Why is it blowing

The reasons for window depressurization can be different. The plastic seals dry out and cracks appear in the slopes. In high-rise buildings, corner windows on the upper floors often suffer - the sashes become warped.

Wooden frames suffer from shrinkage and cracks when the house subsides. Seasonal fluctuations in temperature and humidity are also not good for the tree. Although the shelf life of wood treated with antiseptics is comparable to a person’s life, it also ends someday.

Problems with window sills and slopes require drastic measures - repair or replacement.

Subtleties of choice: manufacturers and prices

When choosing a self-adhesive tape, you should pay attention to the profile and material from which the insulation is made. For cracks with a width of 1-3 mm, profile C or E is suitable, for 3-5 mm - P and V, for 3-7 mm - B and O.

Important: shelf life plays a big role in insulation materials, since the glue dries out over time.

The modern range of insulation products includes many manufacturers:

- rubber insulation, which can be found in any store - from 160 rubles for 5 meters;

- Ultima - Polish foam rubber seals, price from 220 rubles per 12 m;

Penosil - two-component insulation made of EPDM rubber, price from 600 rubles;

- "Penofol" - foil-coated polyethylene foam, price from 108 rubles per m 2.

But you can find out how and where you can use liquid insulation in Polinor cylinders by reading the contents of this article.

It will also be interesting to learn about what kind of insulation to put under linoleum and how to do it correctly.

But what is the price of insulation for a warm water floor and which one should be used, this information will help you understand.

Which floor insulation under screed is the best to use and how to use it correctly, you can read in this article.

But what is the price of foil insulation for the floor and where should such a building material be used, this information will help you understand.

Classification of materials

You can correctly use insulation for wooden windows yourself without outside help. Most materials are designed in such a way that their application requires little or no specialized tools.

There are a lot of options for insulating windows today.

On the shelves of specialized stores there are varieties of materials:

- foam insulation for windows;

- rubber insulation tape for windows;

- polyurethane;

- polyethylene foam;

- insulation for PVC windows (polyvinyl chloride).

Also, finished products are differentiated according to the method of application:

- self-adhesive insulation for windows;

- insulation for windows for the winter, fixed using glue.

A tubular seal made of rubber is in demand. This material can be used repeatedly if necessary. An additional convenience is the ability to open windows during cold periods, since the material is glued to only one of the mating surfaces, unlike tape or paper.

Rubber tubular seal

And this is how it is fixed in the frame

Necessary conditions for insulation

To ensure the reliability of the work performed, a number of important conditions will need to be met. Before gluing window insulation, it is necessary to thoroughly wash the surface to be treated from dust and dirt. If necessary, replace cracked glass, because cold air can also be blown in through these cracks.

It is advisable to carry out all sealing work at positive temperatures in order to preserve the ductility of the materials used.

If the glass is not securely fixed, then it must be “seated” with silicone sealant. This will have an additional positive effect, since the glass will stop “siphoning”, which is already +5% in terms of heat retention in the house.

VIDEO: Insulation of window frames

Choosing the right material

Those wishing to use self-adhesive insulation for rubber windows must select a softer texture. This material, unlike hard material, will provide better penetration into all crevices, and it also has lower thermal conductivity. In addition, it is more problematic to work with hard materials.

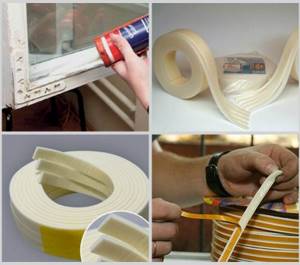

The use of self-adhesive insulation for plastic and wooden windows helps to increase the speed of work. Simply remove the protective layer and apply the sticky side to the desired location.

When using materials without a sticky surface, it is recommended to use silicone insulation (sealant) for windows. It will withstand moisture from condensation and also has a plastic structure.

How to apply silicone sealant

For ease of application, purchase a sealant gun. Such a purchase costs about 200-300 rubles, but it will provide significant help.

Application of thermal insulating film

A practical material is insulating film for windows. It is applied both from the outside and from the inside. Despite the relative high cost of the material, it demonstrates excellent results in terms of energy saving.

As a type - energy-saving window film

Experts recommend installing energy-saving film on the inside of the window to achieve the best effect.

During application of the film, its uniform tension is ensured over the entire surface. A slight sagging of any area can lead to ruptures during a sharp gust of wind. You can get rid of the damage using tape.

More durable brands of films, also used in greenhouse farming, have a yellowish tint. They are able to withstand large temperature changes with virtually no change in their characteristics. They can also be used repeatedly, which will compensate for their increased cost relative to other brands of material.

To attach the film, use the following options:

- using a stapler directly to the frame;

- stuff wooden planks on top of the film with small nails;

- use nails with wide heads or place a strip of roofing felt or leatherette rolled up several times under them;

- fastening is carried out with paper clips.

Instead of film, you can use transparent polyvinyl chloride. The material is environmentally safe and does its job well.

Using a sealant

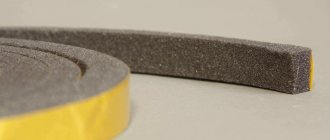

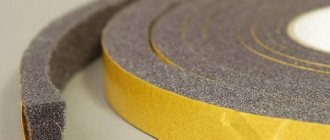

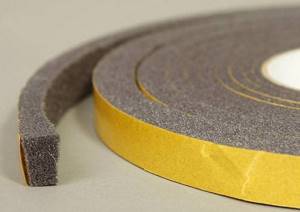

It is easy to find material for seals in hardware stores. Visually, they look like a tape with an adhesive layer on one side. The base consists of polymer or foam rubber. Polymers make it possible to tear off the sashes without any problems, as well as use water to clean the surface. When water regularly gets on foam rubber, the material quickly deteriorates and cannot withstand use for more than one season. It needs to be replaced by next winter.

Rubber compressor

Gluing the tapes is very simple. It is enough to cut the workpiece to the required length and then remove the paper protection from the adhesive side. It is glued both to the window frame and to the stationary part of it. This will provide reliable protection against cracks.

Fighting large cracks on an old frame

Since gluing self-adhesive window insulation in the presence of large cracks will be ineffective, in this situation an additional procedure is carried out to seal the cracks. The cavities are filled with the following materials:

- cotton wool;

- paper;

- rags;

- putty mixtures, etc.

The best way would, of course, be putty, which completely fills the space and does not leave cold bridges. Depending on the size of the crack, the density of the putty can be from liquid - for small cracks, to thick and viscous - for large cracks that need to be sealed.

The surface must first be cleaned of dirt in order to subsequently ensure good sealing. A retaining layer of tape or strips of paper is glued over the closed gap, which is attached to water-soluble glue, for example, PVA.

Working with plastic windows

Insulation for plastic windows is also in demand. In case of initial installation of high-quality materials, it can withstand up to 5 years of reliable protection. After this, the connections may be subject to depressurization.

(10th method) Insulation of the entire perimeter of the window frame

The whole process of insulating a wooden window consists of choosing the material for the work and the method of laying it, taking into account the characteristics of the wooden window. We mainly insulate the cracks, which are located at the junction of the frame and sashes.

If you are guided by Swedish technology, then you need a special tool - a cutter to make a groove inside the perimeter of the window and fill it with a tubular silicone seal that will cover all the smallest cracks and defects. The process is complex; if the window is old, it may not withstand removal and hanging; it is not cheap; the work must be performed by professionals.

An easier way is to place and glue the seal around the perimeter onto the transom of the window. When we close the frame, it will bend the seal and not slide over it; it will fit tightly, closing all the cracks. Such insulation can be laid in rows in several layers. Its use must be combined with the installation of glass on a layer of sealant. The seal installed in this way will last for many years and there will be no need to remove it in the spring and install it in the fall.

Some people continue to insulate their windows with toilet paper or newspapers. But today there are a sufficient number of specialized tools designed to make our everyday life easier. It’s worth mentioning right away: pasting windows is a regular process and it will be repeated every winter. Therefore, it is worth choosing the least labor-intensive method of insulation. In this article we will look at the types of insulation for self-adhesive windows. We will also compare the cost of different types of materials and provide step-by-step installation instructions using one example.

Any self-adhesive insulation always consists of two main elements:

- Warming base;

- Adhesive layer.

The first is designed, in fact, to protect from the cold, the second eliminates the need to dilute and use a special adhesive. This tape-based approach has three significant advantages over traditional methods:

- Reduces insulation installation time;

- Simplifies pasting;

- Eliminates wet processes.

And as a bonus, any adhesive will leave marks on the frame when the owner wants to get rid of the insulating tape. Using special adhesive tape for insulation will not cause diffusion between the frame paint and the adhesive composition of the insulation.

Let's now look at the 4 materials from which self-adhesive window seals are made, and discuss the advantages and disadvantages of each.

Polyurethane foam

Large gaps between the wall and the window frame, under the window sill, are closed with polyurethane foam.

Before work you need to put on gloves and goggles.

- Holding the cylinder in a vertical position, remove the cap from the adapter and put on the gun.

- The container is shaken for 30 seconds.

- The seam is moistened with water or an activator.

- The cylinder is turned over into the working position and work begins.

- The seam is filled using a zigzag motion. If the seam is vertical, then the movement begins from the bottom up.

- If there is foam left in the can and you want to use it, do not remove the gun. Just clean the outside.

The release of foam is accompanied by a sharp increase in volume, so it is necessary to install safety struts against window deformation.

To solve the problem with cracks in frames, you can use old-fashioned methods or buy ready-made insulation in the store.

Tidying up the frames

First of all, you need to take care of the old frames. The service life of frames is usually about ten years. But few people change them at least once during this time, because this is a costly business. As a result, the wood dries out, it begins to warp, and over time, small gaps appear between the frames and the window frame. The glass then shifts, resulting in large cracks. Even if you glue the cracks with paper and plug them with cotton wool, the wind will still seep in, blowing away the heat.

Glass

Inspect the windows, open the shutters, pay attention to the glass. If they do not fit very tightly to the window frames, coat the cracks on both sides with special putty

If somewhere you have applied too much, remove the excess with a rag so that the putty does not interfere with covering the doors. Then strengthen the loose glass by tapping the nails in the glazing beads with a hammer.

Ideally, you need to completely remove the glass and then put it back in with double putty. If you don’t have putty, you can use oil paint; it also covers the cracks well. Take out the glass, cover the folds with an impressive layer of paint and start glazing. At the same time, you should not wait for the paint to dry, otherwise you will ruin the whole thing. Then paint the glazing beads. If you don’t have paint, you can use regular plasticine. But this is not the best option, since plasticine reacts to temperature, and therefore, when exposed to heat, it can leak and stain the windows.

Types of insulating tapes and tape

For sealing use:

- masking tape,

- groove and self-adhesive seals,

- adhesive tapes.

Self-adhesive insulation is:

- foam rubber,

- rubber,

- polyethylene,

- polyvinyl chloride (PVC).

In addition, for work you may need:

- mastic for frames,

- reflective film,

- silicone sealant,

- cotton wool, foam rubber, paper or plastic film.

Preparing the window frame

Before pasting, first fill the gaps. To do this, you can take silicone or acrylic sealant, which is used to fill the gaps between the frame and the window sill, between the glass and the frame, and in the frame itself.

All work is carried out at a temperature not lower than +5°C. Surfaces must be dried and degreased.

It is better to seal the gaps between the sashes from blowing with materials that can be easily removed, so that in the warm season you can ventilate the room and wash the internal surfaces of the window. Depending on the width of the gap, in descending order the following are inserted: strips of foam rubber, cotton wool, tubes of newsprint, polyethylene.

Sealing glass in wood windows involves removing the glass, stripping the wood of old caulk, sanding it down, and then applying sealant. The glass is pressed down and secured with glazing bead. Carefully hammer in the nails. Now for several years you can forget about rattling glass and drafts.

Instead of silicone, you can use regular putty or children's plasticine, but their shelf life is noticeably shorter. In addition, you can choose transparent silicone. It will not be noticeable even if the work was not done very carefully.

Foam rubber delays the passage of cold air better if it is laid loosely, maintaining volume. Cotton wool is used in dry places, in the upper transoms. It is more convenient to work with something sharp and thin - a knife blade, a plastic triangle, a ruler.

Industrial seals significantly simplify the task of retaining heat in apartments and houses.

How to insulate

There are many different materials that you can use for . Let's look at some of them.

Sealing gaskets

Experts say that for windows these are special tubular profiles (they are also called sealing gaskets). They come in different sizes and are made of different materials. The most practical option is foam pads, rubber and polyethylene foam. All of these can be found at any construction market.

We cover the windows with newspapers

This is an old but proven method. We roll each newspaper into a tube, the width of which should be slightly larger than the distance between the window sashes. Then place the resulting rolls vertically close to each other and close the windows. If the room will not be ventilated in winter, then all small cracks can be plugged with tow, foam strips or cotton wool.

Textile

You can also cover the windows with strips of white fabric. It is first moistened with hot water, wrung out, and then thickly lathered with soap. If the cracks are very wide, the window insulation tape is applied in several layers. On the windows, the white fabric is practically invisible, the soap solution serves as an excellent insulator, and with the onset of spring, this entire structure can be easily removed if it is wetted with water. But in winter, due to temperature changes, the fabric may peel off, so everything will have to be redone.

Foam rubber

You can also use foam insulation or cotton wool. First, we fill all the cracks with foam rubber material, then glue them with strips of fabric on top. Strips 4-5 cm wide can be cut from an old sheet. Instead of glue, regular soap is used here too. Instead of fabric, you can use paper, but by the end of winter it will turn yellow and will not look aesthetically pleasing.

Paraffin

You can also insulate using paraffin. Take an ordinary paraffin candle and melt it in a water bath. Hot paraffin is poured into a syringe and injected into the cracks. Once frozen, paraffin becomes a reliable barrier to the cold.

Seals for preparing windows for winter

To prevent blowing through loose frame sashes, it is enough to insert a seal into the grooves or glue its analogue on an adhesive basis. Insulation without glue is also produced. They are cheaper, but choosing a retainer can leave you with some difficult choices. You can use silicone sealant, but it will leave marks and can remove paint from wooden frames.

A seal is a hollow tube that prevents heat from passing through the cracks due to the layer of air it contains.

Depending on the material, the tubes are

- rubber – grayish-white in color, moderately plastic, subject to damage by acids and alkalis, can peel off when exposed to water, last up to 3 years;

- silicone - pure white, elastic, do not react to chemical influences, perform their functions for up to 8 years in a row.

Window seal

Seals are secured at home in various ways.

- The adhesives are released from the protective film and pressed to the surface of the frame with an adhesive base.

- Tubes with a T- or Y-shaped longitudinal holder are inserted into the groove. This type of fastening is the most reliable and is not afraid of dampness.

- Tubular seals without an adhesive layer are glued to glue or silicone.

The protective film should be removed a few centimeters at a time so that dust and moisture do not get on the adhesive base. Be careful not to stretch the seal so that it does not “bounce” off the frame.

Even before the advent of tubular ones, foam rubber strips were produced, and they are still used to plug cracks. Foam rubber does not injure frames and is easy to use. The downside is insufficient reliability; with strong compression, it loses its heat-saving qualities.

How to glue

After selecting a certain insulation, all that remains is to glue it correctly. To do this you need:

- carry out work strictly at temperatures from 5-40 0 C;

- Wash window glass and frames thoroughly. It would be a good idea to degrease the surface with acetone or alcohol. The better the surface is cleaned before applying the adhesive composition with tape, the better it will adhere;

- Inspect the window structure for chips and damage. If there are any, then it is best to replace damaged elements or seal them with special compounds;

- remove old insulation if present;

- seal cracks;

- stick self-adhesive insulation over the foam rubber, removing the protective film from the tape and pressing the insulation tightly to the glass or frame.

Complete adhesion occurs after 2 hours. To check the window for gaps and omissions, you can bring a lighter or candle to the insulation areas. If the flame does not fluctuate, then the insulation is glued correctly and there will be no heat loss. If any breakdowns are detected, the tape should be re-taped.

On the video how to glue self-adhesive insulation for windows:

With self-adhesive window insulation, you can minimize heat loss in the room in a short time and create a comfortable indoor microclimate. The main thing is to carry out work on thermal insulation of windows on time - in early autumn, when the weather is quite warm.

Despite the popularity of energy-saving structures made of metal-plastic profiles, there are still many adherents of wooden windows. A number of reasons force one to make a choice in favor of wooden structures: a healthy indoor microclimate, environmentally friendly material, high decorative qualities of the product.

A positive property - the ability of natural material to “breathe”, has another side - increased heat loss indoors. Owners of wooden windows need to take timely care of reliable insulation for the cold season.

Places on windows with poor seals can be detected with a burning candle. On a windy day, we will carry it along the window frame, where the flame will fluctuate, there is a place for heat leakage. Such areas must be insulated from the inside and outside of the room.

You can invite specialists to do the work, but it won’t be difficult to do it yourself with the help of improvised materials and special materials.

Tape for sealing windows for the winter

Adhesive tapes are divided into:

- Paper . Adhesive paper tapes are inexpensive and are placed on clean joints with sealed cracks. As a budget option, ordinary paper tapes are used, which are lubricated with wet soap or flour paste. The last option is so reliable that it may make you regret using it in the spring.

- Rubber (EPDM) , close small gaps well, do not allow air to pass through, withstand temperature changes from -50°C to +70°C, are easy to use - they are fixed well and are also easy to remove.

- Silicone . An advantage to temperature endurance is chemical inertness. Due to its plasticity, this tape will close large uneven cracks without losing the quality of sealing. It is more expensive than tapes made from other materials, but it justifies its cost.

- PVC . The porous structure gives the tape dustproof characteristics. The downside is low thermal insulation. It is painted under frequent temperature changes, but will serve well for one season.

(1 method) Insulating wooden windows using paper and fabric strips

The simplest, rather primitive, but very economical way is to insulate wooden windows using paper and paper or fabric strips. Completing of the work:

- we tear paper, newspapers, wallpaper into pieces, twist them into strips;

- soak in water and clog the cracks between the window frame and sashes using a knife or ruler;

- Carefully glue strips of paper or fabric of small width (4-5 cm) along the joints, coat them with a solution of laundry soap or make a special glue (paste) from flour or starch.

Paste recipes:

- Flour paste: take flour and water in equal proportions (1:1), mix well until lumps disappear and bring to a boil, stirring constantly.

- Starch-based paste: 2 tbsp. Dissolve the starch in water and add a glass of boiling water in a thin stream, keep it on the fire for a short time.

It is not easy to clean a window from this insulation; sometimes the paint is removed along with the paper, and pieces of it and prints of printing ink remain on the surface of the window frame.

Simple and forgotten insulation also includes window putty and even children's plasticine.

Scotch tape for window insulation

Scotch tape is a name for painting tapes with a different base, on which an adhesive layer of natural or artificial rubber is applied. The base can be paper (crepe) or PVC. There are other varieties, but they are not suitable for covering windows.

Crepe paper differs from regular paper in that it has a corrugated surface. This gives it additional moisture-retaining properties.

How to seal windows for the winter with masking tape

The work is carried out at above-zero temperatures. In colder times, due to condensation, the adhesive layer on the frames will not hold.

The surface to be pasted must be dry, clean and free of grease. The cracks are pre-insulated. First, prepare pieces of tape of the required length according to the principle “measure twice, cut once.” Then they are applied on one side, stretching a little and pressing tightly. Using the palm of your hand, iron the strips across towards the un-glued side, starting from the middle.

To glue a stepped surface, a strip of one third the width is applied to the protruding side. After carefully smoothing, run your hand along the fold to the corner. Finish by fixing the edges around the corner. All actions are carried out from the middle of the strip.

Polyethylene film

Window thermal insulation film is made with a reflective metal layer sprayed on it. It is glued with a protective layer on the outside.

A properly glued film allows sunlight to pass through and is opaque from the street:

- The frame is degreased at the attachment points.

- Double-sided tape is applied around the perimeter of the pasting area.

- The film is cut to the required size.

- Remove the protective tape from the tape.

- The film is applied to the window and pressed from the middle to the edges.

- The work is completed by warming it up with a hairdryer - this way the film lays more evenly.

There is no need to seal the window from the outside. This can lead to the fact that instead of a landscape you will see snow patterns on the window in winter.

Properly carried out window insulation measures will create a warm and cozy atmosphere in your home to survive the winter in comfort.

Select the necessary materials by evaluating their characteristics in the comparison table.

| Insulation materials | Characteristics | pros | Minuses |

| Rubber(synthetic rubber) | Hardness 40-70 units Heat resistance from -30 to +95°C | Resistance in wet and chemical environments | Short service life |

| PVC | Chemically resistant, non-flammable, hardness 70 units. | Resistant to humidity and harmful environments, plastic | Low elasticity, deforms with frequent mechanical impact |

| Silicone | Hardness 10-20 units, non-flammable, good adhesion | Plasticity and adhesiveness | Not resistant to paint, causes metal corrosion |

| Polyurethane foam (polyurethane foam) | Fine-porous light substance, retains its structure when leaving the cylinder at t +5 to +40°C (summer), from -20 to +40°C (winter) | Good adhesion to all materials except polyethylene, silicone and some others. | Destroyed by sunlight Household options for disposable cylinders Fireproof is expensive Hygroscopic |

| Foam rubber | Porous structure | Good sound and heat insulation, resistant to changes in temperature and humidity | Chemically unstable |

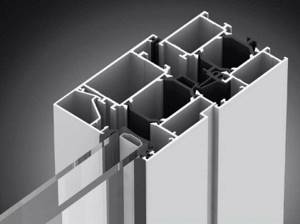

Veka window seals

Another popular manufacturer of window seals is Veka, which also comes from Germany. Seals from Veka have been on the market for more than four decades, which indicates their high quality and demand among customers.

The company produces rubber seals for both window sash and glass, and among the advantages of the company’s products are the following:

- high durability and resistance to deformation;

- withstands temperature changes, humidity, frost and other adverse effects well;

- provide a high level of heat and noise insulation.

On a note! If you have double-glazed windows from Veka installed in your home, then to improve their performance characteristics, it is recommended to use seals from the same company, since the configuration of the windows is very poorly suited for insulation using alternative options.

A meter of sealant from Veka costs about 20-25 rubles. The cost depends on the model of the product and its purpose. For example, a glass gasket costs slightly more than a rebate gasket.

About insulation

Before you begin insulating measures, you need to understand the reason for the occurrence of cold air. The wooden structure serves to retain heat, but over time it can become deformed and stop performing its intended functions. The plastic double-glazed window retains heat and at the same time serves as soundproofing protection.

Several reasons have been identified why a draft occurs through these frames:

- Low-tech window installation. Often workers are dishonest about their work and do the installation quickly but with poor quality.

- Saving raw materials during installation. If the price of a window opening pleases you, then it is underestimated for a reason. Here you will save on insulation sealants, polyurethane foam, etc. As a result, installation and insulation will cost much more.

- Single-layer bags do not provide complete protection; they only protect the room from the street, but not from the penetration of cold.

- When the building shrinks and deforms, the window becomes skewed, after which the window frame no longer fits tightly, and air leaks begin.

Wooden windows

The main disadvantage of wooden double-glazed windows is the formation of cracks. They require constant covering and adhesive. The openings change geometrically. It happens that you just need to adjust the position of the sashes, tighten them, and then the problem will be solved. If this does not help, then you should use paper with cotton wool, sealant, putty or window tape.

For insulation, the first option will require softening the paper in water. Then the mass is taken out, squeezed out, mixed with chalk powder and clay (1:2:1). The resulting mixture is placed into the cracks, leveling is done with a ruler and a large screwdriver. Afterwards, the opening is sealed with adhesive tape.

If the paper is difficult to remove, you can replace it with cotton wool. The seal is only checked periodically, as the wool shrinks when exposed to moisture.

If the problem is a loose fit of the glass to the frame, then it is better to use a sealant, a special mixture.

Plastic windows

In plastic double-glazed windows, the seals dry out, which leads to the penetration of cold air. Heat can also escape through a gap in the slope, or the sash is skewed.

The market and stores sell bases that fit tightly to the window structure and block heat loss: masking tape, foam, putty, film with a reflective coating.

It is better to use foam tape; it is produced as an insulating strip in a roll and has an adhesive base.

Insulation for plastic windows

If plastic windows do not belong to the cheap series, and their installation was carried out at a high, professional level, then there should not be any problems with their tightness. But if they are not the best or defective double-glazed windows and rubber seals are installed, then their insulation is necessary.

The first method involves the use of already known products - silicone sealant or paraffin. They can be used to seal small cracks. Paraffin must be melted and drawn into a syringe, and then squeezed into those places that need to be sealed.

The second method is to insulate the external slopes with polystyrene foam or polyurethane foam. The material is glued to the slopes and finished with putty for exterior use. In the same way you can insulate internal slopes.

Some problems can be solved by adjusting the fittings: it happens that after the shrinkage of recently erected buildings, distortions form in the area of the window openings, which leads to the appearance of cracks. Correct adjustment will eliminate these problems. In some cases, it is impossible to do without replacing the rubber seals (if the design allows). For greater efficiency, you can combine several methods of insulation.

With the onset of cold weather, owners of apartments and houses have a problem in the form of window frames that allow a lot of heat to pass through. And if 5-10 years ago it was necessary to use old methods - from newspapers, cotton wool to strips of fabric, now you can find simple and effective materials on the market. One of these is window insulation that is self-adhesive. What it is and how to work with it can be found out below.

Types of insulating tapes and tape

Insulation sheets and tape have a number of advantages over other methods of window covering:

- The base will last for several years without replacement.

- Pasting is carried out independently, quickly.

- No additional materials are required.

- The adhesive base leaves no traces when peeled off and does not interact with the material to which it is glued.

But it is worth considering the disadvantages of this method:

- Covered openings cannot be opened.

- If the strip is poorly glued or of poor quality, then removal will be difficult and there will be tears.

There are two types of insulation sold in stores and markets:

- Pasting. This type has a lot of grip. Polyvinyl chloride, rubber raw materials, and foam rubber are used for its production. It has good flexibility and simply compresses to the required size. Stripes are available in black, white and brown colors. It is written on the packaging what size gap the fabric is suitable for.

- Sealing. This type is characterized by a void inside the tube, which helps retain heat. One side is equipped with an adhesive layer. The 7 mm gap is tightly blocked and can withstand all temperature changes. The color of the strip is chosen to match the color of the glass unit.

The durability of the glued tape must be checked annually. If replacement is required, then do it for the entire strip or a separate fragment.

Pasting

Tapes of this type have a wide grip. The adhesive composition is applied during manufacturing (self-adhesive type) or during installation work.

To create self-adhesive tape, polyvinyl chloride, rubber and polyethylene foam (foam rubber) are used.

Due to the plasticity of these materials, the tape is easily compressed to the size of the gap. To ensure that the insulation does not stand out against the background of the window, dyes are added: black, brown, white.

Typically the packaging will indicate the size of the gap that the tape will cover. Popular options with sizes 3 - 7 mm.

Foam rubber tapes were the first to be used. Their popularity is explained by a number of advantages:

- high compression ratio;

- the frame does not collapse in places of insulation;

- low cost;

- high protection efficiency.

Such tapes have negative qualities:

- insufficient efficiency for large gaps;

- short service life. Effective during one winter season;

- in cheap models, the adhesive tape does not stick well;

- low resistance to water.

Important! It is more convenient to use self-adhesive tapes on foam rubber for insulation.

They stay on the window longer and regulate the degree of pressing of the sashes.

Sealing

Tapes of this type have a hollow tubular shape, which is why heat is retained. The materials chosen are rubber and polyvinyl chloride.

On one side of the tape there is a groove hook or an adhesive coating with paper protection.

It is believed that the groove is more resistant to mechanical stress.

The following qualities are considered advantages:

- gaps up to 0.7 cm are blocked;

- withstands any temperature changes;

- It is possible to choose a color to match the color of the frame;

- the use of the window is not limited;

- affordable price.

But most of the disadvantages relate to adhesive tapes:

- not suitable for all window designs;

- when temperature changes, the adhesive layer is destroyed;

- with frequent deformations, peeling occurs in the glued places;

- The foam tape quickly gets wet and dust sticks to it. For this reason, frequent replacements are carried out.

Tubular seals are checked annually. If necessary, individual fragments are replaced.

Insulation Izovol (Izovol) - characteristics and types of mineral wool

Rating of products from famous brands

Self-adhesive material Izolon is in first place in popularity. At its core:

- polyethylene foam composite;

- reflective layer;

- sticky side.

The insulation is used equally successfully both for heat and sound insulation of air ducts and for insulating cars.

In second place is an equally popular thermal insulation option - Isolontape. A material with reflective properties and the ability to reduce noise levels, available in two variations: with rubber adhesive on one side or impregnated on both sides.

Third place in the ranking of self-adhesive thermal insulation belongs to Penofol 2000 type C. Just like previous brands, the material has a glue-impregnated side and has a reflective effect.

Tibilite Black Star Dact is sold in sheets with a closed cellular structure. Excellent for thermal insulation of pipes with large diameters, all kinds of tanks and containers, fittings, walls, floors and ceilings. It has all the advantages of modern reflective material from the self-adhesive category.

Next in the rating is PenoProf NPE LF type C - an elastic material with reflective ability due to the foil surface based on polyethylene foam. The heat insulator is additionally equipped with a layer of foil and is simply attached using a self-adhesive layer.

Porilex NPE LF type C also has a reflective effect, demonstrates high performance characteristics and, what is important, is simply fixed to surfaces due to the adhesive layer

A worthy solution is Tepofol S, included in the rating of popular heat insulators with reflective properties. The material is also equipped with a self-adhesive side and is made on the basis of polyethylene foam in tandem with a polished aluminum (metalized) coating.

Thermal insulation PENOLENE NPE MK PET also has an adhesive base for ease of installation. It has reflective properties and does not require additional packaging with glassine, plastic film or roofing felt.

A variation on the theme of the previous material is PENOLENE NPE K, made on the basis of polyethylene foam with an adhesive side. The heat insulator actively reflects radiant energy and does not require reinforcement with glassine and other materials.

A convenient solution is SFP foil, also reflective, based on polyethylene foam with laminated sides and a polished aluminum layer made of a special film. The peculiarity of the material is high strength and low weight.

Adgilin-M NPE is an ideal solution for reflective thermal insulation of ventilation systems and air ducts. The material is based on polyethylene foam. Sold in rolls with a self-adhesive side.

ARMOFOL TK type C is an elastic material for thermal insulation based on fiberglass, resistant to atmospheric influences and UV rays, equipped with an adhesive layer, and has self-reflective ability.

SPMP foil plastic is a variation of the previous brand, suitable for thermal insulation of any surfaces. Made from polyethylene foam, additionally covered with metal polypropylene or aluminum foil.

Porilex type C is also finished with a self-adhesive foil layer and is made on the basis of NPE grade polyethylene.

Stizol LM KS is domestically produced, sold at an affordable price, and demonstrates excellent thermal insulation properties. Allows you to insulate a room while retaining up to 93% of heat.

Rounding out the rating is Megaflex NPE-LK, a self-adhesive material based on polyethylene foam with the main function of reflection. Easy to install due to the convenient adhesive layer.

All of the brands listed are worthy of attention. You should choose among them materials with an optimal ratio of performance characteristics and cost.

Tips for choosing

To buy a quality tape, you need to focus on the following indicators:

- Material: foam rubber, PVC, rubber, PPE. Foam tape is the most affordable, flexible, and can close gaps of different sizes, but the porous structure quickly absorbs moisture, which leads to further deterioration of the raw material. PVC is stronger, resistant to moisture, and stretches. The rubber base can be self-adhesive or sealing tape. It contains rubber, which gives elasticity and resistance to temperatures. PPE is made from foamed polyethylene. Increased flexibility allows use for small window defects. Use at elevated temperatures is unacceptable, as a toxic compound will be released.

- Manufacturers. A lot of them. There are films from domestic representatives, and others from foreign ones. The most common ones can be identified: Profitrast, KIMTEC, Sanok. Domestic brands are not inferior in quality to foreign ones, as they are produced according to European standards and technologies.

- Price. The tape can be purchased by the meter or by the coil. Domestic materials are cheaper than foreign ones. So, Russian-made tape costs about 15 rubles per meter, and German quality tape costs 50 rubles.

By material

- Foam rubber ― has been used for insulation since ancient times. Currently it is included in the tape.

Main advantages:

- low cost;

- high elasticity, allowing you to close gaps of different sizes.

There are also disadvantages:

- Due to the porous structure, moisture is quickly absorbed. The drying process takes a very long time;

- low durability. With prolonged use, the material turns yellow and crumbles.

- Polyvinyl chloride (PVC) ― material with high strength and adhesiveness. It is not afraid of humidity and temperature fluctuations. The tapes are fixed on any surface and stretch well.

Unfortunately, such tapes are rarely used for window insulation, as they increase the cost of window construction by up to 15%.

- Rubber - used to make two types of tapes: self-adhesive and sealing.

Self-adhesive tapes are made on the basis of synthetic rubber and have all its positive qualities: elasticity and resistance to temperature fluctuations.

Rubber seals are not afraid of aggressive environments, so they last a very long time.

- Polyurethane foam (PPE) is a porous material made of foamed polyethylene.

Good insulating qualities. Due to the presence of air in the structure, a thermal insulating environment is created. Its use is limited by its ability to transform into a toxic liquid state at high temperatures.

By manufacturer

In construction stores you can find tapes from different manufacturers.

However, only materials from the following brands are in demand:

- Russia - Profitrast, Economy, Zubr.

- Germany - KIMTEC, Deventer.

- Poland - Sanok.

Domestic manufacturers, as a rule, work using European technologies and produce high-quality material no worse than foreign samples. At the same time, German and Polish ribbons, although more expensive, last longer.

By cost

Insulating tapes are sold retail and in coils from 6 to 10 meters.

Since a standard window requires about 5 meters of self-adhesive insulation, purchases are most often made at retail.

The price range is very wide.

For a linear meter of Russian material you need to pay up to 15 rubles, and the most expensive German rubber insulation will cost 50 rubles.

When choosing, it’s easy to calculate how much it will cost to insulate an apartment with any number of windows.

Types of insulation

Tubular seal

To reduce heat loss through window structures, you can use several types of self-adhesive insulation. When choosing, temperature operating conditions are taken into account as one of the factors for the durability of the seal.

Also, special attention should be paid to the adhesive base. It must be suitable for installation on the specific material from which the window is made

Not all models are designed for installation on plastic or aluminum structures. But the determining parameter of choice remains the seal.

It can be of the following types:

Rubber. This is the cheapest and most accessible material, which has a number of disadvantages. First of all, the change in elasticity index when exposed to negative temperatures. It becomes rigid, which increases the likelihood of heat loss;

Foamed PVC. Even after significant deformation, it quickly returns to its original shape

When choosing, you need to pay attention to the stiffness indicator;

Foam rubber. The best option for sealing windows

Its porous structure contributes to a high degree of thermal insulation.

Window insulation using Swedish technology also has good reviews - you can check it out. After choosing the optimal seal model, it is necessary to perform correct installation.

Insulation with adhesive tape and masking tape

There is nothing complicated about insulation; the main thing is to follow the instructions. The old material can be used to mark the required dimensions of the new one. Insulation with adhesive tape and masking tape begins from the top of the window block. As you stick, the protective strip is removed and the adhesive base is pressed tightly.

The work is carried out slowly to avoid breaks. In the corner parts the material is not cut, but wrapped.

Plastic windows

Insulation is carried out in the following sequence:

- pre-removed old insulation is used, firstly, to purchase similar material, and secondly, to pre-cut the old material to size.

- gluing begins from the top of the window. As you progress, the protective layer is removed in small sections, and the tape is pressed tightly.

More details in our video:

Important!

- 1. The pasted tape should not have many tears.

- 2. In the corners the tape is not cut, but wrapped.

Wooden windows

For these windows, in addition to adhesive tape, thin foam rubber is often used. The work is performed in the following sequence:

- strips of foam rubber are cut along the window opening;

- cut foam rubber is placed between the frames;

- The tape is cut to the size of the window;

- The tape is applied with a sticky layer to the foam rubber and smoothed with a napkin.

This insulation will last up to three years. But it’s better to do it as shown in the video:

Installation

When insulating windows using foam rubber, follow the following sequence:

- We dismantle the previous insulation or its remains, if there was one.

- Initially, the glass and frames with which the insulating strip will come into contact must be clean. We remove the remaining paint and glue from the previous insulation. It is best to wipe the glass itself. (This is especially necessary if you plan to stick thin strips at the junction of glass and frame). After cleaning, go over the frame with a rag to remove any remaining dust.

- Degreasing the surface is an important stage of work. An alcohol solution will do. Thanks to this stage, the self-adhesive foam will stick well and will not fall off.

- We evaluate the gaps between the frame and the wall. If the gap is very large, it is better to use wide strips, driving them into the gap.

- In the case when the wind blows into the windows through narrow cracks or when you need to insulate the gap between the sash and the frame, it is better to use thin (in the form of a narrow strip) self-adhesive foam rubber. Let us remind you that all contact points between the adhesive side and the surface must be degreased.

- You need to carefully glue a special tape over the cracks sealed with foam rubber.

This tape does not leave marks after removal, so you don’t have to worry about the paintwork of the frame.

After sticking the tape, the process of thermal insulation of windows can be considered complete. Until spring, foam rubber will reliably protect your home from the loss of precious heat.

By the way, did you use foam sealant for windows last winter? If so, which manufacturer?

Additional information can be gleaned from a video in which an employee of one of the online stores will talk about the principles of installing foam rubber insulation.

Useful tips

When working with tape, insulation, tape for sealing windows for the winter, you must follow these useful recommendations:

- If you need to cover one window, then on average it takes 5 meters of tape, so it is not advisable to buy a whole roll.

- The material will not last long on a poorly prepared surface.

- It is better to choose the tone of the strip to match the color of the window frame.

- High-quality masking tape will not leave marks on the surface.

- If the window glass is damaged, it should be replaced before insulation, as it will serve as a source of drafts.

Sources

- https://okna-dom.net/skotch-dlya-okon-uteplitel/

- https://www.PortalTepla.ru/uteplenie-okon-i-dverej/samokleushijsya-uteplitel-dlya-okon-kak-kleit-pravilno/

- https://VseProKley.ru/skotch/dlya-zaklejki-okon-na-zimu

- https://balkon4life.ru/osteklenie/okna/lenta-dlya-utepleniya-okon/.html

- https://passaz-okna.ru/raznoe/skotch-dlya-zakleyki-okon-na-zimu-pravila-vybora-i-instrukciya-po-utepleniyu-okon.html

Checking the reliability of the installed seal

Immediately after you have installed the new gasket, you need to check whether everything was done correctly. To do this, you need to check the following points:

- Is it easy to close and open the sash;

- whether the drafts have disappeared;

- Does the seal remain in the grooves when opening and closing the window?

If the answer to all these questions is yes, then you should immediately treat the gasket with silicone lubricant applied to the fabric. It increases the service life of the product and improves its performance characteristics.

On a note! It is not recommended to use lubricant to treat the seal in the cold season. It is best to do this twice a year - in autumn and spring.

If you don’t have the time, effort, skills, tools or simple desire to install the gasket yourself, then you can do this by using the services of experienced specialists who will replace the seal on a plastic window. The price of this work is low - about 1000 rubles, it depends on the type and size of the window, the complexity of the work and a number of other factors.

The tighter the seal fits to the frame, the longer it will last.