basalt wool slabs do not burn at all. In addition, the material can withstand fire, i.e. capable of protecting against fire;

- Durability. The insulation lasts more than 50 years, while the manufacturer provides a guarantee of 30-40 years;

- Good noise insulation properties. This allows Rocklight slabs to be used not only as a heat-insulating, but also as a sound-proofing material;

The slabs retain their shape and volume well

- Shape stability. The slabs do not shrink or deform over time;

- Resistance to negative biological influences. Plates made of basalt wool are not afraid of rodents and insects. In addition, the material is not subject to combustion.

Minuses:

- Instability to moisture. As a result of the fibrous structure of mineral wool, the slabs absorb moisture quite strongly even despite water-repellent impregnations. The latter can only temporarily protect the insulation from moisture. Therefore, when installing slabs, it is imperative to use a hydro-vapor barrier;

When insulating frame structures with mineral wool, it is imperative to use vapor-waterproofing, as shown in the diagram

- Low strength. The material in question has a low density and fairly low strength. Therefore, it can only be used in frame structures where the insulation will not be subject to loads;

- High price. The price of the package is about 600 rubles, the package contains 0.432 m3 of basalt wool. Many thermal insulation materials are cheaper. Keep in mind that the price is current for Spring 2021;

Rock wool, although to a lesser extent than glass wool, still causes irritation when it comes into contact with the skin. Therefore, it is necessary to work with it with gloves. In addition, it is advisable to protect the respiratory system.

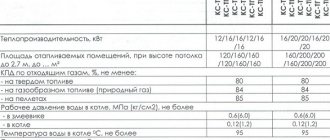

Characteristics

Rocklight insulation has the following characteristics:

| Characteristics | Values |

| Thermal conductivity, W/(m*K) | No more than 0.041 |

| Vapor permeability, mg/(m h Pa) | 0,3 |

| Water absorption,% of volume | 2 |

| Density, kg/m3 | 30-40 |

| Dimensions, mm | 1200Х600 |

| Thickness, mm | 50-150 |

Rocklight slabs can be used for internal wall insulation

Material Specifications

One of the most important advantages of insulation is resistance to cold. No other natural insulator has such high performance. However, when choosing Rocklight insulation, it is advisable to take into account all the positive and negative qualities of the material.

- Thermal conductivity. This indicator corresponds to the established standard - 0.036 W/m. for cold climates.

- Minimum fire factor.

- The density of the material reaches 30 kg/cubic. m. Of course, this value is not very high. However, at the appropriate compression ratio, when insulation is used to insulate an attic space, density plays an important role. During installation, it will be possible to easily determine the permissible level of wool shrinkage without deformation. After reducing the force, the cotton wool will return to its original shape. This density is sufficient for easy installation of a mineral slab on the attic roof.

- The material is supplied to stores in the form of 1200×600 sheets. Only the thickness differs. It can be 50 or 100 mm. These sizes are considered the most popular. With low weight, slabs with these dimensions can be easily installed in any frame. Moreover, this thickness is enough to create good thermal insulation in severe frosts.

If one layer is not enough, for example, when insulating an attic space, it is possible to create several levels.

The main advantages of insulation

The Technonikol company produces a wide range of products. Rocklight insulation, the technical characteristics of which are distinguished by a large number of positive factors, is produced in the form of slabs with a thickness of 50-100 mm. The total size of one sheet does not exceed 0.72 square meters. meters. The insulation is sold in packages containing 4-12 slabs.

A fairly large number of positive characteristics made this material very popular and in demand. The properties of cotton wool are superior in some respects to its main competitor - polystyrene foam. These include:

- Does not burn. The melting point of the material reaches thousands of degrees. Therefore, this mineral wool never smokes, it practically eliminates the occurrence of a fire.

- Moisture resistance. Cotton wool acquires this property when creating waterproofing. Unfortunately, it is considered both a positive and a negative factor. If the insulation is installed inside a building, it is prohibited to cover all surfaces, as the wool will block the access to fresh air. This should not be allowed; the walls must “breathe”.

- Rocklight cotton wool is designed for long-term use - about 50-60 years. The destruction of foam sheets begins after 15-20 years of operation.

- Soundproofing. The structure of stone wool has excellent sound absorption properties. Therefore, the insulation creates a high degree of sound insulation in the room.

- Minimal biological activity protects the material from small rodents, mold and harmful microorganisms.

- Rocklight differs from its analogues in its increased hardness. Insulation boards can easily withstand heavy loads.

- No shrinkage. The original shape of the material is retained after long-term use.

- The insulation is neutral to aggressive environments. Traces of corrosion never appear on its surface.

- The material meets modern environmental requirements. It does not contain toxic substances that are harmful to human health.

- Thanks to excellent vapor permeability, the required humidity is maintained in the room. The building is constantly ventilated.

Main characteristics

Thermal insulator Rocklight is distinguished by its unique characteristics:

- Low thermal conductivity of Rocklight insulation, which can compete with the most expensive and high-quality URSA type slabs.

- Rocklight mineral wool can withstand very high temperatures, open fire sources nearby, and in the event of a fire, it stops the spread of fire in the room.

- Mineral wool does not cake and does not lose its original size for several years. The total service life sometimes reaches 50 years.

- Rocklight mineral insulation can be used to install an interior partition for sound insulation.

- Convenience and ease of insulation. Mineral wool is installed without wet processes - it is much simpler, faster and more convenient.

Important! The best characteristic of this material is its resistance to fire.

Rocklight is able to withstand high temperatures - more than 1 thousand degrees due to its manufacture from stone. If the slab is thinner, its fire resistance does not suffer from this. Because of this property of basalt wool, it is often lined with places where the chimney passes close to wooden structures.

Another distinctive property of basalt wool is the absence of shrinkage even after years of use. The slabs are dense, do not sag or sag. Compared to polystyrene foam insulation, Rocklight is characterized by vapor permeability. The material does not absorb moisture, but simply passes it through to the outside. Condensation does not form on walls and other structures insulated using Rocklight technology. This is especially important during installation between metal profiles. When moisture accumulates in them, they corrode.

Advantages of Rocklight mineral wool TechnoNIKOL

Not every thermal insulation material is universal. Due to its high environmental friendliness, Rocklight TechnoNIKOL should be used for soundproofing rooms, insulating house facades and interfloor ceilings. However, it is better to use polystyrene foam to insulate the base and blind area. Compared to expanded polystyrene, the advantages of Rocklight are the following parameters:

- Resistance to open fire and high temperatures. Mineral wool can withstand high temperatures, unlike polystyrene foam.

- The service life of TechnoNIKOL basalt wool is about 50 years, extruded polystyrene foam slabs are destroyed in just 15-20 years.

- Mineral wool is not attractive to rodents, but the material provides good vapor permeability for all treated structures.

Table. Technical characteristics of Rocklight TechnoNIKOL

TechnoNIKOL products are in demand today in the construction market. Simplicity of installation, low price, long service life and excellent technical characteristics of Rocklight TechnoNIKOL insulation have made the product popular among developers. Read on for the rules for installing Rocklight TechnoNIKOL thermal insulation when insulating vertical and horizontal structures.

Application in various fields of construction

Rocklight insulation mats, thanks to the previously discussed advantages, are actively used in private construction. The scope of application of this material is very wide:

- stone wool is widely used for insulating inclined, vertical and horizontal surfaces;

- slabs are selected when it is necessary to protect structural corner elements;

- the material is often used for thermal insulation of floor slabs, as well as pitched roofs.

Rocklight mineral wool slabs are widely used in the construction of foundations and basements. This high-quality heat insulator is in great demand when insulating light attics and frame buildings.

Specifications

- thermal conductivity, operating conditions A 0.040 W/(m x degrees Celsius);

- thermal conductivity, operating conditions B 0.041 W/(m x degrees Celsius);

- compressibility, no more than 30%;

- vapor permeability, not less than 0.3 mg/(m h Pa);

- humidity by weight, not more than 0.5%;

- water absorption by volume, no more than 2.0%;

- content of organic substances, no more than 2.5%;

- flammability of NG;

- density 30-40kg/m3;

- size 1200x600mm;

- thickness 50, 75, 100, 150mm.

It is important to know: the required insulation thickness differs for each region and must be determined by thermal engineering calculations.

The technical characteristics of rocklite slabs are not inferior to foreign analogues, such as rockwool.

Rocklight stone wool

This heat insulator has recently become very popular; it is an ideal insulation material for private construction. Mineral wool is intended for various works on insulation of vertical, horizontal and inclined surfaces. It is convenient to use in insulating corner elements, floor slabs, pitched roofs, basements, when laying foundations, attics and frame houses.

Rocklight slabs "TechnoNIKOL" are made from mineral wool based on basalt rocks. There are many air layers between the thinnest stone fibers of the material; they help maintain a high level of thermal insulation. Many people know that if there is air in the insulation without movement, this will make it possible to have a higher level of resistance to heat transfer. It is designed for heat and sound insulation of premises and has a number of positive advantages that experienced builders and home craftsmen have already appreciated.

has its own characteristics

In pitched roofs, it is recommended to leave ventilated gaps between the stone wool and the roof. Rocklight slabs are laid directly on the sheathing beams; they must be packed at intervals of 30 cm from each other on the inside.

When used in floor insulation, the mats are placed on waterproofing under the joists, with a plank covering. To cover the facades, you need to install a structure of load-bearing profiles and brackets and screw the slabs on top with dowels. Using this technology, an air layer is created that will reliably protect the entire insulated surface from condensation for many years.

Rocklight mineral wool characteristics

Rocklight mineral wool slabs TechnoNIKOL

Rocklight TechnoNIKOL is a non-flammable slab made of thin threads of rock and 50 or 100 mm thick. The material is intended for heat and sound insulation of residential or industrial premises. The ease of installation of the slabs and excellent qualities were appreciated by numerous specialists from construction companies and private developers.

Rocklight mineral wool is made from rocks and has excellent properties:

1 . low thermal conductivity of Rocklight TechnoNIKOL mineral wool, which can be compared with Knauf ecowool and other high-quality materials; 2 . the material prevents the spread of fire, is resistant to temperatures up to 450 degrees Celsius; 3 . stability of size and shape, the slabs do not shrink or cake for several long years; 4 . high sound absorption, due to which the insulation can be successfully used for sound insulation; 5 . low water absorption, but laying a vapor barrier over basalt wool is mandatory; 6 . the material does not rot or decompose, is resistant to rodents, insects and harmful microorganisms.

Specifications

Rocklight insulation

Rocklight belongs to the category of lightweight non-flammable insulation materials, presented in the form of mineral wool slabs. The material acts as a heat-insulating and sound-proofing agent. Ordinary buyers and construction experts highly value Rocklight for its technical characteristics.

Mineral wool from TechnoNIKOL is made on the basis of basalt rocks. Let's consider the key technical characteristics of the material.

- High heat saving rates. In terms of thermal insulation performance, only ecowool can be compared with Rocklight. In this case, the latter is applied by spraying and requires specialized equipment. The characteristics of Rocklight wool allow you to install it yourself without the help of specialists.

- Temperature stability. Rocklight mineral wool insulation can withstand temperatures up to 450 degrees Celsius.

- Preservation of shape and volume throughout the entire service life. Deformation of mineral wool does not occur during operation, which ensures long-term preservation of the thermal insulation and sound insulation properties of the material.

- Low water absorption rates. Despite this, when installing slabs of 1200x600x100 mm or other dimensions, it is necessary to lay waterproofing and vapor barrier films. Otherwise, the insulation will lose its high technical characteristics under the negative influence of moisture.

- Excellent sound insulation properties. The structure and characteristics of Rocklight mineral wool allow it to additionally act as an effective soundproofing material.

- Resistance to rodents and microorganisms.

- No consequences when interacting with concrete, metal and other surfaces.

- Ease of installation. Installing slabs measuring 1200x600x100 mm with your own hands is not difficult even for a beginner.

Do you have a sauna or bathhouse?

The manufacturer Rockwool also took care of insulating these objects. To do this, we recommend using Sauna Butts slabs. The material also has 2 layers. One side of the insulation is covered with foil, which protects it from steam and is an excellent heat reflector. With the help of such stoves you can maintain heat in a sauna or bathhouse for quite a long time.

The density of Sauna Butts is 40 kg per cubic meter. Can be used at temperatures of +200 degrees.

Short video instructions for insulating a bathhouse with TECHNONICOL Sauna Butts insulation

The Rockwool company has developed a series of mineral wool insulation for floors. Such slabs are called Floor Butts. We recommend using them to thermally insulate acoustic floating floors and floors on the ground. In addition to protection from the cold, they provide excellent sound insulation. The density of the material is 125 kg per cubic meter. Compressive strength – 35 kPa.

For insulating the floors of industrial buildings, Floor Butts I material has been specially developed, the density of which is 150 kg and a meter per cube, and the compressive strength is 50 kPa.

In addition to basalt wool, Rockwool offers many other materials for thermal insulation. Additionally, we recommend using a self-produced membrane for the roof. The material consists of a polymer film and spandbond. Such a membrane will provide additional protection for the roof from moisture and wind.

Installation on vertical structures

Racks can be either made of metal profile or wooden. Before installing thermal insulation, a vapor barrier membrane is attached to the wall. The insulation is fixed to the wall using disc dowels.

It is necessary to ensure a tight fit of the slabs to each other and to the frame posts. Next, a windproof film is fixed along the entire wall.

The final part of the finishing is covering the frame with vinyl or metal siding. A blockhouse or clapboard can also be used.

Please note: rocklite basalt slab cannot be used when installing “wet” facades coated with plaster; for this insulation option it is better to use technofas slabs.

The vapor barrier membrane has an outer and an inner side; pay attention to the correct installation. To soundproof internal walls and partitions, a metal profile frame is mounted on the surface

The height of the profile must correspond to the thickness of the material; as a rule, one layer of slabs 1200x600x50mm is sufficient. After which the frame is filled with mineral wool slabs.

In Knauf frame plasterboard partitions, the insulation is not fixed; when covering brick and foam concrete walls, disc-shaped dowels are used for fastening.

This solution will create a comfortable acoustic environment in the house. A complete description of the insulation installation methods is given in the “Album of Technical Solutions”.

For basic information about Rocklight insulation, see the following video:

Description of insulation and technical parameters

So, what features and characteristics does Rocklight have? One of the main distinguishing features is the fire resistance of the basalt product.

Fire resistance

The material can withstand temperatures exceeding 1000°C. This became possible due to the fact that the material is made from stone. Regardless of the thickness of the mineral wool slabs, the ability of the material does not disappear. Therefore, this insulation is very often used to carry out the insulation procedure in places where the chimney is located near wooden structures. But despite this advantage, it is still advised to take additional actions that are necessary to protect against fire.

Rocklight slabs do not shrink even after a huge period of use.

Maintains shape and volume

This is possible due to the density of the material. Another advantage is vapor permeability, which is absent in polystyrene foam thermal insulators. Moisture is passed through rather than absorbed. This eliminates the occurrence of condensation on walls and other surfaces. This advantage becomes even more valuable when thermal insulation is carried out between metal profiles. If accumulation did occur, then the appearance of rust was inevitable. The material is generally not interesting to rodents and small insects. Mold and mildew are also not harmful to insulation.

Let's look at the table of technical parameters, pay attention to the table:

| Thermal conductivity | Density | Flammability class | Compressibility limit | Vapor permeability |

| 0.039-0.041 W/m×K | 30-40 kg/m3 | NG | 30% | 0.3 mg/m×h×Pa |

Let us consider separately the dimensions of the insulating material:

- length – 1200 millimeters;

- width – 600 millimeters;

- thickness – 5-15 centimeters.

If the package contains slabs of maximum thickness, then it contains four pieces. 12 pieces are included in the package if their thickness is 5 centimeters. In addition to excellent thermal insulation properties, Rocklight has excellent sound insulation properties. The material is lightweight and the installation process is quite simple.

Installation rules for Rocklight TechnoNIKOL

This material is recommended for use in thermal insulation of floors in houses and apartments on the first floors, attic floors, roofs, insulation of building facades under siding, etc. Let's look further at how to correctly install Rocklight basalt wool slabs from the Russian company Technonikol, and also show video instructions with recommendations from the manufacturer at the end of the article.

Insulating the facade of a house with Rocklight mineral wool

To insulate the facade with TechnoNIKOL mineral wool, it is necessary to build a frame from a profile or timber. The width of the vertical guides should be 1-1.5 cm less than the width of the thermal insulation slabs in order to eliminate gaps and cold bridges in the structure. After installing the frame, the entire facade is covered with waterproofing so that the mineral wool does not absorb moisture from the walls. The overlap must be at least 150 mm.

Photo. Insulation of the facade with Rocklight mineral wool TechnoNIKOL

Rocklite thermal insulation is laid spaced between the guide bars. After installing thermal insulation, the mineral wool should be protected with a vapor barrier membrane to protect it from atmospheric moisture. The film is laid with the smooth side to the insulation and secured with a construction stapler to wooden blocks. Next, wooden blocks with a thickness of about 20-30 mm are stuffed on top of the vapor barrier.

The gap between the vapor barrier film and the finishing of the facade is necessary so that moisture from the surface of the film can freely erode

This rule is important to follow when installing any mineral wool, since this material loses its characteristics when wet. Upon completion of the work, the finishing cladding of the facade, for example, siding, is installed on wooden blocks.

Distinctive features and properties

Today, in order to satisfy the needs of customers, construction companies are trying to produce product lines that are of high quality. Firms are trying to come up with something new to attract as many consumers as possible. This is not surprising, because insulation is the key to excellent completion of construction.

Also, many construction companies produce materials that are universal and suitable for other purposes. One of these building products is the Rocklight basalt thermal insulator from the TechnoNIKOL company. Thanks to its excellent technical parameters, the product can be used for various purposes.

Rocklight contains mineral wool, which is one of the best thermal insulation products.

The mineral wool itself is made of basalt fibers. Basalt fibers are obtained by melting mineral rocks.

Basalt fibers

*

Thanks to this production, a dense material is produced that has a long service life. Rocklight has a low level of thermal conductivity.

Rocklight's competitors can only be products made from polystyrene foam from the manufacturer Rockwool. However, expanded polystyrene has its pros and cons.

In any case, polystyrene foam has a much lower cost than stone wool from TechnoNIKOL, because the process of producing stone wool is long and complex and requires much more time, effort and money.

Polystyrene foam has a big disadvantage - it can burn. Expanded polystyrene consists of 90% air, so upon contact with fire it begins to instantly collapse.

Expanded polystyrene

The product does not burn at all, which increases its level of reliability. Therefore, it is recommended to purchase Rocklight from the manufacturer TechnoNIKOL.

The thermal insulator is guaranteed for forty years. Expanded polystyrene lasts for a maximum of twenty years.

Reference! Rocklight does not suffer from the problems associated with mineral wool. Rocklite does not swell after contact with water and is not attractive to rodents.

The mineral wool begins to swell due to the fact that water instantly accumulates in it. Drying mineral wool is incredibly difficult, and it is very difficult to notice this problem right away. TechnoNIKOL slabs do not absorb moisture or water.

TechnoNIKOL slabs do not absorb water

Thanks to this advantage, this heat insulator can be used not only for insulating internal walls and floors, but also for roofs and facades. Reviews say that there are no problems during installation. And thanks to specially designed treatment, rodents and small insects do not prefer to “dine” on this thermal insulator. They have no contact with him.

In addition, Rocklight is an environmentally friendly material and does not harm the human body. Let us briefly list the main advantages and disadvantages of this insulation.

Main advantages:

- huge service life (40 years);

- high level of reliability;

- does not react to moisture, practically does not absorb water;

- belongs to class – NG;

- availability of protection from rodents and small insects;

- good thermal insulation parameters;

- Possibility of application for all construction sites;

- ease of installation of the material;

- low weight compared to other thermal insulation products;

- presence of vapor permeability.

The main disadvantage is the rather high price compared to expanded polystyrene.