Main types of dampers

According to manufacturers, a damper is a specific device that is designed to control the draft force in the smoke exhaust system of heating and cooking stoves, as well as in fireplaces for a country house. The popularity of this product is due to the fact that the good combustion of the filled fuel, the removal of the generated smoke, as well as the rate of heating of the room depend on the draft. If the house is heated by a stove, then it is the damper that will provide the fire safety function.

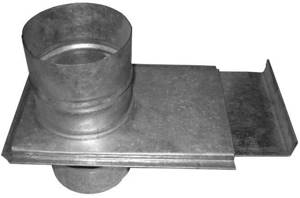

Pull-out model

This type of chimney damper is considered one of the most reliable and powerful in terms of operation. This part consists of a smooth plate on which there is a small longitudinal hole. The movement of the damper occurs thanks to special grooves in the chimney. The installation process occurs only in a horizontal position, the traction force depends on the position of the plate. It is used in brick stoves, as well as in modern chimneys made of steel pipes.

In this video you will learn how to make your own gate:

Cast iron products

The material itself is distinguished by its strength and durability. Most often, this type of gate valve is used for the manufacture of durable furnace valves. The only disadvantage of this product is its heavy weight.

Throttle option

The gate is presented in the form of a durable metal plate, where a special guide piece is welded in the center. Mounted inside the chimney. The end of the guide must be located outside. The traction force can be adjusted by rotating the plate. Among experts, such a product is considered not very reliable, since over time the welding joint weakens, which is why the damper opens slightly in random order. But despite this, a rotary damper is often used in steel chimneys.

There are several variations of the gate

High quality stainless steel gate

The advantage of using this steel is that it is not at all afraid of the negative effects of corrosion, has a long service life, is lightweight and does not affect the efficiency of the furnace. The process of cleaning the chimney is significantly simplified, since soot does not accumulate on the smooth polished surface. In addition, stainless dampers can have absolutely any shape, so they can be installed in both brick and steel chimneys.

Types of gate

Retractable

Retractable gate

The retractable type gate is considered the most convenient and reliable to use. This is a smooth plate with a small longitudinal hole that moves along grooves in the chimney. It is mounted in a horizontal position, the traction force is regulated by the movement of the plate, which reduces or increases the cross-section of the pipe. This type of valve is intended for brick stoves, although it can also be used in chimneys made of steel pipes.

Gate with plate

Rotary gate. The plate that regulates traction is visible

The rotary gate is a metal plate with a guide welded in the center. It is installed inside the chimney, with the end of the guide necessarily leading out. The traction is adjusted by rotating the plate around its axis. This design is less reliable, since over time the welding fastening weakens and the damper comes off. The rotary damper is used in steel chimneys.

The material from which the valves are made is no less important.

Cast iron gates

Cast iron is a very strong and durable material, traditionally used for the manufacture of furnace valves. A cast iron gate has only one drawback - it is heavy.

Cast iron damper for sauna stoves, fireplaces

Cast iron gate

Stainless steel

High quality steel gate unit

Stainless steel is not afraid of corrosion, lasts a long time, weighs little and does not reduce the efficiency of the furnace. The smooth polished surface of the stainless steel valve prevents the accumulation of soot, making cleaning easier. Such dampers can be of any design and can be installed in both brick and steel chimneys.

Steel gate in a brick kiln

Expert advice

Where to install the damper on the chimney

There are 3 options for placing the damper relative to the chimney:

- Placement in the firebox of a fireplace or stove;

- Fastening according to the “pipe to pipe” principle;

- Installation in a ventilation pipe.

Let's consider the first 2 options:

By placing the valve in the furnace firebox or in the outlet pipe

In this case, the damper is located at a height of no more than 1 m from the firebox, on an uninsulated section of the pipe. This location is convenient for adjusting the damper.

Pipe in pipe

Applicable for metal chimneys. This installation option does not require additional fasteners. When purchasing a ready-made system, you should install the valve strictly according to the manufacturer’s instructions.

How to adjust traction

Adjusting the draft using a slider is quite simple. By changing the position towards increasing the gap, we increase the flow of air to the fire and the flame flares up stronger. Reduce the gap - traction decreases. The valve is closed after the flame has completely died out - this way the oven cools down much faster.

Purpose and types of these devices

The chimney valve, or, as it is also called, a damper, is designed to regulate the draft in the chimney. The operation is performed as follows. During combustion, the valve closes a certain section of the chimney channel. By reducing or, conversely, increasing the damper area, you can control the air flow in the chimney and, accordingly, the flame strength in the heating device and draft. After the combustion process stops, the valve closes so that air currents do not carry away heat from the room. However, even in this state, the damper should not completely block the chimney: this is contrary to safety standards. The systems must be installed on almost all types of heating devices except the latest models, where the draft is adjusted automatically using a deflector.

In their shape, chimney valves must very accurately reproduce the cross-section of the pipe. There are two different design options for gate valves:

Retractable. The simplest and most reliable design. Moves only in the horizontal direction. It is most often installed in steel or brick chimneys. It is a smooth plate with holes that easily moves in the guide grooves.

Rotary or throttle.

- The device rotates around its axis, as a result of which it can open or close the smoke channel. Installed in cases where the retractable damper cannot be used for various reasons.

Retractable option. During the combustion process, the gate valve opens. The ability to regulate the overlap area of the smoke channel allows you to adjust the draft. After the fire goes out, the damper closes

The throttle gate valve rotates around its axis, closing or, conversely, opening the smoke channel. Installed in cases where the use of a retractable damper is not possible

The required system option is selected based on the design features of the chimney. In addition to the type of device, the material also plays an important role. Most often used:

- Cast iron. It produces very strong, reliable and durable products. Traditionally used to make devices. The main disadvantage is their heavy weight, so such valves can only be installed on brick pipes.

- Stainless steel. Lightweight, durable and corrosion-resistant material. It does not affect the heat transfer of the heating device, therefore it allows you to achieve maximum efficiency of the stove. Steel gates are usually polished to provide a smooth surface that prevents soot from settling. Installed on any pipes.

How to install a chimney damper

The damper is installed simultaneously with the installation of the heating system. It can be placed in several ways, but the most common is to install a damper on the first meter of the chimney. This placement is quite justified, since in this case the valve is convenient to control. Let's consider this installation method in more detail.

After laying the first row of the brick chimney, you can begin installing the damper. You need to start by cutting out a fragment of the valve. Make a through hole in one of the bricks for the handle and lay out the second row, taking into account the thickness of the layer of sand-cement mixture on which the gate will be placed. Make sure that it fits as tightly as possible to the first one. Eliminate the formation of cracks

Lay subsequent rows on a cement-sand mortar, paying attention to eliminate the risk of cracks forming

Advice! If you are not confident in your abilities and do not know whether you can install the gate yourself, entrust this task to professionals.

DIY chimney damper installation

You can install a damper for a fireplace or heating unit in one of three ways:

- The damper is installed directly in the fireplace insert. It is placed at a distance of 100 centimeters from the heating device, which makes it easy to control.

- Combining the damper with other elements of the heating structure without the use of additional fasteners. This installation method is called “pipe to pipe”.

- The damper is installed in ventilation pipes. It is used to prevent the fan motor from overheating during operation.

Installation must be carried out in the closed position of the gate to prevent excess load on the engine.

Since there are a variety of models of stove units and fireplaces and heating using them is carried out in different ways, each of them requires its own type of valve.

For example, for a stove operating on gas, you will need a classic rotary-type throttle valve or a rotary automatic damper, since they are capable of blocking the chimney pipe completely and then the flame will not be able to escape outside.

At the same time, rotary valves should not be installed when installing a sauna stove, since when closed they will allow steam to pass through, and in the open position they are very difficult to clean.

As a rule, a damper for a fireplace or stove unit is sold as a complete set along with a chimney. But there are smoke exhaust structures without a damper, so you can make one yourself by buying elements for it at a hardware store. The main thing to do before purchasing them is to decide on the required sizes.

How to choose the right damper for a bath for an already installed chimney

The damper is installed on almost all types of fireplaces and stoves. The only exceptions are some new models in which combustion is regulated by controlling the supply of supply air using a deflector.

In gas furnaces, it is best to install a rotary damper, since it can eliminate the risk of completely closing the chimney, and therefore the risk that the flame will accidentally jump out through the ash pan. But if a damper is installed, then it is necessary to ensure that there is always a gap of 30-40% of the cross-sectional area of the chimney.

It is also not recommended to install a rotary damper on a furnace with intermittent operation, since when closed the damper always allows steam to pass through during supply. You also need to remember the following point: many stove makers claim that when the rotary gate is in the open position, then it is very difficult to clean the pipe located below it.

As a rule, the damper and chimney are always sold together, as a set. If you made everything yourself, then you can buy a damper for a bath in any specialized supermarket or order it in an online store. The most important thing in this case is to take accurate measurements in order to know exactly what parameters of the gate you need.

Varieties

Control devices for ventilation are distinguished:

- according to form;

- by type of management;

- by installation method;

- according to the material.

The shape of the closing elements is round or rectangular (square). In each specific case, they are selected in such a way as to match the shape of the air duct.

Round channels have higher efficiency than rectangular ones. But it happens that the design features of the building do not allow air pipes to be installed everywhere due to lack of space.

It is necessary to use rectangular air ducts.

In modern ventilation systems you can find various options for control schemes for shut-off valves. The cheapest and easiest is to manually open and close the dampers.

But with this control method it is difficult to configure the system. That's why other designs exist.

The most common models are those with electric drive. In factories and public buildings, locking elements are often adjusted using hydraulic or pneumatic actuators.

Automation of the control function of control devices allows you to combine them into one circuit and control the valves from a single center.

In this way, it is possible to achieve the maximum possible synchronization in the operation of all dampers installed in the building.

When installing adjusting products, two types of connections are used: flange and socket. The socket connection is used for round air ducts, and the flange connection is used for rectangular ones.

Slide regulators are made from different materials. For example, for chimneys, movable plates are made of stainless steel, which is resistant to high temperatures and aggressive environments.

Products made of chrome or alloy steel are installed in channels with forced ventilation.

For natural ventilation schemes, galvanized models can be used. There are also plastic products.

Description

Gate is a damper used for furnaces, boiler rooms, and water supply systems. During operation, this element becomes an integral unit responsible for the high-quality removal of smoke to the outside. The damper ensures safe operation of the heating system, as it prevents sudden fire.

For proper operation, the device should be located a meter from the pipe. This sector is not covered with thermal insulation materials, so expansion under the influence of high temperatures does not occur. In the absence of a damper, owners of bathhouses often face the problem of increased fuel consumption, since most of the raw materials do not burn through. There is a weak heating effect. The main disadvantage of a chimney system without a damper is the appearance of reverse draft. Once you install a high-quality smoke exhaust speed regulator, you forget about this problem once and for all.

Advantages and technical characteristics

Regulating dampers for chimneys, in most cases, are made of stainless steel one millimeter thick. The surface of the valve is polished, almost perfectly smooth, which greatly facilitates the process of removing soot.

Stainless steel gate

A gate made of such steel. able to withstand temperatures up to 900 degrees Celsius. The smooth surface of the gate allows you to achieve maximum efficiency of the equipment, as it provides excellent traction and does not create obstacles in the path of flue gases.

Also, a stainless steel gate with such characteristics has high resistance to corrosion processes, excellent mechanical and strength characteristics and a low coefficient of thermal expansion. The last of these characteristics allows us to ensure the smallest change in product dimensions during temperature fluctuations. Stainless steel vanes have high thermal conductivity, which makes it possible to use them most effectively in heat exchange systems. Butt seams on chimney dampers are made using the rolling method.

A standard stainless steel chimney damper covers the cross-section of the smoke channel by 85 percent. This percentage is optimal for effective removal of carbon monoxide

This is extremely important in premises such as baths, as it can significantly increase the safety of being in them.

Types of gate

There are two models of gate valves, differing from each other in some design features.

- The horizontal retractable gate allows you to regulate the process by extending the plate, thus changing the cross-sectional area of the smoke channel. This model is most often installed horizontally in brick chimneys. There are also special models for chimneys that are made of stainless steel. There are holes (or a sawn segment) in the covering plate of the retractable gate. Their presence is explained by the fact that even in the closed position the gate valve should not completely close the channel. This complies with building codes and fire safety regulations.

- The rotary gate (throttle valve) is a classic type valve. It is a plate mounted on a rotating axis located inside the pipe or chimney.

Gate location options

The most common options for installing a gate are:

- A damper built directly into the structure (located in the firebox as a separate element or in the outlet pipe). In this case, the chimney damper is installed on the first meter, that is, on the section closest to the heating device. With this arrangement, it is as easy as possible to operate the valve, since the handle rod does not touch the cladding and the portal.

- The damper located in the chimney is connected to other elements without additional fastening, using the “pipe to pipe” method.

- Before installing the gate with your own hands, you need to take into account that this design may have some disadvantages. For example, with a straight chimney it will be difficult to clean the firebox from soot. Also, in some models the gate may occasionally jam.

Frequent errors and problems during installation

Good draft ensures high efficiency of the furnace. With good draft, the fuel in the stove burns completely and its consumption is low. If the draft is poor, the wood does not burn out completely, and there is even a risk of reverse draft occurring. In this article we will try to understand what a bath gate is, what are the features of its design and whether it is possible to make it yourself.

We invite you to familiarize yourself with Laying a brick sauna stove with your own hands

The damper is a draft regulator that ensures the fire safety of stove heating. When the wood in the stove burns, the chimneys are partially blocked by valves, and after complete combustion of the wood, the valve closes the chimney pipe completely. The damper in the heating system exists precisely to regulate the draft force. A modern analogue of a damper is a draft stabilizer.

To install the throttle valve, it is necessary to make markings on the pipe in order to drill holes according to the welded valve structure.

To do this, you need to measure the pipe using a measuring tape and make marks for future holes. After making sure that the marks are symmetrical, use a drill to drill holes for the future rotary handle.

The throttle valve is installed as follows:

- A steel damper circle with a welded tube is inserted into the chimney pipe.

- A metal rod is threaded through the drilled holes in the pipe through a small tube, the end of which is secured with a bolt and nut.

- The end of the rod is bent using pliers for a rotary handle.

Next, you can install the resulting structure in the chimney pipe. To do this, the first piece of pipe is put on the furnace pipe of the stove heating, onto which a structure with a gate valve is installed on top. The next piece of metal pipe is put on the gate. All connections are treated with liquid silicone sealant.

Installation of a retractable damper in a brick chimney occurs during the masonry process. To do this, after 6-8 rows of bricks, a layer of cement masonry mortar is applied, on which a wire frame is installed with the open side facing the performer. You need to insert a latch into the frame and bring it into the closed state.

The frame is covered with mortar on top and bricks continue to be laid according to the standard pattern.

Today, there are two main ways to install a damper on a chimney:

- Installation in a fireplace insert. This installation option implies the location of the gate product in close proximity to the heating equipment. As a rule, in this case the distance from the damper to the heating apparatus is 1 meter. This arrangement is very convenient for regulating the valve.

- Connection with other elements of the heating system. In this case, there is no need to use additional locking elements, so this option is quite common. This type of installation can also be called “pipe to pipe”.

The above options for using valves for chimneys and ventilation systems are used everywhere. It is worth noting that today you can find a huge variety of stoves and fireplaces, which differ from each other from a constructive point of view. This variety of heating devices also influenced the range of gate valves.

- When installing the gate at the stage of laying brickwork, the frame is placed at a height of 6-8 rows from the base of the pipe;

- The frame should stand straight, without blocking the outline of the chimney;

- In stainless steel chimneys, the valve is installed using the “pipe-to-pipe” technology. It is necessary to coordinate its dimensions with the diameter of the channel;

- An important nuance - the damper is installed on an uninsulated section of the chimney;

- The height from the firebox to the damper should not exceed 1 m (for metal channels);

- Pipe height from the floor to the valve - 1.8 - maximum 2 m (for brick);

- The damper in the grooves should move freely;

- Installation of a valve in an insulated area. Under the influence of thermal expansion, the damper may jam;

- Installation of a cast iron part in a metal chimney (cast iron weighs a lot);

- Using too thin steel or stainless steel with a low nickel content for the manufacture of valves. Such a product quickly deforms under the influence of hot gases and can burn out;

- Installation of a gate with a non-smooth surface;

- Installation of a valve without a hole for carbon monoxide release;

- Installation of handles that do not allow monitoring the position of the valve (applies to rotary elements).

The gate, made of stainless steel, is usually polished to perfect smoothness. Soot settles on it poorly, but still settles. Therefore, it must be cleaned periodically.

The horizontal valve can be cleaned simply by pulling it out to the maximum and applying a special solution. Rotary - cleaned through the chimney with a special plastic brush. You should also ensure that the damper moves freely along the guides. It is allowed to periodically lubricate them with an anti-corrosion compound.

Home manufacturing technology

Qualified specialists always emphasize that even a novice craftsman can make a rotary and retractable gate. After all, in order for the finished product to perfectly cope with its main task, you need to correctly take all the necessary measurements

If the finished damper fits tightly into the chimney, then over time it may jam, as it will be exposed to high temperature. And when there is a large gap between the valve and the pipe, it will be difficult to regulate the intensity of the draft during operation.

Multifunctional butterfly valve

To make this type of gate, you need to use a steel angle of 30x30 mm, as well as durable sheet steel, the thickness of which is at least 1.5 millimeters. The manufacturing process itself consists of several main stages, which must be implemented in strict sequence:

- Initially, you need to take measurements of the inside of the chimney. This is done in order to avoid mistakes during the manufacture of a frame from a corner, which is fixed with a welding machine.

- On one side of the frame, exactly in the center, you need to drill a small hole (7-8 mm in diameter). It will be useful for the rotary axis.

- A similar hole must be made on the other side of the frame.

- The plate for the damper must be cut from a steel sheet. This part must fully correspond to the internal dimensions of the manufactured frame.

- To make a guide axis, you need to take a piece of wire with a diameter of 9 mm and a length that will exceed the size of the frame itself by 7 cm. You need to cut a thread on one side of the wire (a die is best for this task).

- The finished axle is carefully threaded into the holes on the frame and secured with a nut.

- All cuts on the plate are processed with a grinding machine and inserted into the frame.

- At this stage, the master must weld the axle exactly in the center of the plate.

- All that remains is to make a comfortable handle for the guide from high-quality scrap materials.

Universal device

Modern gate valves include the valve itself, as well as a special guide frame. That is why, before starting work, the master must measure the internal cross-section of the pipe or brick chimney. In accordance with the available measurements, a neat rectangle is cut out of sheet steel (5 mm thick). A small longitudinal fold is made on one side, the width of which should not exceed 30 mm.

These manipulations are necessary so that the finished damper can be conveniently pulled out. Each cut must be polished, due to which the dimensions of the product are reduced by 2 mm on each side. Such actions by the technician will ensure free movement of the damper inside the chimney.

When the damper is made for a brick fireplace, the frame itself can be made of thick steel wire, the diameter of which is within 6 mm. During this procedure, the metal blank is simply bent into the shape of the letter P in strict accordance with the existing measurements.

If the chimney has a rectangular shape and is made of steel, then it is better to make the frame from a metal strip 2 mm thick and up to 35 mm wide. The prepared strip is bent lengthwise, leaving a neat gap along the thickness of the plate. Only after this can small cuts be made in two places at an angle of 45° to give the workpiece a U-shape. All gaps in the places of cuts must be butt welded.

To connect the ends of a homemade damper, you need to use two pieces of metal, which should be positioned in such a way that the damper blade can pass freely between them. At the end of all these manipulations, the master should come out with a rectangular frame with grooves for the shutter.

To make a valve in a round pipe, you need to take two identical metal sheets 2 mm thick. Round holes are cut in the center in accordance with the diameter of the chimney. The valve plate must be manufactured separately. After this, the sheets are connected to each other using a welding machine.

It is necessary to weld only three sides around the perimeter so that the holes of the finished valve on the pipe match exactly. A gap of 5 mm must be left between the top and bottom sheets. At this point, the damper manufacturing process can be considered complete, since the craftsman can only insert the valve and secure the finished product to the chimney.

Furnace damper support

In a stove with an epancha, the damper should not always tightly close the mouth. When pre-steaming fruits and then boiling them over low heat, it may be inconvenient or impossible to use a lid - for example, when using a wide tank or basin. The jam does not escape if the valve is installed with a gap - so that the gap between the valve and the wall of the mouth is 1.5-3 cm. There is nothing surprising in this. just like in a Russian oven, the damper is moved back and forth, partially covering the heat. Sometimes it is supported on the wall, but in our case it is convenient to install the damper on a spot support - a piece of board 2-3 cm thick and 6-8 cm wide.

The heel is cut out, adjusted, moving along the pole to and from the slab, and chamfered. The cardboard template is shortened from below to the height of the heel and tried on in place. The shield is marked according to the template and, very important, holes are drilled for attaching the handles. If this is not done, the damper will be difficult to manipulate during the adjustment process.

The damper is usually cut out with a jigsaw with the blade tilted towards the back wall. The chamfer of the arc is rounded. Long screws secure the heel. Screw on the handles. And they adjust the damper in place.

Main types of gate valves

Rotary gate. It is also called a “throttle valve”, which is a metal plate mounted on a rotating axis. The axis, in turn, is attached inside the chimney pipe. This device has a removable rotating disk, but with prolonged use it may become unusable. However, the design of the rotating mechanism allows you to repair and replace it yourself. The advantage of this type of device is its ease of operation. This type of gate does not require constant monitoring by the home owner.

Due to the complexity of the DIY design, the rotating mechanism is less often used when laying a fireplace or stove.

The gate design is necessary for wood-burning stoves and heating devices operating on any solid fuel.

Therefore, for a gas boiler, the most practical solution would be to install a rotary mechanism. The temperature of the exhaust gases is less low than when using solid fuel, so the operation of such a mechanism will be the most convenient.

Valve on an insulated chimney

But it is better to refuse to install a rotary mechanism in the bathhouse. The fact is that it will partially allow steam to pass through when closed. And when open, such a mechanism is difficult to clean.

Made of stainless steel, the gate mechanism will not completely block the chimney, but will eliminate the possibility of flames escaping through the ash pan into the room.

There are three options for installing the gate.

- Installing a damper in a fireplace insert. To do this, the damper is mounted at a distance of 1 meter from the heating device, which ensures simple operation.

- The “pipe to pipe” option involves combining the damper with other elements of the heating structure without the additional use of fasteners.

- Installation of a gate valve in a ventilation pipe. But this option is usually used to protect the fan motor from overheating during operation.

But even if the finished kit does not come with this element, you can easily make the gate yourself by choosing the most optimal mechanism option for yourself.

Advantages and disadvantages

Like any engineering solution, a gate has a number of advantages and disadvantages.

Pros:

- Possibility of traction control;

- Fuel economy;

- Dampers help retain heat.

Minuses:

- The devices make it difficult to clean chimneys;

- If installed incorrectly, the gate may jam and negatively affect the movement of gases;

- To make the correct adjustment, you must have some knowledge in the field of smoke exhaust systems.

Differences between retractable and rotary gates

The retractable damper allows you to adjust the working cross-section of the chimney, while the rotary damper only allows you to open or close the pipe. Of course, some tricks are possible - such as securing the hog in an intermediate position in different ways, but the factory equipment does not provide for this. In addition, the rotary gate complicates mechanical cleaning of the pipe.

How to make a gate valve with your own hands

Let's look at how to make both types of chimney valves - retractable and rotary. Each of them has its own manufacturing and installation nuances. Let's start with the retractable view.

Preparation of materials and tools

To create the simplest model of a retractable gate, galvanized steel is suitable. It is lightweight, thanks to its smooth surface it is easy to clean from soot, and if necessary, the moving part can be easily replaced.

Millimeter steel will not work, as it bends easily, and if deformed, it will be difficult to slide the plate into the chimney. The minimum sheet thickness is 1.5 mm, and preferably 2-2.5 mm

The main tools are a welding machine, electrodes, a grinder, metal scissors (choose depending on the thickness of the sheet), a drill with a grinding disc, metal drills, and a file. It is better to carry out work on a workbench with a vice. Among other things, you will need a sheet of paper for a template, a tape measure, and a marker.

Drawing up a diagram (drawing)

Removing dimensions must be taken seriously, since even a few millimeters can cause the chimney to malfunction. To find out the dimensions of the frame, you should use a tape measure to measure the cross-section of the smoke exhaust duct - it will coincide with the dimensions of the inside of the frame. To this value you should add 20-30 mm on three sides and calculate the outer side of the frame.

Drawing of a damper with a wire frame. A wire frame is more difficult to secure to brickwork than a profile with flat wide sides

In order for the latch to slide out easily, without effort, its width should be slightly narrower than the width of the frame (taking into account the outer sides). To simplify the calculations, it is necessary to draw a design diagram and indicate all possible dimensions, so that in the future, when working with metal, you can navigate by them.

For metal pipes, a flat damper design is usually combined with a chimney fragment located perpendicularly.

Design dimensions for a rectangular pipe. The valve must completely block the chimney, but at the same time have small holes for air penetration, drilled with a drill, or a gap

For brick chimneys, a flat frame made of wire or profile with a valve moving along guides (two parallel sides) is sufficient.

Marking and cutting out parts

Having determined the exact dimensions, we cut out the frame for the gate. If the chimney is small (for example, in a bathhouse or in a summer kitchen), you can use thick wire, bending it in the shape of the letter P.

A more comprehensive frame is a durable corner profile. To make it, we cut out a strip from sheet steel and bend it lengthwise at an angle of 90º. To give the profile the desired shape, in the places where the corners are marked, we cut one of the planes. When folded, we get a frame. We weld the bends.

Next, we cut out the damper itself. It should be approximately 5-10 mm narrower than the width of the frame. We adjust the length so that when closed, only a small fragment of the valve peeks out. It can be decorated in different ways: in the form of an ear with a hole or simply a folded edge.

We clean the edges of the cut gate with a disc so that the closing/opening process is easy and silent. Parts cannot be painted.

Gate valve installation steps

The photo shows the stages of installing a factory-made gate. A homemade device is mounted using the same principle.

Image gallery Photo from In accordance with the furnace diagram, we determine the installation location of the gate valve and mark the bricks that need to be trimmed

We take out the bricks that serve as the basis for installing the damper and cut them to the size of the gate frame with a grinder

To fix the valve we use masonry mortar. We apply it to the installation site, and then to the edges of the frame from above.

The valve “stands” on the same level as the rest of the bricks, so there are no obstacles to further masonry; it is carried out in the usual manner - according to the ordering scheme

Step 1 - determining the installation location

Step 2 - cutting bricks around the perimeter of the hole

Step 3 - planting the gate on the solution

Step 4 - brickwork above the gate

The installation height of the damper largely depends on the design of the stove; in sauna stoves it is lower, in home heating stoves it is higher. The minimum height is 0.9-1 m from the floor, the maximum is about 2 m.

Related Posts

- What sizes of sandwich pipes are best to use for a chimney?

- Coaxial chimney for gas boiler

- Dimensions and installation of pipes for a bath

- How to make and install a draft stabilizer for a chimney yourself

- Chimney through the wall: features, rules of calculation and installation. chimney device and its installation (125 photos)

- How to assemble a simple stainless steel chimney

- Chimney in the garage through the wall: stages of arrangement

- Stainless steel chimneys: types and installation principles

- The optimal height of the chimney relative to the roof ridge

- Why chimneys become contaminated with soot and how to get rid of it yourself

- Shut-off valves and their use in pipeline systems

- How to line a chimney with your own hands

- How to weld a metal sauna stove

- Buleryan oven: do it yourself

- Corrugated Stainless Steel Pipe

- How to cut metal using a grinder

- How to make a potbelly stove in the garage with your own hands

- When health is in your hands: a bathhouse that will be the envy of your neighbors

- How to glue fiberglass correctly?

- Fire-battery 7b (thermophor)

- Selection and installation of shut-off valves for water supply

- Alabaster: what is it? how to divorce? where to apply?

- Manufacturing and connecting a sauna stove with a water heat exchanger

- How to make water filters with your own hands?

- Backdraft in the chimney

Read with this

- What sizes of sandwich pipes are best to use for a chimney?

- Coaxial chimney for gas boiler

- Dimensions and installation of pipes for a bath

- How to make and install a draft stabilizer for a chimney yourself

- Chimney through the wall: features, rules of calculation and installation. chimney device and its installation (125 photos)

- How to assemble a simple stainless steel chimney

- Chimney in the garage through the wall: stages of arrangement

- Stainless steel chimneys: types and installation principles

- The optimal height of the chimney relative to the roof ridge

- Why chimneys become contaminated with soot and how to get rid of it yourself

DIY making

It is better to make and install a damper yourself during the process of laying a fireplace or installing a metal chimney.

You can also make and install it if a steel chimney is already installed, but a damper was not provided in it. Depending on the diameter and cross-sectional shape of the chimney, the material used, a retractable damper and a butterfly valve can be made.

To make a simple retractable damper, sheets of galvanized or stainless steel with a thickness of 2-2.5 mm are required. Making guides around the perimeter of the chimney will require 6 mm thick wire.

To complete the work you need equipment and tools:

- grinder or metal scissors;

- grinding disc for angle grinders;

- drills and files for metal;

- marker for marking.

It is advisable to do all the work on a special lathe or typesetting machine. If the shape of the chimney is rectangular, you can make the simplest gate damper by simply cutting a piece of sheet steel of the required size. It is recommended to weld the handle or drill a small hole for ease of adjustment of the gate.

Before starting work, we measure the area and cross-sectional shape of the chimney, and use a marker to make marks on a sheet of cardboard in accordance with them. To make the frame, we bend the wire in the shape of the letter P, the width and length coinciding with the cross-section of the chimney. Using a grinder, we cut out the flap using a cardboard template, and sand the edges with a sanding disc.

Making a butterfly valve requires more tools and time. Most often this type of damper is used for metal chimneys for modern fireplaces and metal freestanding stoves.

Set of tools for work:

- Bulgarian;

- drill;

- pliers;

- welding machine;

- compass;

- roulette;

- marker for marking.

To make a gate, you need sheet steel up to 3 mm thick, a stainless steel pipe with an internal diameter of 6 mm, fasteners (bolts, nuts) 8 mm, and a metal rod.

- First, measure the internal diameter of the chimney pipe using a compass.

- According to it, draw a circle on sheet steel.

- Use a grinder to cut out a circle.

- Place the cut fragment into the pipe and check the tightness of the fit. If necessary, rework the valve with a grinding disc.

- Place a metal tube with a diameter of 6 cm on the circle in the center and make marks on it, retreating 3 mm from each side of the circle.

- Cut off the tube with a grinder.

- In the resulting pipe section, drill the threads to 6.8 mm on both sides.

- Drill holes in the steel circle for welding (one in the center, two 1 cm from the edge on opposite sides).

- Weld the threaded tube to the steel circle.

The slide valve is ready, all that remains is to install it in the chimney pipe.

Gate drawing

Both a retractable and a rotary gate can be made independently if you have a welding machine and a grinder. Assembling both structures is not difficult, the main thing here is the accuracy of the measurements. If the valve fits too tightly into the pipe, it may jam when exposed to high temperatures. If you leave a large gap between the plate and the pipe, this will make it difficult to adjust the draft.

Retractable gate

The design of the gate consists of the valve itself and the guide frame. First you need to measure the internal cross-section of the pipe or brick chimney. According to measurements, a rectangular valve is cut out of sheet steel 4-5 mm thick. On one side, a longitudinal fold 20-30 mm wide is made to make it easier to pull out the flap.

Gate diagram

If the chimney is steel and has a rectangular shape, the frame is made of a steel strip 2 mm thick and 30-35 mm wide. The strip is bent lengthwise, leaving a gap along the thickness of the plate, then cut in two places at an angle of 45 degrees and given a U-shape. The gaps in the places of the cuts are butt welded. The ends of the homemade profile are connected with two pieces of metal, positioned so that the valve blade passes freely between them. You should get a rectangular frame with grooves for the gate. In this case, the internal perimeter of the frame must be equal to the cross-section of the chimney.

Manufacturing of gate valves

Ready-made damper design for a round chimney

Now the sheets need to be connected by welding on three sides around the perimeter so that the holes for the pipe coincide, and there is a gap of 4-5 mm between the top and bottom sheets. After this, all that remains is to insert the valve and secure the gate to the pipe.

We offer detailed instructions for manufacturing the damper already with a finished stove heating, when the design is completed, but the damper mechanism was not provided.

To make and install a gate valve with your own hands, you will need the following materials:

- grinder, cutting and grinding abrasive wheel;

- drill;

- tap;

- oil for lubricating the tap when cutting threads;

- hammer;

- vice;

- pliers;

- welding;

- core;

- electrodes for stainless steel;

- compass;

- roulette;

- permanent marker.

The materials you should immediately prepare are:

- stainless steel sheet 1.5 -2 mm thick.

- stainless steel tube with an internal diameter of 6 mm;

- 2 bolts 8mm,

- nail (or metal rod).

When all the tools and materials are prepared, you can begin to carry out the work.

- Measure the inside diameter of the pipe and mark it on the stainless steel sheet using a compass.

step 1 - Now, using a grinder, cut out a circle according to the markings made.

Step 2 - We try on the cut-out damper and, if necessary, modify it with a grinding wheel until it clearly fits into the pipe.

Trying on the damper - Take the prepared stainless steel tube and apply it to the finished circle.

Use a marker to measure the size of the flap. We make it smaller than the internal diameter by 3 mm on each side. Step 4 - We cut the pipe with a grinder and a cutting wheel.

- We drill an internal hole in the 6.8 mm tube for threading.

When drilling, it is necessary to periodically lubricate the inner surface of the tube with machine oil. Drilling out the tube - We cut an 8mm thread on both sides of the tube with a tap, not forgetting to lubricate the tap in the process.

To remove the cutting chips, it is necessary to make a half turn back every half turn of the tap along the thread. Step 5 - Now you need to make three holes in the damper. Immediately use a marker to make marks.

- Clamp the tube and the valve in a clamp and weld the tube to the valve through these holes (welded rivets).

We start welding from the central hole, then release any one clamp and weld it into the free hole. Step 6 - We mark the future holes on the smoker.

To ensure that the axis of the holes clearly coincides, wrap the pipe with a tape measure and measure the center horizontally and vertically. Let's drill. Making the markings - We assemble the damper into a tube.

Step 7 - Making a template for the damper clamp.

Step 8 - We transfer the markings to the metal sheet.

You can use a compass. Step 9 - Mark the middle for the fastener holes, cut and drill according to the markings.

- We weld it to the pipe.

We weld the clamp

We invite you to familiarize yourself with the Rafter system of a pitched roof diagram

For this option, you need to purchase a ready-made factory stainless steel gate valve. The design represents a frame within which the mechanism moves.

- Lay out 2 rows of the stove or fireplace according to the ordering pattern used.

horizontal sliding gate - On the row where the valve will be installed, we cut grooves in the brick. These are small grooves into which the metal element will fit. It is best to use an angle grinder with a wheel for this work. But if you don’t have such a professional tool, then you can get by with a file.

- The damper is installed.

- It is necessary to cut a recess in the side brick for the movement of the damper handle, because it will need to be cleaned of soot during operation.

We block the gate with a row of bricks - The next row of bricks is laid and all the resulting gaps are well sealed.

As you can see, making a gate does not require much time or much experience. At the same time, this is a very important detail that will significantly increase the efficiency of the boiler or fireplace.