Penoplex Comfort is a modern synthetic material used for thermal insulation.

its unique characteristics thanks to a special manufacturing technology: polystyrene is foamed, saturated with an inert gas, and then the material is passed under pressure through special press nozzles. The result is foam with bubbles 0.1-0.2 mm in diameter.

The standard width of the Comfort penoplex sheet is 60 cm, and the length is 120 cm. The thickness of the sheet can be 2, 3, 4, 5, 6, 8 or 10 cm.

Types of "Penoplex"

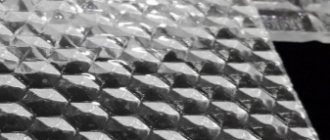

"Penoplex" is one of the types of extruded polystyrene foam. The high technical characteristics of this material are determined by its cellular structure. Cells ranging in size from 0.1 to 0.2 mm are evenly distributed in the material, which gives it strength and a high degree of thermal insulation.

Depending on the type of insulated surface, there are several types of Penoplex:

- “Penoplex roofing” is used for thermal insulation of pitched or flat roofs.

- "Penoplex wall" for insulation of internal and external walls of buildings.

- “Penoplex foundation” is used in the construction of foundations, basements, basements, cellars.

- “Penoplex comfort” - technical characteristics of an improved type are intended for use in houses and apartments.

- “Penoplex base” for insulation of industrial and civil structures.

- “Penoplex 45” is the most specific type; it is used for thermal insulation of runways at airfields.

The most universal of them is “Penoplex comfort”.

Material cutting methods

Bored foundations with a grillage, technical characteristics and scope of application

Since when trying to cut extruded polystyrene foam by conventional methods, it most likely begins to crumble, special devices are used.

Of course, in some cases, a regular hacksaw is sufficient, but it can lead to a less accurate cut. And if you need to cut a fairly thick layer, it is better to use a hand saw.

It is most effective to cut extruded polystyrene foam using heat treatment. For this, a heated nichrome or tungsten string or laser is used.

In the first case, a special apparatus is used, ready-made or assembled with your own hands. It consists of the following elements:

- nichrome string;

- transformer for 22024 V;

- pipe for the lining, which determines the thickness of the final foam sheet.

The tabletop is corrugated board, board or regular table. The string tension is provided by two springs.

When the string is heated, you can start cutting the material. The result is a beautiful, smooth edge with a slight melted crust. It gives greater strength to penoplex and closes the porous structure.

Important: when thermally cutting EPS, good ventilation must be provided, since the melting material gives off an unpleasant odor. The best way out is to cut in an open space. If you need a more curly cut, you can use a thermal cutter

According to the principle of operation, it is similar to a string, but the main cutting element is a nichrome wire, connected at one end to a thermally insulating handle. With the help of such a tool it is convenient to make recesses and specific contours of the product

If you need a more shaped cutting, you can use a thermal cutter. According to the principle of operation, it is similar to a string, but the main cutting element is a nichrome wire, connected at one end to a thermally insulating handle. With the help of such a tool it is convenient to make indentations and specific contours of the product.

Laser cutting of extruded polystyrene foam refers to industrial production, when it is required to produce a product with high precision and accuracy. For example, in the manufacture of interior decoration elements.

Template parts are also cut out using a laser. How much thickness the machine can cut is determined by the focus of the lens. This method can be used at home, but it is better to entrust the matter to professionals.

Extruded polystyrene foam confidently holds a leading position as the best material for providing good thermal insulation. In addition to the fact that it is denser and more uniform than polystyrene foam, and is also resistant to water, its insulation properties remain even after getting wet.

It is also safe and pliable, making it easier to use and when cutting material. At the same time, according to manufacturers, it is quite durable and can be used for a long time.

To test penoplex for strength and fire resistance, watch the video:

"Penoplex comfort": technical characteristics

Thermal insulation sheets have L-shaped edges, which greatly facilitates the installation process and also reduces heat loss.

- The density of Penoplex Comfort is from 25 to 35 kg/m3.

- Compressive strength – 0.2 MPa.

- Water absorption – 0.5% of the total volume in 28 days.

- Flammability category - belongs to group G4.

- Thermal conductivity coefficient is 0.03 at 25 degrees.

- Vapor permeability coefficient is in the range of 0.007-0.008.

Penoplex Comfort slabs are manufactured in thicknesses from 2 to 12 cm, in length - from 120 to 240 cm, in width - 60 cm. For internal insulation, sheets with a thickness of 2 cm to 10 cm are used, for exterior finishing - 8- 12 cm, roof – 4-6 cm.

According to the “Penoplex Comfort” parameters, the technical characteristics allow its operation in temperature conditions from -50 to +75 degrees.

Advantages

This universal insulation has many advantages:

- It is not affected by fungi and mold.

- High resistance to water.

- When slabs get wet, they are not susceptible to rotting, unlike mineral wool.

- High density material, does not crumble or crack like polystyrene foam.

- Fairly light weight.

- It is little susceptible to deformation, as it has a high coefficient of bending and compression.

- Very low thermal conductivity.

- Low moisture absorption coefficient.

The density of penoplex is much higher than polystyrene foam. It does not deform under loads and is easy to cut with a knife. Since the individual elements are attached to each other very tightly, the resulting structure is very resistant to mechanical loads. The composition contains no dust and small fibers, which makes the process of installing Penoplex quite clean.

Flaws

But despite having so many advantages, this material also has a number of disadvantages. At high temperatures, Penoplex insulation releases harmful substances and is destroyed; in the first days after installation, there is a strong odor in the room. Has very low vapor permeability. The effect of ultraviolet radiation is detrimental to Penoplex - it is imperative to create a protective layer. Combustion of the material occurs with the release of a large amount of harmful substances and the formation of acrid smoke. "Penoplex Comfort" has very low noise insulation performance.

Oil paints and solvents can easily destroy the structure of the material, it will lose its thermal insulation properties. But Penoplex is neutral to water-based paints, salts, alkalis, lime, and cement.

Composition and structure of penoplex

Penoplex "Comfort" is a material obtained by mixing several chemicals under high pressure and a temperature of about one hundred and forty degrees Celsius. High pressure and temperature values cause foaming of the following components:

- polystyrene;

- crushed perlite;

- citric acid;

- tetrabromoparaxylene;

- zinc stearate;

- sodium bicarbonate.

These chemical ingredients are combined in a certain proportion. As a result, they form a very dense honeycomb structure, the cavities of which are filled with inert gas.

Installation technology

The problem of how to sheathe a house with Penoplex Comfort is solved in several main stages:

- Preparatory.

- Direct installation of insulation.

- Finishing the surface of the insulation.

Initially, it is necessary to prepare the surface that will be insulated. It is leveled, excess mortar and peeling pieces of the structure are removed. If painting has been done previously, the paint and varnish materials should be completely removed. Places of formation of fungus, mold or moss are cleaned and treated with bactericidal solutions. Structures made of unplastered blocks or bricks must be primed or plastered. The prepared base must be absolutely dry.

Thanks to the precise geometric dimensions, installation is carried out according to the assembly principle of the designer. Sheets of insulation are glued to the surface with special adhesives. The glue is applied to the surface of the Penoplex Comfort board. Additionally, the thermal insulation structure is strengthened using construction dowels. Particular attention should be paid to fastening in the area of openings, sheet joints and in the corners of the structure.

To protect the insulation itself, plastering, finishing with facade facing materials, and roofing are required. When thermally insulating internal surfaces, it is imperative to use a vapor barrier insulation.

Insulation of aerated concrete house with Penoplex

Step 1. Let's look at how a house made of aerated concrete is insulated using Penoplex. So, the first thing you need to do is build the foundation of the building.

First the foundation is built

Step 2. Next, cut-off waterproofing must be laid along the perimeter of the foundation and along the perimeter of all load-bearing walls.

Laying cut-off waterproofing

Step 3. After this, using standard technology, you need to build walls from aerated concrete blocks to the level of the upper border of the window and door openings.

Construction of house walls

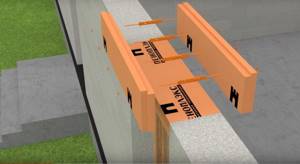

Step 4. The next stage is the installation of window and door openings, and here the use of Penoplex begins. The material is laid on top of the window opening, and then, above it, perpendicular to it, you need to install two pieces of Penoplex, tighten them together with ties.

The material is laid on top of the window opening

Two pieces are installed on top

The segments are contracted

Step 5. Between two sections of Penoplex it is necessary to lay reinforcing bars and continue further construction of walls. The rods will connect two gas blocks lying along the edges of the window opening.

Laying reinforcing bars

The rods will connect two gas blocks together

Step 6. The cavity between two sections of Penoplex needs to be filled with concrete.

The cavity is filled with concrete

Step 7. In this way you need to arrange all the door and window openings.

All door and window openings are equipped

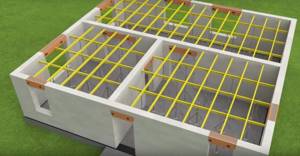

Step 8. After this, formwork is created for arranging the ceiling of the second floor. If there is a staircase in the house, it is important to leave an opening for it according to the design.

The formwork is being created

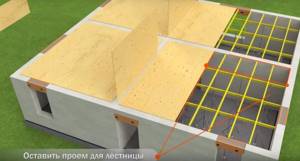

Step 9. Now you should cover the formwork with sheet material, creating a full overlap.

Don't forget to leave an opening for the stairs

Step 10. Next, Penoplex should be laid around the perimeter of the building at the floor level. If necessary, the slabs are cut according to the building design.

Laying material around the perimeter of the building

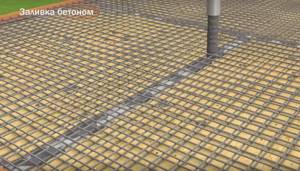

Step 11. After this, the reinforcing mesh is laid and the floor surface is filled with concrete. That is, you need to make a concrete screed. Work can be continued after 7 days.

Pouring concrete

Step 12. The next step repeats step 2 in this instruction - you need to lay the waterproofing.

Waterproofing is being re-installed

Step 13. Next, you need to build the second floor of the house, not forgetting to finish the window and door openings with Penoplex as in the previous steps.

Second floor erected

Step 14. After installing the roof, you can use heat guns to dry the inside of the house.

Drying the house from the inside

Step 15. Now that the building has been erected, you can begin to insulate the facade of the house using insulation boards.

You can start insulating the facade

Step 16. First, Penoplex slabs need to be placed on glue. It must be applied to each slab along the perimeter, 1-3 cm from the edge, as well as to the middle of the slab from one edge to the other along the length.

Applying glue to the slab

Step 17. The slabs need to be glued along the entire facade.

Gluing slabs to the facade

Result of work

Step 18. Now you need to prepare holes for the dowels by drilling both the Penoplex and the concrete underneath to the required depth, focusing on the length of the dowel.

Drilling holes

Depth depends on dowel length

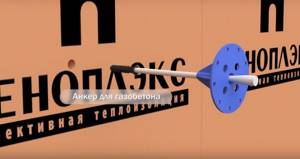

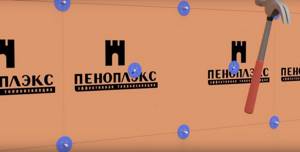

Step 19. Using anchors for aerated concrete, Penoplex is additionally attached. You can knock out the dowel with a hammer.

Anchor for aerated concrete

There should be a small gap

Step 20. Fixing one Penoplex slab with dowels is done in two places in the middle and along the perimeter of the slab (corners, middle of the long side).

Additional fixation of Penoplex

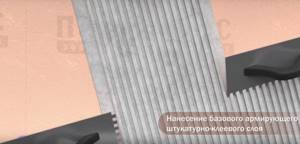

Step 21. Now Penoplex can be processed mechanically, making it rough, and covered with reinforcing plaster and adhesive material. All that remains is to complete the finishing touches, and the insulation of the house is complete.

Mechanical processing of material

Application of a base reinforcing plaster-adhesive layer

Prices for Ceresit glue

Ceresit glue

Features of finishing of individual structures

In city apartments, in order to make the most practical use of the available space, balconies and loggias are often insulated. In this case, in order to save space, Penoplex Comfort insulation with a thickness of 2-5 cm is usually used indoors. This option can be used in pre-glazed loggias, preferably with double or triple glazed windows. When installing external thermal insulation, it is possible to use thicker sheets - up to 10 cm.

When insulating floors, you can lay sheets without constructing a frame. In houses, if there is no basement, Penoplex Comfort is laid out directly on the ground surface. Slabs with a thickness ranging from 3 cm to 10 cm are used. The area prepared for laying must be level and dry.

Insulation of foundations with Penoplex Comfort can be done directly onto the waterproofing layer, without additional mechanical fastening of the structure. The slabs are installed with overlapping rows; they should protrude 40-50 cm above the upper level of the foundation. Then the foundation is backfilled. This material is used for any type of foundation.

Application area

"Penoplex Comfort" is intended for use in insulating foundations, basements, house facades, roofs, as well as internal thermal insulation in private houses or apartments. It is also often used for insulating walls on balconies and loggias, in garages and outbuildings. In suburban construction, it is used as thermal insulation for rooms with high humidity: saunas, baths, swimming pools, basements.

When using heated floors in a system, it is necessary to lay heat-reflecting materials under the Penoplex insulation to reduce heat loss.

Certification

The production of Penoplex Comfort material in Russia is carried out by PA Penoplex LLC. This thermal insulation material has fire safety certificates, fire roofing safety certificates, an environmental certificate, and a certificate of compliance with GOST. Thermal insulation tests for durability and acoustic tests for sound insulation were carried out. The certificate of compliance with sanitary standards received for the Penoplex Comfort insulation confirms the safety of using this material for interior decoration.

Throughout the entire warranty period of the Penoplex Comfort insulation, the technical characteristics of this material remain at a high level. The slabs do not crumble, do not crack, and retain their original density. Durability of 50 years is one of the most significant advantages of this material.

Description of extruded polystyrene foam Penoplex

This thermal insulation material has unique physical and mechanical characteristics and almost zero water absorption, and is also able to withstand heavy loads. And all thanks to the homogeneity and uniformity of its structure. It is produced by Penoplex SPB LLC, the largest manufacturer in Russia.

What is its difference from polystyrene foam? The latter is created by foaming polystyrene using water vapor (without applying pressure). Due to the high temperature (80-100 °C) and the presence of a foaming agent in the granules, they increase in volume 50 times and stick together. During the holding process, air diffusion occurs, which fills the vast majority of the product. The presence of air provides good thermal protection of the product, however, it is very fragile.

The manufacturing technology of Penoplex boards is somewhat different. They are produced by passing raw materials through an extruder under pressure and high temperature. The result is a compressed, high-density, closed-cell polystyrene foam that is suitable for insulating foundations, roofs, and walls inside and outside a building.