When constructing various objects, tape made of bitumen or butyl rubber is often used; its main purpose is waterproofing various structures.

Quite often it is used when installing blocks of windows and doors, installing roofs, at the junction of floors and ceilings with walls, and for corners. There are tapes from various manufacturers on the market, but their basic parameters are similar.

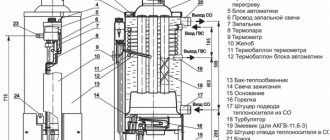

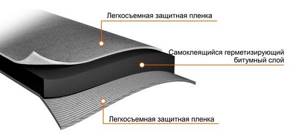

Structure of waterproofing tape

Structure:

- The outside of the film is most often covered with aluminum foil, which is represented by a reinforced structure, but there are also tapes on the market that are based on other materials, as well as in different colors.

- The base is a layer of bitumen or butyl rubber, which easily adheres to any surface and at any angle.

- The material is covered with a special protective film on top, its purpose is to prevent the tape itself from gluing and drying out.

Install the film on a surface that has been specially prepared and cleaned.

When carrying out waterproofing work in places where door and window blocks are installed, the tape should be glued before the construction foam fully expands, this will allow the material to fully stretch and fix tightly.

The price of this product depends both on its width and on the production company.

Familiarization with its various types of structure and application will help you choose a waterproofing material from a variety of proposals.

General installation features ↑

When starting to install any tape, you need to make sure that the base is well cleaned of dirt, dust, grease and oil stains, old paint and other possible poorly adhering layers. A layer of waterproofing solution is applied to the surfaces adjacent to the joint, or to the areas where drains and communications enter. It should be taken into account that the application area should be increased by several centimeters compared to the width of the material. All floor and wall cuffs, internal and external corners and other necessary accessories must be laid before the insulating covering.

The tape is cut and laid in the wet layer of waterproofing so that it completely covers the joint. The coating is carefully pressed into the base with a smooth spatula until all air bubbles are completely removed. In expansion joints, the material is laid in the form of a special “omega” loop. All joints of corner elements, tapes and cuffs must be overlapped by 7 cm. A second layer of waterproofing is applied over the perforated part of the tape, so that the middle part remains uncoated. In this case, the previous layer of waterproofing should be damp, but already hardened.

Outer tape

When installing waterproofing using a special tape, the one that has increased resistance to mechanical stress and temperature changes is used on the outside of buildings. Self-adhesive waterproofing tape “Nikobend” is made specifically for use when installing PVC windows; it is based on polypropylene.

Tape for PVC windows , main characteristics of self-adhesive: highly durable, butyl based, has excellent adhesion to the surface of any material.

Window tape does an excellent job of protecting against various moisture; its use makes it possible not to use expensive sealants. Window tapes, a functional feature of these films is its ability to remove condensation settling on construction foam, as well as preventing moisture from entering the premises from the outside.

External taping work

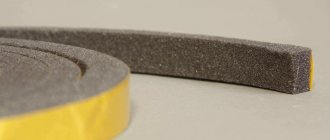

"Tape-PSUL". It is similar to foam rubber and copes well with excess moisture that is formed during the full formation of foam used for installation work on door and window blocks.

A distinctive feature of this product is that it protects the foam from direct sunlight. In addition, thanks to the reliable protection of the foam, there is no need to urgently plaster door and window slopes, and this allows them to be installed even at sub-zero air temperatures. Excellent for window installation.

Basic technical specifications

All types of sealing tapes with waterproofing properties have a similar set of technical parameters, including:

- water resistance not less than 0.25 MPa;

- transverse stretch to break at least 100%;

- operating temperature range from – 20 to + 70 °C;

- the total thickness of the product is at least 0.6 mm.

Naturally, materials from different manufacturers may differ in properties, but the basic parameters are maintained in all cases. Most often, the operating temperature range, thickness and stretchability are increased.

Interior tape

When carrying out waterproofing work indoors, a diffuse tape is used, which will block the penetration of moisture from the mounting foam into the interior.

Italian waterproofing vapor-permeable tape “Plaster” has excellent reliability and durability, and also sets high criteria for moisture and vapor protection. It is based on a special bitumen tape reinforced with special polyethylene. On the outside it is covered with aluminum foil, adhesive strips, have silicone protection, and its thickness is one and a half millimeters.

The scope of application of this tape is not limited to any building materials; it adheres perfectly to concrete, ceramic, cement and other walls. The outer film is available in four different colours, and this tape can be easily painted in any color. Rolls from five to ten meters long are available for sale, and the width can range from five to fifteen centimeters.

Might be interesting

Thermal insulation

What are thermal insulation materials: comparative…

Thermal insulation

How to insulate a roof from the inside and not make mistakes?

Thermal insulation

Roofing and drainage: heating rules

Thermal insulation

Insulated Swedish stove: pros and cons

Internal work on gluing tape

Tape for sealing seams made of Masterflex polyurethane , it is distinguished by elasticity, resistance to mechanical stress, and high protection against the ingress of water under pressure. When installing this film, the contact surfaces require careful processing, but at the same time it is not selective in their composition. This tape is easily glued to surfaces with high humidity, but for excellent tension and adhesion, it can be fixed with nails at a distance of twenty to twenty-five centimeters. This material is used to seal seams.

Roofing tape "Ecobit" is used for waterproofing roofs, and its scope of application is not limited to this; it is successfully used when installing windows, pipes and doors. Tape for plastic windows is completely capricious in the choice of materials on which it will be glued.

It is distinguished by a reinforced reinforced layer and an outer aluminum or copper coating. The outside of the tape is protected by polyester, reaches thirty centimeters in width, covered with silicone film, fixed to any cleaned surface, and porous ones need to be treated with special primers.

Butyl rubber waterproofing tape for windows “Liplent” , place of application: internal window slopes.

There are three types of such tape on the market:

- The base is polyethylene, the reinforcement is fiberglass, and the outside is covered with aluminum foil. Butyl sealant performs the function of adhesive layer.

- Tape for waterproofing, the main composition is butyl sealant.

- “Knauf” has excellent elasticity, is made from polyester, has a long service life, and is used as a hydraulic insulator at various facilities.

Manufacturing materials

Knauf Flachendicht coating waterproofing is a latex-based water dispersion with a pronounced blue color and has reinforcing, chemically inert additives. The product contains no solvents. The mixture does not have a strong chemical odor, so Knauf Flachendicht can be used in enclosed spaces without additional ventilation. It is sold in five-kilogram buckets.

This material does not need to be prepared or mixed with anything. The mastic is already ready for use.

Waterproofing tapes

Material:

- "Comfort" tape. It is a diffuse waterproofing agent that absorbs moisture and then removes it.

- “Titanium” is characterized by excellent protective properties, is resistant to temperature fluctuations, and consists of polyester material. It has both moisture and heat insulating properties; when gluing, it creates a continuous coating.

Delta tape

Consumption

The amount of Knauf waterproofing mixture depends on the porosity of the surface, and accordingly on the moisture resistance of the surface on which the mastic will be applied. If surfaces that poorly absorb liquid are insulated, then 250–350 g of coating agent will be needed per square meter. This application is considered single-layer. Multi-layer application requires up to 1.0 kg/m² of waterproofing.

If the systems being treated strongly absorb water, then the required amount of coating is 500–800 g/m². If the use is multilayer, then up to 2.4 kg/m².

To learn how to work with waterproofing from Knauf Flachendicht, see the following video.

Source

Basics of using waterproofing tape.

Before using any waterproofing tape, it is necessary to thoroughly prepare the surface, since the quality of adhesion and service life depend on this. All listed materials are recommended for use. They are used for sealing work in bathrooms, swimming pools, various tanks, roofs and service systems, as well as for sealing cracks in walls, connections and joints.

The common distinguishing feature of these tapes is their ability to interact perfectly with various types of construction surfaces, as well as those treated with adhesives, mastics and paints.

Before use, you should select the tape that is suitable in width, determine the required length, remove the protective film and press the tape to the beginning of the joint, gradually spreading it over the entire surface, additionally pressing it with a special roller, trying to remove all the air. Only after this, polyurethane foam is applied, after the complete expansion of which the tape is finally fixed and tensioned.

It is important to remember that in the corners of the deformation the tape is applied in the form of an omega loop. Also, the tape is applied wider than the joint by about six centimeters. The second layer is laid along the edges of the tape, leaving the middle free, while the bottom layer should already be dry.

By following the steps described, you can create an excellent waterproofing joint.

Sealing the junctions between the roof and the pipe

Let's look at how the joints between a pipe and a flat surface are sealed (for example, on a concrete pitched roof, ceiling, etc.).

Step 1. The surface on which the bitumen tape will be glued is prepared - cleaned of debris and dust, degreased. To process a concrete surface, it is recommended to use a grinder in tandem with a vacuum cleaner. Also, the surface after such cleaning must be degreased.

Surface preparation

Step 2. Prepare the necessary tools. These are a pressure roller, scissors, a knife and napkins. The latter are useful for cleaning hands and tools during work.

What you need for work

Step 3: This will seal the gap between the pipe and the flat surface. The tape is wrapped around the pipe to determine the required length of the segment.

The tape wraps around the pipe

Step 4. A cut is made on the tape wrapped around the pipe, then the tape is cut according to this cut. The result is a piece that is enough to handle this gap.

Tape cutting

Step 5. Several notches are made on one of the long edges of the tape using ordinary scissors. They are necessary to be able to glue the tape to the pipe and the concrete base at the same time.

Scissors make cuts

Step 6. Next, remove the protective film from the piece of tape.

The protective film is removed

Step 7. The tape without a protective film is applied to the selected location, while the sections with cuts are located on the concrete surface. During gluing, it is important to ensure that no air bubbles form under the tape.

Bonding bitumen tape

Step 8. The tape on the pipe is carefully rolled with a roller.

The tape is rolled with a roller

Step 9. Additional patches cut from bitumen tape are installed in the places of the cuts that are located on the concrete surface. They are also rolled with a roller.

The cuts are sealed with patches